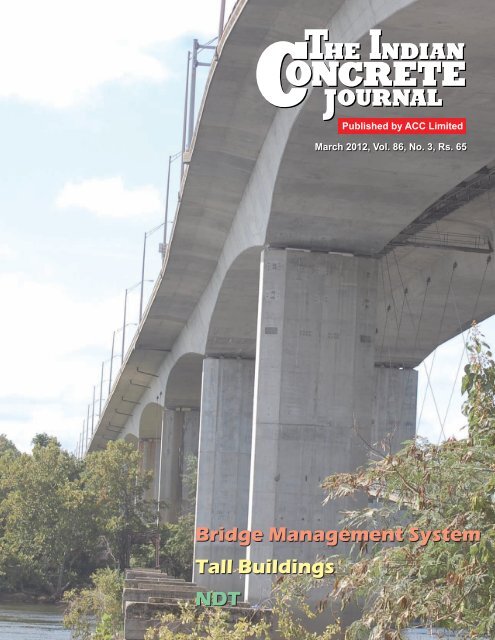

Bridge Management System Tall Buildings NDT - The Indian ...

Bridge Management System Tall Buildings NDT - The Indian ...

Bridge Management System Tall Buildings NDT - The Indian ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Bridge</strong> <strong>Management</strong> <strong>System</strong><br />

<strong>Tall</strong> <strong>Buildings</strong><br />

<strong>NDT</strong><br />

Published by ACC Limited<br />

March 2012, Vol. 86, No. 3, Rs. 65

BASF India Limited<br />

Construction Chemicals Division<br />

Plot No. 37, Chandivali Farm Road, Chandivali<br />

Andheri - East, Mumbai 400072<br />

E-mail: construction-india@basf.com Website: www.basf-cc.co.in<br />

Tel: +9122 28580200 Fax: +9122 28478381

Founded in 1927<br />

Published by ACC Limited, L.B. Shastri Road, Near<br />

Teen Haath Naka, Thane (W) 400604.<br />

<strong>The</strong> contents of this journal are contributions<br />

of individual authors, and reflect their<br />

independent opinions, findings, conclusions<br />

and recommendations and do not necessarily<br />

imply that they reflect the views of the Publisher,<br />

ACC Limited. <strong>The</strong> Publishers are not liable for any<br />

damage or inconvenience, caused to anyone who<br />

may have acted on the information contained in the<br />

publication.<br />

<strong>The</strong> indian Concrete Journal, issn 0019-4565<br />

Copyright © 2012 ACC Limited.<br />

ACC Limited - Registered Office – Cement House,<br />

121, Maharshi Karve Road, Mumbai 400 020.<br />

<strong>The</strong> copyright, database rights and similar rights<br />

in all materials published in <strong>The</strong> <strong>Indian</strong> Concrete<br />

Journal are owned by ACC Limited. None of this<br />

material may be used for any commercial or public<br />

use, other than for the purpose of fair dealing,<br />

research or private study, or review of the contents<br />

of the journal, in part or in whole, and may not<br />

be reproduced or stored in any media for mass<br />

circulation without the prior written consent of the<br />

publisher.<br />

publishing / EdiTorial /<br />

advErTisEmEnT & CirCulaTion offiCE<br />

<strong>The</strong> <strong>Indian</strong> Concrete Journal<br />

ACC Limited<br />

L.B. Shastri Road,<br />

Near Teen Haath Naka<br />

Next to Eternity Mall<br />

Thane (West) 400 604,<br />

Maharashtra, INDIA.<br />

Tel: 00-91-22-33027646<br />

Website: www.icjonline.com<br />

E-mail: info@icjonline.com<br />

icj@acclimited.com<br />

Editor: A.N. Singh<br />

Editorial Team:<br />

Ulhas F. Fernandes<br />

Sushma V. Mathur<br />

for subsCripTion Tariff,<br />

please see page 2<br />

Technical Papers<br />

07<br />

13<br />

33<br />

43<br />

maRch 2012 VOLUmE 86 NUmBER 3<br />

Some studies on the effect of carbonation on the engineering properties<br />

of concrete<br />

B.B. Das, S.K. Rout, D.N. Singh and S.P. Pandey<br />

Review of inspection practices, health indices, and condition states for<br />

concrete bridges<br />

Sanjay S. Wakchaure and Kumar N. Jha<br />

Non destructive evaluation of concrete interlocking paving blocks<br />

M.C. Nataraja and Lelin Das<br />

Superposition principle invalid in IS 13920 design of slender Rc walls<br />

with boundary elements<br />

D.H.H. Rohit, P. Narahari, Arvind Kumar Jaiswal and C.V.R. Murty<br />

Features<br />

03 EdITORIaL<br />

05<br />

27<br />

39<br />

52<br />

53<br />

NEwS & EVENTS<br />

dIScUSSION FORUm<br />

TaLL BUILdINGS: a year in review : Trends of 2011 – Skyscraper<br />

completion reaches new high for fifth year running<br />

Nathaniel Hollister and Antony Wood<br />

LETTER TO ThE EdITOR<br />

POINT OF VIEw: are heritage structures in Tamilnadu seismically<br />

vulnerable?<br />

A. Veerappan<br />

MARCH 2012 ThE INdIaN cONcRETE JOURNaL<br />

1

IndIan tariff, (Rupees) 1 year 2 years 3 years<br />

Online E-Journal 400 800 1200<br />

Paper edition 750 1500 2250<br />

Online E-Journal & paper edition 1100 2200 3300<br />

This is a £ New subscription £ Renewal<br />

My preference is for £ Online E-Journal, £ Paper edition, £ Online E-Journal & paper edition. (see tariff above)<br />

<strong>The</strong> subscription may be started from the month of ____________________<br />

I enclose the payment of Rs. ____________________by cheque/demand draft no._____________________________________<br />

dated__________________ drawn in favour of 'ACC Limited'<br />

S U B S C R I B E T O D A Y!<br />

Tariff for the Year 2012<br />

Subscription Form<br />

OVERSEaS tariff, (US dollars) 1 year 2 years 3 years<br />

Online E-Journal 85 160 240<br />

Paper edition 100 190 275<br />

Online E-Journal & paper edition 120 220 320<br />

Name: _______________________________________________________________________________________________________<br />

(BLOCK LETTERS ONLY)<br />

Delivery address:_____________________________________________________________________________________________<br />

_____________________________________________________________________________________________________________<br />

_____________________________________________________________________________________________________________<br />

City/Town:_______________________________ District:______________________________ State_________________________<br />

Pin Code: ____________________________ Tel: _________________________________ Fax: ______________________________<br />

(PIN CODE IS MANDATORY)<br />

E-mail id:_____________________________________________ Website: ______________________________________________<br />

Signature: ____________________________________________ Date: _________________________________________________<br />

Kindly note that payment by cheques will be accepted for Mumbai (including Navi Mumbai and Thane areas). For those outside Mumbai, kindly<br />

send a Demand Draft of any bank payable at Mumbai. Alternatively, you could either send a cheque adding Rs. 100 (bank charges for outstation<br />

cheques) to the cheque amount. Alternatively you could send a cheque that is authorised as 'Payable at par' in Mumbai without adding bank<br />

charges of Rs. 100.<br />

Kindly send this form to <strong>The</strong> Circulation Manager, <strong>The</strong> <strong>Indian</strong> Concrete Journal, ACC Limited, L.B. Shastri Road, Near Teen Haath<br />

Naka, Next to Eternity Mall, Thane (West) 400 604, Maharashtra, INDIA. Tel: 00-91-22-33027646.<br />

For online payment and other details, please visit www.icjonline.com

Editorial<br />

Utilisation of agricultural residue in housing and<br />

construction has been investigated for many years<br />

with limited commercial success. Rice husk are a residue<br />

produced in significant quantities in India. In broad<br />

terms, one tonne of rice gives 200 kg of husk. For every<br />

1000 kg of rice husk burnt, 200 kg of ash are produced.<br />

This means rice husk ash (RHA) production rate is about<br />

40 kg per ton of rice. 1<br />

In 2009, it was estimated that the world production<br />

of rice was 480 million tonnes. 2 With India currently<br />

producing about 95 million tonnes of rice, the potential<br />

for rice husk ash in our country is about 3.5 million<br />

tonnes. 3 It was estimated that about 1/3 of the available<br />

husk in India can be collected and converted to ash for<br />

use as a Portland cement replacement. So, about one<br />

million tonne of rice husk ash is potentially available as<br />

a mineral admixture.<br />

1. Cement Replacement Materials, Rice Husk Ash, Chapter 6, by D. J. Cook,<br />

Surrey Press (1986)<br />

2. http://www.fao.org/docrep/014/am491e/am491e00.pdf<br />

3. http://www.livemint.com/2011/08/09184142/Rice-production-likely-tosurp.html<br />

