Volume 26 No 2 - Jun 2008 - Australian Institute of Energy

Volume 26 No 2 - Jun 2008 - Australian Institute of Energy

Volume 26 No 2 - Jun 2008 - Australian Institute of Energy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

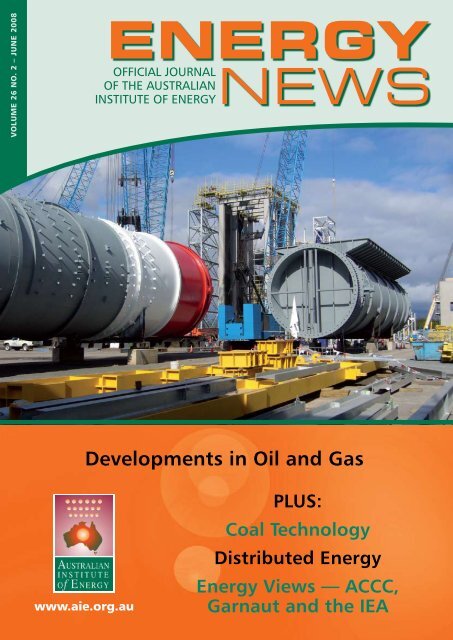

VolUME <strong>26</strong> <strong>No</strong>. 2 – JUNE <strong>2008</strong><br />

www.aie.org.au<br />

OFFICIAL JOURNAL<br />

OF THE AUSTRALIAN<br />

INSTITUTE OF ENERGY<br />

Developments in Oil and Gas<br />

PLUS:<br />

Coal Technology<br />

Distributed <strong>Energy</strong><br />

<strong>Energy</strong> Views — ACCC,<br />

Garnaut and the IEA

ISSN 1445-2227<br />

(International Standard Serial Number allocated<br />

by the National Library <strong>of</strong> Australia)<br />

THE AUSTrAlIAN<br />

INSTITUTE oF ENErgy<br />

ENErgy<br />

News<br />

Journal Correspondence<br />

Joy Claridge<br />

PO Box 298<br />

Brighton, VIC 3186<br />

email: editor@aie.org.au<br />

Advertising<br />

Members (and non-members) may place<br />

advertisements in ENErgyNews on behalf<br />

<strong>of</strong> themselves or their organisations. If you<br />

wish to use this opportunity contact:<br />

Joy Claridge<br />

PO Box 298<br />

Brighton, VIC 3186<br />

email: editor@aie.org.au<br />

Advertisements can include products,<br />

services, consulting, and positions vacant<br />

and required.<br />

Discounts are available for members and for<br />

all advertisements repeated in two or more<br />

issues.<br />

Subscription Information<br />

ENErgyNews is published by The <strong>Australian</strong><br />

<strong>Institute</strong> <strong>of</strong> <strong>Energy</strong> and is provided to<br />

all members as part <strong>of</strong> the membership<br />

subscription. <strong>No</strong>n-members may obtain<br />

copies <strong>of</strong> this journal by contacting either the<br />

Secretariat or the Editor.<br />

Contributions Welcome<br />

Articles on energy matters, letters to<br />

the editor, personal notes and photographs<br />

<strong>of</strong> those involved in the energy sector are<br />

most welcome.<br />

Published By<br />

The <strong>Australian</strong> <strong>Institute</strong> <strong>of</strong> <strong>Energy</strong><br />

ABN 95 001 509 173<br />

Registered Office<br />

Level 1/613 Canterbury Road,<br />

Surrey Hills VIC 3127<br />

Postal Address<br />

PO Box 193<br />

Surrey Hills VIC 3127<br />

Telephone Toll Free: 1800 629 945<br />

Facsimile: (03) 9898 0249<br />

email: aie@aie.org.au<br />

Web Address<br />

http://www.aie.org.au<br />

Print Post Approved <strong>No</strong>. PP 3<strong>26</strong>04/00001<br />

Disclaimer<br />

Although publication <strong>of</strong> articles submitted<br />

is at the sole and absolute discretion <strong>of</strong> the<br />

<strong>Australian</strong> <strong>Institute</strong> <strong>of</strong> <strong>Energy</strong>, statements<br />

made in this journal do not necessarily<br />

reflect the views <strong>of</strong> the <strong>Institute</strong>.<br />

Contents<br />

President’s Message 30<br />

The Price <strong>of</strong> Petrol 31<br />

Distributed <strong>Energy</strong> 32<br />

ETIS & IDgCC 34<br />

The IEA 36<br />

Water and <strong>Energy</strong> 38<br />

Special Feature<br />

Developments in Oil and Gas 39<br />

Articles<br />

An Overview <strong>of</strong> Advanced<br />

Clean Coal Technologies 44<br />

Garnaut Climate Change Review<br />

Government scheme helps deliver<br />

47<br />

cleaner energy 49<br />

Book reviews<br />

The Handbook <strong>of</strong> Biomass Combustion<br />

and Co-Firing 50<br />

Pinch Analysis and Process Integration 51<br />

letters to the <strong>Institute</strong> 51<br />

Membership Matters 53<br />

Cover: Courtesy TRUenergy<br />

ENErgyNews ENErgyNews — <strong>Volume</strong> <strong>26</strong> — <strong>No</strong>. <strong>Volume</strong> 2 <strong>Jun</strong>e <strong>26</strong> <strong>2008</strong> <strong>No</strong>. 2 <strong>Jun</strong>e <strong>2008</strong> 29

President’s Message<br />

The challenge <strong>of</strong> rising energy prices<br />

Murray Meaton, President,<br />

<strong>Australian</strong> <strong>Institute</strong> <strong>of</strong> <strong>Energy</strong><br />

<strong>Energy</strong> costs remain on the front page<br />

in our newspapers with record price<br />

rises for fossil fuels and predictions <strong>of</strong><br />

even higher coal and crude oil prices.<br />

Such price rises would normally be<br />

expected to lead to reduced energy use<br />

but such is the demand from expanding<br />

economies that consumption continues<br />

to rise inexorably. While rising energy<br />

prices will inevitably cause some<br />

slowdown in economic activity, the<br />

rising consumption continues to<br />

increase emissions <strong>of</strong> environmentwarming<br />

greenhouse gases.<br />

In an endeavour to reduce global<br />

emissions, governments <strong>of</strong> all<br />

Special Features<br />

This issue’s feature on Developments in Oil & Gas is timely. As ENErgyNews goes to press the crude oil price<br />

is hovering at around US$130 per barrel.<br />

Hydrogen will be featured in September <strong>2008</strong> issue, and all material will be sourced from presentations to the World<br />

Hydrogen <strong>Energy</strong> Conference (WHEC <strong>2008</strong>) hosted by the <strong>Australian</strong> <strong>Institute</strong> <strong>of</strong> <strong>Energy</strong> and the International<br />

Association <strong>of</strong> Hydrogen <strong>Energy</strong> in Brisbane on 15–19 <strong>Jun</strong>e <strong>2008</strong>.<br />

In December <strong>2008</strong> issue, the topic is Future Liquid Fuels, covering alternatives to petroleum fuels including, but<br />

not limited to, bi<strong>of</strong>uels, synfuels, and coal/gas to oil. So, let the editor know <strong>of</strong> your intention to submit material<br />

by 24 October <strong>2008</strong>, and send copy to editor for publication by 14 <strong>No</strong>vember <strong>2008</strong>.<br />

The first special feature for 2009 will be Skills and Training in the <strong>Energy</strong> Sector. Details to follow in forthcoming<br />

issues <strong>of</strong> ENErgyNews.<br />

Suggestions for further topics in 2009 welcome, and please include contact details <strong>of</strong> expert contributors if known.<br />

