Apparel Testing Program - CSI Vendor Manual

Apparel Testing Program - CSI Vendor Manual

Apparel Testing Program - CSI Vendor Manual

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Section B<br />

<strong>Apparel</strong> <strong>Testing</strong> <strong>Program</strong>

Administrative Procedures<br />

To ensure that Charming Shoppes, Inc. quality expectation levels are met, all suppliers must submit<br />

samples for testing in accordance with the Charming Shoppes, Inc. <strong>Testing</strong> <strong>Program</strong>. All garments sold<br />

to Charming Shoppes, Inc. must be tested regardless of order size. Highlighted below, are the finer<br />

points of this testing program.<br />

1. Package <strong>Testing</strong><br />

Charming Shoppes, Inc. testing program is a Package Based program. Submits are required to be<br />

tested per performance specification. Partial or incomplete testing will not be allowed except for the<br />

following:<br />

Development (Allowed when accompanied by supplemental testing / data)<br />

• Retest<br />

• Data<br />

If partial testing is requested outside of the above requirement, the request will be put on hold and the<br />

vendor will be contacted to correct the test request form.<br />

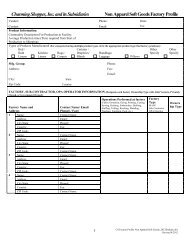

All testing must be accompanied by a Charming Shoppes, Inc. test request form and will be tested in<br />

accordance with the Softlines <strong>Testing</strong> Package outlined on pg B-6. If Charming Shoppes, Inc. Test<br />

Request Form is not used the vendor will still be held responsible for all applicable tests outlined in the<br />

testing package. Failure to use the Charming Shoppes Test Request Form may impede the response<br />

time from the Charming Shoppes, Inc. Quality Assurance department and could result in additional<br />

testing required.<br />

2. <strong>Testing</strong> Stages<br />

We require that all test submits and test reports be identified as one of the below stages of the<br />

production cycle. It must be accurately identified on the test request form and test report. If the stage<br />

is not accurately identified, the submit will be put on hold and the vendor will be contacted within 24<br />

hours for this information.<br />

• Development<br />

o Partial specification is allowed with supplemental testing or data submitted and<br />

confirmed by Charming Shoppes, Inc. Quality Assurance department<br />

o <strong>Testing</strong> prior to fabric and / or garment production<br />

• Fabric<br />

o Full specification testing is required<br />

o <strong>Testing</strong> representative of Bulk Fabric Production<br />

• Garment<br />

o Full specification testing is required<br />

o <strong>Testing</strong> representative of Bulk Garment Production<br />

o Fabric test report number is required to be listed on test request form<br />

• Additional Colorway<br />

o Full specification testing is required only for colorfastness<br />

o <strong>Testing</strong> only for Colorfastness properties by specification<br />

o Original test report number is required to be listed on the test request form<br />

B-1

2. <strong>Testing</strong> Stages (continued)<br />

• Retest<br />

o Partial specification is allowed with original test listed on the test request form<br />

o Additional testing done when improvement is requested due to a failure on the fabric<br />

and / or garment test<br />

• Data<br />

o Partial specification is allowed, but results will be reported as data and not considered<br />

part of the performance specification requirement<br />

o To be selected with prior permission from Charming Shoppes, Inc. Quality Assurance<br />

department only.<br />

- All appropriate tests as outlined in Charming Shoppes, Inc. Test Requirements must be<br />

conducted prior to shipping.<br />

- The submission samples must be representative of actual production.<br />

- It is preferred that those tests which can be done at the fabric stage be conducted prior to<br />

production cutting so that any failures to meet the standards can be addressed before the fabric<br />

is cut. However, fabric testing will not alleviate the supplier from submitting a complete<br />

garment to ensure that all garment components perform compatibly.<br />

3. <strong>Testing</strong> Continuity<br />

We require that all testing to be conducted with one of the nominated lab resources through all<br />

production phases. Once fabric testing has been conducted with a lab resource for production all<br />

subsequent testing for garment, additional colorway and retesting phases must be conducted with the<br />

same resource. Development testing maybe conducted at a separate lab resource as this is considered<br />

part of pre-production.<br />

4. Submission Procedures<br />

• All samples submitted for testing must be representative of what Charming Shoppes, Inc. will<br />

receive in the stores. Applicable colorfastness tests must be performed on all prints, screen<br />

prints as well as all colors of base fabrics used in the finished garment.<br />

• All samples submitted to the laboratory for testing must be accompanied by a Charming<br />

Shoppes, Inc. Test Request Form. This will ensure that all testing is conducted according to<br />

Charming Shoppes, Inc. requirements and that the discount that the laboratories provide to all<br />

Charming Shoppes, Inc. suppliers will be applied.<br />

• Sample submission quantities outlined below must be followed to ensure that there is sufficient<br />

sampling for the testing required. If insufficient samples are submitted, the submission will be<br />

placed on hold and the submitter advised.<br />

- Fabric <strong>Testing</strong>: One to one and a half square yards of fabric, or equivalent, in<br />

each colorway / print / embellishment type.<br />

- Garment <strong>Testing</strong>: Two garments in darkest colorway.<br />

* Note: Additional Colorway Tests for Colorfastness to Multi-Fiber Strip to 3 Home<br />

Launderings / 1 Dry Clean - Submit half square yard of fabric.<br />

B-2

4. Submission Procedures (continued)<br />

• In order to support optimal efficiency in report review and workflow, the following information<br />

must be included in the test report for all submits. If this information is not included on the test<br />

request form, testing will be put on hold and the vendor will be contacted within 24 hours for this<br />

information.<br />

- Submitter Company Name<br />

- Submitter Address<br />

- Submitter Phone<br />

- Submitter Fax<br />

- Submitter Contact Name<br />

- Submitter E-mail Address<br />

- <strong>Vendor</strong> Name / #<br />

- <strong>Vendor</strong> Style<br />

- <strong>Vendor</strong> Contact Name<br />

- <strong>Vendor</strong> E-mail Address<br />

- <strong>CSI</strong> Direct Source (Y/N)<br />

- Charming Shoppes Division<br />

- <strong>CSI</strong> Performance Specification #<br />

- Product Description<br />

- Color(s)<br />

- Fiber Content<br />

- Country of Origin<br />

- Weight<br />

- Style # (Fabric and/or Garment #’s) / Product ID #<br />

- Body Number<br />

5. Care Instructions<br />

All testing requests with exception of Development must be submitted with Charming Shoppes, Inc.<br />

approved Standard Care Method. Non-approved care methods will not be accepted. If request is<br />

submitted with a non-approved care method the request will be put on hold and the vendor will be<br />

contacted within 24 hours for confirmation of Charming Shoppes, Inc. approved Standard Care<br />

Method.<br />

The care method(s) listed in our Care Instruction Guideline are to be used for all testing and labeling<br />

unless testing reveals a more appropriate method or the need for more specific instructions, see pages<br />

B-5 to B-8 for details.<br />

6. <strong>Testing</strong> Acceptance Criteria<br />

• All test results will be measured against Charming Shoppes, Inc. Performance Specifications.<br />

• For styles/colors which are shipped on a replenishment basis, testing is required once per year<br />

unless changes are made in the source of materials, the material themselves, production facilities<br />

or any other change which may impact the consistency of the product quality or performance.<br />

The exception to this is flammability testing reports which must be no older than 6 months from<br />

delivery.<br />

B-3

7. Laboratory Reports<br />

• Laboratory reports will reflect the test results, Charming Shoppes, Inc. standards and whether<br />

the test results meet these standards.<br />

• Any submissions which fail to meet all appropriate Charming Shoppes Inc. standards must be<br />

re-tested on corrected samples unless specified otherwise by the Charming Shoppes Inc.<br />

Quality Assurance Department.<br />

• Report Distribution:<br />

- All test reports rated Failed are forwarded to the Corporate and Lane Bryant Quality<br />

Assurance departments by the laboratory.<br />

- Upon request any additional test reports must be forwarded by the vendor to the appropriate<br />

Quality Assurance department for review prior to shipment. See cover letter for contact<br />

details.<br />

8. <strong>Testing</strong> Turn-Around-Time<br />

Test reports will be faxed or e-mailed to the supplier no later than five (5) working days after receipt of<br />

all appropriate samples, and hard copy reports sent via regular mail on the seventh (7 th ) day.<br />

Depending on the size and nature of the submission, the laboratories can provide rush service at a<br />

surcharge as set forth by each individual laboratory.<br />

9. <strong>Testing</strong> Costs<br />

• Suppliers are responsible for all testing costs.<br />

• Charming Shoppes, Inc. vendors will receive our negotiated package testing prices on all work<br />

submitted to Charming Shoppes’ approved testing laboratories. Prices are as follows and differ<br />

by region. See page D-3 to D-4.<br />

10. Durability<br />

Fabric, trim and garments are required to meet industry durable life expectations. They must be fit<br />

for purpose and end use and must not exhibit a noticeable change in fit or appearance after normal<br />