Rice husk ash<br />

In the conversion process of rice husk to ash, the<br />

combustion process removes the organic matter and<br />

leaves a silica-rich reside. When rice husks are heated,<br />

weight loss occurs at 100 o C due to evaporation of<br />

absorbed water. At 350 o C, the volatiles ignite, causing,<br />

further weight loss and husks commence to burn. From<br />

400 o C to 500 o C, the residue carbon oxidises with the<br />

majority of the weight loss occurring in this period.<br />

<strong>The</strong> silica in the ash is still in an amorphous form<br />

with high reactivity. Above 600 o C, in some cases the<br />

formation of quartz may be detected. Prolonged heating<br />

at temperatures beyond 800 o C produces essentially,<br />

crystalline silica. 1<br />

<strong>The</strong> relative proportion of the forms of silica in the ash<br />

depends not only on the temperature of combustion but<br />

also the duration. Combusting husk at below 500 o C and<br />

up to 680 o C under oxidising atmosphere can produce<br />

amorphous silica provided the hold time is controlled.<br />

Apart from influencing the degree of crystallinity,<br />

the time-temperature relationship also influences the<br />

specific surface area of the ash, a parameter which is<br />

MARCH 2012 <strong>The</strong> IndIan ConCreTe Journal

closely related to the pozzolanic activity of the ash. <strong>The</strong><br />

pozzolanic behavior of rice husk ash is the ability to react<br />

with calcium hydroxide at ambient temperature in the<br />

presence of moisture to form cementitious hydration<br />

products.<br />

Several researches have offered furnace designs for the<br />

production of this kind of ash. After Mehta described the<br />

effect of pyro-processing parameters on the pozzoloanic<br />

reactivity of RHA, Pitt designed a fluidised bed furnace<br />

for controlled combustion of RHA. 4 Until recently, the<br />

RHA generated by the processes that are on the market<br />

had 3% or more graphitic carbon which gave the dark<br />

color to the material, restricting its use in architectural<br />

applications where color is the driver and leads to<br />

excessive demand from water and chemical admixtures<br />

in order to maintain appropriate slump and other<br />

properties in concrete.<br />

Recently, researchers in the USA have developed a new<br />

continuous production process of manufacturing RHA in<br />

which the rotary tube furnace was maintained in aerobic<br />

conditions at 700 o C with a residence time of 40 min to<br />

obtain off-white RHA with a carbon content of less than<br />

0.3%. 5 Another associated group has achieved this feat<br />

under a different set of conditions; using a rotary kiln<br />

furnace in which incineration of rice husk was done<br />

under oxidizing conditions at 400 o C for 4 h. 6<br />

Generally, the findings reported in the literature highlight<br />

the role of RHA as an effective pozolana that increases<br />

4. Mehta P.K., Siliceous ashes and hydraulic cements prepared therefrom,<br />

Belgium Patent 802, 909 (1973).<br />

5. Ferraro R.M., Nanni A, Vempati R.K. and Matta F., Carbon neutral off-white<br />

rice husk ash as a potential white cement replacement , Journal of Materials<br />

in Civil Engineering, October 2010, pp. 1078 -1083.<br />

6. Harish K.V, Rangaraju P.R and Vempati R.K., Fundamental Investigations<br />

into Performance of Carbon –Neutral Rice Husk Ash as Supplementary<br />

Cementitious Material, Transport Research Record: Journal of Transportation<br />