Contact details: Joy Claridge editor@aie.org.au<br />

(03) 9596 3608 0402 078 071<br />

30 ENErgyNews — <strong>Volume</strong> <strong>26</strong> <strong>No</strong>. 2 <strong>Jun</strong>e 2007<br />

persuasions continue to strive to find<br />

a balance between new technologies,<br />

renewable energy development and<br />

energy saving measures. The <strong>2008</strong><br />

<strong>Australian</strong> Government Budget<br />

devoted substantial funding to research<br />

into clean coal technologies and<br />

renewable energy sources. Perhaps<br />

reflecting the challenge <strong>of</strong> choosing<br />

the easier pathway, a very similar<br />

amount was allocated to both fields<br />

<strong>of</strong> work. Specific funding initiatives<br />

included energy storage and hydrogen<br />

as well as geothermal drilling and<br />

bi<strong>of</strong>uel technologies. Solar technology<br />

research will also be boosted by an<br />

<strong>Energy</strong> Innovation Fund. The broad<br />

ranging initiatives and the substantial<br />

funding involved reflect the importance<br />

<strong>of</strong> emission reduction. They also<br />

recognise that energy prices will<br />

continue to rise and economies need to<br />

start adapting to crude oil scarcity.<br />

The large budget sums also reflect the<br />

challenges that lie ahead. While new<br />

technologies <strong>of</strong>fer promise for emission<br />

reductions from new energy sources,<br />

the continuing increase in population<br />

and demand for higher living standards<br />

in developing countries means that<br />

the developed countries will have to<br />

reduce total energy consumption if the<br />

ambitious emission reduction targets<br />

are to be achieved. This cannot be<br />

achieved without a measurable increase<br />

in energy costs or energy-saving<br />

investment. There will be an adjustment<br />

in the economy, and energy-intensive<br />

industries almost certainly will relocate<br />

to countries with less stringent energy<br />

reduction aspirations. Any adjustment<br />

in the mix <strong>of</strong> industry and energy use<br />

patterns involves transitional costs<br />

and social adaptation. Australia is a<br />

wealthy country and, while there will<br />

be resistance from those most affected<br />

by these changes, the nation appears<br />

to have strongly supported emission<br />

reduction targets. It is now time to<br />

develop the strategies that will deliver<br />

those with the lowest transitional cost<br />

and community pain.<br />

<strong>Australian</strong> <strong>Institute</strong> <strong>of</strong> <strong>Energy</strong> Branches<br />

around Australia have been busy in the<br />

past few months with meetings and<br />

seminars on current energy issues.<br />

Two large conferences are scheduled<br />

for <strong>2008</strong>, with support for the 17th<br />

World Hydrogen <strong>Energy</strong> Conference<br />

in Brisbane in <strong>Jun</strong>e and the <strong>Energy</strong> in<br />

Western Australia conference in Perth<br />

in August. A very topical <strong>Energy</strong> in<br />

NSW event is also scheduled for July.<br />

I encourage all members support these<br />

ambitious events as well as regular<br />

Branch meetings.<br />

Murray Meaton<br />

President, AIE

Few nations are as enamoured with the car as Australia.<br />

There are 14.8 million registered vehicles on our roads and,<br />

when surveyed in 2006, 90% <strong>of</strong> households said they kept at<br />

least one car on the property. With 80% <strong>of</strong> those 18 and over<br />

using a car as a primary method <strong>of</strong> transport to get to work<br />

or study, any change in the basic cost <strong>of</strong> motoring potentially<br />

affects a huge section <strong>of</strong> the population. With its widely<br />

dispersed centres <strong>of</strong> agriculture, industry, mining activity,<br />

and large distances, Australia is a society highly dependent<br />

on fuel. Its citizens therefore are keen observers <strong>of</strong> petrol<br />

price fluctuations and harbour deep suspicion <strong>of</strong> factors<br />

that lead to its pricing. As a result there is a long history <strong>of</strong><br />

government involvement in petrol and petrol pricing.<br />

These community suspicions are perhaps driven partly by the<br />

complicated factors that lead to the eventual price paid at the<br />

pump by motorists. Weekly price cycles are one <strong>of</strong> the most<br />

obvious feature to motorists and generate much comment,<br />

especially around public holidays. Petrol price cycles remain<br />

an enigma to authorities, despite numerous investigations<br />

attempting to explain their origins. In terms <strong>of</strong> the standard<br />

<strong>of</strong> fuel sold in Australia, it varies both domestically and in<br />

comparison to standards overseas. There is also frequent<br />

buying and selling <strong>of</strong> petrol between the four major petrol<br />

companies within Australia. Despite the media focus and<br />

clear public concern about the price <strong>of</strong> petrol, <strong>Australian</strong>s<br />

continue to enjoy relatively cheap fuel in relation to other<br />

developed economies in the OECD group. In March 2007<br />

only Mexico, the United States and Canada had lower retail<br />

petrol prices than Australia in this group. The actual cost <strong>of</strong><br />

the fuel remains relatively similar across all countries, with<br />

government taxes making up for most <strong>of</strong> the differences<br />

between the 29 countries included in a 2007 OECD survey.<br />

The ACCC has for some time monitored the seven-day<br />

rolling average <strong>of</strong> retail unleaded petrol prices for the five<br />

largest cities and compared it to a rolling average for the<br />

region’s benchmark price, Singapore MOGAS 95 unleaded.<br />

Comparing the rolling average <strong>of</strong> what motorists pay at<br />

the pump and the regional benchmark (allowing for a lag<br />

<strong>of</strong> around one week) means the ACCC can easily monitor<br />

when <strong>Australian</strong> retailers are inflating prices. During 2007,<br />

the average difference between the wholesale and retail prices<br />

was 61.3 cpl (cents per litre). When that gap increased to<br />

63.8 cpl in January and then again rose to 65.5 cpl in <strong>Jun</strong>e,<br />

the ACCC made the information public and called on the<br />

petrol retailers to give motorists a fair go by pulling their<br />

prices back into line with the benchmark.<br />

The repeated disparities became the catalyst for the<br />

ACCC seeking the national Treasurer’s approval for a<br />

far-reaching inquiry into the industry under Part VIIA <strong>of</strong><br />

the Trade Practices Act. What resulted was an exhaustive,<br />

comprehensive examination <strong>of</strong> Australia’s unleaded<br />

The Price <strong>of</strong> Petrol<br />

Petrol Prices and <strong>Australian</strong> Consumers<br />

Based on a presentation to South Australia Branch<br />

by graeme Samuel, Chairman, ACCC (<strong>Australian</strong> Competition<br />

and Consumer Commission), on 22 February <strong>2008</strong>.<br />

petrol market. That report was<br />

submitted to the government on 14<br />

December 2007, and made a number<br />

<strong>of</strong> important findings. It concluded<br />

that the industry was fundamentally<br />

competitive and that there was no<br />

obvious evidence <strong>of</strong> price fixing. However, it did note there<br />

were concerns in the market. These included a cosy club <strong>of</strong><br />

sellers with a unique ability to control the supply and price<br />

<strong>of</strong> fuel. These suppliers also had an advantage over motorists<br />

in the form <strong>of</strong> real-time price information which allowed<br />

them to closely follow the price <strong>of</strong> competitors and adjust<br />

prices accordingly. Refining was also highly concentrated<br />

and barriers to entry were high for independents wanting to<br />

provide new competition, with one <strong>of</strong> the greatest barriers<br />

being a lack <strong>of</strong> port facilities for importing cheap petrol<br />

from overseas. In order to address these issues, the report<br />

recommended a closer look at the buy/sell arrangements<br />

between the major oil companies and an audit <strong>of</strong> terminals<br />

that would be potentially suitable for importing petrol into<br />

Australia from other markets.<br />

Since the release <strong>of</strong> the petrol report (see www.accc.gov.<br />

au to download a copy), the government has responded by<br />

directing the ACCC to conduct formal monitoring <strong>of</strong> the<br />

prices, costs and pr<strong>of</strong>its related to the supply <strong>of</strong> petroleum<br />

products in the petroleum industry. This requires the<br />

ACCC to produce annual reports to the Commonwealth<br />

Minister for Competition and Consumer Affairs over the<br />

next three years. The government has also announced the<br />

appointment <strong>of</strong> Pat Walker as a commissioner to the ACCC<br />

with special responsibilities in the area <strong>of</strong> petrol. Mr Walker<br />

is a former Commissioner for the Consumer Protection<br />

and Prices Commission in Western Australia. Despite the<br />

extensive work already conducted as a result <strong>of</strong> the petrol<br />

inquiry, there remains much still to be done. As well as an<br />

audit <strong>of</strong> all potential terminals suitable for importing petrol<br />

and the responsibilities <strong>of</strong> ongoing monitoring, there will<br />

also be a closer examination <strong>of</strong> the information sharing<br />

arrangements provided to petrol retailers and a running<br />

watch on developments in shopper docket schemes that may<br />

impact on the competitiveness <strong>of</strong> the market.<br />

Despite this work, to echo the words <strong>of</strong> the minister, Chris<br />

Bowen, “there is no magic bullet that will lead to a sudden<br />

sharp drop in the price <strong>of</strong> petrol in Australia”. Like every<br />

other country, Australia must pay the going price for this<br />

internationally-traded commodity. That said, there is scope<br />

to ensure that at the local level steps are taken to make petrol<br />

pricing as competitive as possible. To ensure motorists get the<br />

best possible price when filling their cars we need to ensure<br />

accountability, transparency and increased opportunities for<br />

competition between sellers, while empowering motorists<br />

with the information to make informed buying decisions.<br />

ENErgyNews — <strong>Volume</strong> <strong>26</strong> <strong>No</strong>. 2 <strong>Jun</strong>e <strong>2008</strong> 31