wash and wear.<br />

This includes but is not limited to:<br />

- Fusible interfacings and appliqués must not delaminate or deteriorate.<br />

- Buttonholes, trims and hems must not ravel or fray.<br />

- Fabric and seams must not twist.<br />

- Elastic must not deteriorate.<br />

- Drawstrings must not fray or stain.<br />

- Buttons and hardware must not discolor or become damaged.<br />

- Fabric must not objectionably pill.<br />

- Fabric or Skins must not have a noticeable change of hand.<br />

B-4

Performance<br />

Specifications<br />

<strong>CSI</strong>-001<br />

<strong>CSI</strong>-002<br />

<strong>CSI</strong>-003<br />

<strong>CSI</strong>-007<br />

<strong>CSI</strong>-008<br />

<strong>CSI</strong>-010<br />

<strong>CSI</strong>-011<br />

<strong>CSI</strong>-001<br />

<strong>CSI</strong>-002<br />

<strong>CSI</strong>-007<br />

<strong>CSI</strong>-010<br />

<strong>CSI</strong>-011<br />

<strong>CSI</strong>-002<br />

<strong>CSI</strong>-001<br />

<strong>CSI</strong>-002<br />

<strong>CSI</strong>-004<br />

<strong>CSI</strong>-006<br />

<strong>CSI</strong>-010<br />

<strong>CSI</strong>-001<br />

<strong>CSI</strong>-002<br />

<strong>CSI</strong>-004<br />

<strong>CSI</strong>-006<br />

<strong>CSI</strong>-010<br />

Care Instruction Guideline – Proposed Laundering Methods<br />

Fiber Content Care Instruction Embellishment / Decoration or<br />

Lightweight Fabric (below 2.6 oz/sq yd)<br />

- 100% Cotton<br />

Machine Wash Cold<br />

Wash Inside Out<br />

- Chief Value Cotton With Like Colors<br />

Machine Wash Cold<br />

Blends<br />

Only Non-Chlorine Bleach When Needed Delicate Cycle<br />

- Synthetic – 100% or Tumble Dry Low<br />

With Like Colors<br />

Blends<br />

Remove Promptly<br />

Only Non-Chlorine Bleach When Needed<br />

Low Iron, If Needed<br />

Line Dry<br />

* For Fashion Bug,<br />

Catherines, Lane Bryant<br />

Outlet and Loop 18<br />

ONLY:<br />

- 100% or Chief Value<br />

Blends of: Modal<br />

Rayon, Tencel, Viscose<br />

Low Iron, If Needed<br />

Iron Wrong Side Only<br />

* For Lane Bryant Hand Wash Cold<br />

Wash Inside Out<br />

ONLY:<br />

Separately<br />

Hand Wash Cold<br />

Only Non-Chlorine Bleach, When Needed Separately<br />

100% or Chief Value Rinse Thoroughly<br />

Only Non-Chlorine Bleach, When<br />

Blends of :<br />

Line Dry<br />

Needed<br />

Linen, Modal,<br />

Low Iron, If Needed<br />

Rinse Thoroughly<br />

Rayon, Silk,<br />

Do Not Steam<br />

Line Dry<br />

Tencel, Viscose<br />

Low Iron, If Needed<br />

Iron Wrong Side Only<br />

Do Not Steam<br />

Broomstick Skirt Machine Wash Cold<br />

Delicate Cycle<br />

With Like Colors<br />

Only Non-Chlorine Bleach, When Needed<br />

Twist and Knot to Dry<br />

Do Not Iron<br />

100% to 75% Wool Dry Clean Only<br />

< 75% Wool Wash Inside Out<br />

Hand Wash Cold<br />

Separately<br />

Only Non-Chlorine Bleach, When Needed<br />

Rinse Thoroughly<br />

Dry Flat<br />

Do Not Iron<br />

B-5

Performance<br />

Specifications<br />

<strong>CSI</strong>-004<br />

<strong>CSI</strong>-005<br />

Fiber Content Care Instruction Embellishment / Decoration or<br />

Lightweight Fabric (below 2.6 oz/sq yd)<br />

- 100% Cotton<br />

- Chief Value Cotton<br />

Blends<br />

- Synthetic – 100% or<br />

Blends<br />

100% or Blends -<br />

Linen, Modal,<br />

Rayon, Silk,<br />

Tencel, Viscose<br />

Both Shell and Lining<br />

contain the following:<br />

- 100% Cotton<br />

- Chief Value Cotton<br />

Blends<br />

- Synthetic – 100% or<br />

Blends<br />

Both Shell and Lining<br />

contain the following:<br />

All Fiber Contents<br />

(depending upon style)<br />

Shell and / or Lining:<br />

100% to 75% Wool<br />

Shell and / or Lining:<br />

< 75% Wool<br />

Wash Inside Out<br />

Machine Wash Cold<br />

Delicate Cycle<br />

With Like Colors<br />

Only Non-Chlorine Bleach, When Needed<br />

Tumble Dry Low<br />

Low Iron, If Needed<br />

Wash Inside Out<br />

Hand Wash Cold<br />

Separately<br />

Only Non-Chlorine Bleach, When Needed<br />

Rinse Thoroughly<br />

Line Dry<br />

Low Iron, If Needed<br />

Do Not Steam<br />

Machine Wash Cold<br />

Delicate Cycle<br />

With Like Colors<br />

Only Non-Chlorine Bleach When Needed<br />

Tumble Dry Low<br />

Remove Promptly<br />

Low Iron, If Needed<br />

Dry Clean<br />

Dry Clean Only<br />

Wash Inside Out<br />

Hand Wash Cold<br />

Separately<br />

Only Non-Chlorine Bleach, When Needed<br />

Rinse Thoroughly<br />

Dry Flat<br />

Do Not Iron<br />

- OR -<br />

Dry Clean (depending upon style)<br />

Wash Inside Out<br />

Machine Wash Cold<br />

Delicate Cycle<br />

With Like Colors<br />

Only Non-Chlorine Bleach, When<br />

Needed<br />

Line Dry<br />

Low Iron, If Needed<br />

Iron Wrong Side Only<br />

Wash Inside Out<br />

Hand Wash Cold<br />

Separately<br />

Only Non-Chlorine Bleach, When<br />

Needed<br />

Rinse Thoroughly<br />

Line Dry<br />

Low Iron, If Needed<br />

Iron Wrong Side Only<br />

Do Not Steam<br />

Wash Inside Out<br />

Machine Wash Cold<br />

Delicate Cycle<br />

With Like Colors<br />

Only Non-Chlorine Bleach When Needed<br />

Line Dry<br />

Low Iron, If Needed<br />

Iron Wrong Side Only<br />

Wash Inside Out<br />

Hand Wash Cold<br />

Separately<br />

Only Non-Chlorine Bleach, When Needed<br />

Rinse Thoroughly<br />

Dry Flat<br />

Do Not Iron<br />

- OR -<br />

Dry Clean (depending upon style)<br />

B-6

Performance<br />

Specifications<br />

<strong>CSI</strong>-006<br />

Fiber Content Care Instruction Embellishment / Decoration or<br />

Lightweight Fabric (below 2.6 oz/sq yd)<br />

- 100% Cotton<br />

- Chief Value Cotton<br />

Blends<br />

- Synthetic – 100% or<br />

Blends<br />

* For Fashion Bug,<br />

Catherines & Lane Bryant<br />

Outlet ONLY:<br />

100% or Chief Value<br />

Blends of:<br />

Modal<br />

Rayon<br />

Tencel<br />

Viscose<br />

* For Lane Bryant<br />

ONLY:<br />

100% or Chief Value<br />

Blends -<br />

Linen<br />

Modal<br />

Rayon<br />

Silk<br />

Tencel<br />

Viscose<br />

Remove Hood Before Wash (if applicable)<br />

Machine Wash Cold<br />

With Like Colors<br />

Only Non-Chlorine Bleach, When Needed<br />

Tumble Dry Low<br />

Remove Promptly<br />

Low Iron, If Needed<br />

Hand Wash Cold<br />

Separately<br />

Only Non-Chlorine Bleach, When Needed<br />

Rinse Thoroughly<br />

Line Dry<br />

Low Iron, If Needed<br />

Do Not Steam<br />

Puffer Coats Machine Wash Cold<br />

Delicate Cycle<br />

Separately<br />

Only Non-Chlorine Bleach, When Needed<br />

Tumble Dry Low With Tennis Balls<br />

Remove Promptly<br />

PU Coats<br />

(crinkled or heavily<br />

embellished)<br />

Crinkled Coats<br />

(not PU)<br />

Low Iron, If Needed<br />

Spot Clean Only<br />

Do Not Iron<br />

Machine Wash Cold<br />

Delicate Cycle<br />

With Like Colors<br />

Only Non-Chlorine Bleach, When Needed<br />

Twist and Knot to Dry<br />

Do Not Iron<br />

Remove Hood Before Wash (if applicable)<br />

Wash Inside Out<br />

Machine Wash Cold<br />

Delicate Cycle<br />

With Like Colors<br />

Only Non-Chlorine Bleach, When Needed<br />

Line Dry<br />

Low Iron, If Needed<br />

Iron Wrong Side Only<br />

Remove Hood Before Wash (if applicable)<br />

Wash Inside Out<br />

Hand Wash Cold<br />

Separately<br />

Only Non-Chlorine Bleach, When Needed<br />

Rinse Thoroughly<br />

Line Dry<br />

Low Iron, If Needed<br />

Iron Wrong Side Only<br />

Do Not Steam<br />

B-7

Performance<br />

Specifications<br />

<strong>CSI</strong>-007<br />

<strong>CSI</strong>-008<br />

<strong>CSI</strong>-009<br />

Fiber Content Care Instruction Embellishment / Decoration or<br />

Lightweight Fabric (below 2.6 oz/sq yd)<br />

Under-Wire Bras and<br />

Under-Wire Garments<br />

Hand Wash Cold<br />

Separately<br />

Only Non-Chlorine Bleach, When Needed<br />

Rinse Thoroughly<br />

Line Dry<br />

Do Not Iron<br />

Panties Machine Wash Warm<br />

With Like Colors<br />

Only Non-Chlorine Bleach When Needed<br />

Tumble Dry Low<br />

Remove Promptly<br />

Low Iron, If Needed<br />

> 1% Spandex and / or<br />

Contains Under-Wire<br />

Hand Wash Cold<br />

Separately<br />

Only Non-Chlorine Bleach, When Needed<br />

Rinse Thoroughly<br />

Line Dry<br />

Low Iron, If Needed<br />

Leather and / or Suede Professional Leather Clean<br />

Washable Leather<br />

and / or Suede<br />

Machine Wash Cold<br />

Delicate Cycle<br />

Separately<br />

Only Non-Chlorine Bleach When Needed<br />

Line Dry<br />

Do Not Iron<br />

Note: Remove “With Like Colors” and add “Separately” if garment has Wash Before Wear tag<br />

Machine Wash Warm<br />

Delicate Cycle<br />

With Like Colors<br />

Only Non-Chlorine Bleach When Needed<br />

Tumble Dry Low<br />

Remove Promptly<br />

Low Iron, If Needed<br />

Iron Wrong Side Only<br />

Wash Inside Out<br />

Hand Wash Cold<br />

Separately<br />

Only Non-Chlorine Bleach, When<br />

Needed<br />

Rinse Thoroughly<br />

Line Dry<br />

Low Iron, If Needed<br />

Iron Wrong Side Only<br />

• The above information is provided to aide in the development of appropriate care instructions for garments. The<br />

information is for technical guidance only.<br />

• Actual care labels are to be verified by testing at the approved third party testing laboratories listed in the<br />

