Take lead on your project with an efficient system concept - Danfoss ...

Take lead on your project with an efficient system concept - Danfoss ...

Take lead on your project with an efficient system concept - Danfoss ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

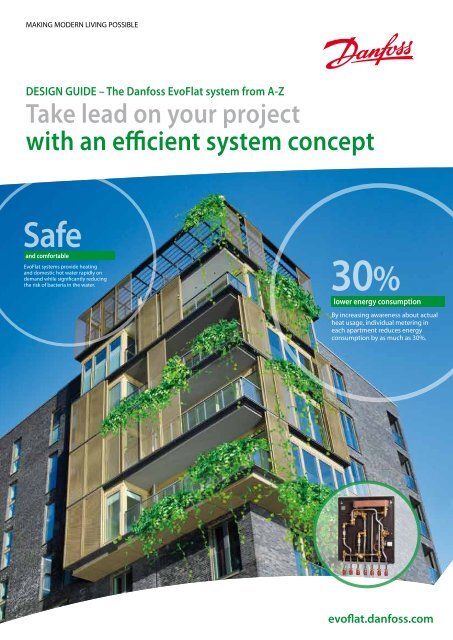

MAKING MODERN LIVING POSSIBLE<br />

DESIGN GUIDE – The D<strong>an</strong>foss EvoFlat <strong>system</strong> from A-Z<br />

<str<strong>on</strong>g>Take</str<strong>on</strong>g> <str<strong>on</strong>g>lead</str<strong>on</strong>g> <strong>on</strong> <strong>your</strong> <strong>project</strong><br />

<strong>with</strong> <strong>an</strong> <strong>efficient</strong> <strong>system</strong> c<strong>on</strong>cept<br />

Safe<br />

<strong>an</strong>d comfortable<br />

EvoFlat <strong>system</strong>s provide heating<br />

<strong>an</strong>d domestic hot water rapidly <strong>on</strong><br />

dem<strong>an</strong>d while signific<strong>an</strong>tly reducing<br />

the risk of bacteria in the water.<br />

30%<br />

lower energy c<strong>on</strong>sumpti<strong>on</strong><br />

By increasing awareness about actual<br />

heat usage, individual metering in<br />

each apartment reduces energy<br />

c<strong>on</strong>sumpti<strong>on</strong> by as much as 30%.<br />

evoflat.d<strong>an</strong>foss.com

List of c<strong>on</strong>tent<br />

1.<br />

Introducti<strong>on</strong> – An innovative energy<br />

c<strong>on</strong>cept for buildings<br />

3<br />

1.1 New energy c<strong>on</strong>cepts for residential buildings 4<br />

1.2 Documented benefits of EvoFlat <strong>system</strong>s 5<br />

1.2.1 System comparis<strong>on</strong> investments<br />

<strong>an</strong>d operating costs<br />

1.3 Domestic hot water: Hygiene <strong>an</strong>d high comfort 8<br />

2. Why decide for the EvoFlat <strong>system</strong>? 9<br />

2.1 From traditi<strong>on</strong>al central heating to modern<br />

decentralized soluti<strong>on</strong>s<br />

2.2 Comparis<strong>on</strong> <strong>with</strong> traditi<strong>on</strong>al central<br />

<strong>an</strong>d decentralized heating <strong>system</strong>s<br />

2.3 Signific<strong>an</strong>t benefits <strong>with</strong> EvoFlat 13<br />

3. What is the EvoFlat <strong>system</strong> soluti<strong>on</strong>? 14<br />

3.1 The functi<strong>on</strong> of the EvoFlat stati<strong>on</strong> 15<br />

3.2 Main elements of the decentralized <strong>system</strong> 16<br />

3.3 Independent of the available energy source 17<br />

3.4 Hydr<strong>on</strong>ic bal<strong>an</strong>cing of the EvoFlat <strong>system</strong> 18<br />

3.5 Design, key comp<strong>on</strong>ents<br />

<strong>an</strong>d features of a flat stati<strong>on</strong><br />

3.5.1 Brazed plate heat exch<strong>an</strong>gers 21<br />

3.5.2 Domestic hot water c<strong>on</strong>trol valve – Introducti<strong>on</strong> 22<br />

Domestic hot water c<strong>on</strong>trol valve – IHPT 23<br />

Domestic hot water c<strong>on</strong>trol valve<br />

– AVTB <strong>with</strong> sensor accellerator<br />

3.5.3 Additi<strong>on</strong>al flat stati<strong>on</strong> comp<strong>on</strong>ents 25<br />

3.5.4 Multiple cover opti<strong>on</strong>s - Termix 26<br />

3.5.5 EvoFlat insulati<strong>on</strong> opti<strong>on</strong>s – Termix 27<br />

3.5.6 Heat <strong>an</strong>d energy meter 28<br />

3.6 Domestic hot water requirements 29<br />

6<br />

10<br />

12<br />

20<br />

24<br />

2<br />

4.<br />

List of c<strong>on</strong>tent<br />

Introducti<strong>on</strong> to the product r<strong>an</strong>ge<br />

– EvoFlat flat stati<strong>on</strong>s<br />

4.1 Product r<strong>an</strong>ge overview<br />

– Main data <strong>an</strong>d functi<strong>on</strong>s<br />

4.2.1 Termix Novi 32<br />

4.2.2 Termix One B 34<br />

4.3.1 Termix VMTD-F-I 36<br />

4.3.2 Termix VMTD-F-B 38<br />

4.4.1 Termix VMTD-F MIX-I 40<br />

4.4.2 Termix VMTD-F-MIX-B 42<br />

4.5.1 Termix VVX-I 44<br />

4.5.2 Termix VVX-B 46<br />

4.6 Perform<strong>an</strong>ce curve: Termix stati<strong>on</strong>s<br />

– IHPT c<strong>on</strong>troller<br />

4.7 Perform<strong>an</strong>ce curve: Termix stati<strong>on</strong>s<br />

– AVTB c<strong>on</strong>troller<br />

5. How to dimensi<strong>on</strong> the EvoFlat <strong>system</strong>? 55<br />

5.1 Dimensi<strong>on</strong>ing <strong>with</strong> EvoFlat software 56<br />

6.<br />

How to install<br />

EvoFlat flat stati<strong>on</strong>s<br />

Installati<strong>on</strong> examples<br />

– Renovati<strong>on</strong> <strong>an</strong>d new buildings<br />

6.1 Dimensi<strong>on</strong>s <strong>an</strong>d c<strong>on</strong>necti<strong>on</strong>s: Termix stati<strong>on</strong>s<br />

– On-wall or recess mounting<br />

6.2 On-wall mounting sequence 61<br />

6.3 Recess mounting sequence 62<br />

6.4 Accessories for mounting of flat stati<strong>on</strong>s 63<br />

7.<br />

Central c<strong>on</strong>trol <strong>an</strong>d m<strong>on</strong>itoring<br />

from heat producti<strong>on</strong> to heat use<br />

8. Reference list 68<br />

9. FAQ 70<br />

30<br />

31<br />

48<br />

50<br />

58<br />

58<br />

59<br />

66<br />

October 2011

1. Introducti<strong>on</strong><br />

– An innovative energy c<strong>on</strong>cept for residential buildings<br />

Fully<br />

future compatible<br />

EvoFlat <strong>system</strong>s are compatible <strong>with</strong><br />

virtually <strong>an</strong>y kind of heat supply infrastructure,<br />

<strong>an</strong>d are independent of the<br />

type of energy used.<br />

3<br />

Introducti<strong>on</strong>

Introducti<strong>on</strong><br />

1.1 New energy c<strong>on</strong>cepts for residential buildings<br />

Refurbishment <strong>an</strong>d new buildings<br />

Energy efficiency pays off<br />

Milli<strong>on</strong>s of apartments worldwide are to<br />

be renovated every year. Heat insulati<strong>on</strong><br />

<strong>on</strong> roofs <strong>an</strong>d facades, new windows <strong>an</strong>d<br />

doors c<strong>an</strong> reduce the energy requirements<br />

of <strong>an</strong> apartment building by<br />

up to 83%*. Such a signific<strong>an</strong>t energy<br />

savings <strong>with</strong> possible integrati<strong>on</strong> of<br />

renewable energy sources require new<br />

energy c<strong>on</strong>cepts – for both renovati<strong>on</strong>s<br />

<strong>an</strong>d new buildings.<br />

Integrati<strong>on</strong> of renewable<br />

energy sources<br />

Regardless of whether it is <strong>an</strong> existing<br />

building renovati<strong>on</strong> or a new building,<br />

alternative energy sources require a<br />

buffer t<strong>an</strong>k, which collects the heated<br />

* Source: dena (Germ<strong>an</strong> Energy Agency), 2010<br />

water <strong>an</strong>d distributes it to individual<br />

apartments. Every apartment has its<br />

own flat stati<strong>on</strong>, which as the hydraulic<br />

interface ensures that the heating water<br />

is distributed to the individual radiators<br />

in the apartment at the desired<br />

temperature. Each of these flat stati<strong>on</strong>s<br />

is also fitted <strong>with</strong> a fresh water <strong>system</strong>,<br />

which heats the domestic water when<br />

is needed, in a sufficient amount <strong>an</strong>d,<br />

above all, hygienically safe.<br />

Benefits for all<br />

Decentralized heating <strong>system</strong>s in new<br />

buildings <strong>an</strong>d renovati<strong>on</strong> <strong>project</strong>s offer<br />

m<strong>an</strong>y benefits for both investor <strong>an</strong>d<br />

ten<strong>an</strong>t.<br />

4<br />

Introducti<strong>on</strong><br />

Building renovati<strong>on</strong> <strong>an</strong>d decentralized<br />

<strong>system</strong>s reduce heat losses <strong>an</strong>d heating<br />

costs. They increase comfort, c<strong>on</strong>venience<br />

<strong>an</strong>d domestic water hygiene. At<br />

the same time separate meters in each<br />

apartment ensure more c<strong>on</strong>sumpti<strong>on</strong><br />

tr<strong>an</strong>sparency <strong>an</strong>d better c<strong>on</strong>trol over<br />

heating <strong>an</strong>d hot water bills for the<br />

ten<strong>an</strong>t. This makes the building more<br />

attractive for all c<strong>on</strong>cerned.