Distributed <strong>Energy</strong><br />

ready, willing and able<br />

Summary <strong>of</strong> the AIE Sydney Branch Symposium held on 16 October 2007,<br />

prepared by Mark Gadd, Director, Autonomous <strong>Energy</strong>.<br />

The New Face <strong>of</strong> DE<br />

By Craig Chambers, GridX Power<br />

Craig Chambers described GridX Power as the ‘lone ranger’<br />

in Australia pushing the distributed energy (DE) ‘barrow’.<br />

GridX Power is a vertically integrated utility and a licensed<br />

DE provider that builds combined heat and power systems<br />

burning natural gas from the mains in an internal combustion<br />

engine for onsite production <strong>of</strong> electricity and heat. In<br />

partnership with Mirvac, GridX has created Australia’s<br />

first residential housing estate powered by natural gas using<br />

trigeneration technology which generates three forms <strong>of</strong><br />

energy (cooling, heating and power) from a single source.<br />

This showcase project is small though highly scalable and<br />

saves 4–7 tonnes <strong>of</strong> CO2-e per house annually. Mr Chambers<br />

explained that in the past 12 to 18 months sustainability<br />

has become the new driver for GridX’s DE systems, and<br />

that building codes, including BASIX and ABGR, have now<br />

become the single biggest driver. GridX views the current<br />

increasing network constraints as another significant driver<br />

and believes its distributed energy systems are an elegant<br />

solution. The benefits <strong>of</strong> the solution are: no noise or visual<br />

impact; higher power reliability and quality; provides lower<br />

cost energy; and results in a reduction in emissions. It is also<br />

possible to upgrade sustainability ratings by installing GridX<br />

power systems; this upgrade would be isolated to the plant<br />

room and is less expensive than GreenPower.<br />

The DE program in APP<br />

By John Jende, Director – Renewable <strong>Energy</strong> Policy, AGO<br />

John Jende provided an update on the work <strong>of</strong> the<br />

Renewable <strong>Energy</strong> and Distributed Generation Task Force.<br />

He commenced with a background on the Asia-Pacific<br />

Partnership on Clean Development and Climate (APP) and<br />

its emphasis on “practical partnerships to develop, deploy<br />

and transfer cleaner, more efficient technologies”, noting that<br />

“private sector engagement is recognized as a key ingredient<br />

<strong>of</strong> success”. Mr Jende described the APP’s Renewable <strong>Energy</strong><br />

and Distributed Generation Task Force (REDGTF) <strong>of</strong> which<br />

Korea is the chair and Australia the co-chair. The goals <strong>of</strong><br />

REDGTF are to accelerate the deployment <strong>of</strong> renewable<br />

energy and DE over the next five years; to identify market<br />

and policy barriers and implement mechanisms to overcome<br />

them; and to close the gap between the cost <strong>of</strong> renewable<br />

energy generation and conventional generation. Australia<br />

is leading a number <strong>of</strong> projects in REDGTF that address<br />

market barriers. There are three broad categories <strong>of</strong> projects:<br />

deployment, market enabling, and RD&D. Examples <strong>of</strong><br />

projects receiving APP funding include: High Efficiency Solar<br />

32 ENErgyNews — <strong>Volume</strong> <strong>26</strong> <strong>No</strong>. 2 <strong>Jun</strong>e <strong>2008</strong><br />

Power Stations for Affordable <strong>Energy</strong> led by Solar Systems,<br />

Identifying High Value Geothermal Resources in China,<br />

Pursuing Clean <strong>Energy</strong> Business in India, and Building<br />

Expertise in Solar <strong>Energy</strong> Engineering led by UNSW. Mr<br />

Jende also highlighted IEA projections <strong>of</strong> electricity demand<br />

by region and contrasted this with current generation and<br />

renewable electricity. Given the large projected increases in<br />

demand in India, China and the US, he does not believe that<br />

renewable energy generation can keep up with this increase<br />

in demand, let alone replace current sources <strong>of</strong> conventional<br />

generation.<br />

MCE Code <strong>of</strong> Practice<br />

By Ryan Thew, <strong>Energy</strong> and Environment, DITR<br />

Ryan Thew’s presentation focused on the economic efficiency<br />

<strong>of</strong> DE and what the national government was doing to review<br />

rules and change the law in order to help the economic<br />

case <strong>of</strong> DE. The Ministerial Council on <strong>Energy</strong> (MCE) was<br />

established in 2001 to reform the national energy market. The<br />

reform <strong>of</strong> the energy market is not driven by environmental<br />

concerns but rather by economic efficiency. The MCE has<br />

established a renewable energy and distributed generation<br />

working group to examine wind energy policy, the code<br />

<strong>of</strong> practice for embedded generation and to improve grid<br />

accessibility. The stated aim is not to bias DE and renewable<br />

energy but rather to level the playing field by removing<br />

barriers and disincentives. The MCE wants to ensure that<br />

connection arrangements are not unduly complex for micro<br />

DE systems. Fundamentally the MCE recognises the need for<br />

equivalent incentives for investment in DE as an alternative<br />

to network investment.<br />

Figure 1: DE Around the World<br />

Source: WADE Annual World Survey <strong>of</strong> DE 2006

Global Opportunities for DE<br />

By David Sweet, WADE<br />

David Sweet is Executive Director WADE (World Alliance<br />

for Distributed <strong>Energy</strong>), which has <strong>of</strong>fices in Edinburgh,<br />

Washington, Edmonton and Beijing. WADE is a non-pr<strong>of</strong>it<br />

research, promotion and advocacy organisation started in<br />

1997. Their mission is to accelerate the worldwide deployment<br />

<strong>of</strong> high-efficiency cogeneration, on-site power and DE<br />

systems. WADE works with a number <strong>of</strong> organisations from<br />

all over the world to promote this mission. In Australia, DE<br />

represents just over 5% <strong>of</strong> total electricity generation — 7th<br />

lowest out <strong>of</strong> the 41 countries surveyed.<br />

WADE is interested in the replicated development <strong>of</strong> economic<br />

models to prove DE. Mr Sweet started his presentation by<br />

stating that he believes energy is the number one factor for<br />

the economy in the future, and that our energy future and<br />

the future for civilisation in general are inextricably linked.<br />

Therefore, there is a need to find alternatives to coal and oil.<br />

He pointed out that DE technology is ready now and able to<br />

improve the environment and the bottom line. <strong>Energy</strong> prices<br />

and climate change will accelerate DE deployment worldwide<br />

and distributed technologies have led to major market shifts in<br />

other areas, such as computing and telecommunications. Mr<br />

Sweet and gave examples <strong>of</strong> these analogies such as mainframes<br />

versus the Internet and landlines versus mobile phones.<br />

Figure 2: Decentralised Technologies. Source: WADE<br />

WADE’s work is cited in the IPCC 4th Report on Climate<br />

Change Mitigation in a section on “Decentralized <strong>Energy</strong>”.<br />

Benefits cited include:<br />

• Reduced need for costly transmission systems<br />

• Shorter lead times<br />

• Substantially reduced grid power losses<br />

• Deferred costs for upgrading transmission and distribution<br />

infrastructure<br />

• Improved reliability<br />

• Increased total energy recovery from 40–50% up to<br />

70–85%, with corresponding reductions in CO2 emissions<br />

<strong>of</strong> 50% or more.<br />

Mr Sweet concluded that DE is a win-win form <strong>of</strong> power<br />

generation which has great potential to reduce CO2<br />

emissions and reduce overall costs <strong>of</strong> supplying power. The<br />

barriers tend to be policy barriers.<br />

Figure 3: Fossil Fuel Emissions by Technology<br />

Source: WADE (based on IEA and DIDEME data)<br />

Plug-in Vehicles<br />

By Richard Hunwick, Hunwick Consultants Pty Ltd<br />

Richard Hunwick’s presentation focused on the potential<br />

future role <strong>of</strong> plug-in vehicles (PEVs) as storage <strong>of</strong> power in<br />

the electricity grid. Mr Hunwick considers storage to be a form<br />

<strong>of</strong> DE, albeit expensive. Up until recently people have only<br />

really looked at stationary forms <strong>of</strong> storage, though emerging<br />

