KOCH - Berkel Sales & Service

KOCH - Berkel Sales & Service

KOCH - Berkel Sales & Service

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

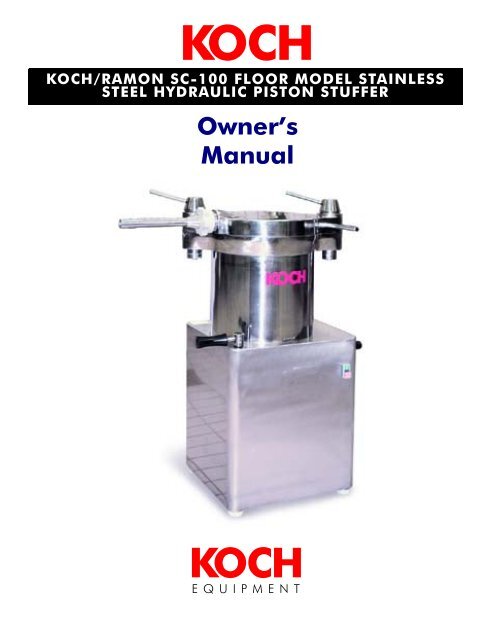

<strong>KOCH</strong><br />

<strong>KOCH</strong>/RAMON SC-100 FLOOR MODEL STAINLESS<br />

STEEL HYDRAULIC PISTON STUFFER<br />

Owner’s<br />

Manual<br />

<strong>KOCH</strong><br />

EQUIPMENT

<strong>KOCH</strong> EQUIPMENT LLC<br />

Owner’s Manual<br />

Koch/Ramon SC-100<br />

Hydraulic Piston Stuffer<br />

W I T H<br />

HYDRAULIC POWER, STAINLESS STEEL CYLINDER,<br />

LID AND PISTON, AND VARIABLE SPEEDS<br />

Rev. 2003<br />

D

I N T R O D U C T I O N PAGE I<br />

<strong>KOCH</strong><br />

EQUIPMENT<br />

<strong>KOCH</strong> EQUIPMENT LLC<br />

Koch/Ramon SC-100 Hydraulic Piston Stuffer Owner’s Manual<br />

Manufactured by<br />

Koch Equipment LLC<br />

1414 West 29 th Street<br />

Kansas City, MO 64108-3604<br />

INTRODUCTION<br />

Congratulations on your Koch/Ramon SC-100 Hydraulic Piston Stuffer purchase. This<br />

piston stuffer was designed to give you years of trouble free operations and to help in<br />

the preparation and packaging of your quality food products.<br />

Please read this owner’s manual to gain the maximum benefits of your piston stuffer<br />

and its different components.<br />

A note about cleaning: Given all the various ways equipment is used in different<br />

environments, we recommend the owner consult sanitation experts on how to properly<br />

clean each piece of machinery in their plant and to do bacterial testing to insure that the<br />

equipment is cleaned properly.<br />

For <strong>Sales</strong>, Call:<br />

Phone (816) 753-2150 • Fax (816) 753-4976<br />

Toll-Free (800) 777-5624<br />

For Replacement Parts, Call:<br />

Phone (816) 753-2150 • Fax (816) 561-2854<br />

Toll-Free (800) 746-1723<br />

For Technical Support, Call:<br />

Phone (816) 753-2150 • Fax (816) 531-1477<br />

Toll-Free (800) 777-5624<br />

© Copyright 2005 Koch Equipment LLC<br />

Koch Equipment LLC Last printed 1/21/2005 2:47:00 PM<br />

1414 West 29th Street Version Rev. 2003D-0<br />

Kansas City, MO 64108-3604<br />

Phone: (816) 753-2150 • Fax: (816) 753-4976<br />

info@kochequipment.com • kochequipment.com

I N T R O D U C T I O N PAGE II<br />

General<br />

Please read these instructions carefully before performing any installation, use, or<br />

maintenance operation.<br />

In case of damage caused during transportation to your plant, claims should be made<br />

immediately to the truck line and driver. Koch Equipment LLC is not responsible for<br />

damage or handling of the machine once it leaves our warehouse.<br />

Koch Equipment LLC cannot be held responsible for drawbacks, breakdowns, accidents,<br />

etc. as a result of the lack of knowledge or non-application of the rules contained in this<br />

operating instruction manual. The same is true for any change, modification and/or for<br />

the installation of non-authorized parts.<br />

Receiving Problems: As in all cases, before signing the bill of lading, be sure all items<br />

have been received as listed and there is no damage in shipment. If needed, a claim must<br />

be made immediately to the local truck line office and noted on the bill of lading.<br />

Model Nr. ________ Serial Nr. ___________<br />

Ship Date: ___________________________<br />

Owner: ___________________________<br />

Location: ___________________________<br />

Electrical service for your SC-100 Piston Stuffer: 220 volt, 60 Hertz, 3 phase<br />