Research Board, No 2164, Transportation Research Board of the National<br />

Academies, Washington, D.C., 2010, pp 26-35.<br />

7. An V. and Ludwig H.-M, Using rice husk ash and ground granulated blastfurnace<br />

slag to replace silica fume in UHPC, Performance –based Specification<br />

for Concrete Proceedings , Editors Frank Dehn and Hans Beushausen,, MFPA<br />

Leipzig GmbH, Institute for Material Research and Testing, Leipzig, June<br />

2011, pp 80-89<br />

<strong>The</strong> IndIan ConCreTe Journal MARCH 2012<br />

Weight composition<br />

strength and durability of Portland cement mixtures<br />

and that the performance of RHA is very comparable to<br />

that of silica fume. However, the compressive strength<br />

in such reports rarely cross 50 MPa. 6<br />

A paper published in 'Performance-based specifications for<br />

concrete' suggests that RHA can be a good supplementary<br />

material to produce ultra high performance concrete<br />

with compressive strength of 120 MPa or more. 7 <strong>The</strong><br />

typical weight composition is given in the Figure.<br />

(Water/binder ratio range : 0.21 -0.23. <strong>The</strong> mix includes<br />

1 % fibres by volume of mixture. Volume of water to<br />

volume of fine material ratio was 0.50 to 0.55.)<br />

<strong>The</strong> combination of RHA and ground granulated blast-<br />

furnace slag (GGBS) improved not only the workability<br />

but also compressive strength.<br />

<strong>The</strong> use of RHA in cement production is essentially<br />

undertaken in small village units. However, the<br />

potential for this material is quite clear from the above<br />

example. Cost reduction, performance , durability and<br />

environmental concerns are the primary characteristics<br />

that can make RHA a valid alternative to partially<br />

substitute Portland cement.<br />

quartz sand, 42%

News & Events<br />

Global Demand for<br />

Construction Aggregates<br />

to Exceed 48 Billion Metric<br />

Tons in 2015<br />

<strong>The</strong> global market for construction<br />

aggregates is expected to increase 5.2<br />

percent per year through 2015 to 48.3<br />

billion metric tons. This represents<br />

a slower rate of growth than during<br />

the 2005-2010 period, reflecting a<br />

moderation in aggregates-intensive<br />

nonbuilding construction activity.<br />

Nevertheless, demand for construction<br />

aggregates will still post solid gains<br />

from 2010 to 2015. <strong>The</strong> Asia/Pacific<br />

region will register the largest increases<br />

in product sales, as construction activity<br />

will rise rapidly, particularly in China<br />

and India. China alone will account<br />

for half of all new aggregates demand<br />

worldwide during the 2010-2015 period.<br />

<strong>The</strong>se and other trends are presented<br />

in World Construction Aggregates, a<br />

new study from <strong>The</strong> Freedonia Group,<br />

Inc., a Cleveland-based industry market<br />

research firm.<br />

Eastern Europe and the Africa/Mideast<br />

region are also expected to undergo<br />

significant growth in consumption of<br />

construction aggregates, stimulated<br />

by infrastructure development projects<br />

and strong growth in general economic<br />

activity. While the Central and South<br />

America market will climb at a somewhat<br />

slower pace, aggregates suppliers will<br />

benefit from gains in regional construction<br />

spending.<br />

Expansions in demand in developed<br />

parts of the world -- the US, Canada,<br />

Japan, Western Europe, South Korea<br />

and Australia -- will not be as strong<br />

as in most industrializing areas. This<br />

is primarily due to the already welldeveloped<br />

infrastructures found in<br />

these countries and the construction<br />

methods utilized, which tend to feature<br />

less concrete.<br />

Demand for crushed stone, sand and<br />

gravel products will post similar growth<br />

rates of just over five percent per<br />

year through 2015. As in 2010, sand<br />

will continue to make up the largest<br />

portion of global sales, followed closely<br />

by crushed stone and then gravel.<br />

Due to more restrictive land use and<br />

environmental regulations, as well as<br />

the depletion of natural aggregates<br />

reserves, sales of recycled, secondary<br />

and other aggregates will climb at an<br />

above-average pace during the 2010-<br />

2015 period. However, despite projected<br />

growth of 7.1 percent per year over this<br />

span, these products will continue to<br />

play a small role in world markets due<br />

World construction aggregates demand (million dollars) % Annual Growth<br />

Item 200 2010 201 200 -2010 2010-201<br />

Construction aggregates demand 27300 37400 48300 6. .2<br />

North America 3280 3010 3710 -1.7 4.3<br />

Western Europe 2920 2630 3050 -2.1 3.0<br />

Asia/Pacific 16000 24750 32600 9.1 5.7<br />

Other 5100 7010 8940 6.6 5.0<br />

© 2012 by <strong>The</strong> Freedonia Group, Inc.<br />

to quality concerns and limitations in the<br />

availability of feed material.<br />

World Construction Aggregates<br />

(published 01/2012, 334 pages) is<br />

available for $5900.<br />

For more details, please contact:<br />

Corinne Gangloff<br />

<strong>The</strong> Freedonia Group, Inc.,<br />

767 Beta Drive, Cleveland,<br />

OH 44143-2326, USA<br />

Tel: 440.684.9600,<br />

Fax 440.646.0484<br />

e-mail: pr@freedoniagroup.com.<br />

Web: www.freedoniagroup.com.<br />

AARCV 2012<br />

<strong>The</strong> School of Architecture and the<br />

Department of Civil Engineering,<br />

M. S. Ramaiah Institute of Technology,<br />

Bangalore, is organising an international<br />

conference on Advances In Architecture<br />

and Civil Engineering (AARCV – 2012)<br />

during June 21 to 23, 2012.<br />

Advances in Civil Engineering and<br />

Architecture are the order of the day<br />

with the rapid industrialization and<br />

urbanization seen in developed and<br />

developing nations. Innovative design and<br />

construction practices are challenging<br />

tasks to the architects and engineers<br />

to meet the ever growing demands<br />

of the society. Keeping these in mind<br />

the present international conference<br />

is being organized. <strong>The</strong> themes of<br />

the conference cover architectural,<br />

structural, geotechnical, transportation,<br />

environmental and urban planning<br />

disciplines.<br />

<strong>The</strong> event is targeted at architects,<br />

engineers, infrastructure and project<br />

managers, academicians, consultants,<br />

designers, builders, equipment and<br />

materials manufacturers, govt.,<br />

semi govt., private and autonomous<br />

MARCH 2012 <strong>The</strong> IndIan ConCreTe Journal

organisations, research scholars and<br />

students.<br />

For more details, please contact:<br />

<strong>The</strong> Convenor<br />

Dept. of Civil Engineering / Architecture<br />

M. S. Ramaiah Institute of Technology<br />

MSR Nagar, MSRIT Post, Bangalore 560 054<br />

Tel: 080-23600822, 23606934<br />

Fax: 23603124, 23606616<br />

Powder & Bulk Solids India<br />

2012<br />

Powder & Bulk Solids India 2012,<br />

formerly known as Bulk Solids India, is<br />

a conference and exhibition, that will be<br />

held from 13th to 15th March, 2012 at<br />

Ahmedabad.<br />

Powder and Bulk Solids India 2012 is a<br />

member of the international Powder &<br />

Bulk Network. <strong>The</strong> event will present<br />

basic processing technologies for powder<br />

and bulk materials, plant engineering and<br />

processing components, as well as a wide<br />

range of specialised products related to<br />

the chemical, food, pharmaceutical,<br />

cement, mining and ports industry<br />

At the powder section of the exhibition,<br />

manufacturers and suppliers of<br />

mechanical processing and material<br />

handling technologies will be showcasing<br />

solutions for conveying, transporting,<br />

storing and size reduction as well as<br />

screening and mixing and the granulation<br />

for powder and bulk solids in the various<br />

industries.<br />

<strong>The</strong>re conference and workshop that will<br />

focus on two main topics: “From Port to<br />

Plant. Challenges in Power Generation”,<br />

which addresses the bulk sector, and<br />

“Powder & Granules in Chemicals<br />

and Plastics Production – Innovative<br />

Approaches for Optimum Results”<br />

addressing the powder sector.<br />

For more details, please contact:<br />

Ms. Priya Sharma<br />

Indo-German Chamber of Commerce<br />

New Delhi, India<br />

Tel: +91-11-47168830<br />

E-mail : priya@indo-german.com<br />

Web: www.powderbulksolidsindia.com<br />

6<br />

<strong>The</strong> IndIan ConCreTe Journal MARCH 2012<br />

Pre-Engineered <strong>Buildings</strong><br />

<strong>The</strong> <strong>Indian</strong> <strong>Buildings</strong> Concrete is holding<br />

its mid term seminar on the theme ‘‘Pre-<br />

Engineered <strong>Buildings</strong> and Innovative<br />

Techniques in Construction Industry’’<br />

during May 25-26, 2012 at Kolkata.<br />

<strong>The</strong> sub-themes of the event are as<br />

follows:-<br />

1.<br />

2.<br />

3.<br />

4.<br />

5.<br />

6.<br />

7.<br />

Scope for use of Pre-<br />

Engineered <strong>Buildings</strong>;<br />

Pre-Engineered Metal<br />

<strong>Buildings</strong>;<br />

Pre-Engineered RCC <strong>Buildings</strong>;<br />

Innovative Techniques in<br />

Construction Industry – Design<br />

Related;<br />

Innovative Techniques<br />

in Construction Industry<br />

– Construction Related;<br />

Innovative Techniques<br />

in Construction Industry<br />

– Maintenance Related and<br />

Case Studies<br />

An abstract of the paper not exceeding<br />

200 words may please be sent to us,<br />

so as to reach us by March 15, 2012.<br />

We expect full paper to be received<br />

within three weeks of communication of<br />

acceptance of the abstract.<br />

For more details, please contact:<br />

P.S. Chadha<br />

<strong>Indian</strong> <strong>Buildings</strong> Congress<br />

Sector VI, R.K. Puram,<br />

New Delhi 110022<br />

Tel: 011-26169531, 26170197<br />

Fax: 011-026196391<br />

Website: www.ibc.org.in<br />

E-mail: info@ibc.org.in<br />

<strong>Indian</strong> carbon nanotubes in<br />

Forbes 30 listing<br />

Vivek Nair, 23, founder, Damascus<br />

Fortune, a Mumbai-based start-up<br />

says "I got listed in Forbes’ ‘30 Under<br />

30’ under the energy category. Carbon<br />

nanotubes are the strongest and stiffest<br />

material known, with a strength-toweight<br />

ratio 117 times greater than<br />

steel. Our company has developed<br />

a technology that converts carbon<br />

emissions from automotive and industrial<br />

plants to produce carbon nanotubes and<br />

nanofibres. One needs to have courage<br />

to initiate things. Due to the cost, I had<br />

to face adminstrative hurdles to make<br />

carbon nanotubes in the university<br />

laboratory. So, I converted flue gas<br />

from Maruti Modern rice mill, and<br />

Neyveli Lignite Corporation’s thermal<br />

power station to carbon nanotubes<br />

and nanofibres. It was a miracle. I<br />

was born in Kerala, and completed<br />

bioengineering in T amil Nadu. Now a<br />

doctoral research student at Singapore’s<br />

Nanyang Technological University. I<br />

am, along with 15 people, working on<br />

developing the technology and finding<br />

new applications such as strong body<br />

parts of buildings, automobiles, ships<br />

and aircraft. Our aim is to install the<br />

technology in almost all flue gas-emitting<br />

industrial plants in India, Middle East,<br />

Africa, Asia Pacific, Europe and US.<br />

This will help reduce global warming on<br />

a large scale and monetise the carbon<br />

nanotubes."<br />

– <strong>The</strong> Economic Times 03.02.2012<br />

Global Cement Expo 2012<br />

Global Cement is pleased to announce<br />

the launch of the Global Cement Expo<br />

2012 (www.GlobalCementExpo.com),<br />

which will take place at the Targi w<br />

Krakowie exhibition centre in Krakow,<br />

Poland, on 14-15 June 2012.<br />

<strong>The</strong> Global Cement Expo will include a<br />

free seminar programme with parallel<br />

sessions that will cover wear and<br />

maintenance, alternative fuels including<br />

RDF and MSW, waste heat recovery<br />

options (ORC and Kalina cycle),<br />

electrical energy efficiency, refractories,<br />

quality control, environmental impact<br />

abatement, mortars and alternatives<br />

to OPC.<br />

For more details, please contact:<br />

Dr. Robert McCaffrey<br />

PRo Publications International Ltd<br />

First Floor, Adelphi Court<br />

1 East Street, Epsom, Surrey<br />

KT17 1BB, UK<br />

e: rob@propubs.com<br />

t: +44-1372840951

Some studies on the effect of<br />

carbonation on the engineering<br />

properties of concrete<br />

This paper reports the effect of carbonation on three<br />

different grades of concrete each cured for 28, 56, 90<br />

and 120 days. Carbonation was carried out by placing<br />

the specimens in a chamber of 10% carbon dioxide for<br />

150 days. <strong>The</strong> tests included compressive strength<br />

and porosity measurement using a compression<br />

testing machine and mercury intrusion porosimeter<br />

respectively. In addition, electrical conductivity was<br />

measured following ASTM C 1202. <strong>The</strong> results indicate<br />

that carbonation increases the compressive strength and<br />

decreases the porosity and electrical conductivity of the<br />

specimen. <strong>The</strong> results give factors for estimating concrete<br />