Charming Shoppes, Inc QA <strong>Manual</strong>.<br />

• The above methods are to be used unless testing reveals a more appropriate method or the need for a more specific<br />

care instruction.<br />

• Actual care instructions and exact wording of care labels must be in compliance with the FTC Care Labeling<br />

Regulations.<br />

B-8

Charming Shoppes, Inc. <strong>Apparel</strong> Performance Specifications<br />

The attached Performance Specifications set forth Charming Shoppes’ quality expectation level.<br />

The following points highlight some important facts regarding these specifications:<br />

• The specifications are structured by end product.<br />

• Each test listed in the specifications has a test method. All laboratories conducting testing on<br />

Charming Shoppes’ behalf must adhere to these methods to ensure consistency.<br />

• The requirements set forth in the specifications reflect Charming Shoppes’ quality expectation<br />

commitment while recognizing the inherent quality limitations in certain fabric types. Any failure<br />

to meet these requirements must be brought to the attention of Charming Shoppes’ Quality<br />

Assurance Department.<br />

• These specifications apply to testing at the fabric stage and the garment stage.<br />

• Charming Shoppes does not allow the use of genuine animal fur in any of its brands’ products.<br />

Specification<br />

Number<br />

<strong>CSI</strong>-001<br />

<strong>CSI</strong>-002<br />

<strong>CSI</strong>-003<br />

<strong>CSI</strong>-004<br />

<strong>CSI</strong>-005<br />

<strong>CSI</strong>-006<br />

<strong>CSI</strong>-007<br />

<strong>CSI</strong>-008<br />

<strong>CSI</strong>-009<br />

<strong>CSI</strong>-010<br />

<strong>CSI</strong>-011<br />

Specification Category<br />

Knit Tops, Bottoms and Dresses (excluding washed /treated styles)<br />

Woven Tops, Bottoms and Dresses (excluding denim & washed /treated styles)<br />

Denim & Physically / Chemically Treated Knits / Wovens<br />

Sweaters<br />

Lined & Constructed Jackets, Bottoms & Dresses (excluding denim & washed /treated)<br />

Outerwear<br />

Sleepwear & Intimate <strong>Apparel</strong><br />

Swimwear & Swim Cover-Up<br />

Leather & Suede <strong>Apparel</strong> (non-synthetic)<br />

Hats, Scarves, Wraps & Gloves<br />

Socks & Hosiery<br />

B-9

PERFORMANCE SPECIFICATIONS<br />

Product: Knit Tops, Bottoms, and Dresses<br />

(excluding physically / chemically treated styles*)<br />

Performance Specification: #<strong>CSI</strong>-001<br />

The below noted tests will be performed when submitting tests using the Charming Shoppes testing<br />

package:<br />

TEST NAME FABRIC GARMENT<br />

TESTS REQUIRED<br />

Fiber Content <br />

Fabric Weight <br />

Dimensional Stability after 3 Launderings / 1 Dry Clean <br />

Skew / Torque <br />

General Appearance after 3 Launderings / 1 Dry Clean <br />

Bursting Strength <br />

Flammability (Suspect Fabrics Only – all colors) <br />

Pile Retention (All Pile Fabrics) <br />

Stretch & Recovery (When Requested) <br />

Colorfastness to Multi-Fiber Strip after 3 Launderings / 1 Dry Clean <br />

Colorfastness to Crocking (All Colors – except solid white) <br />

Colorfastness to Non-Chlorine Bleach <br />

Colorfastness to Water (Contrast Colors & Prints Only) <br />

Colorfastness to Perspiration (Lining Fabric Only) <br />

Zipper Strength<br />

(Functional Zippers Only – except<br />

<br />

nominated suppliers)<br />

Snap Strength <br />

Total Lead Content (PU / PVC Fabrics Only – all colors) <br />

Lead in Surface Coating (PU / PVC Fabrics Only – all colors) <br />

ADDITIONAL COLORWAY TESTS <br />

Colorfastness to Multi-Fiber Strip after 3 Launderings / 1 Dry Clean <br />

Colorfastness to Crocking (All Colors – except solid white) <br />

Colorfastness to Non-Chlorine Bleach <br />

* see Specification <strong>CSI</strong>-003 for Physically / Chemically Treated Styles<br />

B-12

EVALUATION<br />

PHYSICAL TESTS<br />

Fiber Content<br />

REQUIREMENT TEST METHOD<br />

- 100% Fabrics<br />

No Tolerance<br />

AATCC 20A<br />

- Blended Fabrics<br />

+/- 3% maximum deviation<br />

Fabric Weight +/- 5% maximum deviation ASTM D 3776<br />

Dimensional Stability<br />

- 3 Launderings<br />

- Jersey / Interlock / Pointelle<br />

- CVC<br />

- CVS<br />

- Rib / Waffle / Pique / Tricot /<br />

Thermal<br />

- CVC<br />

- CVS<br />

- 6% maximum / + 3% maximum<br />

- 5% maximum / + 3% maximum<br />

- 7 x 6% maximum / + 3% maximum<br />

- 5% maximum / + 3% maximum<br />

- 5% maximum / + 3% maximum<br />

AATCC 135 or 150<br />

- All Others<br />

- 1 Dry Clean<br />

AATCC 158<br />

- CVC / CVS<br />

- 3% maximum / + 2% maximum<br />

- All Others<br />

+/- 2% maximum<br />

Skew / Torque +/- 5% maximum AATCC 179<br />

General Appearance after 3<br />

Launderings / 1 Dry Clean<br />

Bursting Strength – Mullen Method *<br />

Satisfactory Visual<br />

- Fabric<br />

50 psi minimum<br />

ASTM D 3786<br />

- Garment Seams<br />

- Lace<br />

30 psi minimum<br />

- > 4 oz/sq yd<br />

30 psi minimum<br />

- < 4 oz/sq yd<br />

20 psi minimum<br />

Flammability<br />

Pile Retention<br />

Class 1 (Pass) CFR 1610<br />

- Face<br />

Class 4.0 minimum<br />

ASTM D 4685-89<br />

- Back<br />

Class 4.0 minimum<br />

Stretch & Recovery – Stretch Direction Only<br />

Body Fabric<br />

ASTM D 2594<br />

- % Available Stretch<br />

- % Recovery<br />

Record data<br />

- Original<br />

85% at 1 hour<br />

- After Aging<br />

85% at 1 hour<br />

5 hours at 200°F<br />

COLORFASTNESS TESTS – All Colors Must Be Tested<br />

Colorfastness to Multi-Fiber Strip<br />

after 3 Launderings / 1 Dry Clean<br />

Colorfastness to Crocking<br />

Class 4.0 minimum Visual<br />

- Non-Pigments<br />

AATCC 8 / 116<br />

- Dry<br />

Class 4.0 minimum<br />

- Wet<br />

- Pigment / Sulfur / Tie Dye /<br />

Dip Dye<br />

Class 3.0 minimum<br />

- Dry<br />

Class 3.5 minimum<br />

- Wet<br />

Class 2.0 minimum<br />

Colorfastness to Non-Chlorine<br />

Bleach **<br />

Class 4.0 minimum Soak Test<br />

B-13

EVALUATION REQUIREMENT TEST METHOD<br />

Colorfastness To Water<br />

- Color Change Class 4.0 minimum AATCC 107<br />

- Self Staining Class 5.0 minimum<br />

Colorfastness to Perspiration<br />

- Color Change Class 4.0 minimum AATCC 15<br />

- Multi-Fiber Staining Class 3.0 minimum<br />

- Self Staining Class 5.0 minimum<br />

TRIMS TESTS<br />

Zipper Strength<br />

- Chain Crosswise Strength 15 lbs minimum ASTM D 2061<br />

- Slider Lock Holding 10 lbs minimum<br />

- Tab Twist Off 6.9 in·lbs minimum<br />

- Top / Bottom Stop Holding 20 lbs minimum<br />

Strength<br />

Snap Strength 15 lbs minimum CFR 1500<br />

CHEMICAL TESTS<br />

Total Lead Content EPA Methods 3050B / 3051A<br />

- Coated & Printed Surfaces < 90 ppm / 3052<br />

- Other < 200 ppm<br />

Lead in Surface Coating per California Prop 65 16 CFR 1303<br />

* Fabrics / laces with opaque and dense areas are required to have BOTH areas tested. Each area must meet the<br />

listed requirement<br />

** Do not perform for Dry Clean ONLY styles<br />

B-14

PERFORMANCE SPECIFICATIONS<br />

Product: Woven Tops, Bottoms, and Dresses<br />

(excluding denim & physically / chemically treated styles*)<br />

Performance Specification: #<strong>CSI</strong>-002<br />

The below noted tests will be performed when submitting tests using the Charming Shoppes testing<br />

package:<br />

TEST NAME FABRIC GARMENT<br />

TESTS REQUIRED<br />

Fiber Content <br />

Fabric Weight <br />

Dimensional Stability after 3 Launderings / 1 Dry Clean <br />

Torque <br />

General Appearance after 3 Launderings / 1 Dry Clean <br />

Tear Strength <br />

Tensile Strength <br />

Seam Strength <br />

Seam Slippage <br />

Flammability (Suspect Fabrics Only – all colors) <br />

Pile Retention (All Pile Fabrics) <br />

Colorfastness to Multi-Fiber Strip after 3 Launderings / 1 Dry Clean <br />

Colorfastness to Crocking (All Colors – except solid white) <br />

Colorfastness to Non-Chlorine Bleach <br />

Colorfastness to Water (Contrast Colors & Prints Only) <br />

Colorfastness to Perspiration (Lining Fabric Only) <br />

Zipper Strength<br />

(Functional Zippers Only – except<br />

<br />

nominated suppliers)<br />

Snap Strength <br />

Total Lead Content (PU / PVC Fabrics Only – all colors) <br />

Lead in Surface Coating (PU / PVC Fabrics Only – all colors) <br />

ADDITIONAL COLORWAY TESTS <br />

Colorfastness to Multi-Fiber Strip after 3 Launderings / 1 Dry Clean <br />

Colorfastness to Crocking (All Colors – except solid white) <br />

Colorfastness to Non-Chlorine Bleach <br />

* see Specification <strong>CSI</strong>-003 for Physically / Chemically Treated Styles<br />