<strong>KOCH</strong><br />

EQUIPMENT<br />

Koch Equipment LLC Last printed 1/21/2005 2:47:00 PM<br />

1414 West 29th Street Version Rev. 2003D-0<br />

Kansas City, MO 64108-3604<br />

Phone: (816) 753-2150 • Fax: (816) 753-4976<br />

info@kochequipment.com • kochequipment.com

I N T R O D U C T I O N PAGE III<br />

Table of Contents<br />

<strong>KOCH</strong><br />

EQUIPMENT<br />

INTRODUCTION...........................................i<br />

General .......................................................ii<br />

SECTION 1<br />

SAFETY ....................................................... 1<br />

Warning .................................................... 2<br />

General Safety Guidelines........................... 5<br />

SECTION 2<br />

STARTUP ..................................................... 6<br />

SECTION 3<br />

OPERATION.............................................. 10<br />

SECTION 4<br />

MAINTENANCE......................................... 13<br />

SECTION 5<br />

SCHEMATIC.............................................. 16<br />

SECTION 6<br />

PARTS ....................................................... 21<br />

SECTION 7<br />

SERVICE HISTORY ..................................... 26<br />

ICONS<br />

................................... Warning<br />

..................................... Caution<br />

Koch Equipment LLC Last printed 1/21/2005 2:47:00 PM<br />

1414 West 29th Street Version Rev. 2003D-0<br />

Kansas City, MO 64108-3604<br />

Phone: (816) 753-2150 • Fax: (816) 753-4976<br />

koch@kochequipment.com • kochequipment.com

I N T R O D U C T I O N PAGE IV<br />

Index<br />

C<br />

Cleaning..................................................... i, 14<br />

D<br />

Data Plate........................................................ 8<br />

F<br />

Frequently Ordered Parts ............................... 25<br />

G<br />

General ............................................................ii<br />

General Part Identification ............................. 22<br />

General Safety Guidelines................................ 5<br />

General Warnings............................................ 4<br />

I<br />

Important Notice for Users ............................... 4<br />

Installation....................................................... 8<br />

INTRODUCTION............................................... i<br />

M<br />

Maintenance.................................................. 14<br />

MAINTENANCE.............................................. 13<br />

Mechanical Drawings..................................... 17<br />

<strong>KOCH</strong><br />

EQUIPMENT<br />

O<br />

OPERATION................................................... 10<br />

Operator Safety ............................................... 2<br />

P<br />

PARTS ............................................................ 21<br />

Power Requirements ........................................ 9<br />

Problems and Remedies ................................. 15<br />

R<br />

Recommended Use ........................................ 12<br />

S<br />

SAFETY ............................................................ 1<br />

SCHEMATIC................................................... 16<br />

<strong>Service</strong> History ............................................... 27<br />

Standard Operation ....................................... 11<br />

Startup............................................................. 7<br />

STARTUP .......................................................... 6<br />

T<br />

Troubleshooting............................................. 15<br />

W<br />

WARNING ....................................................... 2<br />

Warning Signals............................................... 5<br />

Koch Equipment LLC Last printed 1/21/2005 2:47:00 PM<br />

1414 West 29th Street Version Rev. 2003D-0<br />

Kansas City, MO 64108-3604<br />

Phone: (816) 753-2150 • Fax: (816) 753-4976<br />

koch@kochequipment.com • kochequipment.com

S A F E T Y PAGE 1<br />

SAFETY<br />

Warning .................................................................................. 2<br />

Operator Safety ........................................................................ 3<br />

General Warnings..................................................................... 4<br />

Important Notice for Users ........................................................ 4<br />

Warning Signals........................................................................ 5<br />

General Safety Guidelines......................................................... 5<br />

<strong>KOCH</strong><br />

EQUIPMENT<br />

Section<br />

1<br />

Koch Equipment LLC Last printed 1/21/2005 2:47:00 PM<br />

1414 West 29th Street Version Rev. 2003D-0<br />

Kansas City, MO 64108-3604<br />

Phone: (816) 753-2150 • Fax: (816) 753-4976<br />

koch@kochequipment.com • kochequipment.com

S A F E T Y PAGE 2<br />

WARNING<br />

The following procedures and guidelines must be followed precisely to avoid<br />

problems that can result in property damage, personal injury, or death. If you have<br />

any questions related to this information, please contact the Koch Equipment LLC<br />