performance between carbonated and non-carbonated<br />

specimens.<br />

Keywords: Concrete, carbonation, electrical conductivity,<br />

porosity, and laboratory studies.<br />

Introduction<br />

It is well known that carbonation affects the durability<br />

of concrete, involves CO 2 reaction with the hydration<br />

products of cement to reduce the pH of the concrete<br />

pore solution from about 12 to less than 9 and causes<br />

B.B. Das, S.K. Rout, D.N. Singh and S.P. Pandey<br />

the formation of calcium carbonate. 1-3 <strong>The</strong> following<br />

equation describes the reaction. 4<br />

MARCH 2012 <strong>The</strong> IndIan ConCreTe Journal<br />

......(1)<br />

Researchers have found that the reaction consumes<br />

Ca(OH) 2 from the hydrated paste as calcium silicate<br />

hydrates (CSH) liberating CaO to maintain the<br />

equilibrium. In addition, concrete‘s residual unhydrated<br />

cement compounds such as C 3 S and C 2 S react with CO 2<br />

in the presence of H 2 O further carbonating the concrete. 5<br />

In this manner, the reaction destroys the passivity of<br />

concrete making it prone to corrosion. <strong>The</strong> literature<br />

has several reports on changes in concrete’s physicomechanical<br />

and durability properties resulting from<br />

carbonation. 6-13<br />

Concrete’s conductivity is used to determine its<br />

service life in corrosive environments. Both American<br />

Association of State Highway and Transportation<br />

Officials (AASHTO) and American Society for Testing<br />

and Materials (ASTM 2008) have standardised tests<br />

for electrical conduction (Q). Rapid chloride ion

permeability test (RCPT) is one such well known test<br />

that measures the cumulative electrical charge passing<br />

through a specimen subjected to a 60 V potential for 6<br />

hours.<br />

This paper attempts to understand the influence of<br />

carbonation on the compressive strength, electrical<br />

conductivity and microstructure of concrete.<br />

Materials<br />

Ordinary Portland cement (OPC) conforming to<br />

ASTM Type-I cement was used in this study. <strong>The</strong><br />

fine-aggregates conformed to Zone-III of BS 882 and<br />

had a fineness modulus of 1.99. 14 <strong>The</strong> maximum size<br />

of coarse-aggregates was 20 mm. Table 1 presents the<br />

specific gravity of these materials determined using<br />

an ultra-pycnometer (make Quantachrome, USA). <strong>The</strong><br />

particle-size distribution of the cement was determined<br />

using a Granulometer (Model No. 920, CILAS), which<br />

works on the principle of laser diffraction. Figure 1<br />

shows the particle-size distribution of cement and that<br />

of fine and coarse aggregates determined according to<br />

ASTM C 136-01. 15<br />

<strong>The</strong> fineness of the cement was determined using<br />

Blaine’s air-permeability apparatus following ASTM C<br />

204-00 (Table 1). 16<br />

<strong>The</strong> chemical composition of OPC was determined<br />

using an X-Ray Fluorescence setup and the results are<br />

<strong>The</strong> IndIan ConCreTe Journal MARCH 2012<br />

presented in Table 2. <strong>The</strong> mineralogical composition<br />

of the OPC was determined with the help of an X-Ray<br />

diffraction spectrometer (make D8 Advance-Bruker, AXS<br />

Germany), which employed a graphite monochromator<br />

and Cu-Kα source. <strong>The</strong> sample was scanned from 5°<br />

to 60°. <strong>The</strong> various compounds present in the cement<br />

composition were identified with the help of TOPAS<br />

software (Table 3). 17<br />

Table 1. Physical properties of the materials used in the<br />

study<br />

Material Specific<br />

gravity<br />

Fineness,<br />

m 2 /kg<br />

Ordinary Portland Cement 3.16 294<br />

Coarse<br />

aggregate<br />

Fine aggregate 2.71 NA<br />

NA - Not applicable<br />

10 mm 2.79 NA<br />

20 mm 2.77 NA<br />

Table 2. Chemical composition of the ordinary Portland<br />

cement<br />

Oxide % by weight<br />

Al2O3 5.55<br />

CaO 60.46<br />

Fe2O3 4.98<br />

K2O 0.487<br />

MgO 1.27<br />

Na2O 0.232<br />

SiO2 20.89<br />

(SiO2 +Al2O3 +Fe2O3 ) 31.42<br />

(SiO2 +Al2O3 ) 26.44<br />

LOI 2.26<br />

Table 3. Phases present in the ordinary Portland cement<br />

Compound % by weight<br />

C 3 S 59.38<br />

C 2 S 24.58<br />

C 3 A 5.11<br />

C 4 AF 10.37<br />

Table 4. Mix proportions for different grades of<br />

concrete<br />

Mix<br />

Designation<br />

Cement<br />

content,<br />

kg/m 3<br />

w/c Mix proportion<br />

(OPC: W: FA: CA)<br />

Compacting<br />

factor<br />

C1 300 0.55 1:0.55:2.06:4.37 0.90<br />

C2 320 0.45 1:0.48:1.98:4.60 0.84<br />

C3 360 0.40 1:0.40:1.88:4.59 0.82

Testing methodology<br />

<strong>The</strong> details of the mix and their designation are presented<br />

in Table 4. <strong>The</strong> mixing was done in a rotary mixer for<br />

about 2 minutes. <strong>The</strong> desired compaction of concrete was<br />

achieved with the help of a table vibrator. <strong>The</strong> samples<br />

were first cured at 95±5% relative humidity and 27±2 ˚C.<br />

After 24 h, the cubes were de-molded and cured under<br />

water at 27±2˚C. Four curing periods (t = 28, 56, 90 and<br />

120 days) were chosen for this study. <strong>The</strong> compressive<br />

strength of the cubes at the end of each curing period was<br />

determined by employing an automatic compression<br />

testing machine. Table 5 presents the results.<br />

Cubes of 150 mm and 100 mm were used for determining<br />

the compressive strength (f c ) and the carbonation depth<br />

(d), respectively. In addition, 150 mm×150 mm×700<br />

mm beams ( one beam or more than one ?) were cast<br />

for extracting several cylindrical cores for conducting<br />

the rapid chloride ion penetration test; before and after<br />

carbonation.<br />

<strong>The</strong> porosity (η) of concrete was determined with the<br />

help of an auto scan mercury intrusion porosimeter<br />

which operated up to 60,000 psi (414 MPa). <strong>The</strong> technique<br />

involves the intrusion of mercury (Hg) at high pressure<br />

into a specimen through the use of a penetrometer. Hg<br />

does not penetrate into the pores until such a pressure<br />

is applied that forces the liquid into the pores. <strong>The</strong><br />

ratio between the applied pressure and the size of the<br />

pores is defined by Washburn’s equation, where the<br />

pore diameter is inversely proportional to the applied<br />

pressure: the higher the pressure, the smaller are the<br />

pores into which it is possible to intrude the liquid. <strong>The</strong><br />