B-15

EVALUATION<br />

PHYSICAL TESTS<br />

Fiber Content<br />

REQUIREMENT TEST METHOD<br />

- 100% Fabrics<br />

No Tolerance<br />

AATCC 20A<br />

- Blended Fabrics<br />

+/- 3% maximum deviation<br />

Fabric Weight<br />

Dimensional Stability<br />

+/- 5% maximum deviation ASTM D 3776<br />

- 3 Launderings<br />

+/- 3% maximum<br />

AATCC 135 or 150<br />

- 1 Dry Clean<br />

+/- 2% maximum<br />

AATCC 158<br />

Torque +/- 3% maximum AATCC 179<br />

General Appearance after 3<br />

Launderings / 1 Dry Clean<br />

Tear Strength – Elmendorf Method<br />

Satisfactory Visual<br />

- Warp<br />

3.0 lbs minimum<br />

ASTM D 1424<br />

- Filling<br />

Tensile Strength – Grab Method<br />

2.5 lbs minimum<br />

- > 4 oz/sq yd<br />

ASTM D 5034<br />

- Warp<br />

50 lbs minimum<br />

- Filling<br />

- < 4 oz/sq yd<br />

30 lbs minimum<br />

- Warp<br />

40 lbs minimum<br />

- Filling<br />

Seam Strength<br />

30 lbs minimum<br />

- > 4 oz/sq yd<br />

30 lbs minimum<br />

ASTM D 1683<br />

- < 4 oz/sq yd<br />

25 lbs minimum<br />

Seam Slippage 15 lbs minimum ASTM D 434<br />

Flammability<br />

Pile Retention<br />

Class 1 (Pass) CFR 1610<br />

- Face<br />

Class 4.0 minimum<br />

ASTM D 4685-89<br />

- Back<br />

Class 4.0 minimum<br />

COLORFASTNESS TESTS – All Colors Must Be Tested<br />

Colorfastness to Multi-Fiber Strip<br />

after 3 Launderings / 1 Dry Clean<br />

Colorfastness to Crocking<br />

Class 4.0 minimum Visual<br />

- Non-Pigments<br />

AATCC 8 / 116<br />

- Dry<br />

Class 4.0 minimum<br />

- Wet<br />

- Pigment / Sulfur / Tie Dye /<br />

Dip Dye<br />

Class 3.0 minimum<br />

- Dry<br />

Class 3.5 minimum<br />

- Wet<br />

Class 2.0 minimum<br />

Colorfastness to Non-Chlorine<br />

Bleach **<br />

Colorfastness to Water<br />

Class 4.0 minimum Soak Test<br />

- Color Change<br />

Class 4.0 minimum<br />

AATCC 107<br />

- Self Staining<br />

Colorfastness to Perspiration<br />

Class 5.0 minimum<br />

- Color Change<br />

Class 4.0 minimum<br />

AATCC 15<br />

- Multi-Fiber Staining<br />

Class 3.0 minimum<br />

- Self Staining<br />

Class 5.0 minimum<br />

B-16

EVALUATION REQUIREMENT TEST METHOD<br />

TRIMS TESTS<br />

Zipper Strength<br />

- Chain Crosswise Strength 15 lbs minimum ASTM D 2061<br />

- Slider Lock Holding 10 lbs minimum<br />

- Tab Twist Off 6.9 in·lbs minimum<br />

- Top / Bottom Stop Holding 20 lbs minimum<br />

Strength<br />

Snap Strength 15 lbs minimum CFR 1500<br />

CHEMICAL TESTS<br />

pH Value 5 - 8 AATCC 81<br />

Total Lead Content EPA Methods 3050B / 3051A<br />

- Coated & Printed Surfaces < 90 ppm / 3052<br />

- Other < 200 ppm<br />

Lead in Surface Coating per California Prop 65 16 CFR 1303<br />

* Fabrics / laces with opaque and dense areas are required to have BOTH areas tested. Each area must meet the<br />

listed requirement<br />

** Do not perform for Dry Clean ONLY styles<br />

B-17

PERFORMANCE SPECIFICATIONS<br />

Product: Denim & Physically / Chemically Treated Knits / Wovens<br />

(i.e. Enzyme Wash, Wash Down, Sandblasted, etc.)<br />

Performance Specification: #<strong>CSI</strong>-003<br />

The below noted tests will be performed when submitting tests using the Charming Shoppes testing<br />