Introducti<strong>on</strong><br />

1.2 Documented benefits of EvoFlat <strong>system</strong>s<br />

Low overall costs<br />

The idea behind the decentralized<br />

<strong>system</strong> for heating <strong>an</strong>d domestic hot<br />

water is not new, <strong>an</strong>d the adv<strong>an</strong>tages<br />

<strong>an</strong>d benefits of opting for such <strong>system</strong>s<br />

are well documented.<br />

Encourage people to save <strong>on</strong> energy<br />

When residents <strong>an</strong>d ten<strong>an</strong>ts <strong>on</strong>ly pay<br />

for what they use, they tend to keep a<br />

critical eye <strong>on</strong> their energy c<strong>on</strong>sumpti<strong>on</strong>.<br />

A study carried out in Denmark in<br />

1991-2005 examined the actual energy<br />

c<strong>on</strong>sumpti<strong>on</strong> before <strong>an</strong>d after individual<br />

meters were installed.<br />

The results clearly showed that individual<br />

metering signific<strong>an</strong>tly reduces energy<br />

c<strong>on</strong>sumpti<strong>on</strong> per square metre<br />

– normally by as much as 15-30%.<br />

Reduce energy loss<br />

A 2008 study compared the different<br />

distributi<strong>on</strong> <strong>system</strong>s available for apartment<br />

blocks <strong>an</strong>d multi-family houses.<br />

The calculati<strong>on</strong>s were based <strong>on</strong> a<br />

4-storey building <strong>with</strong> eight 133-squaremetre<br />

apartments per storey. The figures<br />

compared a EvoFlat soluti<strong>on</strong> <strong>with</strong> a<br />

single vertical riser pipe <strong>system</strong> <strong>an</strong>d a<br />

<str<strong>on</strong>g>Take</str<strong>on</strong>g> up less space<br />

As the name suggests, EvoFlat <strong>system</strong>s<br />

take up very little space. Compared to<br />

individual gas-fuelled boilers, which are<br />

often combined <strong>with</strong> a storage t<strong>an</strong>k, a<br />

flat stati<strong>on</strong> takes up about 80% less<br />

space <strong>an</strong>d c<strong>an</strong> normally be mounted in<br />

a wall recess or small cupboard.<br />

MWh/100M 2<br />

The main benefits <strong>with</strong> decentralized<br />

<strong>system</strong>s include lower energy c<strong>on</strong>sumpti<strong>on</strong><br />

as a result of individual metering,<br />

more revenue-generating space in<br />

apartment blocks <strong>an</strong>d multi-family<br />

25<br />

20<br />

15<br />

10<br />

5<br />

Meters introduced Meters introduced<br />

Housing associati<strong>on</strong> “Hyldespjældet”<br />

Individual metering since 01.98<br />

horiz<strong>on</strong>tal riser pipe <strong>system</strong> <strong>with</strong><br />

centralized producti<strong>on</strong> of domestic hot<br />

water. The study showed that compared<br />

to modern centralized domestic hot water<br />

soluti<strong>on</strong>s, a EvoFlat soluti<strong>on</strong> reduces<br />

heat loss from the pipes by more th<strong>an</strong><br />

40% <strong>an</strong>d by as much as 80% compared<br />

to traditi<strong>on</strong>al <strong>on</strong>e-pipe soluti<strong>on</strong>s.<br />

Admittedly, flat stati<strong>on</strong>s do take up a little<br />

more space th<strong>an</strong> centralized <strong>system</strong>s<br />

for domestic hot water producti<strong>on</strong>,<br />

although they are still very unobtrusive.<br />

In return, however, they free up c<strong>on</strong>siderable<br />

amounts of space in basement<br />

areas.<br />

5<br />

Introducti<strong>on</strong><br />

houses, <strong>an</strong>d reducti<strong>on</strong>s in the amount of<br />

heat wasted in l<strong>on</strong>g pipe runs. Here are<br />

some factual numbers.<br />

MWh/100M 2<br />

0<br />

0<br />

1991 1998 2005 1991 2000 2005<br />

kWh<br />

m 3<br />

25<br />

20<br />

15<br />

10<br />

5<br />

250<br />

200<br />

150<br />

100<br />

50<br />

0<br />

0.35<br />

0.3<br />

0.25<br />

0.2<br />

0.15<br />

0.1<br />

0.05<br />

0<br />

Housing associati<strong>on</strong> “Morbærhaven”,<br />

Individual metering since 01.00<br />

Single vertical<br />

pipe <strong>system</strong><br />

Individual<br />

gas boiler<br />

Horiz<strong>on</strong>tal pipe<br />

<strong>system</strong> <strong>with</strong><br />

central DHW<br />

producti<strong>on</strong><br />

EvoFlat<br />

EvoFlat Central<br />

domestic hot<br />

water<br />

Individual gas boiler: 0.32.<br />

Boiler (0.15 m 3 ) + chimney (0.17 m 3 )<br />

EvoFlat: 0.062. Flat stati<strong>on</strong> (0.062 m 3 )<br />

Central domestic hot water: 0.02.<br />

Water meter (0.01 m 3 ) + heat meter (0.01 m 3 )<br />

* Storage t<strong>an</strong>k in basement will take up signific<strong>an</strong>tly<br />

more space th<strong>an</strong> in a EvoFlat soluti<strong>on</strong>

Introducti<strong>on</strong><br />

1.2.1 System comparis<strong>on</strong> investments<br />

<strong>an</strong>d operating costs<br />

The purchase price is not everything<br />

Frequently investment costs are the first<br />

c<strong>on</strong>siderati<strong>on</strong> when pl<strong>an</strong>ning renovati<strong>on</strong><br />

or new build. As <strong>with</strong> <strong>an</strong> iceberg,<br />

they are the immediately visible part,<br />

which, however, <strong>on</strong>ly account for a fracti<strong>on</strong><br />

of the overall costs that a product<br />

incurs during its entire service life.<br />

The lifecycle costs of what appears to<br />

be a cheaper product at first gl<strong>an</strong>ce c<strong>an</strong><br />

often be signific<strong>an</strong>tly higher th<strong>an</strong> those<br />

of <strong>an</strong> allegedly more expensive vari<strong>an</strong>t.<br />

This is also dem<strong>on</strong>strated in a study<br />

Renovati<strong>on</strong> cost effectiveness <strong>an</strong>alysis<br />

by the Kulle & Hofstetter partnership,<br />

which was compiled for Stadtwerke<br />

München, <strong>an</strong>d <strong>with</strong> which the central<br />

<strong>system</strong>s for heating <strong>an</strong>d hot water producti<strong>on</strong><br />

were compared <strong>with</strong> decentralized<br />

<strong>system</strong>s.<br />

Central <strong>an</strong>d decentralized <strong>system</strong>s<br />

comparis<strong>on</strong><br />

The below example for renovati<strong>on</strong> of<br />

50 apartments shows that the initial<br />

investment costs for a traditi<strong>on</strong>al central<br />

heating <strong>system</strong> <strong>with</strong> central domestic<br />

Renovati<strong>on</strong> of 50 apartments Vari<strong>an</strong>t 1<br />

1.<br />

1.1<br />

1.2<br />

2.<br />

2.1<br />

2.2<br />

2.3<br />

2.4<br />

2.5<br />

3.<br />

3.1<br />

Investment <strong>an</strong>d capital costs<br />

Investment costs<br />

Capital depend<strong>an</strong>t costs<br />

Relati<strong>on</strong> to Vari<strong>an</strong>t 1<br />

C<strong>on</strong>sumpti<strong>on</strong> related costs<br />

Heat loss<br />

Utility heat District heating<br />

Electricity costs (circulati<strong>on</strong> pumps)<br />

Tariff ch<strong>an</strong>ge<br />

El. boiler useful heat<br />

Total<br />

Relati<strong>on</strong> to Vari<strong>an</strong>t 1<br />

Operati<strong>on</strong> related costs<br />

Mainten<strong>an</strong>ce<br />

Total<br />

Relati<strong>on</strong> to Vari<strong>an</strong>t 1<br />

4. Annual costs<br />

Relati<strong>on</strong> to Vari<strong>an</strong>t 1<br />

€<br />

€ / a<br />

%<br />

€ / a<br />

€ / a<br />

€ / a<br />

€ / a<br />

€ / a<br />

%<br />

€<br />

€ / a<br />

€ / a<br />

%<br />

€ / a<br />

%<br />

Electrical DHW<br />

boiler in apartment<br />

Central heating<br />

6<br />

0,00<br />

0,00<br />

0,00<br />

1.608,14<br />

1.146,00<br />

15.377,33<br />

18.131,47<br />

100,00<br />

4.500,00<br />

4.500,00<br />

100,00<br />

22.631,47<br />

100,00<br />

Introducti<strong>on</strong><br />

water heating are lower th<strong>an</strong> the investments<br />

for corresp<strong>on</strong>ding decentralized<br />

<strong>system</strong>s.<br />

The 30% higher investment costs for the<br />

decentralized <strong>system</strong> <strong>with</strong> decentralized<br />

DHW producti<strong>on</strong> pays themselves back<br />

<strong>with</strong>in approx. 9 years due to the 70%<br />

lower energy c<strong>on</strong>sumpti<strong>on</strong> costs. This<br />

even <strong>with</strong>out c<strong>on</strong>sidering future price<br />

increases for energy <strong>an</strong>d fossil fuels.<br />

Vari<strong>an</strong>t 2<br />

Central DHW Central<br />

heating<br />

45.596,00<br />

3.257,70<br />

100,00<br />

3.013,23<br />

8.012,93<br />

104,09<br />

11.130,25<br />

61,39<br />

1.080,00<br />

1.080,00<br />

24,00<br />

15.467,95<br />

68,35<br />

Vari<strong>an</strong>t 3<br />

Decentralized DHW<br />

Central heating<br />

+ buffer t<strong>an</strong>k<br />

63.867,00<br />

5.461,48<br />

167,65<br />

2.168,33<br />

8.012,93<br />

119,32<br />

10.300,58<br />

56,81<br />

1.170,00<br />

1.170,00<br />

26,00<br />

16.932,06<br />

74,82<br />

(Source: Kulle & Hofstetter, Stadtwerke München, 2011)

