Systematic development of coarse-grained polymer models Patrick ...

Systematic development of coarse-grained polymer models Patrick ...

Systematic development of coarse-grained polymer models Patrick ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

3.6. Effective Persistence Length 29<br />

best-fit λ<br />

0<br />

2.0<br />

10<br />

Ns<br />

20 30 40<br />

1.8<br />

1.6<br />

1.4<br />

1.2<br />

1.0<br />

λ<br />

20<br />

15<br />

10<br />

5<br />

0<br />

0.0 0.1 0.2<br />

1/ν<br />

0.3<br />

0.8<br />

0.00 0.02 0.04<br />

1/ν<br />

0.06 0.08 0.10<br />

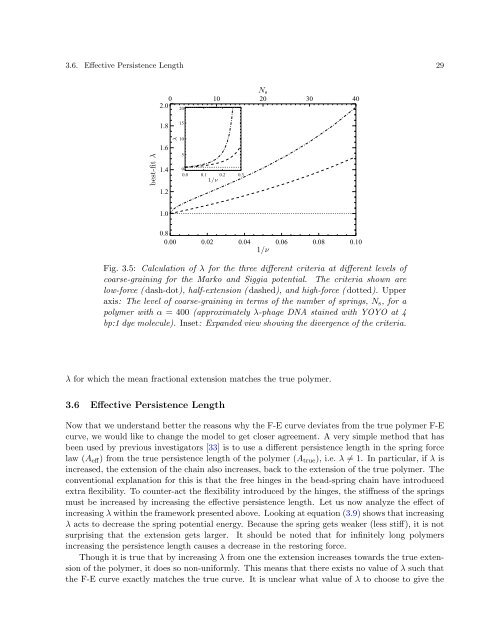

Fig. 3.5: Calculation <strong>of</strong> λ for the three different criteria at different levels <strong>of</strong><br />

<strong>coarse</strong>-graining for the Marko and Siggia potential. The criteria shown are<br />

low-force ( dash-dot), half-extension ( dashed), and high-force ( dotted). Upper<br />

axis: The level <strong>of</strong> <strong>coarse</strong>-graining in terms <strong>of</strong> the number <strong>of</strong> springs, Ns, fora<br />

<strong>polymer</strong> with α = 400 (approximately λ-phage DNA stained with YOYO at 4<br />

bp:1 dye molecule). Inset: Expanded view showing the divergence <strong>of</strong> the criteria.<br />

λ for which the mean fractional extension matches the true <strong>polymer</strong>.<br />

3.6 Effective Persistence Length<br />

Now that we understand better the reasons why the F-E curve deviates from the true <strong>polymer</strong> F-E<br />

curve, we would like to change the model to get closer agreement. A very simple method that has<br />

been used by previous investigators [33] is to use a different persistence length in the spring force<br />

law (Aeff) from the true persistence length <strong>of</strong> the <strong>polymer</strong> (Atrue), i.e. λ = 1. In particular, if λ is<br />

increased, the extension <strong>of</strong> the chain also increases, back to the extension <strong>of</strong> the true <strong>polymer</strong>. The<br />

conventional explanation for this is that the free hinges in the bead-spring chain have introduced<br />

extra flexibility. To counter-act the flexibility introduced by the hinges, the stiffness <strong>of</strong> the springs<br />

must be increased by increasing the effective persistence length. Let us now analyze the effect <strong>of</strong><br />

increasing λ within the framework presented above. Looking at equation (3.9) shows that increasing<br />

λ acts to decrease the spring potential energy. Because the spring gets weaker (less stiff), it is not<br />

surprising that the extension gets larger. It should be noted that for infinitely long <strong>polymer</strong>s<br />

increasing the persistence length causes a decrease in the restoring force.<br />

Though it is true that by increasing λ from one the extension increases towards the true extension<br />

<strong>of</strong> the <strong>polymer</strong>, it does so non-uniformly. This means that there exists no value <strong>of</strong> λ such that<br />

the F-E curve exactly matches the true curve. It is unclear what value <strong>of</strong> λ to choose to give the