package:<br />

TEST NAME FABRIC GARMENT<br />

TESTS REQUIRED<br />

Fiber Content <br />

Fabric Weight <br />

Dimensional Stability after 3 Launderings / 1 Dry Clean <br />

Skew / Torque <br />

General Appearance after 3 Launderings / 1 Dry Clean <br />

Tear Strength (Woven) <br />

Tensile Strength (Woven) <br />

Bursting Strength (Knit) <br />

Seam Strength (Woven) <br />

Seam Slippage (Woven) <br />

Flammability (Suspect Fabrics Only – all colors) <br />

Pile Retention (All Pile Fabrics) <br />

Water Resistance (When Claimed) <br />

Water Repellency (When Claimed) <br />

Colorfastness to Multi-Fiber Strip after 3 Launderings / 1 Dry Clean <br />

Colorfastness to Crocking (All Colors – except solid white) <br />

Colorfastness to Non-Chlorine Bleach <br />

Colorfastness to Water (Contrast Colors & Prints Only) <br />

Colorfastness to Perspiration (Lining Fabric Only) <br />

Zipper Strength<br />

(Functional Zippers Only – except<br />

<br />

nominated suppliers)<br />

Snap Strength <br />

pH Value <br />

Total Lead Content (PU / PVC Fabrics Only – all colors) <br />

Lead in Surface Coating (PU / PVC Fabrics Only – all colors) <br />

ADDITIONAL COLORWAY TESTS <br />

Colorfastness to Multi-Fiber Strip after 3 Launderings / 1 Dry Clean <br />

Colorfastness to Crocking (All Colors – except solid white) <br />

Colorfastness to Non-Chlorine Bleach <br />

pH Value <br />

* perform testing on Washed Fabric<br />

B-18

EVALUATION<br />

PHYSICAL TESTS<br />

Fiber Content<br />

REQUIREMENT TEST METHOD<br />

- 100% Fabrics<br />

No Tolerance<br />

AATCC 20A<br />

- Blended Fabrics<br />

+/-3 % maximum deviation<br />

Fabric Weight +/-5 % maximum deviation ASTM D 3776<br />

Dimensional Stability<br />

Knits<br />

- 3 Launderings<br />

- Jersey / Interlock / Pointelle<br />

- CVC<br />

- CVS<br />

- Rib / Waffle / Pique / Tricot /<br />

Thermal<br />

- CVC<br />

- CVS<br />

- All Others<br />

- 1 Dry Clean<br />

- CVC / CVS<br />

- All Others<br />

Wovens<br />

- 3 Launderings<br />

- Denim<br />

- All Others<br />

- 6% maximum / + 3% maximum<br />

- 5% maximum / + 3% maximum<br />

- 7 x 6% maximum / + 3% maximum<br />

- 5% maximum / + 3% maximum<br />

- 5% maximum / + 3% maximum<br />

- 3% maximum / + 2% maximum<br />

+/- 2% maximum<br />

AATCC 135 or 150<br />

AATCC 158<br />

AATCC 135 or 150<br />

- 1 Dry Clean<br />

Skew / Torque<br />

- 5% maximum / + 3% maximum<br />

+/- 3% maximum<br />

+/- 2% maximum AATCC 158<br />

- Knits<br />

+/- 5% maximum<br />

AATCC 179<br />

- Wovens<br />

+/- 3% maximum<br />

General Appearance after 3<br />

Launderings / 1 Dry Clean<br />

Tear Strength – Elmendorf Method<br />

Satisfactory Visual<br />

- Denim > 8 oz/sq yd<br />

ASTM D 1424<br />

- Warp<br />

5.0 lbs minimum<br />

- Filling<br />

- Denim < 8 oz/sq yd<br />

4.0 lbs minimum<br />

- Warp<br />

4.0 lbs minimum<br />

- Filling<br />

- All Others<br />

3.5 lbs minimum<br />

- Warp<br />

3.0 lbs minimum<br />

- Filling<br />

Tensile Strength – Grab Method<br />

2.5 lbs minimum<br />

- Denim<br />

ASTM D 5034<br />

- Warp<br />

50 lbs minimum<br />

- Filling<br />

- All Others<br />

- > 4 oz/sq yd<br />

50 lbs minimum<br />

- Warp<br />

50 lbs minimum<br />

- Filling<br />

- < 4 oz/sq yd<br />

30 lbs minimum<br />

- Warp<br />

40 lbs minimum<br />

- Filling<br />

30 lbs minimum<br />

B-19

EVALUATION REQUIREMENT TEST METHOD<br />

Bursting Strength – Mullen Method *<br />

- Fabric<br />

- Garment Seams<br />

- Lace<br />

- > 4 oz/sq yd<br />

- < 4 oz/sq yd<br />

Seam Strength<br />

- Denim<br />

- > 4 oz/sq yd<br />

- < 4 oz/sq yd<br />

50 psi minimum<br />

30 psi minimum<br />

30 psi minimum<br />

20 psi minimum<br />

35 lbs minimum<br />

30 lbs minimum<br />

25 lbs minimum<br />

ASTM D 3786<br />

ASTM D 1683<br />

Seam Slippage 15 lbs minimum ASTM D 434<br />

Flammability<br />

Class 1 (Pass) CFR 1610<br />

Pile Retention<br />

- Face<br />

Class 4.0 minimum<br />

ASTM D 4685-89<br />

- Back<br />

Class 4.0 minimum<br />

Water Resistance<br />

Water Repellency<br />

1 g maximum AATCC 35<br />

- Original<br />

90 minimum<br />

AATCC 22<br />

- After 3 Washes<br />

70 minimum<br />

COLORFASTNESS TESTS - All Colors Must Be Tested<br />

Colorfastness to Multi-Fiber Strip after<br />

3 Launderings / 1 Dry Clean<br />

Colorfastness to Crocking<br />

Class 4.0 minimum Visual<br />

- Denim – Dark Wash (indigo,<br />

overdyed, black, sulphur, etc.)<br />

- Original<br />

AATCC 8 /116<br />

- Dry<br />

Class 3.0 minimum<br />

- Wet<br />

- After 1 Wash<br />

Class 1.0 minimum<br />

- Dry<br />

Class 3.0 minimum<br />

- Wet<br />

- All Other Denim Washes<br />

Class 1.5 minimum<br />

- Dry<br />

Class 3.0 minimum<br />

- Wet<br />

- All Other Fabrics<br />

- Non-Pigments<br />

Class 2.0 minimum<br />

- Dry<br />

Class 4.0 minimum<br />

- Wet<br />

- Pigment / Sulfur / Tie Dye /<br />

Dip Dye<br />

Class 3.0 minimum<br />

- Dry<br />

Class 3.5 minimum<br />

- Wet<br />

Class 2.0 minimum<br />

Colorfastness to Non-Chlorine<br />

Bleach **<br />

Colorfastness to Water<br />

Class 4.0 minimum Soak Test<br />

- Color Change<br />

Class 4.0 minimum<br />

AATCC 107<br />

- Self Staining<br />

Class 5.0 minimum<br />

B-20

EVALUATION REQUIREMENT TEST METHOD<br />

Colorfastness to Perspiration<br />

- Color Change Class 4.0 minimum AATCC 15<br />

- Multi-Fiber Staining Class 3.0 minimum<br />

- Self Staining Class 5.0 minimum<br />

TRIMS TESTS<br />

Zipper Strength<br />

- Chain Crosswise Strength 15 lbs minimum ASTM D 2061<br />

- Slider Lock Holding 10 lbs minimum<br />

- Tab Twist Off 6.9 in·lbs minimum<br />

- Top / Bottom Stop Holding 20 lbs minimum<br />

Strength<br />

Snap Strength 15 lbs minimum CFR 1500<br />

CHEMICAL TESTS<br />

pH Value 5 - 8 AATCC 81<br />

Total Lead Content EPA Methods 3050B / 3051A<br />

- Coated & Printed Surfaces < 90 ppm / 3052<br />

- Other < 200 ppm<br />

Lead in Surface Coating per California Prop 65 16 CFR 1303<br />

* Fabrics / laces with opaque and dense areas are required to have BOTH areas tested. Each area must meet the<br />

listed requirement<br />

** Do not perform for Dry Clean ONLY styles<br />

B-21

Product: Sweaters<br />

Performance Specification: #<strong>CSI</strong>-004<br />

PERFORMANCE SPECIFICATIONS<br />

The below noted tests will be performed when submitting tests using the Charming Shoppes testing<br />

package:<br />

TEST NAME GARMENT<br />

TESTS REQUIRED<br />

Fiber Content <br />

Garment Weight <br />

Dimensional Stability after 3 Launderings / 1 Dry Clean <br />

Skew / Torque <br />

General Appearance after 3 Launderings / 1 Dry Clean <br />

Bursting Strength <br />

Flammability (Suspect Fabrics Only – all colors) <br />

Colorfastness to Multi-Fiber Strip after 3 Launderings / 1 Dry Clean <br />

Colorfastness to Crocking (All Colors – except solid white) <br />

Colorfastness to Non-Chlorine Bleach <br />

Colorfastness to Water (Contrast Colors & Prints Only) <br />

Colorfastness to Perspiration (Lining Fabric Only) <br />

Zipper Strength<br />

(Functional Zippers Only – except<br />

<br />

nominated suppliers)<br />

Snap Strength <br />

Total Lead Content (PU / PVC Fabrics Only – all colors) <br />

Lead in Surface Coating (PU / PVC Fabrics Only – all colors) <br />

ADDITIONAL COLORWAY TESTS<br />

Colorfastness to Multi-Fiber Strip after 3 Launderings / 1 Dry Clean <br />

Colorfastness to Crocking (All Colors – except solid white) <br />

Colorfastness to Non-Chlorine Bleach <br />

B-22

EVALUATION REQUIREMENT TEST METHOD<br />

PHYSICAL TESTS<br />

Fiber Content<br />

- 100% Fabrics No Tolerance AATCC 20A<br />

- Blended Fabrics +/- 3% maximum deviation<br />

Garment Weight +/- 5% maximum deviation Lbs / dozen<br />

Dimensional Stability<br />

- 3 Launderings +/- 5% maximum AATCC 135 or 150<br />

- 1 Dry Clean +/- 2% maximum AATCC 158<br />

Skew / Torque +/- 5% maximum AATCC 179<br />

General Appearance after 3 Satisfactory Visual<br />

Launderings / 1 Dry Clean<br />

Bursting Strength – Mullen Method *<br />

- Fabric 50 psi minimum ASTM D 3786<br />

- Garment Seams 30 psi minimum<br />

- Lace<br />

- > 4 oz/sq yd 30 psi minimum<br />

- < 4 oz/sq yd 20 psi minimum<br />

Flammability Class 1 (Pass) CFR 1610<br />

COLORFASTNESS TESTS – All Colors Must Be Tested<br />

Colorfastness to Multi-Fiber Strip after Class 4.0 minimum Visual<br />

3 Launderings / 1 Dry Clean<br />

Colorfastness to Crocking<br />

- Dry Class 4.0 minimum AATCC 8 / 116<br />

- Wet Class 3.0 minimum<br />

Colorfastness to Non-Chlorine Class 4.0 minimum Soak Test<br />

Bleach **<br />

Colorfastness to Water<br />

- Color Change Class 4.0 minimum AATCC 107<br />

- Self Staining Class 5.0 minimum<br />

Colorfastness to Perspiration<br />

- Color Change Class 4.0 minimum AATCC 15<br />

- Multi-Fiber Staining Class 3.0 minimum<br />

- Self Staining Class 5.0 minimum<br />

TRIMS TESTS<br />

Zipper Strength<br />

- Chain Crosswise Strength 15 lbs minimum ASTM D 2061<br />

- Slider Lock Holding 10 lbs minimum<br />

- Tab Twist Off 6.9 in·lbs minimum<br />

- Top / Bottom Stop Holding 20 lbs minimum<br />

Strength<br />

Snap Strength 15 lbs minimum CFR 1500<br />

CHEMICAL TESTS<br />

Total Lead Content EPA Methods 3050B / 3051A /<br />

- Coated & Printed Surfaces < 90 ppm 3052<br />

- Other < 200 ppm<br />

Lead in Surface Coating per California Prop 65 16 CFR 1303<br />

B-23

PERFORMANCE SPECIFICATIONS<br />

Product: Lined and Constructed Jackets, Bottoms and Dresses<br />

(excluding denim & physically / chemically treated styles*)<br />

Performance Specification: #<strong>CSI</strong>-005<br />

The below noted tests will be performed when submitting tests using the Charming Shoppes testing<br />

package:<br />

TEST NAME FABRIC GARMENT<br />

TESTS REQUIRED<br />

Fiber Content <br />

Fabric Weight <br />

Dimensional Stability after 3 Launderings / 1 Dry Clean <br />

Skew / Torque <br />

General Appearance after 3 Launderings / 1 Dry Clean <br />

Tear Strength (Woven) <br />

Tensile Strength (Woven) <br />

Bursting Strength (Knit) <br />

Seam Strength (Woven) <br />

Seam Slippage (Woven) <br />

Flammability (Suspect Fabrics Only – all colors) <br />

Pile Retention (All Pile Fabrics) <br />

Colorfastness to Multi-Fiber Strip after 3 Launderings / 1 Dry Clean <br />

Colorfastness to Crocking (All Colors – except solid white) <br />

Colorfastness to Non-Chlorine Bleach <br />

Colorfastness to Water (Contrast Colors & Prints Only) <br />

Colorfastness to Perspiration (Lining Fabric Only) <br />

Zipper Strength<br />

(Functional Zippers Only – except<br />

<br />

nominated suppliers)<br />

Snap Strength <br />

Total Lead Content (PU / PVC Fabrics Only – all colors) <br />

Lead in Surface Coating (PU / PVC Fabrics Only – all colors) <br />

ADDITIONAL COLORWAY TESTS <br />

Colorfastness to Multi-Fiber Strip after 3 Launderings / 1 Dry Clean <br />

Colorfastness to Crocking (All Colors – except solid white) <br />

Colorfastness to Non-Chlorine Bleach <br />

* see Specification <strong>CSI</strong>-003 for Physically / Chemically Treated Styles<br />