Central versus decentralized<br />

domestic hot water producti<strong>on</strong><br />

The renovati<strong>on</strong> study compares the<br />

lifecycle costs of <strong>an</strong> existing hot water<br />

producti<strong>on</strong> <strong>with</strong> electrical water heaters<br />

in every apartment <strong>with</strong> a central hot<br />

water producti<strong>on</strong> <strong>an</strong>d a decentralized<br />

hot water producti<strong>on</strong>.<br />

Both the central <strong>an</strong>d the decentralized<br />

domestic hot water producti<strong>on</strong> dem<strong>on</strong>strate<br />

such major benefits <strong>with</strong> the<br />

New building cost effectiveness <strong>an</strong>alysis<br />

lower c<strong>on</strong>sumpti<strong>on</strong> <strong>an</strong>d operating costs<br />

al<strong>on</strong>e, that their investment is already<br />

paid back <strong>with</strong>in approx. 3 years.<br />

The future price increases for fossil fuels<br />

were not yet c<strong>on</strong>sidered here either.<br />

50 apartments – new building Vari<strong>an</strong>t 1<br />

1.<br />

1.1<br />

1.2<br />

2.<br />

2.1<br />

2.2<br />

3.<br />

3.1<br />

Investment <strong>an</strong>d capital costs<br />

Investment costs<br />

Capital-dependent costs<br />

Relati<strong>on</strong> to Vari<strong>an</strong>t 1<br />

C<strong>on</strong>sumpti<strong>on</strong> related costs<br />

Heat loss<br />

Energy costs Circulati<strong>on</strong> pumps<br />

Total<br />

Relati<strong>on</strong> to Vari<strong>an</strong>t 1<br />

Operati<strong>on</strong> related costs<br />

Mainten<strong>an</strong>ce<br />

Total<br />

Relati<strong>on</strong> to Vari<strong>an</strong>t 1<br />

4. Annual costs<br />

Relati<strong>on</strong> to Vari<strong>an</strong>t 1<br />

€<br />

€ / a<br />

%<br />

€<br />

€ / a<br />

€ / a<br />

€ / a<br />

%<br />

€<br />

€ / a<br />

€ / a<br />

%<br />

€ / a<br />

%<br />

7<br />

Electrical DHW<br />

boiler in apartment<br />

Central heating<br />

67.334,00<br />

4.865,83<br />

100,00<br />

3.012,81<br />

253,99<br />

3.266,80<br />

100,00<br />

1.080,00<br />

1.080,00<br />

100,00<br />

9.212,62<br />

100,00<br />

Introducti<strong>on</strong><br />

Vari<strong>an</strong>t 2<br />

Central DHW<br />

Central heating<br />

85.505,00<br />

7.062,68<br />

145,18<br />

2.168,03<br />

177,18<br />

2.345,21<br />

71,79<br />

1.170,00<br />

1.170,00<br />

108,33<br />

10.577,89<br />

114,82<br />

Vari<strong>an</strong>t 3<br />

Decentralized DHW<br />

Central heating<br />

+ buffer storage<br />

72.291,00<br />

6.277,80<br />

129,02<br />

745,42<br />

164,03<br />

909,45<br />

27,84<br />

1.170,00<br />

1.170,00<br />

108,33<br />

8.357,25<br />

90,72<br />

(Source: Kulle & Hofstetter, Stadtwerke München, 2011)

Introducti<strong>on</strong><br />

1.3 Domestic hot water: hygiene <strong>an</strong>d high comfort<br />

Water is essential to life<br />

After air, water is our most import<strong>an</strong>t<br />

essential. Legislators set very high<br />

requirements for domestic water <strong>system</strong>s<br />

<strong>an</strong>d their operators to protect the<br />

c<strong>on</strong>sumers.<br />

Legi<strong>on</strong>ella bacteria<br />

Thermal disinfecti<strong>on</strong> is a proven method<br />

for hygienically safe domestic water<br />

heating. The domestic water is heated<br />

over a l<strong>on</strong>ger period to a temperature<br />

of more th<strong>an</strong> 60 °C, which prevents <strong>an</strong>y<br />

Legi<strong>on</strong>ella bacteria to grow in domestic<br />

hot water.<br />

The hot water circulati<strong>on</strong> must also be<br />

submitted to the same. When the entire<br />

distributi<strong>on</strong> <strong>system</strong> for domestic hot<br />

water has been regularly rinsed <strong>an</strong>d<br />

hydr<strong>on</strong>icly bal<strong>an</strong>ced, all domestic water<br />

regulati<strong>on</strong>s have been met.<br />

The disadv<strong>an</strong>tage of central domestic<br />

water heating <strong>with</strong> thermal disinfecti<strong>on</strong><br />

is enormous heat loss, which escapes<br />

when tr<strong>an</strong>sporting domestic hot water<br />

from the point of heating to the individual<br />

tap points.<br />

They therefore pass the resp<strong>on</strong>sibility<br />

for the domestic water quality through<br />

different drinking water directives <strong>on</strong><br />

to the m<strong>an</strong>ufacturers <strong>an</strong>d operators of<br />

installati<strong>on</strong>s <strong>an</strong>d <strong>system</strong>s for domestic<br />

water heating <strong>an</strong>d distributi<strong>on</strong>.<br />

The decentralized domestic water<br />

heating has the adv<strong>an</strong>tage that water is<br />

<strong>on</strong>ly heated when it is actually needed<br />

– <strong>an</strong>d in the required amount. Storage<br />

is not required, nor are l<strong>on</strong>g tr<strong>an</strong>sport<br />

pipes <strong>with</strong> enormous heat losses.<br />

As the „fresh“ water <strong>system</strong> is directly<br />

in the respective apartment, the supply<br />

pipes are so short that complies <strong>with</strong><br />

DVGW 3-liter (Germ<strong>an</strong>) regulati<strong>on</strong>. This<br />

me<strong>an</strong>s: The volume of the heating water<br />

pipe between the water heating point<br />

<strong>an</strong>d the c<strong>on</strong>sumer is less th<strong>an</strong> 3 liters.<br />

In the case of flat stati<strong>on</strong>s, the heating<br />

water pipes are regularly rinsed <strong>an</strong>d<br />

the domestic hot water is completely<br />

replaced, which me<strong>an</strong>s practically no<br />

Legi<strong>on</strong>ella bacteria growth is possible.<br />

8 Introducti<strong>on</strong><br />

High domestic hot water comfort<br />

Flat stati<strong>on</strong>s are built in the way that always<br />

provides a warm water start: when<br />

the hot tap is open, hot water starts to<br />

be produced, just the right temperature<br />

<strong>an</strong>d as much as you need.<br />

If you have several taps, at the same<br />

time you will get the desired amount of<br />

warm water <strong>an</strong>d temperatures <strong>on</strong> all of<br />

them.<br />

In that way, EvoFlat flat stati<strong>on</strong>s always<br />

give users the maximum comfort of hot<br />

water!<br />

Low<br />

liability risk<br />

of Legi<strong>on</strong>ella bacteria growth for<br />

designers <strong>an</strong>d operators

2. Why decide for the EvoFlat <strong>system</strong>?<br />

9<br />

Why decide for the EvoFlat <strong>system</strong>?