technologies such as PEVs now beg the question: What about<br />

transport? There is potentially large storage potential in<br />

PEVs. Power can flow both ways — grid to vehicle (G2V) and<br />

vehicle to grid (V2G) — and this can be very favourable for<br />

renewable energy by absorbing and storing some <strong>of</strong> the energy<br />

produced. PEVs could also eliminate peak capacity and defer<br />

the need for generation, transmission and distribution capacity<br />

augmentation. They can supplement shortcomings <strong>of</strong> grid<br />

supply to host buildings providing UPS and ‘high nines’ supply<br />

reliability. The business case for distributed storage is yet to be<br />

made, with batteries being the limiting factor. However they<br />

are improving all the time and the cost is halving each year. Mr<br />

Hunwick believes that if incumbent car manufacturers resist<br />

the trend then demand will be met by Chinese and Indian<br />

manufacturers. Combined with smart meters and appropriate<br />

control s<strong>of</strong>tware, PEVs promise to have a disruptive but<br />

positive effect on our electricity supply system.<br />

The Intelligent Grid<br />

Stuart White, <strong>Institute</strong> for Sustainable Futures, UTS<br />

Stuart White’s presentation outlined the interdisciplinary<br />

project that he is leading which involves collaboration<br />

between CSIRO and several <strong>Australian</strong> universities. The<br />

project integrates and to the greatest extent possible<br />

harmonises a number <strong>of</strong> research and development projects<br />

and aims to increase the understanding <strong>of</strong> the real benefits<br />

<strong>of</strong> DE; develop a robust and transparent model to measure<br />

the value <strong>of</strong> DE options in network development (such as<br />

avoided network costs); and effect more public debate on<br />

the role <strong>of</strong> DE. The intelligent grid will use information<br />

and communications control technology to integrate the<br />

electricity network with DE resources, and will enhance<br />

network stability and control. Broadly there are three<br />

dimensions <strong>of</strong> research: technological, economic and<br />

social. The research is focused on generating solutions and<br />

addressing and overcoming the myriad barriers that are<br />

preventing optimal economic and environmental outcomes,<br />

thus moving us closer to best practice.<br />

ENErgyNews — <strong>Volume</strong> <strong>26</strong> <strong>No</strong>. 2 <strong>Jun</strong>e <strong>2008</strong> 33

ETIS & IDGCC<br />

<strong>Energy</strong> Technology Innovation and Hrl<br />

Presentation by Dr Peter Redlich, Director <strong>Energy</strong> Technology Innovation,<br />

Victorian Department <strong>of</strong> Primary Industries, and Gordon Carter,<br />

Managing Director, HRL Limited, to Melbourne Branch on 27 February <strong>2008</strong>.<br />

Dr Redlich explained Victoria’s <strong>Energy</strong> Technology<br />

Innovation Strategy (ETIS) program and Mr Carter provided<br />

an overview <strong>of</strong> the 400 MW Integrated Drying Gasification<br />

and Combined Cycle (IDGCC) project proposed for the<br />

Latrobe Valley.<br />

ETIS<br />

The <strong>Energy</strong> Technology Innovation Division <strong>of</strong> the Victorian<br />

Department <strong>of</strong> Primary Industries is responsible for the<br />

ETIS program, which manages the cross-government<br />

investment <strong>of</strong> over A$180 million in precommercial energy<br />

and related greenhouse gas reduction technologies. ETIS<br />

ensures that Victoria’s total investment is coordinated and<br />

delivers the best commercial and environmental outcomes<br />

for the state.<br />

A position paper in 2004 set out the Victorian Government’s<br />

strategy to reduce greenhouse emissions from the stationary<br />

Figure 1: ETIS brown coal projects<br />

34 ENErgyNews — <strong>Volume</strong> <strong>26</strong> <strong>No</strong>. 2 <strong>Jun</strong>e <strong>2008</strong><br />

energy sector. It included support for:<br />

• a national emissions trading scheme (ETS);<br />

• low-emission technologies (ETIS);<br />

• a strong renewable energy industry (VRET); and<br />

• enhanced energy efficiency.<br />

Collectively these commitments affect all aspects <strong>of</strong> energy<br />

supply and demand, including household end-use. A primary<br />

objective <strong>of</strong> the ETIS program is to drive energy and related<br />

greenhouse gas reduction technologies down their respective<br />

cost curves to optimise Victoria’s economic development<br />

and security <strong>of</strong> supply in a carbon constrained world. ETIS<br />

facilitates a coordinated approach to the advancement<br />

<strong>of</strong> precommercial low-emissions energy technologies<br />

across brown coal (see Figure 1) and sustainable energy<br />

technologies. It does not operate in areas that have no<br />

technical risk (ie commercial projects).

Figure 2: Estimated Latrobe Valley CO2 Emissions and Water Use<br />

IDGCC<br />

Victoria is fortunate to have access to some <strong>of</strong> the world’s<br />

largest and cheapest reserves <strong>of</strong> brown coal. However,<br />

Victoria will face some serious policy issues when emissions<br />

trading is introduced in 2010. There are a number <strong>of</strong><br />

options facing industry and government. For example, we<br />

could replace current older brown coal power stations with<br />

state-<strong>of</strong>-the-art new ones; shut down all energy-intensive<br />

industries; convert the existing brown coal power stations<br />

to using lower emissions imported black coal; and/or build<br />

new very-low-emission brown coal power stations with new<br />

technology, such as HRL’s IDGCC technology.<br />

IDGCC is a new highly-efficient process for generating<br />

electricity from brown coal. It combines pressurised drying<br />

and gasification <strong>of</strong> the coal with gas turbine combined cycle<br />

power generation. Brown coal is pressurised and dried in a<br />

dryer using the heat in the gas generated by the gasification<br />

process. It is then converted to a combustible gas in the<br />

fluidised bed gasifier. Inside the pressurised dryer the coal<br />

comes into direct contact with hot gas leaving the gasifier.<br />

This dries the coal and cools the hot gas at the same time. The<br />

cooled gas is cleaned prior to combustion in a gas turbine to<br />

produce electricity. The water vapour released from drying<br />

the coal forms part <strong>of</strong> the gas going to the gas turbine. The hot<br />

exhaust gas from the gas turbine still contains useful energy<br />

which is recovered by a heat recovery boiler and steam turbine<br />

to produce extra electricity in the combined cycle process.<br />

To demonstrate the potential <strong>of</strong> the technology, consider<br />

replacing all existing brown coal power generation in the<br />

Latrobe Valley with new technology like IDGCC. Figure 2<br />

shows the impact on CO2 emissions (and water usage).<br />

The IDGCC technology is capable <strong>of</strong> reducing CO2 emissions<br />

from brown coal power generation by up to 30% when<br />

compared to the current most efficient brown coal power<br />

generation in the Latrobe Valley, and by over 40% when<br />

compared to the older power stations. If the current existing<br />

brown coal power plants in the Latrobe Valley were replaced<br />

with IDGCC brown coal power generation, the potential<br />

impact on emissions and water consumption would be<br />

significant. CO2 emissions would fall from about 57 to 35<br />

million tonnes (Mt) per annum, and water consumption would<br />

fall from about 98 to 43 gigalitres per annum. The addition <strong>of</strong><br />

carbon capture and dry cooling reduces annual emissions by<br />

a further 25 Mt (down to about 10 Mt per annum) and water<br />

consumption is negligible.<br />

Replacing all the current existing brown coal power<br />

stations in the Latrobe Valley with natural gas combined<br />

cycle technology (NGCC) would also reduce emissions<br />

significantly to about 17 Mt per annum, and would achieve<br />

about the same reduction in water consumption as IDGCC<br />

(without carbon capture and dry cooling).<br />

This scenario analysis, although simplistic, demonstrates<br />

what is technically achievable, and demonstrates that<br />

IDGCC has an important role to play in achieving the state’s<br />

goals. There are three building blocks to get to where we<br />

need to go with new technology: efficient and cheap power<br />

generation; efficient and competitive carbon capture; and cost<br />

effective sequestration. With IDGCC technology, the cost <strong>of</strong><br />

generation is expected to be lower than alternative generation<br />

technologies currently available. The challenge is to reduce<br />

the cost <strong>of</strong> carbon capture and overcome the legal and<br />

regulatory issues <strong>of</strong> carbon transport and sequestration.<br />

And, that’s another story! (Ed.)<br />

ENErgyNews — <strong>Volume</strong> <strong>26</strong> <strong>No</strong>. 2 <strong>Jun</strong>e <strong>2008</strong> 35

The IEA<br />

The IEA: <strong>Energy</strong> Security and Sustainability<br />

Presentation by <strong>No</strong>buo Tanaka, Executive Director, International <strong>Energy</strong> Agency<br />