B-24

EVALUATION<br />

PHYSICAL TESTS<br />

Fiber Content<br />

REQUIREMENT TEST METHOD<br />

- 100% Fabrics<br />

No Tolerance<br />

AATCC 20A<br />

- Blended Fabrics<br />

+/- 3% maximum deviation<br />

Fabric Weight +/- 5% maximum deviation ASTM D 3776<br />

Dimensional Stability<br />

Knits<br />

- 3 Launderings<br />

- Jersey / Interlock / Pointelle<br />

- CVC<br />

- CVS<br />

- Rib / Waffle / Pique / Tricot /<br />

Thermal<br />

- CVC<br />

- CVS<br />

- All Others<br />

- 1 Dry Clean<br />

- CVC / CVS<br />

- All Others<br />

Wovens<br />

- 3 Launderings - 5% maximum<br />

- 6% maximum / + 3% maximum<br />

- 5% maximum / + 3% maximum<br />

- 7 x 6% maximum / + 3% maximum<br />

- 5% maximum / + 3% maximum<br />

- 5% maximum / + 3% maximum<br />

- 3% maximum / + 2% maximum<br />

+/- 2% maximum<br />

AATCC 135 or 150<br />

AATCC 158<br />

AATCC 135 or 150<br />

- 1 Dry Clean<br />

Skew / Torque<br />

+ 3% maximum<br />

+/- 2% maximum AATCC 158<br />

- Knits<br />

+/-5% maximum<br />

AATCC 179<br />

- Wovens<br />

+/-3% maximum<br />

General Appearance after 3<br />

Launderings / 1 Dry Clean<br />

Tear Strength – Elmendorf Method<br />

Satisfactory Visual<br />

- Warp<br />

3.0 lbs minimum<br />

ASTM D 1424<br />

- Filling<br />

Tensile Strength – Grab Method<br />

2.5 lbs minimum<br />

- Shell<br />

ASTM D 5034<br />

- Warp<br />

50 lbs minimum<br />

- Filling<br />

- Lining<br />

30 lbs minimum<br />

- Warp<br />

30 lbs minimum<br />

- Filling<br />

Bursting Strength – Mullen Method *<br />

30 lbs minimum<br />

- Fabric<br />

50 psi minimum<br />

ASTM D 3786<br />

- Garment Seams<br />

- Lace<br />

30 psi minimum<br />

- > 4 oz/sq yd<br />

30 psi minimum<br />

- < 4 oz/sq yd<br />

20 psi minimum<br />

Seam Strength 30 lbs minimum ASTM D 1683<br />

Seam Slippage 15 lbs minimum ASTM D 434<br />

Flammability<br />

Pile Retention<br />

Class 1 (Pass) CFR 1610<br />

- Face<br />

Class 4.0 minimum<br />

ASTM D 4685-89<br />

- Back<br />

Class 4.0 minimum<br />

B-25

EVALUATION REQUIREMENT TEST METHOD<br />

COLORFASTNESS TESTS – All Colors Must Be Tested<br />

Colorfastness to Multi-Fiber Strip after Class 4.0 minimum Visual<br />

3 Launderings / 1 Dry Clean<br />

Colorfastness to Crocking<br />

Shell<br />

- Dry<br />

- Wet<br />

Lining<br />

- Dry<br />

Class 4.0 minimum<br />

Class 3.0 minimum<br />

AATCC 8 / 116<br />

- Wet<br />

Class 4.0 minimum<br />

Class 3.0 minimum<br />

Colorfastness to Non-Chlorine<br />

Bleach **<br />

Colorfastness to Water<br />

Class 4.0 minimum Soak Test<br />

- Color Change Class 4.0 minimum AATCC 107<br />

- Self Staining<br />

Colorfastness to Perspiration<br />

Class 5.0 minimum<br />

- Color Change Class 4.0 minimum AATCC 15<br />

- Multi-Fiber Staining Class 3.0 minimum<br />

- Self Staining<br />

TRIMS TESTS<br />

Zipper Strength<br />

Class 5.0 minimum<br />

- Chain Crosswise Strength 15 lbs minimum ASTM D 2061<br />

- Slider Lock Holding 10 lbs minimum<br />

- Tab Twist Off 6.9 in·lbs minimum<br />

- Top / Bottom Stop Holding<br />

Strength<br />

20 lbs minimum<br />

Snap Strength<br />

CHEMICAL TESTS<br />

15 lbs minimum CFR 1500<br />

Total Lead Content EPA Methods 3050B / 3051A /<br />

- Coated & Printed Surfaces < 90 ppm 3052<br />

- Other < 200 ppm<br />

Lead in Surface Coating per California Prop 65 16 CFR 1303<br />

* Fabrics / laces with opaque and dense areas are required to have BOTH areas tested. Each area must meet the<br />

listed requirement.<br />

** Do not perform for Dry Clean ONLY styles<br />

B-26

Product: Outerwear<br />

Performance Specification: #<strong>CSI</strong>-006<br />

PERFORMANCE SPECIFICATIONS<br />

The below noted tests will be performed when submitting tests using the Charming Shoppes testing<br />

package:<br />

TEST NAME FABRIC GARMENT<br />

TESTS REQUIRED<br />

Fiber Content <br />

Fabric Weight <br />

Dimensional Stability after 3 Launderings / 1 Dry Clean <br />

Skew / Torque <br />

General Appearance after 3 Launderings / 1 Dry Clean <br />

Tear Strength (Woven) <br />

Tensile Strength (Woven) <br />

Bursting Strength (Knit) <br />

Seam Strength (Woven) <br />

Seam Slippage (Woven) <br />

Flammability (Suspect Fabrics Only – all colors) <br />

Pile Retention (All Pile Fabrics) <br />

Water Resistance (When Claimed) <br />

Water Repellency (When Claimed) <br />

Colorfastness to Multi-Fiber Strip after 3 Launderings / 1 Dry Clean <br />

Colorfastness to Crocking (All Colors – except solid white) <br />

Colorfastness to Non-Chlorine Bleach <br />

Colorfastness to Water (Contrast Colors & Prints Only) <br />

Colorfastness to Perspiration (Lining Fabric Only) <br />

Zipper Strength<br />

(Functional Zippers Only – except<br />

<br />

nominated suppliers)<br />

Snap Strength <br />

Total Lead Content (PU / PVC Fabrics Only – all colors) <br />

Lead in Surface Coating (PU / PVC Fabrics Only – all colors) <br />

ADDITIONAL COLORWAY TESTS <br />

Colorfastness to Multi-Fiber Strip after 3 Launderings / 1 Dry Clean <br />

Colorfastness to Crocking (All Colors – except solid white) <br />

Colorfastness to Non-Chlorine Bleach <br />

B-27

EVALUATION<br />

PHYSICAL TESTS<br />

Fiber Content<br />

REQUIREMENT TEST METHOD<br />

- 100% Fabrics No Tolerance<br />

AATCC 20A<br />

- Blended Fabrics +/- 3% maximum deviation<br />

Fabric Weight +/- 5% maximum deviation ASTM D 3776<br />

Dimensional Stability<br />

Knits<br />

- 3 Launderings<br />

- Jersey / Interlock / Pointelle<br />

- CVC<br />

- CVS<br />

- Rib / Waffle / Pique / Tricot /<br />

Thermal<br />

- CVC<br />

- CVS<br />

- All Others<br />

- 1 Dry Clean<br />

- CVC / CVS<br />

- All Others<br />

Wovens<br />

- 3 Launderings - 5% maximum<br />

- 6% maximum / + 3% maximum<br />

- 5% maximum / + 3% maximum<br />

- 7 x 6% maximum / + 3% maximum<br />

- 5% maximum / + 3% maximum<br />

- 5% maximum / + 3% maximum<br />

- 3% maximum / + 2% maximum<br />

+/- 2% maximum<br />

AATCC 135 or 150<br />

AATCC 158<br />

AATCC 135 or 150<br />

- 1 Dry Clean<br />

Skew / Torque<br />

+ 3% maximum<br />

+/- 2% maximum AATCC 158<br />

- Knits<br />

+/-5% maximum<br />

AATCC 179<br />

- Wovens<br />

+/-3% maximum<br />

General Appearance after 3 Launderings<br />

/ 1 Dry Clean<br />

Tear Strength – Elmendorf Method<br />

Satisfactory Visual<br />

- Warp<br />

3.0 lbs minimum<br />

ASTM D 1424<br />

- Filling<br />

Tensile Strength – Grab Method<br />

2.5 lbs minimum<br />

- Warp<br />

50 lbs minimum<br />

ASTM D 5034<br />

- Filling<br />

Bursting Strength – Mullen Method*<br />

30 lbs minimum<br />

- Fabric<br />

50 psi minimum<br />

ASTM D 3786<br />

- Garment Seams<br />

Seam Strength<br />

30 psi minimum<br />

- Knits 30 psi minimum ASTM D 3786<br />

- Wovens 30 lbs minimum ASTM D 1683<br />

Seam Slippage 15 lbs minimum ASTM D 434<br />

Flammability<br />

Pile Retention<br />

Class 1 (Pass) CFR 1610<br />

- Face<br />

Class 4.0 minimum<br />

ASTM D 4685-89<br />

- Back<br />

Class 4.0 minimum<br />

Water Resistance<br />

Water Repellency<br />

1 g maximum AATCC 35<br />

- Original<br />

90 minimum<br />

AATCC 22<br />

- After 3 Washes<br />

70 minimum<br />

B-28

EVALUATION REQUIREMENT TEST METHOD<br />

COLORFASTNESS TESTS – All Colors Must Be Tested<br />

Colorfastness to Multi-Fiber Strip after Class 4.0 minimum Visual<br />

3 Launderings / 1 Dry Clean<br />

Colorfastness to Crocking<br />

Shell<br />

- Dry<br />

- Wet<br />

Lining<br />

- Dry<br />

Class 4.0 minimum<br />

Class 3.0 minimum<br />

AATCC 8 / 116<br />

- Wet<br />

Class 4.0 minimum<br />

Class 3.0 minimum<br />

Colorfastness to Non-Chlorine<br />

Bleach **<br />

Colorfastness to Water<br />

Class 4.0 minimum Soak Test<br />

- Color Change Class 4.0 minimum AATCC 107<br />

- Self Staining<br />

Colorfastness to Perspiration<br />

Class 5.0 minimum<br />

- Color Change Class 4.0 minimum AATCC 15<br />

- Multi-Fiber Staining Class 3.0 minimum<br />

- Self Staining<br />

TRIMS TESTS<br />

Zipper Strength<br />

Class 5.0 minimum<br />

- Chain Crosswise Strength 15 lbs minimum ASTM D 2061<br />

- Slider Lock Holding 10 lbs minimum<br />

- Tab Twist Off 6.9 in·lbs minimum<br />

- Top / Bottom Stop Holding<br />

Strength<br />

20 lbs minimum<br />

Snap Strength<br />

CHEMICAL TESTS<br />

15 lbs minimum CFR 1500<br />

Total Lead Content EPA Methods 3050B / 3051A /<br />

- Coated & Printed Surfaces < 90 ppm 3052<br />

- Other < 200 ppm<br />

Lead in Surface Coating per California Prop 65 16 CFR 1303<br />

* Fabrics / laces with opaque and dense areas are required to have BOTH areas tested. Each area must meet the<br />

listed requirement.<br />

** Do not perform for Dry Clean ONLY styles<br />

B-29

PERFORMANCE SPECIFICATIONS<br />

Product: Sleepwear and Intimate <strong>Apparel</strong><br />

Performance Specification: #<strong>CSI</strong>-007<br />

The below noted tests will be performed when submitting tests using the Charming Shoppes testing<br />