<strong>Service</strong> Department at (800) 777-5624.<br />

Read the entire Owner’s Manual before use and retain for future reference. Read and<br />

pay attention to all Warnings and Instructions on the machine.<br />

Place the machine on a stable surface.<br />

Only specialized and expert operators authorized by the manufacturer should carry out<br />

all routine and unexpected maintenance operations of the machine.<br />

Herein specified as “operator” is the person(s) charged with installing, running,<br />

adjusting, servicing, cleaning, repairing and transporting the machine.<br />

These operating instructions form an integral part of the machine and must accompany<br />

the piston stuffer for its entire lifetime until demolition.<br />

The manufacturer recommends that these instructions be read carefully before<br />

performing any installation/use/maintenance operation. All operators attending the<br />

machine must know the directions contained in this operating instructions manual.<br />

Provide this manual to any other user or successive owner of the machine.<br />

Perform service on the machine only as directed in this manual.<br />

<strong>KOCH</strong><br />

EQUIPMENT<br />

Koch Equipment LLC Last printed 1/21/2005 2:47:00 PM<br />

1414 West 29th Street Version Rev. 2003D-0<br />

Kansas City, MO 64108-3604<br />

Phone: (816) 753-2150 • Fax: (816) 753-4976<br />

koch@kochequipment.com • kochequipment.com

S A F E T Y PAGE 3<br />

Operator Safety<br />

Before starting work with the machine, the operator must be clearly aware of the<br />

position and the working of all the controls and of the characteristics of the machine<br />

described in these operating instructions.<br />

Never tamper with the safety devices.<br />

Never remove or change the protection and safety devices, especially those installed at<br />

the meat inlet.<br />

Never tamper with the electric system.<br />

Always disconnect from power supply before performing any cleaning, servicing or<br />

maintenance operation.<br />

The use of the machine in environments with explosive atmosphere is forbidden.<br />

Do not touch the moving device if the machine is not completely stopped.<br />

The working position is in front of the start and stop push buttons.<br />

Never go near the machine with loose hair, clothes, bracelets, chains, rings, ties, etc. to<br />

avoid the chance that they become tangled in the moving parts of the machine.<br />

As a consequence, the operator shall wear suitable clothes for the working environment<br />

and the situation he/she is in.<br />

Always keep the working place clear and free from oil residues.<br />

The room where the machine is installed must not have dark areas, dazzling lights or<br />

stroboscopic effects due to the lighting system.<br />

<strong>KOCH</strong><br />

EQUIPMENT<br />

Koch Equipment LLC Last printed 1/21/2005 2:47:00 PM<br />

1414 West 29th Street Version Rev. 2003D-0<br />

Kansas City, MO 64108-3604<br />

Phone: (816) 753-2150 • Fax: (816) 753-4976<br />

koch@kochequipment.com • kochequipment.com

S A F E T Y PAGE 4<br />

General Warnings<br />

Operations that may be dangerous for operators are indicated by the “CAUTION”<br />

symbol, shown above.<br />

Make sure that the voltage of the outlet is the same as the voltage required by the<br />

machine (refer to the label).<br />

The manufacturer must authorize any modification to the machine.<br />

Never use a spray of water to clean the machine.<br />

The voltage inside the machine is 208 volt or 230 volt.<br />

Always use original spare parts that guarantee perfect working order and the safety of<br />

the machine.<br />

The electric cable must be checked regularly and carefully (a worn cable or a cable in<br />

less than perfect condition is always a serious electrical danger).<br />

Important Notice for Users<br />

Removal of the safety device on the machine is not allowed.<br />

Koch Equipment LLC is not liable for any damage to humans, animals or material<br />

objects resulting from the following:<br />

• Removal of safety devices;<br />

• Unauthorized uses of the machine or uses not expressly listed in this operating<br />

instructions manual in the Technical Features section; or<br />

• Tampering of the machine.<br />

The manufacturer cannot take any responsibility for modifications made to the original<br />

piston stuffer other than those mentioned in these operating instructions.<br />

<strong>KOCH</strong><br />

EQUIPMENT<br />

Koch Equipment LLC Last printed 1/21/2005 2:47:00 PM<br />

1414 West 29th Street Version Rev. 2003D-0<br />

Kansas City, MO 64108-3604<br />

Phone: (816) 753-2150 • Fax: (816) 753-4976<br />

koch@kochequipment.com • kochequipment.com

S A F E T Y PAGE 5<br />

The manufacturer takes no responsibility for damages caused by operating the machine<br />

incorrectly.<br />

The manufacturer does not take any responsibility for any anomaly that can happen in<br />

the operation and performance of the machine by not observing these operating<br />

instructions.<br />

Warning Signals<br />

WARNING non-indelible adhesive labels are placed on the machine.<br />

They must be replaced with the labels supplied when it becomes difficult to read them.<br />

Read these labels before operating the machine.<br />

General Safety Guidelines<br />

Obvious safety guidelines should be observed.<br />

⇒ Be sure to turn off power to your piston stuffer before any maintenance work is<br />

performed.<br />

⇒ Never reach into or put anything into the ventilation slots of the machine.<br />