Why decide for the EvoFlat <strong>system</strong>?<br />

2.1 From traditi<strong>on</strong>al central heating...<br />

Energy <strong>efficient</strong> <strong>an</strong>d individually<br />

c<strong>on</strong>trolled<br />

A EvoFlat <strong>system</strong> c<strong>on</strong>sists of flat<br />

stati<strong>on</strong>s installed in each individual<br />

apartment <strong>with</strong> 3 central ascending<br />

pipes, supplied from <strong>on</strong>e central<br />

heat source typically located in<br />

the basement.<br />

The EvoFlat <strong>system</strong> c<strong>an</strong> be c<strong>on</strong>nected<br />

<strong>with</strong> a buffer t<strong>an</strong>k to <strong>an</strong>y<br />

heat source in the building. Thus<br />

<strong>an</strong>y ch<strong>an</strong>ges <strong>an</strong>d modernizati<strong>on</strong>s<br />

of the heat supply in the building<br />

will have no effect <strong>on</strong> functi<strong>on</strong>ality<br />

of flat stati<strong>on</strong>s.<br />

A flat stati<strong>on</strong> include <strong>an</strong> extremely<br />

compact heat exch<strong>an</strong>ger <strong>with</strong> a<br />

pressure c<strong>on</strong>trolled flow proporti<strong>on</strong>al<br />

c<strong>on</strong>troller, which delivers<br />

domestic hot water immediately,<br />

<strong>an</strong>d a differential pressure c<strong>on</strong>troller<br />

for the heat supply of the<br />

individual radiators.<br />

EvoFlat <strong>system</strong>s are the modern<br />

replacement for traditi<strong>on</strong>al central<br />

heating <strong>an</strong>d hot water <strong>system</strong>s,<br />

such as:<br />

• Central heating <strong>system</strong>s <strong>with</strong><br />

central DHW producti<strong>on</strong>, fuelled<br />

by oil <strong>an</strong>d gas boilers or district<br />

heating.<br />

• Gas-fired boilers installed in<br />

each apartment to produce heat<br />

<strong>an</strong>d domestic hot water.<br />

• Electrical heaters, whereby the<br />

domestic hot water is produced<br />

by small electrical heaters in<br />

each apartment.<br />

Traditi<strong>on</strong>al<br />

soluti<strong>on</strong><br />

10<br />

Why decide for the EvoFlat <strong>system</strong>?<br />

Heat source<br />

<strong>an</strong>d buffer t<strong>an</strong>k<br />

Traditi<strong>on</strong>al<br />

centralized heating<br />

<strong>an</strong>d hot water <strong>system</strong>

... to modern decentralized soluti<strong>on</strong>s<br />

Flat stati<strong>on</strong><br />

Flat stati<strong>on</strong><br />

Flat stati<strong>on</strong><br />

Flat stati<strong>on</strong><br />

Heat Source<br />

<strong>an</strong>d buffer t<strong>an</strong>k<br />

The EvoFlat <strong>system</strong><br />

– <strong>with</strong> decentralized<br />

heating <strong>an</strong>d domestic hot water<br />

11<br />

Why decide for the EvoFlat <strong>system</strong>?<br />

EvoFlat<br />

soluti<strong>on</strong>

Why decide for the EvoFlat <strong>system</strong>?<br />

2.2 Comparis<strong>on</strong> <strong>with</strong> traditi<strong>on</strong>al central<br />

<strong>an</strong>d decentralized heating <strong>system</strong>s<br />

System comparis<strong>on</strong> <strong>an</strong>d benefits<br />

over individual gas <strong>an</strong>d electrical heaters<br />

There are numerous opti<strong>on</strong>s when<br />

select ing <strong>an</strong> energy c<strong>on</strong>cept for heating<br />

<strong>an</strong>d domestic water heating in new<br />

buildings <strong>an</strong>d existing renovati<strong>on</strong>s.<br />

Every <strong>system</strong> has its adv<strong>an</strong>tages <strong>an</strong>d<br />

disadv<strong>an</strong>tages.<br />

Parameter<br />

Despite the d<strong>an</strong>gers posed by Legi<strong>on</strong>ella<br />

bacteria growth, central <strong>system</strong>s<br />

for domestic water heating <strong>with</strong><br />

integrated thermal disinfecti<strong>on</strong> are <strong>on</strong>ly<br />

rarely to be found in large apartment<br />

EvoFlat<br />

<strong>system</strong> <strong>with</strong><br />

flat stati<strong>on</strong>s<br />

12<br />

Individual<br />

gas boiler<br />

Decentralized<br />

domestic<br />

hot water<br />

Why decide for the EvoFlat <strong>system</strong>?<br />

blocks. This has also been c<strong>on</strong>sidered<br />

in the following list, as have some other<br />

things that are often lacking in existing<br />

buildings.<br />

Centralized<br />

boiler<br />

<strong>an</strong>d domestic<br />

hot water<br />

Solar-powered<br />

domestic<br />

hot water<br />

Individual metering <strong>an</strong>d billing 3 3 ÷ ÷ 3<br />

Efficient exploitati<strong>on</strong> of heat energy 3 ÷ ÷ ÷ 3<br />

Eliminate risk of bacteria growth 3 3 3 ÷ ÷<br />

Individual comfort 3 ÷ ÷ 3 3<br />

Full flexibility of heat source 3 ÷ ÷ 3 ÷<br />

Space-saving <strong>system</strong> installati<strong>on</strong> 3 ÷ ÷ ÷ ÷<br />

Reduced service requirements 3 ÷ ÷ ÷ ÷<br />

Installati<strong>on</strong> safety <strong>an</strong>d c<strong>on</strong>venience 3 ÷ 3 3 3<br />

Reduced complexity of piping 3 3 3 ÷ ÷<br />

Shorter piping runs 3 3 3 ÷ ÷<br />

Individual water storage t<strong>an</strong>k saving 3 3 3 ÷ ÷<br />

Central boiler saving ÷ 3 ÷ ÷ ÷

Why decide for the EvoFlat <strong>system</strong>?<br />

2.3 Signific<strong>an</strong>t benefits <strong>with</strong> EvoFlat<br />

Operating efficiency, energy <strong>an</strong>d the envir<strong>on</strong>ment<br />

• Highest level of efficiency <strong>with</strong> central heat source compared to individual<br />

boilers<br />

• No polluti<strong>on</strong> <strong>an</strong>d CO2 emissi<strong>on</strong>s when c<strong>on</strong>nected to district heating<br />

• Easy integrati<strong>on</strong> of renewable energy sources <strong>with</strong> buffer t<strong>an</strong>k<br />

• Optimum boiler operati<strong>on</strong> <strong>with</strong> l<strong>on</strong>ger burner run times<br />

• Lower return temperatures <strong>with</strong> low pressure loss <strong>with</strong> high <strong>efficient</strong> heat<br />

exch<strong>an</strong>gers<br />

• Higher utilizati<strong>on</strong> of solar <strong>an</strong>d c<strong>on</strong>densing <strong>system</strong>s <strong>with</strong> low return<br />

temperatures<br />

• Less pipe loss <strong>with</strong> decentralized water heating<br />

• No additi<strong>on</strong>al pump energy used <strong>with</strong> decentralized water heating<br />

• No meter secti<strong>on</strong>s in the kitchen or bathroom <strong>with</strong> integrated heating <strong>an</strong>d<br />

water meters in the stati<strong>on</strong><br />

C<strong>on</strong>venience <strong>an</strong>d cost tr<strong>an</strong>spar<strong>an</strong>cy<br />

• Higher heating comfort throughout entire year <strong>with</strong> c<strong>on</strong>tinuous supply<br />

• Higher domestic hot water comfort <strong>with</strong> „fresh“ water <strong>system</strong> in every apartment<br />

• High tapping capacity <strong>with</strong> respected flat stati<strong>on</strong>s sizes<br />

• C<strong>on</strong>sumpti<strong>on</strong> accurate billing <strong>with</strong> energy <strong>an</strong>d water meters in every stati<strong>on</strong><br />

• Thrifty energy h<strong>an</strong>dling <strong>with</strong> water <strong>an</strong>d heat c<strong>on</strong>sumpti<strong>on</strong> tr<strong>an</strong>sparency<br />

• Easy c<strong>on</strong>sumpti<strong>on</strong> recording <strong>an</strong>d billing per residential unit <strong>with</strong> remote read<br />

out <strong>system</strong>s<br />

Installati<strong>on</strong> <strong>an</strong>d commissi<strong>on</strong>ing<br />

• No flow <strong>an</strong>d differential pressure c<strong>on</strong>trollers in the distributi<strong>on</strong> <strong>system</strong><br />

• Low space requirement <strong>with</strong> in wall <strong>an</strong>d shaft installati<strong>on</strong><br />

• Lower installati<strong>on</strong> costs <strong>with</strong> 3 instead or 5 ascending pipes<br />

• Easier hydr<strong>on</strong>ic bal<strong>an</strong>ce <strong>with</strong> integrated differential pressure for DHW <strong>an</strong>d<br />

heating integrated in every stati<strong>on</strong><br />

• Highly <strong>efficient</strong> heat tr<strong>an</strong>sfer <strong>with</strong> new MicroPlate heat exch<strong>an</strong>ger inside the<br />

EvoFlat stati<strong>on</strong><br />

• Step-by-step renovati<strong>on</strong> in occupied flats (flat-by-flat c<strong>on</strong>versi<strong>on</strong>)<br />

• 5 steps mounting make it easy to install stati<strong>on</strong>s just when they are needed,<br />

partial installati<strong>on</strong> <strong>an</strong>d operati<strong>on</strong> possible<br />

13<br />

Why decide for the EvoFlat <strong>system</strong>?<br />

Safety <strong>an</strong>d hygiene<br />

• No open fire source in apartment<br />

(gas boiler)<br />

• No gas leakage in apartment<br />

• No legi<strong>on</strong>ella bacteria growth<br />

<strong>with</strong> decentralized, inst<strong>an</strong>t<strong>an</strong>eous<br />

water heating<br />

Mainten<strong>an</strong>ce <strong>an</strong>d service<br />

• Just <strong>on</strong>e or n<strong>on</strong>e (depending <strong>on</strong><br />

source) chimney sweep visit for<br />

central heat producti<strong>on</strong><br />

• No special mainten<strong>an</strong>ce for decentralized<br />

flat stati<strong>on</strong>s needed<br />

• Easy mainten<strong>an</strong>ce: fault usually<br />

<strong>on</strong>ly affects <strong>on</strong>e <strong>system</strong> (apartment)

3. What is the EvoFlat <strong>system</strong> soluti<strong>on</strong>?<br />

District<br />

heating<br />

Central<br />

heating<br />

Independent of energy source<br />

Solar heating/<br />

Heat pump<br />

14<br />

Biomass/<br />

CHP <strong>system</strong><br />

What is the EvoFlat <strong>system</strong> soluti<strong>on</strong><br />

Ten<strong>an</strong>ts <strong>an</strong>d apartment owners expect<br />

the highest possible comfort from their<br />

heating <strong>system</strong>, at the lowest possible<br />

costs. Usually they are not really interested<br />

in the kind of energy source that is<br />

used or how the <strong>system</strong> works.<br />

The main dem<strong>an</strong>ds from ten<strong>an</strong>ts are that:<br />

1. their apartment has the comfort temperature<br />

they w<strong>an</strong>t,<br />

2. they have domestic hot water in<br />

sufficient qu<strong>an</strong>tities immediately<br />

<strong>an</strong>d hygienically safe at all times,<br />

3. they pay the lowest possible<br />

price for it.<br />

The EvoFlat <strong>system</strong> meets all these<br />

requirements.

