06280-fht16-01gb6011 PAPYEXI600HP modif

06280-fht16-01gb6011 PAPYEXI600HP modif

06280-fht16-01gb6011 PAPYEXI600HP modif

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

O 9001: 2000<br />

ISO 14001<br />

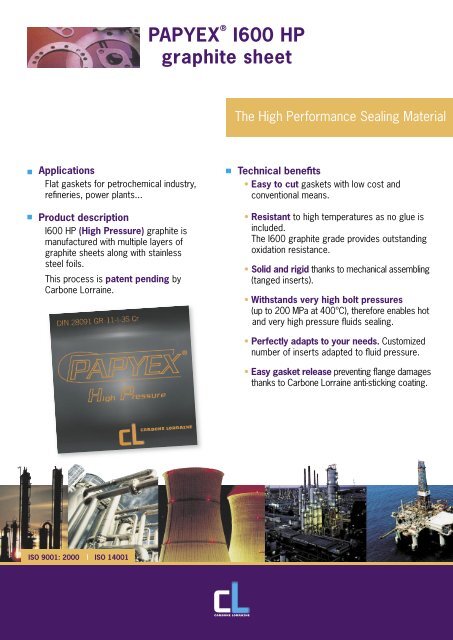

PAPYEX ®<br />

Applications<br />

Flat gaskets for petrochemical industry,<br />

refi neries, power plants...<br />

Product description<br />

I600 HP (High Pressure) graphite is<br />

manufactured with multiple layers of<br />

graphite sheets along with stainless<br />

steel foils.<br />

This process is patent pending by<br />

Carbone Lorraine.<br />

ISO 9001: 2000 ISO 14001<br />

I600 HP<br />

graphite sheet<br />

The High Performance Sealing Material<br />

Technical benefi ts<br />

• Easy to cut gaskets with low cost and<br />

conventional means.<br />

• Resistant to high temperatures as no glue is<br />

included.<br />

The I600 graphite grade provides outstanding<br />

oxidation resistance.<br />

• Solid and rigid thanks to mechanical assembling<br />

(tanged inserts).<br />

• Withstands very high bolt pressures<br />

(up to 200 MPa at 400°C), therefore enables hot<br />

and very high pressure fl uids sealing.<br />

• Perfectly adapts to your needs. Customized<br />

number of inserts adapted to fl uid pressure.<br />

• Easy gasket release preventing fl ange damages<br />

thanks to Carbone Lorraine anti-sticking coating.

WORLDWIDE SPECIALIST IN INDUSTRIAL COMPONENTS<br />

DESIGNATION PAPYEX HP<br />

Graphite grade<br />

Insert type<br />

Residual Stress P qr at 50 MPa<br />

Maximal surface pressure Q smax<br />

Thickness mm 1 1.5 2 3 4<br />

Ash content %<br />

Total sulfur content ppm<br />

Total chloride content ppm<br />

Oxidation stability at 500°C in air weight<br />

loss<br />

% / h<br />

Stainless steel 316 (L)<br />

Thickness mm 0.05 mm<br />

Number of inserts 1 2 3 5 7<br />

Type tanged insert<br />

Temperature °C<br />

MPa<br />

CARBONE LORRAINE Group :<br />

6,200 employees and an extensive industrial and commercial network covering<br />

around 40 countries, working hand in hand with our clients to pursue permanent<br />

innovation through a broad range of top-class products and services.<br />

Contact for America<br />

CARBONE OF AMERICA<br />

900 Harrison Street<br />

Bay City, MI48708, USA<br />

Phone: +1 989 894 29 11<br />

Fax: +1 989 895 77 40<br />

E-mail: jerome.dewasch@carbonelorraine.com<br />

www.carbone-support.com<br />

20°C 300°C<br />

0.99 0.94<br />

> 220 > 220<br />

Compression at 20°C ksw % 30 - 40<br />

Recovery at 20°C krw % 4 - 5<br />

Creep compression at 300°C wsw % < 4<br />

Recovery at 300°C wrw % 4 - 5<br />

ASTM<br />

Available width<br />

I600<br />

- m factor 2.5<br />

- y stress Minimum gasket pressure psi 3,000<br />

mm 1,000 x 1,000<br />

Developed End of 2006 mm 1,500 x 1,500<br />

< 1<br />

< 700<br />

< 25<br />

0.02<br />

Mechanical tests according to EN 13555 - Thickness 2 mm - Gasket width 20 mm<br />

MPa<br />

250<br />

200<br />

150<br />

100<br />

50<br />

0<br />

Deformation factors DIN28090-2<br />

Maximal surface pressure<br />

Q smax at 300°C<br />

2 3 4 5 6 7 8 9 10 11 12<br />

ratio gasket width/ gasket thickness<br />

For any information, please get in touch with Sales Department.<br />

Tel.: +33 (0)1 41 85 45 87 / 43 66<br />

papyex@carbonelorraine.com<br />

Contact for Europe<br />

CARBONE LORRAINE COMPOSANTS<br />

41 rue Jean Jaurès - BP 148<br />

F-92231 GENNEVILLIERS Cedex - FRANCE<br />

Tel. : +33 (0)1 41 85 45 87<br />

Fax : +33 (0)1 41 85 45 88<br />

E-mail : papyex@carbonelorraine.com<br />

www.carbonelorraine.com<br />

N9985<br />

< 0.15<br />

< 500<br />

< 20<br />

0.02<br />

400°C<br />

0.92<br />

200 MPa<br />

newsandpaper.com<br />

Data herein contained are provided for general information purpose only and are not binding. Carbone Lorraine shall have no liability whatsoever with respect to information contained herein.<br />

HT16-01GB6011