⇒ Care should be taken at all times, especially when there is a need to remove any of<br />

the internal, overhead panels.<br />

⇒ The best safety precaution around any machine is to keep it clean! Always keep a fire<br />

extinguisher (Type BC) close to the machine. (See more on cleaning in following<br />

pages.)<br />

<strong>KOCH</strong><br />

EQUIPMENT<br />

Koch Equipment LLC Last printed 1/21/2005 2:47:00 PM<br />

1414 West 29th Street Version Rev. 2003D-0<br />

Kansas City, MO 64108-3604<br />

Phone: (816) 753-2150 • Fax: (816) 753-4976<br />

koch@kochequipment.com • kochequipment.com

S T A R T U P PAGE 6<br />

STARTUP<br />

Startup...................................................................................... 7<br />

Installation................................................................................ 8<br />

Data Plate................................................................................. 8<br />

Power Requirements ................................................................. 9<br />

Section<br />

2

S T A R T U P PAGE 7<br />

Startup<br />

Before starting the machine for the first time, the oil tank (44) must be filled. To do this,<br />

remove the machine side cover, take out the filler cap (58) and fill the oil tank.<br />

The following oils are recommended (15-liters):<br />

TELLUS 33 (SHELL)<br />

TERESSO 52 (ESSO)<br />

NUTO 32 (ESSO)<br />

343 HYDRAULIC (GULF)<br />

After filling the oil tank, replace the filler cap and cover to normal position. Replace the<br />

handle (20), to facilitate opening the cover (15), and also the control lever (47).<br />

Before starting every cycle of operation it is essential to clean the machine with<br />

biodegradable soap in order to eliminate any bacteria that might be present.<br />

Once the machine is switched on and has started operating, check that the start and<br />

stop pushbuttons, as well as all of the other safety devices, operate properly. Afterward,<br />

make sure that the hydraulic pump rotates in the right direction. To check it, just press<br />

the green start switch (I), then push pedal (47) forward. If the meat pressing piston does<br />

not move, it means that the motor is rotating in the wrong direction. To correct this<br />

problem, the two cores in the plug wire must be interchanged.<br />

Once all this has been carried out, work can start as follows:<br />

Loosen nut (4) and open cylinder cover (15). Load the cylinder with meat. We<br />

recommend that the operator press the meat down with his/her hands to expel as much<br />

air as possible from the cylinder. Then choose the correct funnel size (1, 2, 3) and fix the<br />

selected funnel to the cover with nut (14). Push lever forward (47) to lift piston (71).<br />

Then release the lever so that it springs back to neutral position. To bring the piston<br />

down, move lever (47) backward. To do this, it is not necessary to keep pressing the<br />

lever backward, as it will remain in that position until you restore it to its neutral<br />

position. When the piston reaches the lowest point, there is no reason to be concerned,<br />

because a safety valve will open to prevent stress on the machine.<br />

To select the meat output speed desired, adjust command (29). Turn it clockwise to<br />

increase the speed by raising the pressure or turn it counterclockwise if a lower meat<br />

output speed is required.<br />

<strong>KOCH</strong><br />

EQUIPMENT<br />

Koch Equipment LLC Last printed 1/21/2005 2:47:00 PM<br />

1414 West 29th Street Version Rev. 2003D-0<br />

Kansas City, MO 64108-3604<br />

Phone: (816) 753-2150 • Fax: (816) 753-4976<br />

koch@kochequipment.com • kochequipment.com

S T A R T U P PAGE 8<br />

Installation<br />

The piston stuffer must be unpacked carefully and the shipment label checked to ensure<br />

that it is the correct machine. Once unpacked, please read the instructions carefully and<br />

take the following precautions:<br />

1. Make sure that the personnel in charge of installing the piston stuffer are fully<br />

qualified in dealing with this kind of machine.<br />

2. Check that the mains into which the machine will be plugged has the right<br />

current.<br />

3. Check that all the components of the piston stuffer are correctly placed and<br />

that they have not in any way been affected by transportation.<br />

Data Plate<br />

Place the data plate on the right-hand side of the machine base, at the right lower<br />

angle, in accordance with the drawing below.<br />

<strong>KOCH</strong><br />

EQUIPMENT<br />

Koch Equipment LLC Last printed 1/21/2005 2:47:00 PM<br />

1414 West 29th Street Version Rev. 2003D-0<br />

Kansas City, MO 64108-3604<br />

Phone: (816) 753-2150 • Fax: (816) 753-4976<br />

koch@kochequipment.com • kochequipment.com

S T A R T U P PAGE 9<br />

Power Requirements<br />

The piston stuffer must be plugged into a grounding outlet. If for any reason no<br />

grounding outlet is available, a 10A differential switch with a maximum sensitivity of<br />

15mA should be installed.<br />

The feed line, if in a fixed conduit, must be a 750 VAT wire with a double insulation<br />

layer. If the piston stuffer is plugged to a wire not fixed in a conduit, the wire must be of<br />