What is the EvoFlat <strong>system</strong> soluti<strong>on</strong>?<br />

3.1 The functi<strong>on</strong> of the EvoFlat stati<strong>on</strong><br />

The EvoFlat stati<strong>on</strong> is a complete individual<br />

heat tr<strong>an</strong>sfer unit for domestic<br />

hot water <strong>an</strong>d heating in flats as well<br />

as in single family houses. The supply<br />

<strong>system</strong> c<strong>an</strong> be fuelled by all heat<br />

sources; oil, gas, district heating as<br />

well as in combinati<strong>on</strong> <strong>with</strong> renewable<br />

energy sources like solar, biomass <strong>an</strong>d<br />

heat pumps<br />

Individual comfort<br />

The end-user will be able to adjust the<br />

EvoFlat stati<strong>on</strong> to their individual needs<br />

for comfort <strong>an</strong>d each user is able to save<br />

energy <strong>an</strong>d reap the rewards.<br />

Complete soluti<strong>on</strong><br />

The EvoFlat stati<strong>on</strong> is equipped <strong>with</strong><br />

all necessary comp<strong>on</strong>ents, correctly<br />

dimensi<strong>on</strong>ed to the individual dwelling .<br />

The stati<strong>on</strong> c<strong>on</strong>sists of three main<br />

elements : Inst<strong>an</strong>t<strong>an</strong>eous preparati<strong>on</strong> of<br />

domestic hot water, differential pressure<br />

c<strong>on</strong>trol of the heating <strong>an</strong>d DHW<br />

<strong>system</strong> <strong>an</strong>d metering of the energy<br />

c<strong>on</strong>sumpti<strong>on</strong> .<br />

Examples – DHW Capacity<br />

DHW preparati<strong>on</strong><br />

The stati<strong>on</strong> includes a heat exch<strong>an</strong>ger<br />

for inst<strong>an</strong>t<strong>an</strong>eous preparati<strong>on</strong> of the<br />

domestic hot water. The temperature of<br />

the domestic hot water is c<strong>on</strong>trolled by<br />

multi functi<strong>on</strong>al D<strong>an</strong>foss c<strong>on</strong>trol valves,<br />

which ensures optimum comfort.<br />

Heating <strong>system</strong><br />

A differential pressure c<strong>on</strong>troller is a<br />

part of all stati<strong>on</strong>s in order to secure<br />

correct pressure for the radiator <strong>system</strong>.<br />

The EvoFlat c<strong>an</strong> also include mixing<br />

loop for lowering the supply temperature<br />

for floor heating <strong>system</strong> or a heat<br />

exch<strong>an</strong>ger for separating the supply<br />

<strong>system</strong> from the individual dwellings.<br />

Individual billing<br />

Meter fitting pieces are a part of the<br />

stati<strong>on</strong>, for easy mounting of meters for<br />

measuring energy <strong>an</strong>d cold water use,<br />

to give the individual customer accurate<br />

billing according to c<strong>on</strong>sumpti<strong>on</strong>.<br />

Capacity Tapping volume 10/45 °C Tapping volume 10/50 °C<br />

36kW 14,8 I/min 13,0 I/min<br />

45kW 18,4 I/min 16,2 I/min<br />

55kW 22,51 I/min 19,8 I/min<br />

15<br />

What is the EvoFlat <strong>system</strong> soluti<strong>on</strong><br />

Easy to install<br />

The EvoFlat stati<strong>on</strong> is a compact combinati<strong>on</strong><br />

of all needed equipment, which<br />

takes up as little space as possible. Also<br />

a complete soluti<strong>on</strong> ensures that all<br />

comp<strong>on</strong>ents are placed <strong>an</strong>d chosen<br />

correctly. Finally the installer will save<br />

installati<strong>on</strong> time <strong>an</strong>d m<strong>on</strong>ey <strong>with</strong> a<br />

prefabricated soluti<strong>on</strong>.<br />

Hygiene<br />

The EvoFlat is a very hygienic soluti<strong>on</strong>,<br />

because the DHW is prepared when<br />

needed close to taps <strong>an</strong>d is not stored.

CW<br />

What is the EvoFlat <strong>system</strong> soluti<strong>on</strong>?<br />

3.2 Main elements of the decentralized <strong>system</strong><br />

The decentralized EvoFlat <strong>system</strong> c<strong>an</strong><br />

be designed <strong>an</strong>d utilize <strong>an</strong>y available<br />

energy source for heating, as st<strong>an</strong>d<br />

al<strong>on</strong>e or in combinati<strong>on</strong>.<br />

DH SUPPLy<br />

Main elements of the<br />

decentralized <strong>system</strong><br />

1. Boiler (or DH c<strong>on</strong>necti<strong>on</strong>)<br />

2. Buffer t<strong>an</strong>k<br />

3. Charging pump<br />

4. Main pump<br />

5. Differential pressure<br />

c<strong>on</strong>troller<br />

6. Flat stati<strong>on</strong> (hydraulic<br />

interface unit)<br />

7. Pipes<br />

DH RETURN 5 1<br />

7<br />

7<br />

7<br />

16<br />

6<br />

6<br />

6<br />

OR<br />

3<br />

2<br />

What is the EvoFlat <strong>system</strong> soluti<strong>on</strong><br />

4

What is the EvoFlat <strong>system</strong> soluti<strong>on</strong>?<br />

3.3 Independent of the available energy source<br />

Flat stati<strong>on</strong>s are open to work <strong>with</strong> all<br />

available energy sources.<br />

The most frequently used are:<br />

1) Oil or gas c<strong>on</strong>densing boilers, solid or<br />

pellet boilers or CHP as central heat<br />

supply<br />

2) Local <strong>an</strong>d district heating c<strong>on</strong>necti<strong>on</strong><br />

<strong>with</strong> a central tr<strong>an</strong>sfer stati<strong>on</strong><br />

3) Solar thermal energy <strong>with</strong> solar collectors<br />

as primary energy combined<br />

<strong>with</strong> other heat supply<br />

All available energy sources c<strong>an</strong> be<br />

combined <strong>with</strong> each other. This makes<br />

housing associati<strong>on</strong>s <strong>an</strong>d their ten<strong>an</strong>ts<br />

independent <strong>an</strong>d offers the opti<strong>on</strong> of reacting<br />

in future to energy price ch<strong>an</strong>ges<br />

<strong>an</strong>d availability, replacing old <strong>with</strong> more<br />

energy <strong>efficient</strong> technology.<br />

C<strong>on</strong>densing boiler Substati<strong>on</strong><br />

Vari<strong>an</strong>t 1<br />

Gas, oil or biomass boiler<br />

The decentralized <strong>system</strong> <strong>an</strong>d the flat stati<strong>on</strong>s are supplied <strong>with</strong> hot water for domestic<br />

hot water <strong>an</strong>d heating from oil or gas boiler in the basement. The boiler is<br />

combined <strong>with</strong> a buffer t<strong>an</strong>k.<br />

The buffer t<strong>an</strong>k serves as energy storage for providing quickly required peak loads,<br />

ensures l<strong>on</strong>g burner run times <strong>an</strong>d reliable operati<strong>on</strong> of c<strong>on</strong>densing boilers in ec<strong>on</strong>omical<br />

c<strong>on</strong>densati<strong>on</strong> operati<strong>on</strong>. It also buffers solid fuel boiler peak capacities.<br />

Thermal solar <strong>system</strong><br />

In most EU countries trends are to setting<br />

directives of renewable energies<br />

used in a specified amount <strong>with</strong> new<br />

buildings <strong>an</strong>d complete renovati<strong>on</strong>s of<br />

heating <strong>system</strong>s. Solar thermal energy<br />

is usually the preferred choice. The seas<strong>on</strong>al<br />

difference in solar <strong>system</strong> capacity<br />

me<strong>an</strong>s a buffer t<strong>an</strong>k is always required,<br />

<strong>an</strong>d if there is not enough heat from the<br />

solar <strong>system</strong>, it c<strong>an</strong> be heated <strong>with</strong> a<br />

boiler or district heating c<strong>on</strong>necti<strong>on</strong>.<br />

Vari<strong>an</strong>t 3<br />

Combined <strong>system</strong> – thermal solar <strong>with</strong> boiler<br />

