D55dv-ing 01-16(attualeG1).PMD

D55dv-ing 01-16(attualeG1).PMD

D55dv-ing 01-16(attualeG1).PMD

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

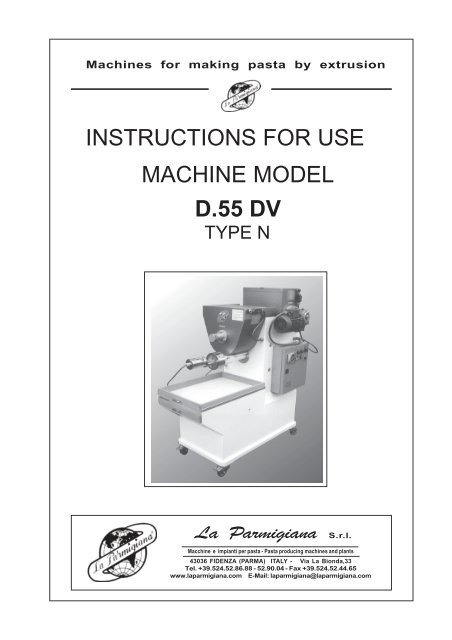

Machines for mak<strong>ing</strong> pasta by extrusion<br />

INSTRUCTIONS FOR USE<br />

MACHINE MODEL<br />

D.55 DV<br />

TYPE N<br />

La Parmigiana S.r.l.<br />

Macchine e impianti per pasta - Pasta produc<strong>ing</strong> machines and plants<br />

43036 FIDENZA (PARMA) ITALY - Via La Bionda,33<br />

Tel. +39.524.52.86.88 - 52.90.04 - Fax +39.524.52.44.65<br />

www.laparmigiana.com E-Mail: laparmigiana@laparmigiana.com

2<br />

INSTRUCTIONS<br />

D.55 DV<br />

Second Edition<br />

November 1997<br />

La Parmigiana S.r.l. Fidenza ITALY<br />

Second edition November 1997<br />

by La Parmigiana S.r.l.<br />

CERTIFICATION<br />

LA PARMIGIANA S.r.l.<br />

Via La Bionda, 33<br />

43036 Fidenza (PR)<br />

as. In person:<br />

Mrs. Dina Giordani<br />

Sole Administrator<br />

DECLARES<br />

under its own responsibility that the machine for the production of alimentary<br />

pasta mod.<br />

........................<br />

Serial no : ________<br />

to which this declaration refers is<br />

in Conformity<br />

with the legislative regulations with the follow<strong>ing</strong> directives:<br />

Machinery directive 89/392 CEE and/or further modifications<br />

Machinery directive 98/37<br />

Electro-magnetic compatibility directive 89/336<br />

Low tension directive73/23<br />

Date: Signature

INSTRUCTIONS<br />

D.55 DV<br />

Second Edition<br />

November 1997<br />

La Parmigiana S.r.l. Fidenza ITALY<br />

The instructions for use are an integral part of the machine which<br />

must accompany it throughout its work<strong>ing</strong> life until it is demolished.<br />

Always refer to the instructions for the carry<strong>ing</strong> out of all operations.<br />

Do not allow the machine to be used by operators who are not familiar<br />

with the contents of the instruction manual.<br />

Keep the instructions in good, legible condition in a place which is<br />

easily accessible to operators.<br />

La Parmigiana S.r.l. does not accept responsibility for malfunctions, breakages, accidents<br />

etc. caused by failure to read or to follow the instructions contained in this<br />

manual. The same applies to modifications, variations and/or installation of accessories<br />

carried out without prior authorization.<br />

All rights reserved. No part of this manual may be reproduced, either partially or totally, without the prior<br />

written consent of “La Parmigiana S.r.l.”.<br />

3

4<br />

INSTRUCTIONS<br />

D.55 DV<br />

Second Edition<br />

November 1997<br />

Contents<br />

La Parmigiana S.r.l. Fidenza ITALY<br />

General Precaution...................................................... 5<br />

Operator Safety........................................................... 7<br />

Mechanical faults......................................................... 7<br />

Hygiene and Clean<strong>ing</strong>.................................................. 8<br />

Technical Characteristics........................................... 9<br />

Machine description..................................................... 10<br />

Manufacturer.............................................................. 11<br />

Pack<strong>ing</strong> and transportation............................................ 11<br />

Use........................................................................... 12<br />

Environmental conditions.............................................. 12<br />

Technical assistance.................................................... 12<br />

Demolition.................................................................. 12<br />

Installation standards................................................ 13<br />

Checks...................................................................... 14<br />

Lift<strong>ing</strong> and transportation.............................................. 14<br />

Precautions................................................................ 14<br />

Preliminary clean<strong>ing</strong>.................................................... 15<br />

Start<strong>ing</strong> up................................................................. 15<br />

Production................................................................ 17<br />

Ingredients................................................................. 18<br />

Recipes..................................................................... 18<br />

Prepar<strong>ing</strong> the pasta dough............................................ 19<br />

Start<strong>ing</strong> production...................................................... 20<br />

Long pasta (Photo V)................................................... 21<br />

Short pasta (Photo T)................................................... 22<br />

Die substitution........................................................... 23<br />

Cool<strong>ing</strong> (see draw<strong>ing</strong>).................................................. 23<br />

Clean<strong>ing</strong> and Maintenance......................................... 25<br />

Clean<strong>ing</strong>.................................................................... 26<br />

Precautions................................................................ 27<br />

Periodical check-ups................................................... 28<br />

Spares...................................................................... 31<br />