(IEA), to Canberra Branch, 17 March <strong>2008</strong>.<br />

The IEA is an energy policy advisor to its 27 member<br />

countries and was founded during the first oil crisis. The<br />

initial role was to respond to oil supply emergencies. But<br />

during the last decades, energy markets have changed, and<br />

so has the IEA. In now focuses beyond oil security to broader<br />

energy issues, including climate change, market reform,<br />

energy technology collaboration and outreach. Mr Tanaka<br />

took over as Executive Director last September and aims for<br />

the IEA to become known as a truly global comprehensive<br />

energy policy body.<br />

Environmental concerns, ongoing high prices and energy<br />

security considerations, are stimulating support for measures<br />

that could increase the uncertainty over the longer-term<br />

demand for oil. However, there is no need to close the<br />

valves on the oil pumps just yet. After all, IEA analysis<br />

continues to demonstrate that even if measures to moderate<br />

demand growth are introduced, and are a success, there is<br />

relatively little doubt that demand will remain robust over<br />

the foreseeable future. That is not to say that these policies<br />

are not worth pursuing, but simply reflects the time they<br />

will take to make an impact. Although the situation in 2030<br />

or 2050 is less certain, the investment decisions that will<br />

deliver supply at that time need not be taken for decades to<br />

come, particularly as the planning horizon for incremental<br />

capacity can be relatively short if investors have access to<br />

the resource base.<br />

However, while we are sure that the demand will be there,<br />

there are growing doubts on the supply side in the shortto-medium<br />

term. For this reason the IEA remains adamant<br />

that there is an urgent need to strengthen the flow <strong>of</strong> capital<br />

into upstream oil. After all, surging prices, diminishing<br />

discoveries and, in some cases, poor data on remaining<br />

reserves are fuelling concerns amongst some about the<br />

availability <strong>of</strong> the hydrocarbon reserves base. We remain<br />

comfortable with the adequacy <strong>of</strong> the world’s hydrocarbon<br />

reserves, but we are anxious to mitigate the above ground<br />

risks that complicate today’s markets.<br />

The EU countries, Japan and Canada have pledged to reduce<br />

emissions by 50% in 2050. The leaders <strong>of</strong> the G8 countries<br />

agreed at their summit in Heiligendamm in July 2007 that<br />

they would ‘seriously consider’ to follow suit. This push for<br />

action gained momentum last December in Bali when 178<br />

countries at the UN climate conference signed <strong>of</strong>f on the ‘Bali<br />

Roadmap’, which will take up where the Kyoto treaty leaves<br />

<strong>of</strong>f. After witnessing firsthand the negotiations in Bali, I am<br />

extremely grateful that the IEA’s job is not to broker deals on<br />

climate change. However, while the entire world’s attention<br />

36 ENErgyNews — <strong>Volume</strong> <strong>26</strong> <strong>No</strong>. 2 <strong>Jun</strong>e <strong>2008</strong><br />

has been focusing on negotiations to set the reduction target,<br />

it is important that we do not lose sight <strong>of</strong> the fact that a<br />

target alone will not miraculously solve the problem. What<br />

is needed is practical action to transform our energy system.<br />

To this end, the IEA has analysed the steps that would be<br />

required to actually achieve a 50% cut in emissions, which<br />

corresponds to the IPCC’s scenarios <strong>of</strong> limiting the increase<br />

in global temperatures to 2.4°C. To understand the extent <strong>of</strong><br />

this challenge we first need to appreciate the current level <strong>of</strong><br />

emissions and the outlook for their growth.<br />

CO2 emissions from the energy sector currently stand at<br />

27 gigatonnes (Gt). One gigatonne <strong>of</strong> CO2 emissions is<br />

equivalent to the emissions produced each year by 300<br />

coal-fired power plants, each <strong>of</strong> 500 MW, operating at base<br />

load. According to the World <strong>Energy</strong> Outlook 2007, in the<br />

absence <strong>of</strong> strong policy action, emissions will rise to 42 Gt<br />

in 2030 and 62 Gt in 2050, and we will be on track for an<br />

increase in global temperature <strong>of</strong> 6°C. In contrast, to achieve<br />

the goal <strong>of</strong> cutting emissions by 50%, emissions would have<br />

to peak during the next decade and decline to 14 Gt in 2050<br />

a reduction <strong>of</strong> 48 Gt from the reference. An upcoming<br />

IEA publication, titled <strong>Energy</strong> Technology Perspectives<br />

<strong>2008</strong>, will outline what would need to be done in practical<br />

terms to achieve this goal. It will show that improving<br />

energy efficiency is top <strong>of</strong> the list. Next we would need to<br />

decarbonise electricity generation. And finally, we would<br />

need to revolutionise the transportation sector.<br />

<strong>Energy</strong> Efficiency<br />

Improving energy efficiency is fundamental. However,<br />

currently it is not happening. The improvement in energy<br />

efficiency in IEA member countries in the past ten years has

een poor, and only about half the rate <strong>of</strong> improvement in<br />

previous decades. A fundamental turnaround is needed. To<br />

achieve the 50% cut in emissions we would have to improve<br />

energy intensity from the current rate <strong>of</strong> just 1.6% annually<br />

to 2.7 % annually. Thankfully, we know what to do. The IEA<br />

has identified 16 concrete recommendations for improving<br />

energy efficiency covering all energy end uses. These were<br />

endorsed by leaders at the past two G8 Summits and, if fully<br />

implemented, they could save up to 5.7 Gt CO2 by 2030.<br />

<strong>Energy</strong> efficiency is a ‘triple win’ solution. Firstly, it delivers<br />

the same service to the user, at lower cost. Second, it leads<br />

to lower dependence on imported fuels. Third, it improves<br />

the environment. Based on this triple win, I have some very<br />

blunt advice which is applicable to all countries, whether or<br />

not they are ready to adopt greenhouse gas targets: “We have<br />

shown you the policies to improve energy efficiency, now it<br />

is up to you to implement! implement! implement!”<br />

Power Generation<br />

Any meaningful emission reduction in coming decades<br />

implies a virtual decarbonisation <strong>of</strong> the power generation<br />

sector. After all, the rapid growth in CO2 emissions from<br />

coal-fired power stations led to the surge in global emissions<br />

in the past few years. China alone added over 70 GW <strong>of</strong> new<br />

coal-fired capacity in 2007 — the equivalent <strong>of</strong> a new unit<br />

every two-and-a-half days. Thankfully, its new units are large<br />

(500 MW) and are mostly state-<strong>of</strong>-the-art technologies.<br />

Deployment <strong>of</strong> carbon capture and storage (CSS) will<br />

therefore be vital as coal will undoubtedly remain the lowest<br />

cost and most accessible fuel for some <strong>of</strong> the most dynamic<br />

developing economies. The IEA has calculated that, given<br />

the growing demand for electricity, 38 coal and 20 gas-fired<br />

power plants would have to be fitted with CCS technology,<br />

each and every year between 2010 and 2050. In addition, we<br />

would have to build an additional <strong>26</strong> new nuclear plants each<br />

year throughout that period. Furthermore, renewables would<br />

have to play a much stronger role. For example, wind capacity<br />

would have to increase by 17,500 turbines each year.<br />

Transport Sector<br />

To achieve a 50% cut in emissions we would also have to make<br />

an eightfold reduction <strong>of</strong> the carbon intensity <strong>of</strong> transport.<br />

This represents the most difficult and costly step due to the<br />

ongoing rapid demand growth and limited potential based on<br />

existing technology. Cost effective efficiency improvements<br />

<strong>of</strong> up to 50% are already possible, provided that the trend<br />

towards heavier vehicles can be contained. But we would<br />

also require the widespread deployment <strong>of</strong> new technologies.<br />

Advanced bi<strong>of</strong>uels and hydrogen fuel cells, and advanced<br />

plug-in hybrid and electric vehicles fuelled by carbon-free<br />

electricity, are possible options, but it is hard to tell which<br />

technology or combination <strong>of</strong> technologies will prevail.<br />

The Challenge<br />

IEA preliminary analysis suggests that investment <strong>of</strong> around<br />

