Mini-Squing prevents ink spills - RS Components

Mini-Squing prevents ink spills - RS Components

Mini-Squing prevents ink spills - RS Components

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

LEVEL PRODUCTS<br />

<strong>Mini</strong>-<strong>Squing</strong> <strong>prevents</strong> <strong>ink</strong> <strong>spills</strong><br />

BENEFITS<br />

n <strong>Mini</strong>mum intrusion into the tank<br />

n Unaffected by agitation in tank<br />

n Integral LED local alarm indication<br />

APPLICATION<br />

Different printing <strong>ink</strong>s in vertical steel cylinders manufactured by an<br />

OEM for the printing industry.<br />

Three <strong>ink</strong> tanks are combined on a skid which is integrated into the<br />

printers production line.<br />

CHALLENGES<br />

Many processes have batching and header tanks, and there is usually<br />

the need to control a pump to maintain levels between set points,<br />

keeping the process supply line going. The products in the tanks are<br />

<strong>ink</strong>s and dyes and the filling level in the tanks must be monitored to<br />

prevent overflow and costly waste of product.<br />

There are stirrer blades in the tank, therefore minimum intrusion of the<br />

level instrument is required.<br />

SOLUTION<br />

The <strong>Mini</strong>-<strong>Squing</strong> from Mobrey Measurement offers short fork<br />

technology allowing minimum intrusion into the tank.<br />

The <strong>Mini</strong>-<strong>Squing</strong>s are mounted via taper threaded connection into<br />

stainless steel vessels.<br />

Some of the tanks have agitation ‘stirrers’; this does not effect the<br />

<strong>Mini</strong><strong>Squing</strong>, as splashes on the forks do not cause spurious alarms. For<br />

a switch in the <strong>Mini</strong><strong>Squing</strong> output to occur, in this case the high level<br />

alarm, the fork must be partially immersed in the product. Each unit<br />

is factory calibrated to switch at 13mm (½”) up the fork (horizontally<br />

or vertically mounted) in water. If the liquid is more dense, the<br />

switchpoint will be slightly lower then 13mm (½”) and if the liquid is<br />

less dense the switchpoint will be slightly higher than 13mm (½”).<br />

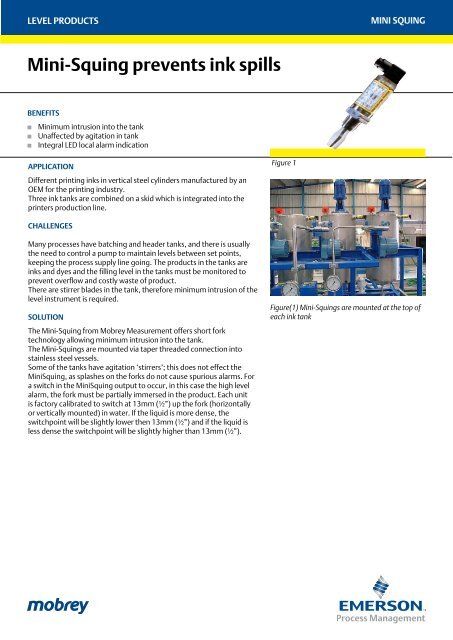

Figure 1<br />

MINI SQUING<br />

Figure(1) <strong>Mini</strong>-<strong>Squing</strong>s are mounted at the top of<br />

each <strong>ink</strong> tank

LEVEL PRODUCTS MINI SQUING<br />

The <strong>Mini</strong><strong>Squing</strong> switching time is set to 1s wet to dry/dry to wet. This<br />

means that the unit must be immersed in the liquid for one second<br />

before the output will change.<br />

Mobrey Measurement<br />

158 Edinburgh Avenue, Slough,<br />

Berks UK SL1 4UE<br />

Tel: +44 (0)1753 756600<br />

Fax: +44 (0)1753 823589<br />

e-mail: mobrey.sales@<br />

EmersonProcess.com<br />

www.mobrey.com<br />

Mobrey GmbH Deutschland tel: 0211/99 808-0<br />

Mobrey Ltd China tel: 021 6232 7972<br />

Mobrey sp z o o Polska tel: 022 871 7865<br />

Mobrey AB Sverige tel: 08-725 01 00<br />

Mobrey SA France tel: 01 30 17 40 80<br />

Mobrey SA-NV Belgium tel: 02/465 3879<br />

Application Reference : an msq 001<br />

Mobrey Inc.<br />

19408 Park Row, Suite 320,<br />

Houston, TX 77084 USA<br />

Tel: 281 398 7890<br />

Fax: 281 398 7891<br />

e-mail: mobrey.sales@<br />

EmersonProcess.com<br />

www.mobrey.com<br />

Figure 2<br />

Schematic shows the mounting of the <strong>Mini</strong>-<strong>Squing</strong><br />

abcdef<br />

The right is reserved to amend details<br />

given in this publication without notice