package:<br />

TEST NAME FABRIC GARMENT<br />

TESTS REQUIRED<br />

Fiber Content <br />

Fabric Weight <br />

Dimensional Stability after 3 Launderings / 1 Dry Clean <br />

Skew / Torque <br />

General Appearance after 3 Launderings / 1 Dry Clean <br />

Tear Strength (Woven) <br />

Tensile Strength (Woven) <br />

Bursting Strength (Knit) <br />

Seam Strength (Woven) <br />

Seam Slippage (Woven) <br />

Flammability (Suspect Fabrics Only – all colors) <br />

Stretch & Recovery of Fabric (Bra & Panty Only) <br />

Stretch & Recovery of Functional Elastic Trims (Bra & Panty Only) <br />

Dimensional Stability of Functional Elastic Trims (Bra & Panty Only) <br />

Colorfastness to Multi-Fiber Strip after 3 Launderings / 1 Dry Clean <br />

Colorfastness to Crocking (All Colors – except solid white) <br />

Colorfastness to Non-Chlorine Bleach <br />

Colorfastness to Water (Contrast Colors & Prints Only) <br />

Colorfastness to Perspiration (All Sleepwear & Intimates) <br />

Colorfastness to Burnt Gas Fumes (White / Pastel Molded Bra Only) <br />

Zipper Strength<br />

(Functional Zippers Only – except<br />

<br />

nominated suppliers)<br />

Snap Strength <br />

Hook & Eye Tension (Bra Only) <br />

pH Value (Intimate <strong>Apparel</strong> Only) <br />

Formaldehyde Release (Intimate <strong>Apparel</strong> Only) <br />

Total Lead Content (PU / PVC Fabrics Only – all colors) <br />

Lead in Surface Coating (PU / PVC Fabrics Only – all colors) <br />

ADDITIONAL COLORWAY TESTS <br />

Colorfastness to Multi-Fiber Strip after 3 Launderings / 1 Dry Clean <br />

Colorfastness to Crocking (All Colors – except solid white) <br />

Colorfastness to Non-Chlorine Bleach <br />

B-30

EVALUATION<br />

PHYSICAL TESTS<br />

Fiber Content<br />

REQUIREMENT TEST METHOD<br />

- 100% Fabrics<br />

No Tolerance<br />

AATCC 20A<br />

- Blended Fabrics<br />

+/- 3% maximum deviation<br />

Fabric Weight +/- 5% maximum deviation ASTM D 3776<br />

Dimensional Stability<br />

Knits<br />

- 3 Launderings<br />

- Jersey / Interlock / Pointelle<br />

- CVC<br />

- CVS<br />

- Rib / Waffle / Pique / Tricot /<br />

Thermal<br />

- CVC<br />

- CVS<br />

- All Others<br />

- 1 Dry Clean<br />

- CVC / CVS<br />

- All Others<br />

Wovens<br />

- 3 Launderings<br />

- 1 Dry Clean<br />

- 6% maximum / + 3% maximum<br />

- 5% maximum / + 3% maximum<br />

- 7 x 6% maximum / + 3% maximum<br />

- 5% maximum / + 3% maximum<br />

- 5% maximum / + 3% maximum<br />

- 3% maximum / +2% maximum<br />

+/- 2% maximum<br />

AATCC 135 or 150<br />

AATCC 158<br />

+/- 3% maximum<br />

+/- 2% maximum<br />

AATCC 135 or 150<br />

Functional Elastic Trims<br />

Skew / Torque<br />

+/- 3% maximum AATCC 135 or 150<br />

- Knits<br />

+/- 5% maximum<br />

AATCC 179<br />

- Wovens<br />

+/- 3% maximum<br />

General Appearance after 3<br />

Launderings / 1 Dry Clean<br />

Tear Strength – Elmendorf Method<br />

Satisfactory Visual<br />

- Warp<br />

3.0 lbs minimum<br />

ASTM D1424<br />

- Filling<br />

Tensile Strength – Grab Method<br />

2.5 lbs minimum<br />

- > 4 oz/sq yd<br />

ASTM D5034<br />

- Warp<br />

50 lbs minimum<br />

- Filling<br />

- < 4 oz/sq yd<br />

30 lbs minimum<br />

- Warp<br />

40 lbs minimum<br />

- Filling<br />

Bursting Strength – Mullen Method *<br />

30 lbs minimum<br />

- Fabric<br />

50 psi minimum<br />

ASTM D 3786<br />

- Garment Seams<br />

- Lace<br />

30 psi minimum<br />

- > 4 oz/sq yd<br />

30 psi minimum<br />

- < 4 oz/sq yd<br />

Seam Strength<br />

20 psi minimum<br />

- > 4 oz/sq yd<br />

30 lbs minimum<br />

ASTM D 1683<br />

- < 4 oz/sq yd<br />

25 lbs minimum<br />

Seam Slippage 15 lbs minimum ASTM D 434<br />

Flammability<br />

Class 1 (Pass) CFR 1610<br />

B-31

EVALUATION REQUIREMENT TEST METHOD<br />

Stretch & Recovery<br />

- Fabric<br />

- % available stretch<br />

- % recovery<br />

- Original<br />

- After Aging<br />

- Functional Elastic Trims<br />

(After aging 5 hours at 200° F)<br />

- Per Elastic Content of Trim<br />

- 1.0% - 5.0%<br />

- 5.1% - 10.0%<br />

- 10.1% +<br />

Data<br />

85% at 1 hour<br />

85% at 1 hour<br />

5 hours at 200° F<br />

Growth 7.0% maximum<br />

(growth & recovery after 60 mins)<br />

Growth 5.0% maximum<br />

(growth & recovery after 60 mins)<br />

Recover 85% minimum<br />

(recovery after 60 seconds)<br />

ASTM D 2594<br />

ASTM D 4964<br />

COLORFASTNESS TESTS - All Colors Must Be Tested<br />

Colorfastness to Multi-Fiber Strip<br />

after 3 Launderings / 1 Dry Clean<br />

Colorfastness to Crocking<br />

Class 4.0 minimum Visual<br />

- Dry<br />

Class 4.0 minimum<br />

AATCC 8 /116<br />

- Wet<br />

Class 3.0 minimum<br />

Colorfastness to Non-Chlorine<br />

Bleach **<br />

Colorfastness to Water<br />

Class 4.0 minimum Soak Test<br />

- Color Change<br />

Class 4.0 minimum<br />

AATCC 107<br />

- Self Staining<br />

Colorfastness to Perspiration<br />

Class 5.0 minimum<br />

- Color Change<br />

Class 4.0 minimum<br />

AATCC 15<br />

- Multi-Fiber Staining<br />

Class 3.0 minimum<br />

- Self Staining<br />

Class 5.0 minimum<br />

Colorfastness to Burnt Gas Fumes –<br />

1 Cycle<br />

TRIMS TESTS<br />

Zipper Strength<br />

Class 4.0 minimum AATCC 23<br />

- Chain Crosswise Strength 15 lbs minimum<br />

ASTM D 2061<br />

- Slider Lock Holding<br />

10 lbs minimum<br />

- Tab Twist Off<br />

6.9 in·lbs minimum<br />

- Top / Bottom Stop Holding<br />

Strength<br />

20 lbs minimum<br />

Snap Strength 15 lbs minimum CFR 1500<br />

Hook & Eye Tension<br />

No breakage, deformation,<br />

<strong>CSI</strong> 1.0<br />

This test can only be performed at detachment, shifting or other damage<br />

the following labs:<br />

after 30 lb hold for 10 seconds.<br />

- Bureau Veritas – Hong Kong All hooks and eyes are required to<br />

& Sri Lanka<br />

- Intertek – Hong Kong<br />

meet requirements.<br />

B-32

EVALUATION REQUIREMENT TEST METHOD<br />

CHEMICAL TESTS<br />

pH Value 5 - 8 AATCC 81<br />

Formaldehyde Release 75 ppm AATCC 112<br />

Total Lead Content EPA Methods 3050B / 3051A /<br />

- Coated & Printed Surfaces < 90 ppm 3052<br />

- Other < 200 ppm<br />

Lead in Surface Coating per California Prop 65 16 CFR 1303<br />

* Fabrics / laces with opaque and dense areas are required to have BOTH areas tested. Each area must meet the<br />

listed requirement.<br />

** Do not perform for Dry Clean ONLY styles<br />

B-33

PERFORMANCE SPECIFICATIONS<br />

Product: Swimwear and Swim Cover-Up<br />

Performance Specification: #<strong>CSI</strong>-008<br />

The below noted tests will be performed when submitting tests using the Charming Shoppes testing<br />