mercury intrusion porosimetry procedure for concrete<br />

samples was published earlier. 18<br />

accelerated carbonation studies<br />

Cured cubes and cores extracted from the beams were<br />

taken out of the curing tank and stored at 60% relative<br />

humidity and 27˚ C for 15 days to stabilise their internal<br />

humidity. 19 <strong>The</strong>se specimens were next transferred to an<br />

a chamber containing 10% concentration of CO 2 at 27˚ C<br />

Table 5. Compressive strength of different grades of<br />

the concrete<br />

Curing period<br />

Compressive Strength, MPa<br />

days<br />

C1 C2 C3<br />

28 31.76 42.81 51.20<br />

56 38.06 46.14 53.82<br />

90 39.44 46.25 54.13<br />

120 40.12 47.82 56.48<br />

and 65% relative humidity for accelerated carbonation.<br />

(<strong>The</strong> CO 2 concentration in the air is about 0.03%). To<br />

provide an uninterrupted ingress of CO 2 , the specimens<br />

were placed on a wire mesh. After 150 days of exposure<br />

(T=150), cubes were taken out of the chamber and cut<br />

into two equal parts in the direction perpendicular to<br />

the plane of casting. Next, the depth of carbonation was<br />

determined by spraying 1% phenolphthalein in 70%<br />

ethyl alcohol that changes from colourless to purple<br />

when pH is >9. 20<br />

So the colour of the carbonated portion of the specimen<br />

remained unchanged, while that of the uncarbonated<br />

portion became purple. Based on this, the average<br />

depth of the carbonation in the cubes (corresponding<br />

to the four cut faces of the cube) was measured. <strong>The</strong><br />

average of three results gave the carbonation depth d<br />

for a particular grade of concrete. <strong>The</strong> carbonated cores<br />

were subjected to rapid chloride ion permeability test<br />

as described below.<br />

rapid chloride ion penetration test<br />

<strong>The</strong> test apparatus used was from Control, Italy and<br />

conformed to ASTM C-1202. 21 <strong>The</strong> test method involved<br />

obtaining a 100 mm diameter core or cylinder sample<br />

from the concrete being tested. A 50 mm specimen was<br />

cut from the sample. <strong>The</strong> side of the cylindrical specimen<br />

was coated with epoxy, and after the epoxy dried out, it<br />

was put in a vacuum chamber for 3 hours. <strong>The</strong> specimen<br />

was vacuum saturated for 1 hour and allowed to soak<br />

for 18 hours. It was then placed in the test device. <strong>The</strong><br />

left-hand side (–) of the test cell was filled with a 3%<br />

NaCl solution. <strong>The</strong> right-hand side (+) of the test cell<br />

was filled with 0.3N NaOH solution. <strong>The</strong> system was<br />

then connected and a 60-volt potential was applied for 6<br />

hours. Readings were taken every 30 minutes. At the end<br />

of 6 hours the sample was removed from the cell and the<br />

amount of coulombs passed through the specimen was<br />

calculated. Table 6 shows the chloride ion permeability<br />

following ASTM C 1202.<br />

Table 6. Chloride Ion permeability based on charge<br />

passed (ASTM C 1202)<br />

Charge passed,<br />

Coulomb<br />

Chloride<br />

permeability<br />

Typical concrete<br />

>4000 High High w/c (>0.60)<br />

2000-4000 Moderate Moderate w/c (0.40-0.50)<br />

1000-2000 Low Low w/c (

<strong>The</strong> average charge Q (in Coulomb) from three identical<br />

cores of a specific grade of concrete was taken as the<br />

electrical conductivity of that grade of concrete.<br />

results and discussions<br />

Carbonation depth<br />

Table 7 presents the carbonation depth results. <strong>The</strong><br />

carbonation resistance of the concrete can be expressed<br />

using Fick’s first law of diffusion as under 11<br />

d = K (t) 0.5<br />

10<br />

<strong>The</strong> IndIan ConCreTe Journal MARCH 2012<br />

......(2)<br />

where, d is the carbonation depth in mm and t is<br />

the curing period in weeks and K is the carbonation<br />

coefficient expressed in mm/weeks 0.5 .<br />

Table 7. Carbonation depth for different grades of<br />

concrete specimens<br />

t<br />

(days)<br />

Table 8. Compressive strength of different grades of<br />

non-carbonated and carbonated concrete<br />

t<br />

(days)<br />

T=150<br />

Carbonation depth, d (mm) % reduction<br />

C1 C2 C3 C1 C2 C3<br />

28 28.2 24.2 19 NA NA NA<br />

56 25 22.1 16.5 11.35 8.68 13.16<br />

90 22.2 19 13 21.28 21.49 31.58<br />

120 18.6 15.2 10 34.04 37.19 47.37<br />

NA - Not applicable<br />

f c (MPa)<br />

T = 0 (Non- carbonated<br />

concrete)<br />

T = 150 (Carbonated<br />

concrete)<br />

C1 C2 C3 C1 C2 C3<br />

28 31.76 42.81 51.20 41.79 54.19 64.00<br />

56 38.06 46.14 53.82 49.43 56.96 65.63<br />

90 39.44 46.25 54.13 51.22 56.40 66.01<br />

120 40.12 47.82 56.48 50.15 57.61 68.88<br />

Table 9. Ratio of the properties of non-carbonated<br />

concrete to carbonated concrete<br />

t<br />

fc Q η<br />

(Days)<br />

C1 C2 C3 C1 C2 C3 C1 C2 C3<br />

28 0.76 0.79 0.80 3.24 3.06 2.96 1.04 1.12 1.16<br />

56 0.77 0.81 0.82 2.89 2.86 2.78 1.04 1.18 1.18<br />

90 0.77 0.82 0.82 2.75 2.71 2.61 1.05 1.20 1.20<br />

120 0.80 0.83 0.82 2.65 2.62 2.56 1.10 1.20 1.23<br />

Figure 2 is a plot of carbonation coefficient and curing<br />

period at three levels of water to cement ratios. This<br />

figure suggests that w/c ratio has a strong influence<br />

on the carbonation resistance of concrete. With w/c<br />

decreasing from 0.55 to 0.40 carbonation coefficient<br />

K reduced by a factor of 3. <strong>The</strong> data on carbonation<br />

depth and curing in Table 7 suggests that curing period<br />

plays an important role in developing the carbonation<br />

resistance of concrete. <strong>The</strong> reduction in carbonation<br />

ranged from about 8% to about 47%. Considering the<br />

28 day specimen as control, the carbonation depth in the<br />

specimen of w/c ratio 0.55 reduced by 11.35%, 21.28%<br />

and 34% at 56, 90 and 120 day respectively.<br />

Compressive strength<br />

Table 8 presents the compressive strength of both<br />

carbonated and non carbonated specimens. From this<br />

table, it is evident that carbonation leads to an increase<br />

in compressive strength. <strong>The</strong> formation of CaCO 3<br />

which is known to occupy more volume than Ca(OH) 2 ,<br />

reduces the porosity in concrete resulting in a higher<br />

compressive strength. <strong>The</strong> results show the strength<br />

improvement is more in the case of low strength<br />

concrete. <strong>The</strong> compressive strength of the carbonated<br />

concretes increased as compared to the non carbonated<br />

concretes. Table 9 shows that the compressive strength<br />

ratio of non carbonated concrete to carbonated concrete<br />

at 28 days is lower by 0.76, 0.79, and 0.80 for w/c ratio<br />

of 0.55. 0.45 and 0.40 respectively. <strong>The</strong>se ratio reduction<br />

can be considered as the factors to be used to determine<br />

the actual compressive strength of carbonated concretes<br />

in structures. However, Table 9 data is not a clear<br />

function of curing period t. It means the carbonation<br />

has less influence on the compressive strength if the

concrete is cured for a longer time. A lower concrete<br />

porosity resulting from a longer curing time explains<br />

this observation.<br />

electrical conductivity<br />

Figures 3 and 4 show the electrical conductivity of non<br />

carbonated and carbonated specimens respectively. <strong>The</strong><br />

specimens' curing period and water to cement ratios<br />

were varied. It can be observed from the figures that<br />

the electrical conductivity of the carbonated concrete<br />

decreased by a factor of 3 as compared to that of the<br />

non-carbonated concrete. Figure 4 suggests that the<br />

electrical conductivity deceased as the grade of concrete<br />

increased. It can also be noted from Table 9 that the<br />

electrical conductivity of carbonated concrete cured for<br />

28 days decreased by a factor of 3.24, 3.06 and 2.96 for<br />

w/c ratio of 0.55, 0.45 and 0.40 respectively. <strong>The</strong> reducing<br />

chloride ion penetration indicates that carbonation<br />

of higher grades of concrete results in decreasing the<br />

specimen’s porosity. It can be observed from Figure 4<br />

that the electrical conductivity is inversely proportional<br />

to curing period (t). At the w/c ratio of 0.40 the electrical<br />

conductivity of carbonated concrete decreased by a<br />

factor of 2.96, 2.78, 2.61 and 2.56 for curing period of<br />

28, 56, 90 and 120 days respectively. So carbonated<br />

specimens with longer curing periods show reduced<br />

electrical conductivity.<br />

Porosity<br />

Figures 5 and 6 show the effect of carbonation on the<br />

porosity of non-carbonated and carbonated specimens<br />

respectively. It can be observed from the figures that<br />

the porosity is inversely related to w/c ratio for both<br />

carbonated and non-carbonated concretes. <strong>The</strong> porosity<br />

MARCH 2012 <strong>The</strong> IndIan ConCreTe Journal<br />

11

eduction factors of 28 day specimens was 1.04, 1.12 and<br />

1.16 times for w/c ratio of 0.55, 0.45 and 0.40 respectively.<br />

<strong>The</strong> factors for other specimens are given in Table 9.<br />

Based on the porosity of non-carbonated specimens<br />

cured for 28 days, the porosity of both carbonated and<br />

non carbonated concrete decreased with increasing<br />

curing period as tested. In comparison to the noncarbonated<br />

concrete, for the w/c ratio of 0.40 the porosity<br />

for carbonated concrete decreased by a factor of 1.16,<br />

1.18, 1.20 and 1.23 at 28 days, 56 days, 90 days and 120<br />

days respectively (Table 9).<br />

Conclusions<br />

<strong>The</strong> following conclusions can be drawn from this<br />

experimental work:<br />

12<br />

1.<br />

2.<br />

3.<br />

Both carbonation coefficient and depth decreased<br />

with the increase in the curing period. <strong>The</strong><br />

compressive strength increased with the<br />

increase in the curing period and decrease in the<br />

water /cement ratios.<br />

Under these conditions of w/c ratio and curing<br />

periods, the electrical conductivity of the<br />

carbonated concrete decreased by a factor of 3<br />

compared to the non-carbonated specimen.<br />

As the curing period increased, the porosity<br />

decreased in both carbonated and non carbonated<br />

concrete specimens. Also there was a reduction in<br />

the porosity with the lowering of water/cement<br />

ratios. <strong>The</strong> factor of reduction was different for<br />

carbonated and non-carbonated specimens.<br />

<strong>The</strong> difference could be due to the extent of<br />

carbonation and resulting CaCO 3 formation.<br />

references<br />

1.<br />

2.<br />

3.<br />

4.<br />

5.<br />

6.<br />

7.<br />

Haque, M. N., and Kawamura, M., “Carbonation and Chloride-induced<br />

Corrosion of Reinforcement in Fly Ash Concretes,” ACI Materials Journal,<br />

Vol. 89 (1), 1993, pp. 41-48.<br />

Ihekwaba, N. M., Hope, B. B., and Hansson, C. M., “Carbonation and<br />

Electrochemical Chloride Extraction from Concrete”, Cement and Concrete<br />

Research, Vol. 26 (7), 1996, pp. 1095–1107.<br />

Basheer, P. A. M., Chidiac, S. E., and Long, A. E., “Predictive Models for<br />

Deterioration of Concrete Structures”, Construction and Building Materials,<br />