1,000 VAC.<br />

Before switching on the machine, make sure that it is correctly installed and that the<br />

safety devices are attached to the machine. Carry out overload tests and wire insulation<br />

tests to guarantee minimum causes of direct or indirect contact.<br />

Before connecting the machine to the mains, please make sure that the electric system<br />

conforms to the features set out on the data plate. If not, perform the following:<br />

1. Change connections in motor terminal box, as indicated in Fig. 1.<br />

2. Change the contact.<br />

<strong>KOCH</strong><br />

EQUIPMENT<br />

Fig. 1<br />

220V 380V<br />

Take into account that the piston stuffer motor operates only on one voltage and cannot<br />

be changed. If the piston stuffer voltage needs to be changed, please contact our<br />

technical service staff, as a great deal of specialized hard work is required.<br />

If the above-mentioned verifications are not applied, the piston stuffer motor and<br />

electric components can suffer serious damage. Koch Equipment LLC will not accept any<br />

responsibility for damages that the machine may suffer by not observing the precautions<br />

outlined.<br />

Koch Equipment LLC Last printed 1/21/2005 2:47:00 PM<br />

1414 West 29th Street Version Rev. 2003D-0<br />

Kansas City, MO 64108-3604<br />

Phone: (816) 753-2150 • Fax: (816) 753-4976<br />

koch@kochequipment.com • kochequipment.com

O P E R A T I O N PAGE 10<br />

OPERATION<br />

Standard Operation ................................................................ 11<br />

Recommended Use ................................................................. 12<br />

<strong>KOCH</strong><br />

EQUIPMENT<br />

Section<br />

3<br />

Koch Equipment LLC Last printed 1/21/2005 2:47:00 PM<br />

1414 West 29th Street Version Rev. 2003D-0<br />

Kansas City, MO 64108-3604<br />

Phone: (816) 753-2150 • Fax: (816) 753-4976<br />

koch@kochequipment.com • kochequipment.com

O P E R A T I O N PAGE 11<br />

Standard Operation<br />

The piston stuffer is intended for filling natural or synthetic skins with various types of<br />

meat and ingredients in order to obtain the kind of sausage desired.<br />

The piston stuffer is completely made of stainless steel (with the exception of the piston<br />

and cover, which are manufactured in corrosion-proofed anodized aluminum). The<br />

piston and cover can be provided in stainless steel as an option.<br />

The machine has been designed in such a way that it is easy to clean and practically no<br />

maintenance is required. The machine is also fitted with wheels so it can be moved<br />

when required.<br />

The piston stuffer construction fulfils all EEC safety requirements:<br />

• The machine is prevented from starting up unexpectedly when the electric supply<br />

is restored after electricity cut.<br />

• As the machine is accessible from all sides, the stop pushbutton can also be used<br />

as an emergency stop.<br />

• The hydraulic oil tank is tightly closed to prevent any risk of explosion or ignition<br />

in the machine in case it came into contact with an electric spark.<br />

<strong>KOCH</strong><br />

EQUIPMENT<br />

Koch Equipment LLC Last printed 1/21/2005 2:47:00 PM<br />

1414 West 29th Street Version Rev. 2003D-0<br />

Kansas City, MO 64108-3604<br />

Phone: (816) 753-2150 • Fax: (816) 753-4976<br />

koch@kochequipment.com • kochequipment.com

O P E R A T I O N PAGE 12<br />

Recommended Use<br />

The piston stuffer was designed and built for the sole stuffing of all kinds of fresh meat<br />

and ingredients, in suitable casings and without bone parts, flesh or tendons.<br />

The main case is solid and built in stainless steel. The machine is equipped with<br />

supporting. It is fully equipped with safety devices for the operator’s safety.<br />

The minimum temperature of the meat to be processed must be not less than +1° C.<br />

It is not advisable to use the machine to stuff frozen meat.<br />

Any use different from the recommended use is not allowed and may be dangerous for<br />

the machine and the operator. Koch Equipment LLC is not liable for damage to humans,<br />

animals or material objects resulting from uses that are not expressly described in this<br />

operating instruction manual.<br />

Always and only use the attachments supplied.<br />

Only one operator at a time can operate the machine.<br />

For working operations, the operator must stay in front of the start and stop push<br />

buttons.<br />

<strong>KOCH</strong><br />

EQUIPMENT<br />

Koch Equipment LLC Last printed 1/21/2005 2:47:00 PM<br />

1414 West 29th Street Version Rev. 2003D-0<br />

Kansas City, MO 64108-3604<br />

Phone: (816) 753-2150 • Fax: (816) 753-4976<br />

koch@kochequipment.com • kochequipment.com

M A I N T E N A N C E PAGE 13<br />

MAINTENANCE<br />

Cleaning................................................................................. 14<br />