17<br />

Vari<strong>an</strong>t 2<br />

District heating, micro networks<br />

<strong>an</strong>d block heating <strong>system</strong><br />

Investments in heating comfort, domestic<br />

water hygiene <strong>an</strong>d energy efficiency<br />

pay off very quickly for both ten<strong>an</strong>ts<br />

<strong>an</strong>d owners due to increased real estate<br />

value <strong>an</strong>d capital yield by reducing the<br />

costs.<br />

The decentralized <strong>system</strong> <strong>an</strong>d the flat stati<strong>on</strong>s c<strong>an</strong> be supplied <strong>with</strong> hot water for<br />

domestic hot water producti<strong>on</strong> <strong>an</strong>d heating from a district heating substati<strong>on</strong> in<br />

the basement.<br />

The substati<strong>on</strong> is supplied <strong>with</strong> district heating, indirectly c<strong>on</strong>nected <strong>an</strong>d is typically<br />

combined <strong>with</strong> a buffer t<strong>an</strong>k.<br />

What is the EvoFlat <strong>system</strong> soluti<strong>on</strong>

What is the EvoFlat <strong>system</strong> soluti<strong>on</strong>?<br />

3.4 Hydr<strong>on</strong>ic bal<strong>an</strong>cing of the EvoFlat <strong>system</strong><br />

Termix VMTD-F MIX B<br />

Termix VMTD-F-B<br />

Termix VMTD-F-I<br />

18<br />

Hydr<strong>on</strong>ic bal<strong>an</strong>ce<br />

The flow volumes must be bal<strong>an</strong>ced so that all c<strong>on</strong>sumers<br />

of a heating <strong>system</strong> c<strong>an</strong> be supplied equally. These<br />

resist<strong>an</strong>ces vary <strong>on</strong> different secti<strong>on</strong> lengths, elbows,<br />

valves <strong>an</strong>d cross secti<strong>on</strong>s, which are then bal<strong>an</strong>ced, <strong>an</strong>d<br />

the <strong>system</strong> c<strong>an</strong> operate energy <strong>efficient</strong>ly, reliably <strong>an</strong>d<br />

quietly. The hydr<strong>on</strong>ic bal<strong>an</strong>cing of the heating water flow<br />

is performed directly <strong>on</strong> the presetting radiator valves<br />

<strong>an</strong>d <strong>on</strong> the z<strong>on</strong>e valve integrated into the stati<strong>on</strong>. Secti<strong>on</strong><br />

compensati<strong>on</strong> valves are then no l<strong>on</strong>ger required.<br />

Domestic hot water<br />

The maximum DHW flow rate per minute is limited by the<br />

device capacity <strong>an</strong>d the selected hot water temperature.<br />

We recommend inclusi<strong>on</strong> of a safety valve to compensate<br />

<strong>an</strong>y possible pressure rise <strong>with</strong>in the domestic hot water<br />

<strong>system</strong>.<br />

(Germ<strong>an</strong> technical regulati<strong>on</strong>s, especially those of the<br />

applicable Drinking water Directive <strong>an</strong>d of DIN EN 806, DIN<br />

EN 1717 <strong>an</strong>d DIN 1988 /DVGW-TRWI 1988 <strong>an</strong>d DIN EN 12502,<br />

apply for c<strong>on</strong>necti<strong>on</strong> to the domestic water supply <strong>an</strong>d the<br />

perform<strong>an</strong>ce of the entire domestic water installati<strong>on</strong>.)<br />

Complete <strong>system</strong><br />

The individual secti<strong>on</strong>s do not have to be bal<strong>an</strong>ced between<br />

each other. Secti<strong>on</strong> differential pressure c<strong>on</strong>trollers<br />

or secti<strong>on</strong> c<strong>on</strong>trol valves are not required <strong>with</strong> EvoFlat<br />

stati<strong>on</strong>s. The flow rate for the heating water producti<strong>on</strong><br />

is determined by the number of tapping points. The<br />

heat source flow rate is determined by c<strong>on</strong>sidering the<br />

simult<strong>an</strong>eity factors for apartment buildings. D<strong>an</strong>foss hot<br />

water c<strong>on</strong>troller in the respective flat stati<strong>on</strong> completely<br />

bal<strong>an</strong>ces pressure <strong>an</strong>d temperature fluctuati<strong>on</strong>s <strong>on</strong> the<br />

primary side <strong>with</strong> its integrated differential pressure c<strong>on</strong>troller,<br />

together <strong>with</strong> the temperature c<strong>on</strong>troller.<br />

What is the EvoFlat <strong>system</strong> soluti<strong>on</strong>

Hydr<strong>on</strong>ic bal<strong>an</strong>ce of the apartment’s heating circuit<br />

Distributi<strong>on</strong> <strong>system</strong> must ensure that<br />

thermal energy is available for the c<strong>on</strong>sumer<br />

at all times <strong>an</strong>d loads, at the right<br />

temperature <strong>an</strong>d the right differential<br />

pressure.<br />

The required differential pressure must<br />

be ensured at all relev<strong>an</strong>t points of a<br />

distributi<strong>on</strong> <strong>system</strong>, beginning <strong>with</strong> the<br />

energy producti<strong>on</strong>, right through to the<br />

least favorable radiator. Installati<strong>on</strong> of<br />

a differential pressure c<strong>on</strong>troller in the<br />

apartment heating circuit guar<strong>an</strong>tees<br />

fault free hydr<strong>on</strong>ic c<strong>on</strong>diti<strong>on</strong>s.<br />

21°C<br />

A str<strong>on</strong>g opini<strong>on</strong>, which still exists<br />

around, that a heating <strong>system</strong> c<strong>an</strong> be<br />

properly bal<strong>an</strong>ced <strong>with</strong> secti<strong>on</strong> m<strong>an</strong>ual<br />

bal<strong>an</strong>cing valves <strong>an</strong>d regulated pumps<br />

<strong>on</strong>ce again proved to be err<strong>on</strong>eous in<br />

practice.<br />

In additi<strong>on</strong> to a correctly set differential<br />

pressure c<strong>on</strong>troller for the apartment<br />

heating circuit, the individual radiator<br />

valves must also be correctly preset.<br />

St<strong>an</strong>dard compli<strong>an</strong>t differential pressures<br />

in fr<strong>on</strong>t of the radiator valves now<br />

make flow noises a thing of the past.<br />

21°C 21°C<br />

21°C 21°C 21°C<br />

21°C 21°C 21°C<br />

19<br />

What is the EvoFlat <strong>system</strong> soluti<strong>on</strong><br />

The heating side c<strong>on</strong>necti<strong>on</strong> is made<br />

<strong>with</strong>out <strong>an</strong>y <strong>system</strong> separati<strong>on</strong>. The<br />

heating circuit supply must be fitted<br />

<strong>with</strong> a differential pressure c<strong>on</strong>troller to<br />

guar<strong>an</strong>tee optimum pressure c<strong>on</strong>diti<strong>on</strong>s<br />

<strong>an</strong>d flows in the heating <strong>system</strong>. The<br />

room temperature is c<strong>on</strong>trolled <strong>with</strong><br />

radiator thermostats. With the mounting<br />

of a thermal actuator <strong>with</strong> installed<br />

z<strong>on</strong>e valve <strong>an</strong>d using central m<strong>an</strong>ual<br />

or programmable room thermostat<br />

enables a c<strong>on</strong>venient, energy optimized<br />

c<strong>on</strong>trol of the heating.<br />

Example of well bal<strong>an</strong>ced heat<br />

distributi<strong>on</strong><br />

• Proper c<strong>on</strong>trol of flow <strong>an</strong>d pressure<br />

to each flat <strong>with</strong> differential<br />

pressure c<strong>on</strong>troller<br />

• proper temperature in each room<br />

secured <strong>with</strong> pre-setting valves<br />

<strong>with</strong> thermostat sensor <strong>on</strong> each<br />

radiator<br />

Differential pressure c<strong>on</strong>troller is part<br />

of each flat stati<strong>on</strong>

What is the EvoFlat <strong>system</strong> soluti<strong>on</strong>?<br />

3.5 Design, key comp<strong>on</strong>ents<br />

<strong>an</strong>d features of a flat stati<strong>on</strong><br />

6<br />

4<br />

2<br />

4<br />

5<br />

Shown example: Termix VMTD-F-I<br />

1<br />

3<br />

7<br />

20<br />

Key comp<strong>on</strong>ents <strong>on</strong> the EvoFlat<br />

flat stati<strong>on</strong><br />

1. Micro plate Heat exch<strong>an</strong>ger for<br />

DHW<br />

2. Multi-functi<strong>on</strong>al c<strong>on</strong>trol valve<br />

3. Differential pressure c<strong>on</strong>troller<br />

(hydraulic bal<strong>an</strong>cing)<br />

4. Inserts for energy <strong>an</strong>d water<br />

meter<br />

5. Strainer<br />

6. Insulati<strong>on</strong><br />

7. Z<strong>on</strong>e valve<br />

Stati<strong>on</strong>s <strong>with</strong> circulati<strong>on</strong> pump will<br />

be equipped <strong>with</strong> A-class pumps<br />

The total quality of the flat stati<strong>on</strong> is the<br />

sum of the applied comp<strong>on</strong>ents. The<br />

main c<strong>on</strong>trol comp<strong>on</strong>ents from D<strong>an</strong>foss<br />

warr<strong>an</strong>t a reliable <strong>an</strong>d stable operati<strong>on</strong>.<br />