Vol. 10, 1996, pp. 27–37.<br />

Johannesson, B., and Utgenannt, P., “Microstructural Changes Caused by<br />

Carbonation of Cement Mortar”, Cement and Concrete Research, Vol.31, 2001,<br />

pp. 925-931<br />

Claisse, P. A., El-Sayad, H., and Shaaban, I. G., “Permeability and Pore<br />

Volume of Carbonated Concrete”, ACI Materials Journal, Vol.96 (3), 1999,<br />

pp. 378-381.<br />

Jerga, J., “Physico-mechanical Properties of Carbonated Concrete’,<br />

Construction and Building Materials, Vol.18, 2004, pp. 645-652.<br />

Silva, C. A. R., Reis, R. J. P., Lameiras, F. S. And Vasconcelos, W. L.,<br />

“Carbonation-Related Microstructural Changes in Long-Term Durability<br />

Concrete”, Materials Research, Vol. 5 (3), 2002, pp. 287-293.<br />

<strong>The</strong> IndIan ConCreTe Journal MARCH 2012<br />

8. Xiao, J., Li, J., Zhu, B., and Fan, Z., “Experimental Study on Strength and<br />

Ductility of Carbonated Concrete Elements”, Construction and Building<br />

Materials, Vol. 16, 2002, pp. 187-192.<br />

9. Chang, C. F., and Chen, J. W., “Strength and Elastic Modulus of Carbonated<br />

Concrete”, ACI Materials Journal, Vol. 102 (5), 2005, pp. 315-321.<br />

10. Song, H. W., and Kwon, S. J., “Permeability Characteristics of Carbonated<br />

Concrete Considering Capillary Pore Structure”, Cement and Concrete<br />

Research, Article in press.<br />

11. Valcuende,M. and Parra,C., “Natural Carbonation of Self Compacting<br />

Concrete”, Construction and Building Materials, Vol. 24 (5), 2010, pp. 848-<br />

853.<br />

12. Vaysburd, A. M., Sabnis, G. M., and Emmons, P. H., “Concrete Carbonation—<br />

A Fresh Look,” <strong>Indian</strong> Concrete Journal, V. 67, No. 5, May 1997, pp. 215-220.<br />

13. Chi, J.M., Huang, R., and Yang, C. C., “Effects Of Carbonation On Mechanical<br />

Properties And Durability Of Concrete Using Accelerated Testing Method”,<br />

Journal of Marine Science and Technology, Vol. 10, No. 1,2002, pp. 14-20.<br />

14. ______BS 882. “Specification for Aggregates from Natural Source for<br />

Concrete”, British Standards Institution, London, 1992.<br />

15. ______ASTM C 136-01, “Standard Test Method for Sieve Analysis of Fine<br />

and Coarse Aggregates, Annual book of ASTM Standards”, Vol. 04.02, ASTM,<br />

West Conshohocken, PA, 2002.<br />

16. ______ASTM C 204-00, “Standard Test Method for Fineness of Hydraulic<br />

Cement by Air-Permeability Apparatus”, Annual book of ASTM Standards,<br />

Vol. 04.01, ASTM, West Conshohocken, PA, 2002.<br />

17. TOPAZ 2.1, “Diffract Plus”, Bruker AXS GmbH, Karlsruhe, Germany, 2003.<br />

18. Das, B. B., Singh, D. N., and Pandey, S. P., “Characterization of Concrete<br />

by three ASTM Specified Techniques for Determination of Pore Volume”,<br />

<strong>Indian</strong> Concrete Journal, December 2010.<br />

19. Sulapha, P., Wong, S. F., Wee, T. H., and Swaddiwudhipong, S., “Carbonation<br />

of Concrete Containing Mineral Admixtures”. Journal of Materials in Civil<br />

Engineering, ASCE, Vol. 15 (2), 2003, pp. 134-143.<br />

20. ______CPC-18. “Measurement of Hardened Concrete Carbonation Depth”,<br />

Materials and Structures, Vol. 17 (6), 1988, pp. 453-455.<br />

21. ______ASTM C 1202, “Standard test method for electrical indication of<br />

concrete’s ability to resist chloride ion penetration.” Annual book of ASTM<br />

Standards, Vol. 04.02, ASTM, West Conshohocken, PA, 2002.<br />

Dr. B.B. Das is an Associate Professor at KIIT<br />

Deemed University, Bhubaneswar, He has been<br />

a Post-Doctoral Research Associate and Adjunct<br />

Professor in the Department of Civil Engineering<br />

at Lawrence Technological University, Southfield,<br />

Michigan, USA. His areas of research include<br />

microstructure characterization of materials, nondestructive<br />

testing of concrete, corrosion of reinforcement<br />

and durability studies on concrete.<br />

S.K. Rout is a Graduate Student at the<br />

Department of Civil Engineering, Lawrence<br />

Technological University, Southfield, Michigan,<br />

USA. His present area of research interest is in<br />

structural engineering and structural materials.<br />

Dr. D.N. Singh holds a Civil Engineering from<br />

IIT Kanpur and PhD. in Geotechnical Engineering.<br />

He is a Professor in the Department of Civil<br />

engineering, <strong>Indian</strong> Institute of Technology,<br />

Mumbai. His major research focus is in the field<br />

of Environmental Geotechnology.<br />

Dr. S.P. Pandey holds a PhD in solid-state<br />

chemistry from Gorakhpur University, U.P. He is<br />

Vice President of Central R&D, UltraTech Cement<br />

Ltd., Mumbai. His research interests are in<br />

Cement chemistry and material science.