Maintenance........................................................................... 14<br />

Troubleshooting: Problems & Remedies ................................... 15<br />

<strong>KOCH</strong><br />

EQUIPMENT<br />

Section<br />

4<br />

Koch Equipment LLC Last printed 1/21/2005 2:47:00 PM<br />

1414 West 29th Street Version Rev. 2003D-0<br />

Kansas City, MO 64108-3604<br />

Phone: (816) 753-2150 • Fax: (816) 753-4976<br />

koch@kochequipment.com • kochequipment.com

M A I N T E N A N C E PAGE 14<br />

Cleaning<br />

1. Clean the machine in accordance with instructions in this section.<br />

2. Always clean the machine after use.<br />

3. Place the machine in a hygienically appropriate environment.<br />

To clean the piston, dismount as follows:<br />

Move piston (71) to its highest point, place part (77) into part (70) and turn<br />

counterclockwise in order to unscrew and remove part (82). This operation must be<br />

carried out with pedal (47) pressed forward to prevent eye (73) from turning. Then screw<br />

on part (78) into part (72) to remove piston.<br />

To replace piston, place it horizontally on the cylinder, with piston shaft (73) at the top.<br />

To get the piston back into the cylinder, keep screwing on part (72).<br />

Maintenance<br />

The piston stuffer has been made to reduce maintenance almost to zero. We<br />

recommend that the hydraulic oil be changed approximately every two years.<br />

<strong>KOCH</strong><br />

EQUIPMENT<br />

Koch Equipment LLC Last printed 1/21/2005 2:47:00 PM<br />

1414 West 29th Street Version Rev. 2003D-0<br />

Kansas City, MO 64108-3604<br />

Phone: (816) 753-2150 • Fax: (816) 753-4976<br />

koch@kochequipment.com • kochequipment.com

M A I N T E N A N C E PAGE 15<br />

Troubleshooting<br />

Problems and Remedies<br />

A spare parts list is included so that parts can be obtained from Koch Equipment LLC.<br />

Our piston stuffers are manufactured with first class materials subject to very strict<br />

quality control and the components or additional equipment not manufactured by us are<br />

supplied to us with a reliability certificate. A breakdown, however, may occur:<br />

When trying to start the piston stuffer, if it does not go into motion:<br />

• Electric power can be lacking—the operator must wait.<br />

• Button on head blocked or dirty—clean it.<br />

• The power switch has deteriorated—it must be replaced.<br />

The piston stuffer stops after being in operation:<br />

• There may be a direct contact inside the motor—the motor will have to be<br />

rewound.<br />

• Defective insulation in some feed wire or in the machine control circuit—it will<br />

have to be checked with a voltage meter and the defective wire replaced.<br />

The motor is on, but the machine does not operate:<br />

• The pump rotates counterclockwise—correct by interchanging the two cores in the<br />

plug wire.<br />

• Lack of oil—add more oil.<br />

The piston moves up irregularly:<br />

• There is air in the hydraulic circuit—correct this by raising and lowering the piston<br />

a couple times. The air will be expelled automatically.<br />

• Lack of oil—add more oil.<br />

<strong>KOCH</strong><br />

EQUIPMENT<br />

Koch Equipment LLC Last printed 1/21/2005 2:47:00 PM<br />

1414 West 29th Street Version Rev. 2003D-0<br />

Kansas City, MO 64108-3604<br />

Phone: (816) 753-2150 • Fax: (816) 753-4976<br />

koch@kochequipment.com • kochequipment.com

S C H E M A T I C PAGE 16<br />

SCHEMATIC<br />

Mechanical Drawings.............................................................. 17<br />