US$50 trillion would be needed for a 50% reduction in<br />

emissions, on top <strong>of</strong> what would be required under a business<br />

as usual scenario. This amounts to roughly 1% <strong>of</strong> total GDP<br />

from 2005-2050.<br />

The impact would be more significant for certain sectors,<br />

regions and countries. Predictable and long-term incentives<br />

alongside stable government policy would be needed to<br />

empower industry to accept the risk associated with this<br />

huge investment. However, there are other challenges<br />

which may prove to be more difficult than attracting<br />

investment. Technical issues have to be overcome before<br />

many <strong>of</strong> the promising new energy technologies could be<br />

widely deployed. The public would also have to become<br />

more accepting <strong>of</strong> living with wind farms in their backyards,<br />

not to mention nuclear reactors. We would also have<br />

to dramatically boost the numbers <strong>of</strong> engineering and<br />

technical graduates. Questions exist on the availability<br />

<strong>of</strong> sufficient geological formations for captured CO2 or<br />

geologically stable sites for nuclear reactors or waste storage.<br />

In short, meeting the target <strong>of</strong> a 50% cut in emissions<br />

represents a formidable challenge. We would require<br />

immediate policy action and technological transformation<br />

on an unprecedented scale. We would also need the<br />

participation <strong>of</strong> all major economies. It would essentially<br />

require a third industrial revolution, or an energy revolution,<br />

which would completely transform the way we produce and<br />

use energy and entail painful adjustments.<br />

Governments have a key role to play in this new energy<br />

revolution. They must be prepared to invest in researching<br />

and developing key technologies that are not yet commercial.<br />

This will not be easy — energy research budgets <strong>of</strong> IEA<br />

governments have declined both absolutely and as a<br />

percentage <strong>of</strong> GDP since the early 1980s. But in the end, it<br />

will be left to industry to consider the policy options and then<br />

put them to work to deliver the desired results. Government,<br />

industry, financial markets, and consumers will all have to<br />

work together.<br />

Time to Act<br />

The world’s energy economy is on a pathway that is not<br />

sustainable, on many fronts. This statement is not new. But<br />

it is nevertheless shocking, particularly given the political<br />

capital that has been devoted to improving the situation<br />

in recent years. In terms <strong>of</strong> the short-to-medium-term oil<br />

market, the situation is not sustainable as we continue to<br />

remain in a period <strong>of</strong> high and volatile prices, low spare<br />

capacity and low stock coverage. There is an urgent need for<br />

investment to ensure an adequate cushion between supply<br />

and demand. At the same time, the energy economy is not<br />

sustainable from an environmental perspective. But things<br />

can change. The IEA has identified policies and technologies<br />

that can lead to very substantial savings in energy<br />

consumption and CO2 emissions. For these to be achieved,<br />

decisions have to be taken now and implementation has to<br />

begin now. The primary scarcity facing the planet is not <strong>of</strong><br />

natural resources or money, but time. We will need to start<br />

putting our words and commitments into actions. Delay is<br />

no longer an option. It is time to act.<br />

Mr Tanaka’s presentation to the AIE was sponsored by ACIL<br />

Tasman, one <strong>of</strong> Australia’s leading economic and policy<br />

consultants.<br />

ENErgyNews — <strong>Volume</strong> <strong>26</strong> <strong>No</strong>. 2 <strong>Jun</strong>e <strong>2008</strong> 37

<strong>Energy</strong> and Water<br />

<strong>Energy</strong> and Water in Tasmania<br />

Presentation to Melbourne Branch, by Andrew Catchpole, Hydro Tasmania,<br />

as part <strong>of</strong> the afternoon discussion with key industry representatives <strong>of</strong> the<br />

“Increasing Interactions between <strong>Energy</strong> and Water Markets” on <strong>26</strong> March <strong>2008</strong>.<br />

Hydro Tasmania owns and operates 29 hydropower stations,<br />

59 major dams, 188 headwork gates and valves, 22 canals,<br />

19 tunnels, 43 pipelines, and 63 generators. Its hydropower<br />

generating capacity <strong>of</strong> 2,<strong>26</strong>0 MW is supplemented by 228 MW<br />

<strong>of</strong> gas-fired thermal capacity at Bell Bay. Hydro Tasmania<br />

generates 10,000 GWh per annum, which is about half <strong>of</strong><br />

Australia’s renewable energy and more than twice the energy<br />

output <strong>of</strong> the Snowy scheme (from half the installed capacity).<br />

It is also 50% owner <strong>of</strong> R40s: Woolnorth (130MW); Musselroe<br />

(129MW, proposed); Cathedral Rocks in South Australia;<br />

Waterloo in Victoria; and 11 overseas (nine commissioned or<br />

under development in China and two in India).<br />

Tasmania has valuable water resources but rainfall distribution<br />

is uneven in both location and time. Rainfall is predominantly<br />

from the west, and mostly in winter and spring. The catchment<br />

area <strong>of</strong> 21,000 square kilometres (total area <strong>of</strong> Tasmania is<br />

64,000 square kilometres) receives around 15,000 GL (gigalitres)<br />

annually. The long-term average yield is 10,000 GWh per<br />

annum, and on-island annual demand <strong>of</strong> approximately 11,000<br />

GWh is met by hydro, gas and Basslink imports. Increasingly,<br />

hydro systems are becoming peak load suppliers.<br />

38 ENErgyNews — <strong>Volume</strong> <strong>26</strong> <strong>No</strong>. 2 <strong>Jun</strong>e <strong>2008</strong><br />

Basslink is the world’s longest undersea high voltage direct<br />

current cable. It allows Hydro Tasmania to take the place <strong>of</strong> a 600<br />

MW peak generator in Victoria, and allows Tasmania to import<br />

up to 450 MW in <strong>of</strong>f-peak energy. Since commissioning in April<br />

2006, 3,568 GWh <strong>of</strong> energy has been imported to Tasmania,<br />

while 921 GWh has been exported to Victoria. Victoria avoids<br />

the cost <strong>of</strong> building generation to meet peak demand and<br />

Tasmania avoids the cost <strong>of</strong> building generation to meet energy<br />

load and insures against drought.<br />

Other uses <strong>of</strong> water in Tasmania are irrigation (204 GL in<br />

2005–06) and industrial (48 GL in 2004–05); but by far the<br />

biggest user <strong>of</strong> water is hydropower generation (38,162 GL in<br />

2004–05, including multiple use through two or more power<br />

stations. Hydro Tasmania is Australia’s biggest water manager,<br />

and is affected by the current drought. Although this year’s<br />

rainfall is only 20% down on average, it comes on top <strong>of</strong> 10 dry<br />

years. This highlights the value <strong>of</strong> fuel diversity through hydro,<br />

wind, gas and imports. It is not just hydropower generation that<br />

is affected. We need to manage a range <strong>of</strong> environmental and<br />

stakeholder impacts, including threatened species, recreational<br />

fishing, water quality (eg algal blooms), other recreational uses,<br />

and visual amenity.<br />

For the past 30 years, we have received 5% less rain than the<br />

long-term average; and in the past 10 years, 5% less again. Is it<br />

climate change? We don’t know, but it is prudent to act just in<br />

case it is. Adapting to climate changed involves changing the<br />

business model, finding the ‘lost’ energy in the system and the<br />

Tasmanian Climate Futures Project.<br />

As the value <strong>of</strong> water rises, peak generation becomes more focused<br />

towards higher prices. This biases the business model towards<br />

peak generation and away from base load generation. Generating<br />

to meet peak load requires much less water than base load supply.<br />

However generation for shorter periods means asset cost must be<br />

recovered over a shorter time period. This is achieved by selling<br />

contracts, such as caps — insurance for retailers, with very short<br />

periods <strong>of</strong> export to back the contract portfolio.<br />

The major areas <strong>of</strong> focus to recover 1000 GWh <strong>of</strong> energy in the<br />

Tasmanian system are:<br />

Canal maintenance Dam raising<br />

Conveyance upgrade Dam construction<br />

Major redevelopments Storage increase<br />

Catchment diversions Small hydro<br />

Turbine runner improvements.<br />

Tasmanian Climate Futures Project is a 3-year partnership<br />

working with a range <strong>of</strong> scenarios to 2100. Partners are:<br />

Antarctic CRC CSIRO<br />

Tasmanian Government Hydro Tasmania<br />

University <strong>of</strong> Tasmania Bureau <strong>of</strong> Meteorology<br />

Tasmanian state emergency services<br />

Tasmanian Partnership for Advanced Computing<br />

Tasmanian <strong>Institute</strong> <strong>of</strong> Agricultural Research<br />

Commonwealth Environment Research Facilities Programme<br />

Geoscience Australia.