Review of inspection practices, health<br />

indices, and condition states for<br />

concrete bridges<br />

A bridge is a structure built to span physical obstacles<br />

such as a body of water, valley, road or railway for the<br />

purpose of providing passage over the obstacle. A weak<br />

bridge can either reduce the load carrying capacity or<br />

compromise on safety, hindering the flow of traffic and<br />

affecting the economy. Hence, it is necessary to maintain<br />

the traffic-worthiness of bridges with requisite levels of<br />

safety and serviceability. However, those responsible<br />

for such works often feel that the funds made available<br />

to them are insufficient. One of the ways to address<br />

this challenge is to utilise the available resources in an<br />

optimal manner using scientific methods and tools.<br />

Instituting a bridge management system or BMS is a<br />

good way for managing design, construction, operation<br />

and maintenance of bridges. Many countries have<br />

developed such systems. A BMS guides the decision<br />

making processes regarding the maintenance, planning<br />

by ascertaining the present condition and pointing out<br />

the immediate maintenance requirements of a bridge.<br />

It does not wholly rely on the physical condition of<br />

bridges, which is often described by discrete condition<br />

states on the basis of visual inspection. Since the results<br />

of visual inspection are subjective and vary according<br />

to the knowledge and judgment of the bridge inspector,<br />

most BMS systems make use indices as one of the tools<br />

for decision making.<br />

Keywords: <strong>Bridge</strong> management system, bridge inspection,<br />

condition states, bridge health index<br />

Sanjay S. Wakchaure and Kumar N. Jha<br />

This paper compares the condition states and bridge<br />

indices used by various countries. Included in the paper<br />

are definition of a bridge, types of inspection, bridge<br />

health index, and condition states. <strong>The</strong> paper attempts<br />

to point out the limitation and constraints in BMS for<br />

adopting them universally and evolving a structure for<br />

comprehensive condition states and bridge index. <strong>The</strong><br />

study reveals that there is no unanimity among bridge<br />

authorities across the globe regarding length of a bridge,<br />

the condition states and bridge indices. A comprehensive<br />

and universal categorisation of condition scales and<br />

bridge index would go a long way in improving the<br />

understanding about the performance of concrete<br />

bridges regardless of their location.<br />

Introduction<br />

<strong>The</strong> history of bridges is almost as old as that of human<br />

civilisation. <strong>Bridge</strong>s have greatly contributed to the<br />

human endeavour by providing passage over obstacles<br />

such as a body of water, valley, road or railway and<br />

improving mobility. India has one of the largest road<br />

and rail networks in the world, with the total road<br />

length being 4.1 million kilometers (http://www.morth.<br />

nic.in), and rail length being 64,099 km (http://www.<br />

indianrailways.gov.in). Both roads and railways run<br />

across the length and breadth of the country, connected<br />

by many bridges, negotiating the varied terrains and<br />

environmental conditions in the country.<br />

MARCH 2012 <strong>The</strong> IndIan ConCreTe Journal<br />

13

Table 1. Minimum length to be traversed to be classified as a bridge<br />

<strong>The</strong>re are more than 92, 000 bridges and over 1.1 million<br />

culverts (length ≤ 6 m) of different types along <strong>Indian</strong><br />

roads. 1 Out of the 92,000 bridges, about 14,500 bridges<br />

are on the National Highways. Out of these, 1713<br />

bridges are in a ‘distressed’ condition and require<br />

repair/rehabilitation, while 2018 bridges are old, weak<br />

and need reconstruction. 2<br />

Like roads, bridges are inseparable parts of the <strong>Indian</strong><br />

Railways. <strong>The</strong>re are about 1.27 million bridges of<br />

different types and varying spans on <strong>Indian</strong> railway<br />

tracks. About 40 percent of these bridges are over 100<br />

years old and 16 percent are reported to be deficient,<br />

requiring rehabilitation and strengthening. 3,4<br />

<strong>Bridge</strong> owners all over the world face difficulties in<br />

maintaining bridges with the available funds. Before<br />

allocating resources for the maintenance of bridges, it<br />

is necessary to ascertain their present condition, their<br />

immediate and future maintenance requirements. This<br />

need has led to the development of bridge management<br />

system (BMS). BMS consists of various scientific methods<br />

and tools for efficient allocation of funds. Reliable data<br />

on the history of bridge condition and maintenance are<br />

of prime importance to the development of this system.<br />

<strong>The</strong> assessment of bridge condition is mostly based on<br />

visual inspection by inspectors and is expressed in terms<br />

of discrete condition states which often dependent on<br />

the judgment and experience of the inspector. Hence,<br />

the development of a method that does not solely<br />

depend on subjective data is essential. 5 <strong>The</strong> application<br />

of condition states in the assessment of bridges in BMS<br />

and decision making has not been much attended<br />

to by researchers. 6 Further, there is no established<br />

methodology or systematic approach in this regard<br />

though bridge engineers and decision makers routinely<br />

face the problem of prioritizing the maintenance needs.<br />

Ranking of bridges for the purpose of maintenance very<br />

often follows a personal judgment. 6<br />

Considering the importance of inspection, bridge health<br />

index and condition states in efficient allocation of funds,<br />

this paper embarks on reviewing the practices followed<br />

in different parts of world based on the available<br />

literature. As it will be seen in subsequent sections there<br />

is a wide disparity in the manner in which bridges are<br />

maintained and the funds are allocated. In fact there<br />

14<br />

Country Austria Denmark France Norway Slovenia United Kingdom United States India<br />

Length in ‘m’ >2 ≥ 5 > 2 m ≥ 2.5 ≥ 5 > 3 > 6.10 > 6<br />

<strong>The</strong> IndIan ConCreTe Journal MARCH 2012<br />

is no unanimity in the bridge definition itself to start<br />

with. <strong>The</strong> review is aimed at comparing the current<br />

practices, pointing out the limitations and constraints<br />

in the existing practices and thereby proposing suitable<br />

recommendations.<br />

<strong>Bridge</strong> definition<br />

In order to be classified as a bridge, a structure should<br />

be of a minimum length. 7 <strong>The</strong> <strong>Indian</strong> Roads Congress<br />

defines a bridge as a structure having a length of more<br />

than six metres and meant for carrying vehicular<br />

traffic across rivers, canals, viaducts, structures for<br />

interchanges including underpasses and flyovers across<br />

the highway/railways, aqueducts/siphon. 8 National<br />

<strong>Bridge</strong> Inspection Standards published in the Code<br />

of Federal Regulations (23 CFR 650.3), USA, defines a<br />

bridge as ‘a structure including supports erected over a<br />

depression or an obstruction, such as water, highway, or<br />

railway; having a track or passageway for carrying traffic<br />

or other moving loads, and having an opening measured<br />

along the centre of the roadway of more than 20 feet<br />

(6.1 m) between under copings of abutments or spring<br />

lines of arches, or extreme ends of openings for multiple<br />

boxes; it may also include multiple pipes, where the clear<br />

distance between openings is less than half of the smaller<br />

contiguous opening. 9 In simple words, a bridge can be<br />

defined as a structure meant for carrying vehicular traffic<br />

across an artificial or natural obstruction. Although a<br />

structure has to be of a minimum length in order to be<br />

classified as a bridge, there is no unanimity on the exact<br />

length. <strong>The</strong> minimum length of bridge specified by<br />

bridge authorities varies from two to six metres 7 . Table 1<br />

gives the minimum bridge lengths prescribed in select<br />

countries. According to IRC: 5-1998, bridges having<br />

length up to 60 m are classified as minor bridges while<br />

bridges having length more than 60 m are classified as<br />

major bridges.<br />

<strong>Bridge</strong> management<br />

<strong>Bridge</strong>s can be regarded as a separate infrastructural<br />

facility owing to their distinct importance. Infrastructure<br />

management is the process by which agencies monitor,<br />

maintain and repair deteriorating facilities within<br />

stipulated budgets so as to improve their performance. 10<br />

Federal Highway Administration manual (USA) defines<br />

‘asset management’ in the following manner. 11

“Asset management is a systematic process of<br />

maintaining, upgrading, and operating physical assets<br />

cost-effectively. It combines engineering principles with<br />

sound business practices and economic theory and it<br />

provides tools to facilitate a more organized, logical<br />

approach to decision-making”.<br />

A weak bridge in a network of roads leads to either<br />

reduction in load carrying capacity and safety, change<br />

of route(s) thereby increasing the length of transit or<br />

complete stoppage of traffic in the absence of alternate<br />

route(s). This, in turn, adversely affects the movement<br />

of men and goods which may result in an increase in<br />

transportation cost of road users, and thereby affecting<br />

the commerce and economy of the region, or even of the<br />

whole country. Hence, it is necessary to maintain trafficworthiness<br />

of bridges with requisite levels of safety<br />

and serviceability. Like any other structure, bridges<br />

are to be planned, constructed, maintained, operated<br />

and replaced at the end of their service lives. Usually,<br />

concrete bridges are designed for 50-60 years. 12<br />

Often, the funds available for maintaining bridges<br />

are scanty. Hence, the most important task of bridge<br />

engineers is to minimise the cost of maintenance. This<br />

can be accomplished by the application of rational<br />

and scientific methods in all the activities pertaining<br />

to management of bridges throughout their lifespan.<br />

A scientific <strong>Bridge</strong> <strong>Management</strong> <strong>System</strong> (BMS) thus<br />