<strong>KOCH</strong><br />

EQUIPMENT<br />

Section<br />

5<br />

Koch Equipment LLC Last printed 1/21/2005 2:47:00 PM<br />

1414 West 29th Street Version Rev. 2003D-0<br />

Kansas City, MO 64108-3604<br />

Phone: (816) 753-2150 • Fax: (816) 753-4976<br />

koch@kochequipment.com • kochequipment.com

S C H E M A T I C PAGE 17<br />

Mechanical Drawings<br />

<strong>KOCH</strong><br />

EQUIPMENT<br />

Koch Equipment LLC Last printed 1/21/2005 2:47:00 PM<br />

1414 West 29th Street Version Rev. 2003D-0<br />

Kansas City, MO 64108-3604<br />

Phone: (816) 753-2150 • Fax: (816) 753-4976<br />

koch@kochequipment.com • kochequipment.com

S C H E M A T I C PAGE 18<br />

Mechanical Drawings (continued)<br />

<strong>KOCH</strong><br />

EQUIPMENT<br />

Koch Equipment LLC Last printed 1/21/2005 2:47:00 PM<br />

1414 West 29th Street Version Rev. 2003D-0<br />

Kansas City, MO 64108-3604<br />

Phone: (816) 753-2150 • Fax: (816) 753-4976<br />

koch@kochequipment.com • kochequipment.com

S C H E M A T I C PAGE 19<br />

Mechanical Drawings (continued)<br />

<strong>KOCH</strong><br />

EQUIPMENT<br />

Koch Equipment LLC Last printed 1/21/2005 2:47:00 PM<br />

1414 West 29th Street Version Rev. 2003D-0<br />

Kansas City, MO 64108-3604<br />

Phone: (816) 753-2150 • Fax: (816) 753-4976<br />

koch@kochequipment.com • kochequipment.com

S C H E M A T I C PAGE 20<br />

Mechanical Drawings (continued)<br />

<strong>KOCH</strong><br />

EQUIPMENT<br />

Koch Equipment LLC Last printed 1/21/2005 2:47:00 PM<br />

1414 West 29th Street Version Rev. 2003D-0<br />

Kansas City, MO 64108-3604<br />

Phone: (816) 753-2150 • Fax: (816) 753-4976<br />

koch@kochequipment.com • kochequipment.com

P A R T S PAGE 21<br />

PARTS<br />

General Part Identification ...................................................... 22<br />

Frequently Ordered Parts ........................................................ 25<br />