package:<br />

TEST NAME FABRIC GARMENT<br />

TESTS REQUIRED<br />

Fiber Content <br />

Fabric Weight <br />

Dimensional Stability after 3 Launderings / 1 Dry Clean <br />

Skew / Torque <br />

General Appearance after 3 Launderings / 1 Dry Clean <br />

Tear Strength (Woven) <br />

Tensile Strength (Woven) <br />

Bursting Strength (Knit) <br />

Seam Strength (Woven) <br />

Seam Slippage (Woven) <br />

Flammability (Suspect Fabrics Only – all colors) <br />

Colorfastness to Multi-Fiber Strip after 3 Launderings / 1 Dry Clean <br />

Colorfastness to Crocking (All Colors – except solid white) <br />

Colorfastness to Non-Chlorine Bleach <br />

Colorfastness to Light <br />

Colorfastness to Chlorinated Pool Water <br />

Colorfastness to Sea Water <br />

Colorfastness to Water (Contrast Colors & Prints Only) <br />

Colorfastness to Perspiration (Lining Fabric Only) <br />

Zipper Strength<br />

(Functional Zippers Only – except<br />

<br />

nominated suppliers)<br />

Snap Strength <br />

pH Value (Swimwear Only) <br />

Formaldehyde Release (Swimwear Only) <br />

Total Lead Content (PU / PVC Fabrics Only – all colors) <br />

Lead in Surface Coating (PU / PVC Fabrics Only – all colors) <br />

ADDITIONAL COLORWAY TESTS <br />

Colorfastness to Multi-Fiber Strip after 3 Launderings / 1 Dry Clean <br />

Colorfastness to Crocking (All Colors – except solid white) <br />

Colorfastness to Non-Chlorine Bleach <br />

Colorfastness to Light <br />

B-34

EVALUATION<br />

PHYSICAL TESTS<br />

Fiber Content<br />

REQUIREMENT TEST METHOD<br />

- 100% Fabrics<br />

No Tolerance<br />

AATCC 20A<br />

- Blended Fabrics<br />

+/- 3% maximum deviation<br />

Fabric Weight +/- 5% maximum deviation ASTM D 3776<br />

Dimensional Stability<br />

Knits<br />

- 3 Launderings<br />

- Jersey / Interlock / Pointelle<br />

- CVC<br />

- CVS<br />

- Rib / Waffle / Pique / Tricot /<br />

Thermal<br />

- CVC<br />

- CVS<br />

- All Others<br />

- 1 Dry Clean<br />

- CVC / CVS<br />

- All Others<br />

Wovens<br />

- 3 Launderings<br />

- 1 Dry Clean<br />

Skew / Torque<br />

- Knits<br />

- Wovens<br />

General Appearance after 3<br />

Launderings / 1 Dry Clean<br />

Tear Strength – Elmendorf Method<br />

- Warp<br />

- Filling<br />

Tensile Strength – Grab Method<br />

- Warp<br />

- Filling<br />

Bursting Strength – Mullen Method*<br />

- Fabric<br />

- 6% maximum / + 3% maximum<br />

- 5% maximum / + 3% maximum<br />

- 7 x 6% maximum / + 3% maximum<br />

- 5% maximum / + 3% maximum<br />

- 5% maximum / + 3% maximum<br />

- 3% maximum / + 2% maximum<br />

+/- 2% maximum<br />

+/- 3% maximum<br />

+/- 2% maximum<br />

AATCC 135 or 150<br />

AATCC 158<br />

AATCC 135 or 150<br />

+/-5% maximum<br />

+/-3% maximum<br />

AATCC 179<br />

Satisfactory Visual<br />

3.0 lbs minimum<br />

2.5 lbs minimum<br />

50 lbs minimum<br />

30 lbs minimum<br />

ASTM D1424<br />

ASTM D5034<br />

50 psi minimum<br />

ASTM D 3786<br />

- Garment Seams<br />

30 psi minimum<br />

Seam Strength 30 lbs minimum ASTM D 1683<br />

Seam Slippage 15 lbs minimum ASTM D 434<br />

Flammability Class 1 (Pass) CFR 1610<br />

COLORFASTNESS TESTS - All Colors Must Be Tested<br />

Colorfastness to Multi-Fiber Strip<br />

after 3 Launderings / 1 Dry Clean<br />

Colorfastness to Crocking<br />

Class 4.0 minimum Visual<br />

- Dry<br />

Class 4.0 minimum<br />

AATCC 8 /116<br />

- Wet<br />

Class 3.0 minimum<br />

Colorfastness to Non-Chlorine<br />

Bleach **<br />

Colorfastness to Light – 20 Hours<br />

Class 4.0 minimum Soak Test<br />

- Non-neons<br />

Class 4.0 minimum<br />

AATCC 16E<br />

- Neons<br />

Class 3.0 minimum<br />

B-35

EVALUATION REQUIREMENT TEST METHOD<br />

Colorfastness to Chlorinated Pool Water<br />

- Color Change Class 4.0 minimum AATCC 162<br />

Colorfastness to Sea Water<br />

- Color Change<br />

- Self Staining<br />

Class 4.0 minimum<br />

Class 5.0 minimum<br />

AATCC 106<br />

Colorfastness to Water<br />

- Color Change Class 4.0 minimum AATCC 107<br />

- Self Staining Class 5.0 minimum<br />

Colorfastness to Perspiration<br />

- Color Change Class 4.0 minimum AATCC 15<br />

- Multi-Fiber Staining Class 3.0 minimum<br />

- Self Staining Class 5.0 minimum<br />

TRIMS TESTS<br />

Zipper Strength<br />

- Chain Crosswise Strength 15 lbs minimum ASTM D 2061<br />

- Slider Lock Holding 10 lbs minimum<br />

- Tab Twist Off 6.9 in·lbs minimum<br />

- Top / Bottom Stop Holding 20 lbs minimum<br />

Strength<br />

Snap Strength 15 lbs minimum CFR 1500<br />

CHEMICAL TESTS<br />

pH Value 5 - 8 AATCC 81<br />

Formaldehyde Release 75 ppm AATCC 112<br />

Total Lead Content EPA Methods 3050B / 3051A /<br />

- Coated & Printed Surfaces < 90 ppm 3052<br />

- Other < 200 ppm<br />

Lead in Surface Coating per California Prop 65 16 CFR 1303<br />

* Fabrics / laces with opaque and dense areas are required to have BOTH areas tested. Each area must meet the<br />

listed requirement.<br />

** Do not perform for Dry Clean ONLY styles<br />

B-36

PERFORMANCE SPECIFICATIONS<br />

Product: Leather and Suede <strong>Apparel</strong><br />

(non-synthetic)<br />

Performance Specification: #<strong>CSI</strong>-009<br />

The below noted tests will be performed when submitting tests using the Charming Shoppes testing<br />

package:<br />

TEST NAME FABRIC GARMENT<br />

TESTS REQUIRED<br />

Leather Identification <br />

Fabric Weight <br />

Dimensional Stability after Leather Cleaning / 1 Dry Clean <br />

Skew / Torque <br />

General Appearance after Leather Cleaning / 1 Dry Clean <br />

Tensile Strength (Leather Only) <br />

Seam Strength <br />

Tear Strength (Lining Only) <br />

Seam Slippage (Lining Only) <br />

Flammability (Suspect Fabrics Only – all colors) <br />

Zipper Strength<br />

(Functional Zippers Only – except<br />

<br />

nominated suppliers)<br />

Snap Strength <br />

Total Lead Content (All colors) <br />

Lead in Surface Coating (All colors) <br />

Spewing <br />

Colorfastness to Crocking (All Colors – except solid white) <br />

ADDITIONAL COLORWAY TESTS <br />

Colorfastness to Crocking (All Colors – except solid white) <br />

B-37

EVALUATION<br />

PHYSICAL TESTS<br />

REQUIREMENT TEST METHOD<br />

Leather Identification Confirm Species of Leather <strong>Vendor</strong> must supply species<br />

documentation<br />

Fabric Weight<br />

Dimensional Stability<br />

+/- 5% maximum deviation ASTM D 3776<br />

- Leather Cleaning +/- 2% maximum Professional Leather Cleaning<br />

- 1 Dry Clean<br />

Skew / Torque<br />

+/- 2% maximum AATCC 158<br />

- Knits +/- 5% maximum AATCC 179<br />

- Wovens +/- 3% maximum<br />

General Appearance after Leather<br />

Cleaning / 1 Dry Clean<br />

Tear Strength – Elmendorf Method<br />

Satisfactory Visual<br />

- Warp 3.0 lbs minimum ASTM D1424<br />

- Filling<br />

Tensile Strength – Grab Method<br />

2.5 lbs minimum<br />

- Leather / Suede 40 lbs minimum ASTM D5034<br />

- Lining 30 lbs minimum<br />

Seam Strength 30 lbs minimum ASTM D 1683<br />

Seam Slippage 15 lbs minimum ASTM D 434<br />

Flammability Class 1 (Pass) CFR 1610<br />

COLORFASTNESS TESTS -All Colors Must Be Tested<br />

Colorfastness to Crocking<br />

- Dry Class 3.0 minimum AATCC 8 /116<br />

- Wet<br />

TRIMS TESTS<br />

Zipper Strength<br />

Class 2.0 minimum<br />

- Chain Crosswise Strength 15 lbs minimum ASTM D 2061<br />

- Slider Lock Holding 10 lbs minimum<br />

- Tab Twist Off 6.9 in·lbs minimum<br />

- Top / Bottom Stop Holding<br />

Strength<br />

20 lbs minimum<br />

Snap Strength<br />

CHEMICAL TESTS<br />

15 lbs minimum CFR 1500<br />

Total Lead Content EPA Methods 3050B / 3051A /<br />

- Coated & Printed Surfaces < 90 ppm<br />

3052<br />

- Other<br />

< 200 ppm<br />

Lead in Surface Coating per California Prop 65 16 CFR 1303<br />

Spewing No Spewing Evident 48 Hours @ 50° C / 90%<br />

Relative Humidity; Then 6<br />

Hours @ -20° C<br />

B-38

PERFORMANCE SPECIFICATIONS<br />

Product: Hats, Scarves, Wraps & Gloves<br />

Performance Specification: #<strong>CSI</strong>-010<br />

The below noted tests will be performed when submitting tests using the Charming Shoppes testing<br />

package:<br />

TEST NAME FABRIC GARMENT<br />

TESTS REQUIRED<br />

Fiber Content <br />

Fabric Weight <br />

Dimensional Stability after 3 Launderings / 1 Dry Clean <br />

Skew / Torque <br />

General Appearance after 3 Launderings / 1 Dry Clean <br />

Tear Strength (Woven) <br />

Tensile Strength (Woven) <br />

Bursting Strength (Knit) <br />

Seam Strength (Woven) <br />

Seam Slippage (Woven) <br />

Flammability (Suspect Fabrics Only – all colors) <br />

Colorfastness to Multi-Fiber Strip after 3 Launderings / 1 Dry Clean <br />

Colorfastness to Crocking (All Colors – except solid white) <br />

Colorfastness to Non-Chlorine Bleach <br />

Colorfastness to Water (Contrast Colors & Prints Only) <br />

Colorfastness to Perspiration (Lining Fabric Only) <br />

Zipper Strength<br />

(Functional Zippers Only – except<br />

<br />

nominated suppliers)<br />

Snap Strength <br />

Total Lead Content (PU / PVC Fabrics Only – all colors) <br />

Lead in Surface Coating (PU / PVC Fabrics Only – all colors) <br />

ADDITIONAL COLORWAY TESTS <br />

Colorfastness to Multi-Fiber Strip after 3 Launderings / 1 Dry Clean <br />

Colorfastness to Crocking (All Colors – except solid white) <br />

Colorfastness to Non-Chlorine Bleach <br />

B-39

EVALUATION<br />

PHYSICAL TESTS<br />

Fiber Content<br />