helps in making right decisions regarding maintenance<br />

and using the available resources in the best possible<br />

manner.<br />

Status of management of road bridges<br />

in India<br />

<strong>Indian</strong> Roads Congress (IRC) is responsible for the<br />

development of guidelines for various aspects of roads<br />

and bridges in India. It has developed a manual to<br />

provide guidelines for Highway <strong>Bridge</strong> Maintenance<br />

Inspection (IRC:SP-18). 13 In addition IRC:SP-35 is being<br />

used as a manual of guidelines on the inspection and<br />

maintenance of culverts, minor bridges, and major<br />

bridges including submersible bridges, but excluding<br />

cable-stayed and suspension bridges. 14 <strong>The</strong> latter<br />

document summarizes the status of bridge management<br />

in the following manner:<br />

•<br />

•<br />

•<br />

Present practices of bridge management vary<br />

from state to state.<br />

Inspection and maintenance are mostly carried out<br />

by State Public Works Departments (PWDs).<br />

Databases are usually inadequate.<br />

•<br />

•<br />

•<br />

•<br />

Maintenance policy is reactive and not<br />

responsive.<br />

Very little funds are allocated for bridge<br />

maintenance and repair.<br />

No organization exists exclusively for inspection<br />

and maintenance of bridges.<br />

<strong>The</strong>re are no avenues of formal institutional<br />

training.<br />

IRC:SP-35 also summarises the requirements for research<br />

and development in the maintenance of bridges as the<br />

need to: 14<br />

•<br />

•<br />

•<br />

•<br />

Investigate the effectiveness of present methods<br />

of maintenance.<br />

Develop criteria for evaluating the performance/<br />

efficacy of different maintenance strategies.<br />

Develop improved materials and techniques for<br />

bridge maintenance.<br />

Study of the economics of maintenance of bridges<br />

of various ages and types.<br />

Jain has highlighted the issues in the development<br />

and implementation of scientific BMS in India. Some<br />

important ones are: 4<br />

•<br />

•<br />

•<br />

<strong>The</strong> study of the desirability and practicality<br />

of application of BMS to highway and railway<br />

bridges in India.<br />

<strong>The</strong> development of procedures for compilation<br />

of data on bridges, particularly old and deficient<br />

ones.<br />

<strong>The</strong> development of procedures for bridge<br />

inspection and rating.<br />

<strong>The</strong> following characteristics of the current maintenance<br />

practices of the National Highways in India are mentioned<br />

in the Guidelines for Maintenance <strong>Management</strong> of<br />

Primary, Secondary and Urban Roads. 15<br />

•<br />

•<br />

•<br />

•<br />

<strong>The</strong> maintenance work is based on subjective<br />

judgment and engineering experience.<br />

Analytical tools are generally not used in decision<br />

making.<br />

Life cycle cost analysis is not a criterion for the<br />

selection of the best strategies of maintenance.<br />

<strong>The</strong> causes of deterioration of bridges and of the<br />

effectiveness of different maintenance strategies<br />

are often unevaluated due to non-availability of<br />

requisite data.<br />

MARCH 2012 <strong>The</strong> IndIan ConCreTe Journal<br />

15

On the basis of the study of bridge inventory and<br />

inspection reports of 5237 bridges spread across various<br />

National Highways in 20 States of India managed by<br />

different State Public Works Departments, the following<br />

observations were made: 2<br />

16<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

<strong>The</strong> inventory of bridges was not updated.<br />

<strong>The</strong> year of construction of about 30 per cent of<br />

the bridges studied was not known.<br />

In the majority of cases, the condition of bridge<br />

components was mentioned as good without any<br />

quantitative criteria for such assessment.<br />

<strong>The</strong> types of distresses of various bridge<br />

components were mentioned, but their extent<br />

and severity were not.<br />

<strong>The</strong> history of inspections and maintenance works<br />

was either missing or not properly recorded.<br />

<strong>The</strong> lack of data was found to be the main hurdle<br />

in developing a scientific BMS.<br />

<strong>The</strong> fund allocation for bridge maintenance was about<br />

2% of the total allocation for the total highway budget. 16<br />

Table 2. Objectives, activities and modules of BMS<br />

Objectives of BMS Activities associated<br />

with BMS<br />

To maintain a bridge or a network of<br />

bridges in a satisfactory condition<br />

To guarantee the safety of the users<br />

with specified risk<br />

To ensure a targeted level of service<br />

To allocate and use limited resources<br />

in a judicious manner<br />

To determine present needs for<br />

maintenance, rehabilitation, and<br />

replacement of bridges<br />

To predict future needs among the<br />

various alternatives<br />

To prioritize bridges for<br />

maintenance, rehabilitation and<br />

replacement<br />

To predict the remaining service life<br />

and minimize life cycle costs<br />

To ensure collection of objective<br />

information on all bridges<br />

To ensure techno-economical<br />

feedback<br />

To provide information to the road<br />

users<br />

Maintaining an<br />

appropriate data base<br />

Inspecting bridges<br />

Defining bridge<br />

conditions<br />

Predicting bridge<br />

requirement<br />

Prioritizing bridges for<br />

maintenance, repair,<br />

rehabilitation and<br />

replacement<br />

Allocation of funds<br />

Identifying bridges for<br />

posting (monitoring and<br />

rating of bridges)<br />

Cost-effective alternative<br />

for each bridge<br />

Scheduling maintenance<br />

Accounting for actual<br />

bridge expenditure, and<br />

Tracking minor<br />

maintenance activities<br />

<strong>The</strong> IndIan ConCreTe Journal MARCH 2012<br />

In the case of India, only 40 % of the amount required<br />

for maintenance of highways is generally available. As<br />

the funds allocated are meagre, it is imperative that they<br />

are spent judiciously.<br />

objectives, activities and modules of<br />

bridge management system<br />

A scientific <strong>Bridge</strong> <strong>Management</strong> <strong>System</strong> (BMS) helps<br />

in making right decisions regarding maintenance and<br />

optimal utilization of the available resources. <strong>The</strong><br />

Organization for Economic Cooperation and Development<br />

(OECD) report on bridge management defines BMS as a<br />

tool for assisting highway and bridge agencies in making<br />

the right choice of optimum improvements to the bridge<br />

network that is consistent with their policies, long-term<br />

objectives, and budgetary constraints. 7 Scherer and<br />

Glagola have defined BMS as a rational and systematic<br />

approach to organizing and carrying out all the activities<br />

relating to managing a network of bridges. 17 <strong>The</strong><br />

literature on bridges mentions a number of functions<br />

of BMS. <strong>The</strong> various BMS objectives and associated<br />

activities with various BMS modules are summarised in<br />

Table 2. 7, 14, 17 to 24 <strong>The</strong> BMS is purported to optimize the<br />

selection of maintenance and improvement activities<br />

BMS Modules<br />

<strong>Bridge</strong> inventory – It contains all administrative and technical<br />

information pertaining to a bridge or a network of bridges e.g., location,<br />

type, age, etc.<br />

Inspection and reports – Collection and maintenance of reports of all<br />

inspections and maintenance work carried out since opening to traffic.<br />

Many of the BMS modules are developed by using this information.<br />

Condition state – Present physical state indicating soundness of a bridge<br />

determined on the basis of an inspector’s judgment and/or testing<br />

Deterioration rate – How the structure has deteriorated since opening to<br />

traffic due to increasing age and erosive effect of traffic and environment?<br />

Prediction of life – Minimum expected life at the time of design/<br />

maximum period up to which bridge can be subjected to traffic flow to<br />

serve as intended function<br />

Requirement of inspection, maintenance, repair, rehabilitation and<br />

replacement – when, what and how much?<br />

Cost of inspection, maintenance, repair, rehabilitation and replacement<br />

of a bridge or a network of bridges<br />

Estimation of LCC of bridge/bridge stock considering both direct and<br />

indirect costs<br />

Rating - Method by which ability of a bridge to safely bear the present<br />

volume of traffic is ascertained<br />

Prioritization of maintenance, repair, rehabilitation and replacement – By<br />

ranking of bridges based on rating and/or LCC<br />

Optimal utilization of funds for maintenance, repair, rehabilitation and<br />

replacement, reprioritization depending on the availability of funds

in order to maximize the benefits and minimize the<br />

costs. BMS assists decision making, but does not replace<br />

human judgment. Though the requirements and general<br />

principles of bridge management remain same, the art<br />

and practice vary from country to country and even from<br />

state to state within a country owing to factors, such<br />

as goals and objectives of the concerned organization,<br />

bridge stock and its characteristics, environmental<br />

factors, the type of personnel employed, availability<br />

of funds, construction and maintenance practices,<br />

availability of materials, minimum serviceability<br />

requirement and so on.<br />

<strong>Bridge</strong> inspection practices<br />

For effective repair and rehabilitation of bridges, proper<br />

understanding of their existing conditions is required<br />

and this starts with inspection. 25 Environmental factors<br />

perennially impact the condition of bridges and are<br />

beyond human control. A newly built bridge requires<br />

due attention right from the day it is opened to traffic.<br />

Due consideration may also be required in the upkeep<br />

of the constructed parts of bridges if the construction<br />

period spans more than a year as otherwise by the time<br />

construction is completed some components might have<br />

been deteriorated. Eventually, the condition at the time<br />

of opening a bridge to traffic may not be the same as<br />

anticipated and will impact the overall performance of<br />

the bridge.<br />

Table 3. Types of inspection in different countries<br />

No. Country Type of inspection<br />

1 Austria 7<br />

2 Denmark 7<br />

3 France 7<br />

4 Germany 7<br />

5 Norway 7<br />

6 Slovenia 7<br />

7 United Kingdom 7<br />

8 United States 26<br />

9 Vietnam 27<br />

10 Taiwan 28<br />

11 Ireland 29<br />

12 Sweden 30<br />

13 India (a) Road bridges 13,14<br />

14 India (b) Railway bridges 3<br />

Initial /<br />

Preliminary /<br />

Acceptance<br />

Superficial /<br />

Routine / Regular /<br />

Assessment<br />

Visual inspection is the cheapest and easiest way of<br />

assessing the condition of bridges although a better<br />

appraisal can be done only with detailed testing<br />

and/or sophisticated health monitoring means, tools<br />

and equipments. Regular inspection ensures sound<br />

performance of a bridge, timely identification of<br />

distresses and remedial measures, creation, updating<br />

and maintenance of data base, and right feedback to the<br />

3, 13<br />

designer, owner, and road user.<br />

Depending on the objective of inspections, the type<br />

of inspection and its frequency vary. <strong>The</strong> inspection<br />

may be daily patrol, preliminary inspection, and end<br />

of guarantee inspection, routine inspection, general<br />

inspection, major inspection, special inspection and<br />

exceptional inspection.<br />