Developments in oil and gas<br />

Special Feature<br />

As the price <strong>of</strong> crude oil hovers around US$130 per barrel, it is timely<br />

to consider what is happening in the upstream petroleum sector in Australia.<br />

According to the February <strong>2008</strong> <strong>Energy</strong>Quest Quarterly<br />

Report, “the <strong>Australian</strong> petroleum sector grew strongly in<br />

2007, reflecting continuing high oil prices, surging world<br />

LNG demand (and prices) and higher domestic demand for<br />

gas-fired generation to <strong>of</strong>fset reductions in hydro and coalfired<br />

generation. <strong>Australian</strong> petroleum production grew by<br />

4.6% in 2007, almost reaching the 2000 record <strong>of</strong> 474 million<br />

barrels (MMbbl) <strong>of</strong> oil equivalent. Oil production increased<br />

by 3.2%, the first increase in <strong>Australian</strong> oil production since<br />

2000. Production <strong>of</strong> natural gas increased by 6.0% to a<br />

record 1,705 petajoules (PJ). Coal seam methane production<br />

climbed by 40.2% to reach 113 PJ, representing 17.4% <strong>of</strong> east<br />

coast production.”<br />

However, these record levels <strong>of</strong> production are not expected<br />

to last. As the Hon Martin Ferguson, Minister for <strong>Energy</strong>,<br />

pointed out: “With only about a decade <strong>of</strong> known oil<br />

resources remaining at today’s production rates, Australia<br />

is looking down the barrel <strong>of</strong> a A$25 billion trade deficit in<br />

petroleum products by 2015.”<br />

Mr Ferguson was speaking at the <strong>Australian</strong> Petroleum<br />

Production and Exploration Association (APPEA) conference<br />

in April <strong>2008</strong>. At the conference, under the theme Energising<br />

Change, Mr Ferguson pointed out that, “… together with<br />

increasing concern about climate change, the insatiable thirst<br />

for energy means that energy security is one <strong>of</strong> the big issues<br />

confronting Australia and the world today”.<br />

“Access to energy resources is the key to continuing economic<br />

growth and the challenges <strong>of</strong> meeting global energy demand<br />

– in a sustainable way – are daunting,” he said.<br />

“Australia not only has to look to its own future when it<br />

comes to energy security and cleaner energy sources and<br />

technology, it has to be part <strong>of</strong> the solution to economic<br />

growth in the region – and its environmental impact.<br />

Almost 20% <strong>of</strong> our total exports are energy resources – and<br />

that is growing. ‘Energising change’ is about seizing the<br />

opportunities we have to unlock the wealth <strong>of</strong> Australia’s<br />

vast resource potential, particularly our natural gas — not<br />

only for the benefit <strong>of</strong> the <strong>Australian</strong> community but for our<br />

friend, Japan, which has been with us from the beginning<br />

in developing the <strong>Australian</strong> resources sector; and for the<br />

hundreds <strong>of</strong> millions <strong>of</strong> people being lifted out <strong>of</strong> poverty in<br />

developing Asian nations, such as China and India — also<br />

highly valued and growing trade and investment partners.<br />

“The <strong>Australian</strong> Government knows that we face strong<br />

competition from other nations <strong>of</strong>fering alternative petroleum<br />

exploration and project development opportunities. It is a<br />

real challenge to find the next Bass Strait — or anything<br />

like it. The <strong>Australian</strong> Government is looking to focus<br />

the exploration industry’s attention on new frontiers.<br />

Geoscience Australia’s current precompetitive work is highly<br />

respected by the petroleum exploration industry for its<br />

provision <strong>of</strong> leading-edge, low cost, high-quality information.<br />

We are committed to Geoscience Australia’s continuing<br />

work in this area and it will form part <strong>of</strong> the exploration<br />

incentives package I have asked my Department to prepare<br />

in consultation with the industry and the Treasury.<br />

“It is vitally important to encourage exploration in our<br />

frontier basins because they are the most likely places<br />

where a big new oil province may be discovered. Energising<br />

change is also about expanding the ways in which we use<br />

our gas resources — for LNG exports, as a domestic fuel<br />

for <strong>Australian</strong> industry and power generation, and for new<br />

export industries like ultra-clean GTL (gas to liquids) diesel.<br />

Balancing our desire to grow exports while ensuring there is<br />

sufficient gas available at a fair market price to meet the needs<br />

<strong>of</strong> <strong>Australian</strong> industry and consumers is a great challenge.<br />

New gas developments such as Kipper, Blacktip and Reindeer<br />

will help meet Australia’s domestic gas demand. But more<br />

needs to be done, particularly in Western Australia, and I<br />

intend to work closely with the industry to facilitate more<br />

commercial domestic gas projects in the next few years.”<br />

This special feature focuses on activity in Australia. The first<br />

two articles come from Geoscience Australia. Although fairly<br />

technical in content (which will appeal to the petroleum<br />

geologists in our readership), they demonstrate to all that<br />

there is still much to find out about the extent <strong>of</strong> oil and gas<br />

resources in <strong>Australian</strong> onshore and <strong>of</strong>fshore basins using<br />

the latest techniques.<br />

The importance <strong>of</strong> gas to the future mix is exemplified<br />

by the development <strong>of</strong> the Kipper Gas Project in the Bass<br />

Strait. Project Manager Peter Symes made a presentation<br />

to AIE Melbourne Branch on 16 April and a summary is<br />

reproduced here.<br />

Mr Ferguson also talked about the importance <strong>of</strong> a safe and<br />

secure working environment for all those involved in the<br />

oil and gas industry. The final article in this special feature<br />

covers the National Offshore Petroleum Safety Authority’s<br />

(NOPSA’s) safety awareness campaign.<br />

EN<br />

ENErgyNews — <strong>Volume</strong> <strong>26</strong> <strong>No</strong>. 2 <strong>Jun</strong>e <strong>2008</strong> 39

Is Onshore <strong>Australian</strong> Really ‘Dry’?<br />

Opening the untapped oil and gas potential <strong>of</strong> old basins<br />

By Thomas Bernecker, Onshore <strong>Energy</strong> & Minerals Division, Geoscience Australia<br />

In response to the declining oil supply, the <strong>Australian</strong><br />

Government provided Geoscience Australia with funding<br />

for the <strong>Energy</strong> Security Program (2006-2011). The purpose<br />

<strong>of</strong> this program is to supply precompetitive data to stimulate<br />

exploration in under-explored regions <strong>of</strong> Australia,<br />

including assessments <strong>of</strong> uranium, thorium, geothermal<br />

and hydrocarbon resources. The Onshore Petroleum Project<br />

focuses on those sedimentary basins (outside the proven<br />

Cooper/Eromanga hydrocarbon province) that are thought<br />

to be prospective for oil and gas, as indicated by previously<br />

recorded hydrocarbon shows.<br />

Australia’s onshore basins contain elements<br />

<strong>of</strong> petroleum systems <strong>of</strong> Neoproterozoic to<br />

Late Mesozoic age, whereas <strong>of</strong>fshore basins<br />

host petroleum systems almost exclusively<br />

<strong>of</strong> Late Palaeozoic to Tertiary age. This<br />

difference in basin fill ages is likely to have a<br />

pr<strong>of</strong>ound impact on the overall distribution<br />

<strong>of</strong> commercially viable hydrocarbons as<br />

many <strong>of</strong> the geologically older onshore<br />

provinces were overprinted by at least<br />

one major orogenic phase. Therefore, the<br />

various preservation stages <strong>of</strong> generated<br />

hydrocarbons in these old basins are key<br />

issues that impact on prospectivity and are<br />

the subject <strong>of</strong> current investigations.<br />

Geoscience Australia’s newly acquired<br />

potential field data (aeromagnetics and<br />

gravimetry) provide modern images<br />

<strong>of</strong> basement terranes and associated<br />

lineaments that have a controlling influence<br />

on basin formation and evolution. Of<br />

special interest are the occurrence and<br />

distribution <strong>of</strong> sub-basins and depocentres<br />

that, so far, have remained hidden beneath<br />

thick sediment cover. The regional deep<br />

seismic program continues in <strong>2008</strong> with<br />

the acquisition <strong>of</strong> data across the Gawler<br />

and Curnamona cratons, which will<br />

include a section across the southern<br />

Arrowie Basin. Later in the year, a deep<br />

seismic survey will be acquired across the<br />

eastern Officer Basin as far north as the southern Amadeus<br />

Basin. Another major survey is planned for 2009–10 across<br />

the Kidson Sub-basin, possibly along the Canning Stock<br />

Route. It is anticipated that the processed data will allow the<br />

delineation <strong>of</strong> structural styles in great detail and highlight<br />

unconformities and reactivation surfaces.<br />

40 ENErgyNews — <strong>Volume</strong> <strong>26</strong> <strong>No</strong>. 2 <strong>Jun</strong>e <strong>2008</strong><br />