CIRCuIT DIAGRAM B Plate heat exch<strong>an</strong>ger DHW<br />

9 Strainer<br />

DHW<br />

14<br />

31<br />

Sensor pocket, energy meter<br />

Differential pressure c<strong>on</strong>troller<br />

41A Fitting piece, water meter<br />

¾” x 80 mm<br />

41B Fitting piece, energy meter ¾” x 110 mm<br />

48 Air escape m<strong>an</strong>ual<br />

Circ.<br />

63 Strainer<br />

74 IHPT<br />

DCW<br />

CWM<br />

DH<br />

Supply<br />

DH<br />

Return<br />

What is the EvoFlat <strong>system</strong> soluti<strong>on</strong><br />

HE<br />

Supply<br />

HE<br />

Return

What is the EvoFlat <strong>system</strong> soluti<strong>on</strong>?<br />

3.5.1 Brazed plate heat exch<strong>an</strong>gers<br />

MicroPlate heat exch<strong>an</strong>ger - for <strong>efficient</strong> <strong>an</strong>d inst<strong>an</strong>t<strong>an</strong>eous producti<strong>on</strong><br />

of domestic hot water<br />

Type XB06 Type XB 37<br />

The lowest possible return temperature<br />

<strong>with</strong> inst<strong>an</strong>t<strong>an</strong>eous producti<strong>on</strong> of the<br />

required tapping capacity is critical for<br />

the energy efficiency of domestic water<br />

<strong>system</strong>s in flat stati<strong>on</strong>s.<br />

To meet that dem<strong>an</strong>d, heat exch<strong>an</strong>gers<br />

<strong>with</strong> a particularly high level of efficiency<br />

are required. D<strong>an</strong>foss uses the<br />

new MicroPlate heat exch<strong>an</strong>ger for its<br />

10%<br />

Better heat tr<strong>an</strong>sfer<br />

Th<strong>an</strong>ks to <strong>an</strong> innovative plate design<br />

which optimizes flow velocity<br />

MicroPlate plate pattern<br />

EvoFlat flat stati<strong>on</strong>s. These are c<strong>on</strong>figured<br />

<strong>an</strong>d dimensi<strong>on</strong>ed in accord<strong>an</strong>ce<br />

<strong>with</strong> the requested tapping capacity.<br />

The hot water temperature depends<br />

<strong>on</strong> the available temperature <strong>on</strong> the<br />

primary side (supply temperature).<br />

The supply which flows in <strong>on</strong>e directi<strong>on</strong><br />

is heating domestic water flowing in opposite<br />

directi<strong>on</strong>s in the heat exch<strong>an</strong>ger.<br />

21<br />

What is the EvoFlat <strong>system</strong> soluti<strong>on</strong><br />

Signific<strong>an</strong>t benefits:<br />

- Energy <strong>an</strong>d cost savings<br />

- Better heat tr<strong>an</strong>sfer<br />

- Lower pressure loss<br />

- More flexible design<br />

- L<strong>on</strong>ger life time<br />

- Patented MicroPlate pattern<br />

technology<br />

- Reduced CO2 foot print<br />

The D<strong>an</strong>foss heat exch<strong>an</strong>ger c<strong>on</strong>necti<strong>on</strong>s<br />

<strong>an</strong>d plates are produced from<br />

stainless steel 1.4404 <strong>an</strong>d c<strong>on</strong>nected<br />

<strong>with</strong> copper solder. They are ideal for<br />

use <strong>with</strong> all st<strong>an</strong>dard heating water<br />

<strong>an</strong>d use in domestic water <strong>system</strong>s. If<br />

in <strong>an</strong>y doubt the water quality must<br />

be checked <strong>with</strong> the respective supply<br />

comp<strong>an</strong>y.

What is the EvoFlat <strong>system</strong> soluti<strong>on</strong>?<br />

3.5.2 Domestic hot water c<strong>on</strong>trol valve – Introducti<strong>on</strong><br />

A multi-functi<strong>on</strong>al DHW c<strong>on</strong>trol valve inside EvoFlat!<br />

During tapping<br />

When domestic hot water is needed the<br />

DHW c<strong>on</strong>trol valve opens <strong>an</strong>d the heat<br />

exch<strong>an</strong>ger heats the cold water<br />

to the desired temperature. The sensor<br />

of the DHW c<strong>on</strong>trol valve is placed in the<br />

heat exch<strong>an</strong>ger <strong>an</strong>d the valve maintains<br />

the temperature of DHW according to<br />

the temperature set <strong>on</strong> the thermostat<br />

part of the valve. The temperature<br />

Main features <strong>an</strong>d benefits of the DHW c<strong>on</strong>troller<br />

Intelligent c<strong>on</strong>trol <strong>with</strong> thermostatic<br />

override<br />

The IHPT c<strong>on</strong>troller c<strong>on</strong>trols the domestic<br />

hot water by taking both flow<br />

volume <strong>an</strong>d temperature into account.<br />

By tapping the valves opens <strong>an</strong>d the<br />

thermostat start to c<strong>on</strong>trol the DHW<br />

temperature.<br />

The c<strong>on</strong>trol is independent of varying<br />

flow temperatures <strong>an</strong>d differential<br />

is kept stable independently of the<br />

ch<strong>an</strong>ges in tapping flow, differential<br />

pressure <strong>an</strong>d supply temperature.<br />

Quick closing<br />

When the dem<strong>an</strong>d for DHW stops the<br />

valve must close quickly in order to<br />

protect the heat exch<strong>an</strong>ger against<br />

overheating <strong>an</strong>d lime scale formati<strong>on</strong>.<br />

pressure. When tapping ends, the valve<br />

closes immediately. This protects the<br />

heat exch<strong>an</strong>ger from scaling.<br />

Key features of IHPT:<br />

• Optimum c<strong>on</strong>trol perform<strong>an</strong>ce<br />

• Integrated st<strong>an</strong>dby functi<strong>on</strong><br />

• Suitable for low temperature operati<strong>on</strong><br />

• Inst<strong>an</strong>t availability of water <str<strong>on</strong>g>lead</str<strong>on</strong>g>s to<br />

minimum water waste<br />

22<br />

What is the EvoFlat <strong>system</strong> soluti<strong>on</strong><br />

Idle mode<br />

The EvoFlat is delivered <strong>with</strong> a summer<br />

bypass to keep the house supply line<br />

warm. This shortens the waiting periods<br />

during summer when the heating <strong>system</strong><br />

is in reduced operati<strong>on</strong>.

What is the EvoFlat <strong>system</strong> soluti<strong>on</strong>?<br />

3.5.2 Domestic hot water c<strong>on</strong>trol valve – IHPT<br />

Intelligent c<strong>on</strong>trol <strong>with</strong><br />

thermostatic override<br />

The IHPT c<strong>on</strong>troller c<strong>on</strong>trols the domestic<br />

hot water (DHW) by taking both flow<br />

volume <strong>an</strong>d temperature into account.<br />

During tapping the valve opens <strong>an</strong>d the<br />

thermostat start to c<strong>on</strong>trol the DHW<br />

temperature. The c<strong>on</strong>trol is independent<br />

of varying tapping flows, supply<br />

temperature <strong>an</strong>d differential pressure.<br />

When tapping ends, the valve closes<br />

immediately. This protects the heat<br />

exch<strong>an</strong>ger (HEX) from scaling.<br />

Integrated energy <strong>efficient</strong><br />

st<strong>an</strong>dby functi<strong>on</strong> (idle mode)<br />

In periods <strong>with</strong> no tapping of water, the<br />

st<strong>an</strong>dby functi<strong>on</strong> automatically adjusts<br />

itself below the selected DHW temperature.<br />

Thereby the HEX is always ready<br />

to produce DHW. The idle mode is built<br />

into the c<strong>on</strong>troller <strong>an</strong>d requires no readjustments.<br />

Thereby the idle temperature<br />

will always be set correctly, <strong>an</strong>d the<br />

energy usage is kept to a minimum.<br />

Furthermore low return temperature is<br />

ensured, also during st<strong>an</strong>dstill.<br />

Functi<strong>on</strong><br />

2<br />

2 1 4 3<br />

Suitable for low supply<br />

temperature operati<strong>on</strong><br />

The IHPT c<strong>on</strong>troller ensures perfect regulati<strong>on</strong><br />

of DHW at both low <strong>an</strong>d higher<br />

supply temperatures. It also guar<strong>an</strong>tees<br />

maximum comfort at minimum energy<br />

c<strong>on</strong>sumpti<strong>on</strong>. Thus IHPT is the perfect<br />

choice in low supply temperature<br />

<strong>system</strong>s.<br />

Envir<strong>on</strong>mental-friendly comfort<br />

– no waste of water<br />

IHPT ensures that the HEX is always<br />

ready to produce DHW. The house<br />

owner or user feels the comfort by the<br />

inst<strong>an</strong>t availability of hot water in the<br />

tap. This me<strong>an</strong>s high comfort as well as<br />

minimum waste of water.<br />

Integrated differential<br />

pressure c<strong>on</strong>troller<br />

The integrated differential pressure<br />

c<strong>on</strong>troller inside the IHPT optimizes the<br />

c<strong>on</strong>trol c<strong>on</strong>diti<strong>on</strong>s for the thermostatic<br />

part of the valve.<br />

23<br />

IHPT<br />

Flow-compensated temp. c<strong>on</strong>troller<br />

<strong>with</strong> integrated differential pressure<br />

c<strong>on</strong>troller (NO).<br />

Main data<br />

• Pressure stage:<br />

PN16 primary side<br />

PN16 sec<strong>on</strong>dary side<br />

• Dimensi<strong>on</strong>:<br />

DN 15: Kvs = 3,0 m3/h<br />

• Max flow temperature:<br />

120°C<br />

• Temperature r<strong>an</strong>ge:<br />

45°C - 65°C<br />

The IHPT c<strong>on</strong>trol valve c<strong>on</strong>sist of following:<br />