<strong>KOCH</strong><br />

EQUIPMENT<br />

Section<br />

6<br />

Koch Equipment LLC Last printed 1/21/2005 2:47:00 PM<br />

1414 West 29th Street Version Rev. 2003D-0<br />

Kansas City, MO 64108-3604<br />

Phone: (816) 753-2150 • Fax: (816) 753-4976<br />

info@kochequipment.com • kochequipment.com

P A R T S PAGE 22<br />

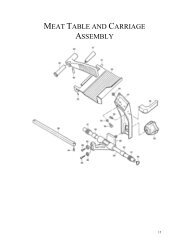

General Part Identification<br />

Only use original spare parts and do not wait for the parts to be<br />

completely worn out before replacing them.<br />

Ref.<br />

Koch<br />

Nr. Mfg. Nr. Item Nr. Description<br />

1 500046 Nozzle, 35mm diameter<br />

2 300031 Nozzle, 20mm diameter<br />

3 500048 Nozzle, 12mm diameter<br />

4 500026 Column nut<br />

5 500016<br />

6 5011430 Screw M12 x 30<br />

7<br />

8<br />

51114 Flat washer, 12mm diameter<br />

9 5320612 Screw, stainless steel, 6 x 12<br />

10<br />

11<br />

60814 O-ring, ¼-in.<br />

12 30614 Copper washer, ¼-in.<br />

13 30514 Tin cap (¼-in.)<br />

14<br />

15<br />

300033 48 00 51 Nut cylinder cover<br />

16 6091550 48 00 20 O-ring, cylinder<br />

17<br />

18<br />

19<br />

500031 Stainless steel cylinder<br />

20<br />

21<br />

7010 Cable, ceneflex<br />

22 5320408 Screw M4 x 8<br />

23<br />

24<br />

6091050 48 00 21 O-ring, piston<br />

25<br />

26<br />

500009 Lower cap cylinder<br />

27 500061 Foot machine<br />

28 5020616 Allen screw 6 x 16<br />

29<br />

30<br />

500027 Handle<br />

31 607756507 48 00 53 Oil seal<br />

32 500050 Cap piston driving bushing<br />

33 606756513 48 00 55 Collar<br />

34 500007 Driving bushing<br />

35 60510145 48 00 57 O-ring<br />

<strong>KOCH</strong><br />

EQUIPMENT<br />

Koch Equipment LLC Last printed 1/21/2005 2:47:00 PM<br />

1414 West 29th Street Version Rev. 2003D-0<br />

Kansas City, MO 64108-3604<br />

Phone: (816) 753-2150 • Fax: (816) 753-4976<br />

info@kochequipment.com • kochequipment.com

P A R T S PAGE 23<br />

General Part Identification (continued)<br />

Ref.<br />

Koch<br />

Nr. Mfg. Nr. Item Nr. Description<br />

36 6051402 48 00 58 O-ring<br />

37 500006 Top plunger piston<br />

38 6049906 48 00 61 O-ring<br />

39 Collar<br />

40 500006 Bottom plunger piston<br />

41 51014 Flat washer<br />

42<br />

43<br />

44<br />

45<br />

46<br />

51714 Self-locking nut<br />

47 130196 48 00 63 Command lever<br />

48<br />

49<br />

6052203 48 00 64 O-ring (20 x 26 x 3)<br />

50 456141715 Bushing (Selfoil A.14.17.15)<br />

51 500033 Command axle, distributor<br />

52 649 Distributor<br />

53<br />

54<br />

5020860 Allen screw (M8 x 60)<br />

55 60838 Gasket (3/8-in.)<br />

56 657 Raccord (3/8-in. - 10)<br />

57<br />

58<br />

59<br />

60<br />

60510145 O-ring<br />

61<br />

62<br />

63<br />

500004 Hydraulic cylinder<br />

64 655 48 00 68 Oil filter<br />

65<br />

66<br />

657 Raccord (3/8-in. - 10)<br />

67 652 48 00 69 Coupling<br />

68 691 48 00 71 Pump<br />

69<br />

70<br />

71<br />

72<br />

73<br />

74<br />

5020620 Allen screw (M-6 x 20)<br />

<strong>KOCH</strong><br />

EQUIPMENT<br />

Koch Equipment LLC Last printed 1/21/2005 2:47:00 PM<br />

1414 West 29th Street Version Rev. 2003D-0<br />

Kansas City, MO 64108-3604<br />

Phone: (816) 753-2150 • Fax: (816) 753-4976<br />

info@kochequipment.com • kochequipment.com

P A R T S PAGE 24<br />

General Part Identification (continued)<br />

Ref.<br />

Koch<br />

Nr.<br />

75<br />

76<br />

77<br />

78<br />

79<br />

80<br />

81<br />

82<br />

83<br />

Mfg. Nr. Item Nr. Description<br />

84 300044 48 00 73 Screw, piston tightening<br />

85 500025 Piston<br />

86 500012 48 00 75 Coupling, piston-rod<br />

87<br />

88<br />

89<br />

500005 Rod<br />

90 130126 48 00 76 Handle<br />

91 300019 48 00 79 Extractor<br />

92<br />

93<br />

300045 48 00 81 Piston extractor<br />

94 1009 Drainpipe<br />

95 Circlip<br />

96 Wheel<br />

97 694 Coupling drainpipe<br />

98 500075 Cover oil tank<br />

99 30514 Cap level support<br />

100 500074 Set pression regulation<br />

101 130165 Support<br />

102 4441817 48 00 67 Engine<br />

103 31611 Clamp<br />

104 500070 Oil tank<br />

105 500071 Base<br />

106 7394 Pushbutton<br />

<strong>KOCH</strong><br />

EQUIPMENT<br />

Koch Equipment LLC Last printed 1/21/2005 2:47:00 PM<br />

1414 West 29th Street Version Rev. 2003D-0<br />

Kansas City, MO 64108-3604<br />

Phone: (816) 753-2150 • Fax: (816) 753-4976<br />

info@kochequipment.com • kochequipment.com

P A R T S PAGE 25<br />

Frequently Ordered Parts<br />

Date Part Nr. Qty. Part Ordered<br />

<strong>KOCH</strong><br />

EQUIPMENT<br />

Koch Equipment LLC Last printed 1/21/2005 2:47:00 PM<br />

1414 West 29th Street Version Rev. 2003D-0<br />

Kansas City, MO 64108-3604<br />

Phone: (816) 753-2150 • Fax: (816) 753-4976<br />

info@kochequipment.com • kochequipment.com

S E R V I C E H I S T O R Y PAGE 26<br />

SERVICE HISTORY<br />

<strong>Service</strong> History ........................................................................ 27<br />

<strong>KOCH</strong><br />

EQUIPMENT<br />

Section<br />

7<br />

Koch Equipment LLC Last printed 1/21/2005 2:47:00 PM<br />

1414 West 29th Street Version Rev. 2003D-0<br />

Kansas City, MO 64108-3604<br />

Phone: (816) 753-2150 • Fax: (816) 753-4976<br />

info@kochequipment.com • kochequipment.com

S E R V I C E H I S T O R Y PAGE 27<br />

<strong>Service</strong> History<br />

Date <strong>Service</strong> Provided<br />

<strong>KOCH</strong><br />

EQUIPMENT<br />

Koch Equipment LLC Last printed 1/21/2005 2:47:00 PM<br />

1414 West 29th Street Version Rev. 2003D-0<br />

Kansas City, MO 64108-3604<br />

Phone: (816) 753-2150 • Fax: (816) 753-4976<br />

info@kochequipment.com • kochequipment.com

Koch Equipment LLC<br />

1414 West 29th Street<br />

Kansas City, MO 64108-3604<br />

800-777-5624<br />

Regular Telephone: (816) 753-2150<br />

Fax: (816) 753-4976<br />

E-mail: info@kochequipment.com<br />

Internet: kochequipment.com<br />

Koch Replacement Parts<br />

(800) 746-1723<br />

Fax: (816) 561-2854<br />

Koch Equipment <strong>Service</strong>s Inc.<br />

(800) 777-5624<br />

Fax: (816) 531-1447<br />

<strong>KOCH</strong><br />

EQUIPMENT