The new data will be made available to industry to assist<br />

current and future explorers in their efforts to unlock the<br />

untapped hydrocarbon potential in these frontier regions.<br />

The challenge exists to overcome the perception that any<br />

hydrocarbon discoveries made in Australia’s old onshore<br />

basins are likely to be small. It should be noted that many<br />

older Palaeozoic basins around the world are proven<br />

hydrocarbon producers. These include the Tarim Basin in<br />

China (where the Ordovician source rock interval alone is<br />

believed to be able to produce 800 MMbbl <strong>of</strong> oil and 4 trillion<br />

Map showing sedimentary basins and generalised hydrocarbon distribution in<br />

onshore Australia. Insert at top right shows the petroleum wells drilled to date,<br />

highlighting the under-explored status <strong>of</strong> the continent<br />

cubic feet (Tcf) <strong>of</strong> gas), and the onshore Oman salt basins<br />

(where a 50,000 square-kilometre Cambrian source rock area<br />

produces up to 2,200 MMbbl <strong>of</strong> oil and 24 TcF <strong>of</strong> gas). There<br />

is still a lot <strong>of</strong> ground to cover in onshore Australia!<br />

renew your Membership online<br />

http://www.pams.com.au/aienat<br />

EN

Offshore <strong>Energy</strong> Security Initiative and Core Petroleum Program<br />

An update <strong>of</strong> future surveys and new directions<br />

By Peter Southgate, Edward Bowen, Barry Bradshaw, Marita Bradshaw, Dianne Edwards,<br />

Robert Langford, Nadege Rollet and Jennie Totterdell, Petroleum Prospectivity & Promotions<br />

Group, Petroleum & Marine Division, Geoscience Australia<br />

The <strong>Australian</strong> Government’s Offshore <strong>Energy</strong> Security<br />

Initiative (2006-2011) will provide precompetitive data and<br />

information to stimulate petroleum exploration in Australia.<br />

The forward program has been developed in consultation<br />

with industry and the respective state and territory geological<br />

surveys. It will focus on three <strong>of</strong>fshore frontier regions:<br />

remote frontiers in <strong>of</strong>fshore eastern Australia, south-west<br />

margin; and southern margin.<br />

Petroleum systems modelling in producing regions will form<br />

part <strong>of</strong> the ongoing core petroleum program. These studies<br />

are aimed at improved resource estimates and stimulating<br />

further exploration. Negotiations are currently underway<br />

with a number <strong>of</strong> organisations to partner with Geoscience<br />

Australia to deliver these models.<br />

Remote Eastern Frontiers<br />

Between December 2006 and January 2007, Geoscience<br />

Australia acquired approximately 6,000 kilometres (km) <strong>of</strong><br />

industry standard 2D seismic data in the Capel and Faust<br />

basins, 800 km east <strong>of</strong> Brisbane. The survey identified<br />

numerous depocentres, some 150 km in length and 40 km in<br />

width, with up to 7 km <strong>of</strong> sediment fill. Initial interpretation<br />

has identified a potential pre-rift succession, three synrift<br />

phases (clastic/volcanic), two post-rift carbonate<br />

packages, and episodes <strong>of</strong> post-rift igneous activity. Possible<br />

correlations with the Capricorn, Great South and deepwater<br />

Taranaki basins have been suggested.<br />

In late 2007 the RV Tangaroa completed a marine<br />

reconnaissance survey <strong>of</strong> the Capel and Faust basins.<br />

Geophysical datasets acquired on this survey included<br />

gravity, magnetics, multibeam sonar, and sub-bottom<br />

pr<strong>of</strong>iler data. An accompanying seafloor sampling program<br />

acquired geological and biological samples from potential<br />

seepage sites and representative areas <strong>of</strong> the sea floor,<br />

to search for indications <strong>of</strong> active petroleum systems<br />

and to document marine biodiversity and habitats. The<br />

multibeam sonar revealed seafloor features that appear<br />

to reflect the underlying basin structure. The gravity and<br />

magnetic coverages are expected to significantly improve<br />

the delineation <strong>of</strong> depocentre boundaries. Seafloor sampling<br />

and camera footage provided information on the substrate<br />

composition and potential fluid escape sites. Current work<br />

involves interpreting and integrating these datasets to define<br />

the rift basin architecture and tectonostratigraphic history to<br />

better understand the region’s petroleum prospectivity.<br />

South-West Margin<br />

Between <strong>No</strong>vember <strong>2008</strong> and March 2009, Geoscience<br />

Australia will undertake two major surveys to investigate the<br />

Mentelle, north Perth and southern Carnarvon basins and<br />

Abrolhos, Houtman and Zeewyck sub-basins.<br />

Seismic acquisition in the Mentelle basin will infill the 50<br />

km grid interpreted under the New Petroleum Program,<br />

to provide a dataset with a line spacing <strong>of</strong> 20–30 km. The<br />

improved seismic grid will provide critical data on basin shape<br />

and sediment architecture, permitting petroleum systems<br />

models to be developed at the regional scale. The schedule<br />

for seismic acquisition, processing and interpretation suggest<br />

a 2010 date for release <strong>of</strong> acreage in the Mentelle basin.<br />

The deep water Houtman and Zeewyck sub-basins and the<br />

north Perth and south Carnarvon basins will be the focus for<br />

acquisition <strong>of</strong> new 2D seismic and the reprocessing <strong>of</strong> open-file<br />

industry seismic. As the petroleum exploration well information<br />

is limited in the deeper water Houtman and Zeewyck subbasins,<br />

open-file seismic data from the shallow water Abrolhos<br />

sub-basin will be used to constrain the stratigraphies.<br />

The Wallaby Plateau is a poorly understood fragment<br />

<strong>of</strong> continental crust located in the southern parts <strong>of</strong> the<br />

Carnarvon basin. It has been suggested that a reconnaissance<br />

seismic acquisition grid and geological sampling program<br />

would provide insight into the location <strong>of</strong> potential<br />

depocentres and whether or not gas-producing stratigraphies<br />

<strong>of</strong> the Exmouth Plateau may extend to the southwest.<br />

Southern Margin<br />

The southern margin synthesis study aims to integrate the<br />

results <strong>of</strong> earlier studies to better understand the breakup<br />

history between Australia and Antarctica, resolve<br />

outstanding stratigraphic correlation problems and permit<br />

improved resource prediction.<br />

A cooperative National Geoscience Agreement project<br />

between Geoscience Australia and the Tasmanian Geological<br />

Survey is funding the acquisition <strong>of</strong> about 104,000 line km<br />

<strong>of</strong> airborne magnetics data at a line spacing <strong>of</strong> 800 metres in<br />

the Bass and Sorell basins, <strong>of</strong>fshore Tasmania. Acquisition<br />

commenced in January <strong>2008</strong> and will be completed by April.<br />

The new data will permit improved resolution <strong>of</strong> <strong>of</strong>fshore<br />

structure and distribution <strong>of</strong> volcanic rocks and intrusive<br />

bodies. In subsequent years <strong>of</strong> the program, 2D seismic is<br />

scheduled to be acquired in the Sorell basin and possibly<br />

over the South Tasman Rise.<br />

Between February and March 2007, a prospectivity<br />

validation survey <strong>of</strong> the Bight basin recovered source rocks <strong>of</strong><br />

Cenomanian-Turonian age, with TOC values <strong>of</strong> 2–6.2 % and<br />

HI values <strong>of</strong> 274–479. This clearly demonstrates the existence<br />

<strong>of</strong> a good quality source rock in the Bight basin and studies<br />

are underway to establish if possible correlations may exist<br />

between these rocks and the asphaltite strandings common<br />

on the southern margin. 2D petroleum systems modelling<br />

studies are also underway for the Bight basin to further<br />

support upcoming acreage release in 2009 and 2010. EN<br />

ENErgyNews — <strong>Volume</strong> <strong>26</strong> <strong>No</strong>. 2 <strong>Jun</strong>e <strong>2008</strong> 41

Bass Strait Gas Rises Again<br />

By Peter Symes, Kipper Gas Project Manager, Esso Australia<br />

The first major hydrocarbon fields discovered in Australia<br />

were the Bass Strait gas fields — Barracouta in 1965 and<br />

Marlin in 1966. In those days, and until fairly recently, gas<br />

was always a consolation prize in the hunt for oil. Since those<br />

first discoveries a lot <strong>of</strong> oil has been found in Bass Strait and<br />

a lot more gas in the process.<br />

The Bass Strait fields fundamentally changed the economic<br />