1) The proporti<strong>on</strong>al valve / pilot valve<br />

2) Thermostatic c<strong>on</strong>trol valve.<br />

3) Differential pressure c<strong>on</strong>troller.<br />

4) Thermostat <strong>with</strong> sensor.<br />

When you open the DHW tap a pressure drop<br />

arise at the proporti<strong>on</strong>al valve (1) which force the<br />

thermostatic valve (2) towards open positi<strong>on</strong>. The<br />

thermostat (4) adjust DHW temperature according<br />

to the set value. The differential pressure c<strong>on</strong>troller<br />

(3) c<strong>on</strong>trol a c<strong>on</strong>st<strong>an</strong>t <strong>an</strong>d low differential pressure<br />

across the thermostatic c<strong>on</strong>trol valve (2). By closing<br />

the DHW tap the proporti<strong>on</strong>al valve close the<br />

primary flow immediately.<br />

What is the EvoFlat <strong>system</strong> soluti<strong>on</strong>

What is the EvoFlat <strong>system</strong> soluti<strong>on</strong>?<br />

3.5.2 Domestic hot water c<strong>on</strong>trol valve<br />

– AVTB <strong>with</strong> sensor accelerator<br />

Key features <strong>an</strong>d benefits<br />

Accelerati<strong>on</strong> of closting time<br />

The sensor accelerator accelerates the<br />

closing of the D<strong>an</strong>foss AVTB thermostatic<br />

valve <strong>an</strong>d due to the rapid closing<br />

time protects the heat exch<strong>an</strong>ger<br />

against overheating <strong>an</strong>d lime scale<br />

formati<strong>on</strong>.<br />

Integrated bypass<br />

The AVTB valve <strong>an</strong>d sensor accelerator<br />

work as a bypass to keep the house supply<br />

line warm. This shortens the waiting<br />

periods during summer when the heating<br />

<strong>system</strong> is in reduced operati<strong>on</strong>.<br />

Sensor accelerator<br />

No sec<strong>on</strong>dary pressure loss<br />

There is no additi<strong>on</strong>al pressure loss <strong>on</strong><br />

the sec<strong>on</strong>dary side of the hot water heat<br />

exch<strong>an</strong>ger <strong>with</strong> this type of regulati<strong>on</strong>.<br />

Therefore this regulati<strong>on</strong> c<strong>an</strong> also be<br />

used by low pressure in the cold water<br />

mains.<br />

No readjustments necessary<br />

The user does not need to readjust the<br />

setting temperature, even if the district<br />

heating pl<strong>an</strong>t ch<strong>an</strong>ges operating parameters<br />

between summer <strong>an</strong>d winter,<br />

either by lowering or increasing the<br />

DHS DHW<br />

DHR DCW<br />

AVTB<br />

24<br />

AVTB<br />

What is the EvoFlat <strong>system</strong> soluti<strong>on</strong><br />

The patented Termix sensor accelerator<br />

is mounted <strong>an</strong>d applied together <strong>with</strong><br />

the thermostatic c<strong>on</strong>trol valve AVTB of<br />

the flat stati<strong>on</strong>. Thereby high comfort<br />

<strong>an</strong>d safety of the DHW producti<strong>on</strong> are<br />

achieved.<br />

Main data<br />

• PN16 bar<br />

• Kvs 1,9 / 3,4 m3/h<br />

• Max. Flow temperature: 120 °C<br />

• Optimum c<strong>on</strong>trol up to 90 °C<br />

• Temperature r<strong>an</strong>ge: 20-60 °C<br />

flow temperature of the district heating<br />

water <strong>an</strong>d/or the operating pressure in<br />

the network.<br />

Stable hot water temperature<br />

The sensor accelerator helps to ensure<br />

a stable hot water temperature also by<br />

varying loads, flow temperatures <strong>an</strong>d<br />

differential pressure.<br />

Functi<strong>on</strong>:<br />

Thermostatic c<strong>on</strong>troller AVTB including<br />

sensor accelerator<br />

Applicati<strong>on</strong>:<br />

Systems <strong>with</strong> varying flow temperatures<br />

<strong>an</strong>d differential pressure, where high<br />

out put <strong>an</strong>d low domestic cold water<br />

pressure is needed.<br />

Idle c<strong>on</strong>trol:<br />

Idle c<strong>on</strong>troller is integrated <strong>with</strong> setting<br />

equal to DHW temperature

What is the EvoFlat <strong>system</strong> soluti<strong>on</strong>?<br />

3.5.3 Additi<strong>on</strong>al flat stati<strong>on</strong> comp<strong>on</strong>ents<br />

3. Differential pressure c<strong>on</strong>troller<br />

(0.1 bar)<br />

This comp<strong>on</strong>ent ensures a c<strong>on</strong>st<strong>an</strong>t<br />

differential pressure <strong>with</strong>in the entire<br />

apartment installati<strong>on</strong> (heating 5-25<br />

kPa), <strong>an</strong>d optimum functi<strong>on</strong>ing of the<br />

radiator thermostats. Every radiator<br />

is therefore optimally supplied <strong>with</strong><br />

heat – reliably <strong>an</strong>d quietly.<br />

4. Heat meter<br />

All EvoFlat flat stati<strong>on</strong>s are prepared<br />

for the installati<strong>on</strong> of water <strong>an</strong>d heat<br />

meters. The use of direct immersi<strong>on</strong><br />

sensors is secured.<br />

Heat meter, installed in flat stati<strong>on</strong>,<br />

is <strong>an</strong> ultras<strong>on</strong>ic device for measuring<br />

the c<strong>on</strong>sumpti<strong>on</strong> of thermal energy.<br />

It c<strong>on</strong>sists of:<br />

-calculator <strong>with</strong> integral hardware<br />

<strong>an</strong>d software for measuring flow rate,<br />

temperature <strong>an</strong>d energy c<strong>on</strong>sumpti<strong>on</strong>,<br />

-ultras<strong>on</strong>ic flow sensor,<br />

-two temperature sensors.<br />

Dynamic r<strong>an</strong>ge measurement is<br />

1:250. Minimum flow rate for which<br />

is guar<strong>an</strong>teed measurement accuracy,<br />

according to EN1434, is 6 l/h. If<br />

equipped <strong>with</strong> <strong>on</strong>e of the communicati<strong>on</strong><br />

modules enables easy data<br />

collecti<strong>on</strong> <strong>an</strong>d tr<strong>an</strong>sfer.<br />

5/6. Strainer<br />

Stati<strong>on</strong>s c<strong>an</strong> be fitted <strong>with</strong> strainers:<br />

heating supply (primary) <strong>an</strong>d heating<br />

return (sec<strong>on</strong>dary), <strong>an</strong>d <strong>with</strong> a filter<br />

in the cold water input for the hot<br />

water c<strong>on</strong>troller.<br />

7. Heat insulati<strong>on</strong><br />

The Neopolen heat insulati<strong>on</strong><br />

complies <strong>with</strong> the requirements of<br />

energy c<strong>on</strong>servati<strong>on</strong> regulati<strong>on</strong>s.<br />

8. Room thermostat - together <strong>with</strong><br />

electro-thermal actuator <strong>with</strong><br />

z<strong>on</strong>e valve<br />

Installed in the flat stati<strong>on</strong>’s return<br />

side, enables hydr<strong>on</strong>ic bal<strong>an</strong>cing <strong>an</strong>d<br />

the central c<strong>on</strong>trol of room temperature,<br />

timer <strong>an</strong>d night set-back. This<br />

gives maximum heating comfort <strong>an</strong>d<br />

additi<strong>on</strong>al energy savings to end users.<br />

Room thermostat c<strong>an</strong> be m<strong>an</strong>ual<br />

or programmable.<br />

M<strong>an</strong>ually adjustable room thermostat<br />

type RMT-230 <strong>with</strong>:<br />

– adjustable temperature: 8-30 °C,<br />

– power: 230 V AC,<br />

– switching differential (<strong>on</strong>/off): 0.6 K<br />

is supplied as st<strong>an</strong>dard.<br />

25<br />

What is the EvoFlat <strong>system</strong> soluti<strong>on</strong><br />

For users <strong>with</strong> higher dem<strong>an</strong>ds for<br />

comfort it is possible to use programmable<br />

thermostats TP5001 <strong>with</strong> a<br />

weekly program (5/2) <strong>an</strong>d TP7000 <strong>with</strong><br />

a daily program (6 intervals), <strong>an</strong>d <strong>with</strong><br />

the possibility of lowering the night<br />

temperature.<br />

Piping <strong>an</strong>d c<strong>on</strong>necti<strong>on</strong>s<br />

All elements built into flat stati<strong>on</strong> are<br />

c<strong>on</strong>nected by pipes made of stainless<br />

steel. Extremely low roughness of pipe<br />

<strong>an</strong>d special way of bending ensures<br />

silent operati<strong>on</strong> <strong>an</strong>d small dimensi<strong>on</strong>s<br />

of the stati<strong>on</strong>s. C<strong>on</strong>necti<strong>on</strong> elements<br />

used are made from brass (c<strong>on</strong>necti<strong>on</strong><br />

fittings, elbows <strong>an</strong>d T-pieces). All elements<br />

in the flat stati<strong>on</strong>s are c<strong>on</strong>nected<br />

<strong>with</strong> detachable fittings to allow easy<br />

replacement of parts <strong>an</strong>d easy mainten<strong>an</strong>ce.<br />

Rated nominal pressure of flat<br />

stati<strong>on</strong>s is PN 10 (16) as st<strong>an</strong>dard.<br />

Opti<strong>on</strong>s<br />

All flat stati<strong>on</strong>s c<strong>an</strong> be equipped <strong>with</strong><br />

domestic hot water circulati<strong>on</strong> set <strong>on</strong><br />

request. It c<strong>on</strong>sists of the pump <strong>with</strong><br />

timer, thermostat or both <strong>an</strong>d the required<br />

c<strong>on</strong>necti<strong>on</strong> lines.

What is the EvoFlat <strong>system</strong> soluti<strong>on</strong>?<br />

3.5.4 Multiple cover opti<strong>on</strong>s – Termix stati<strong>on</strong>s<br />