Spare parts request form.............................................. 39<br />

Guarantee............................................................... 40

INSTRUCTIONS<br />

D.55 DV<br />

Second Edition<br />

November 1997<br />

General<br />

Precautions<br />

La Parmigiana S.r.l. Fidenza ITALY<br />

Operations which could be potentially dangerous for machine operators are marked<br />

with the symbol shown in the margin.<br />

5

6<br />

INSTRUCTIONS<br />

D.55 DV<br />

Second Edition<br />

November 1997<br />

There are “CAUTION” stickers on the machine.<br />

Look at these carefully before use.<br />

(Their positions are indicated in the draw<strong>ing</strong>).<br />

“CAUTION” stickers<br />

La Parmigiana S.r.l. Fidenza ITALY<br />

Oil Screw Sticker<br />

Oil Screw Sticker<br />

PRIMA DI METTERE IN FUNZIONE LA MACCHINA APRIRE IL<br />

COPERCHIO POSTERIORE E TOGLIERE LA VITE SUL<br />

BOLLINO BIANCO AUTOADESIVO DAL RIDUTTORE PER<br />

RIDURRE LA PRESSIONE<br />

BEFORE OPERATING THE MACHINE, OPEN THE BACK COVER<br />

AND REMOVE THE SCREW IN THE WHITE STICKER TO REDU-<br />

CE THE OIL PRESSURE<br />

First “CAUTION” Sticker<br />

ATTENZIONE<br />

NON INTRODURRE LE MANI NELLA VASCA IMPASTATRICE<br />

STACCARE LA SPINA, PRIMA DI PULIRE LA MACCHINA<br />

CAUTION<br />

DO NOT INTRODUCE YOUR HANDS INTO THE MIXING HOPPER<br />

UNPLUG THE MACHINE BEFORE CLEANING<br />

ATTENTION<br />

NE PAS INTRODUIRE LES MAINS DANS LA VASQUE DE MELANGE<br />

DETACHER LA FICHE AVANT DE NETTOYER LA MACHINE<br />

ACHTUNG<br />

DIE HANDE NICHT IN DIE KNETWANNE GEBEN<br />

BEVOR DER MASCHINENREINIGUNG, DEN STECKER HERAUSNEHMEN<br />

ATENCION<br />

NO INTRODUCIR LAS MANOS EN EL TANQUE MEZCLADOR<br />

DESCONECTAR EL ENCHUFE ANTES DE LIMPIAR LA MAQUINA<br />

Second “CAUTION” Sticker<br />

ATTENZIONE<br />

NON USARE LA MACCHINA SENZA IL COPERCHIO DELLA VASCA IMPASTATRICE<br />

NON MANOMETTERE I DISPOSITIVI DI SICUREZZA<br />

CAUTION<br />

DO NOT USE THE MACHINE WITHOUT THE LID OF THE MIXING HOPPER<br />

DO NOT BYPASS THE SAFETY DEVICES<br />

ATTENTION<br />

NE PAS UTILIZER LA MACHINE SANS LE COUVERCLE DE LA VASQUE DE MELANGE<br />

NE PAS FORCER LES DISPOSITIFS DE SURETE<br />

ACHTUNG<br />

DIE MASCHINE NICHT OHNE KNETWANNENDECKEL BENUTZEN<br />

DIE SCHUTZVORRICHTUNGEN NICHT BERUHREN<br />

ATENCION<br />

NO USAR LA MAQUINA SIN LA TAPA DEL TANIQUE MEZCLADOR<br />

NO DESCONECTAR LOS DISPOSITIVOS DE SEGURIDAD

INSTRUCTIONS<br />

D.55 DV<br />

Second Edition<br />

November 1997<br />

La Parmigiana S.r.l. Fidenza ITALY<br />

Operator Safety<br />

Never tamper with the safety devices<br />

Keep this manual for future reference.<br />

Do not remove or modify the protective devices.<br />

Check that the microswitches (No. 1 photo C) on the basins are always in perfect work<strong>ing</strong><br />

order; on open<strong>ing</strong> a cover, the motor of the basin connected to it must always stop. In<br />

the event of malfunction<strong>ing</strong>, replace the broken components immediately and do not use<br />

the machine until this has been done.<br />

Always unplug the machine before clean<strong>ing</strong> it.<br />

Never use the machine in a potentially explosive environment.<br />

Keep f<strong>ing</strong>ers away from the pasta cutter blades.<br />

The machine must always be used by one<br />

operator only. The operator position is in<br />

front of the electric board.<br />

Always stop the d.c. motor of the pasta<br />

cutter before remov<strong>ing</strong> it from the<br />

metal rods of the die-hold<strong>ing</strong> r<strong>ing</strong> nut.<br />

Look closely at draw<strong>ing</strong> E143 on page 32<br />

which illustrates the safety system of the<br />

basin covers in detail.<br />

While the machine is operat<strong>ing</strong>, the<br />

covers must always be closed.<br />

Do not tamper with the electrical system.<br />

Always lock the wheels before us<strong>ing</strong><br />

the machine.<br />

Remove garments or personal accessories<br />

such as ties and bracelets, and roll<br />

up long sleeves.<br />

Dwg.2<br />

Mechanical faults<br />

Ensure that the voltage of the electrical<br />

sockets corresponds to the voltage required<br />

by the machine. The plate on the<br />

electric board (No.3 Dwg.2) lists information<br />

such as:<br />

Machine model D55DV.<br />

Volts 380.<br />

Hz 50.<br />

Ph (phases) 3.<br />

Motor KW 1.65<br />

No. of motors 2<br />

Photo C<br />

3<br />

7

8<br />

INSTRUCTIONS<br />

D.55 DV<br />

Second Edition<br />

November 1997<br />

La Parmigiana S.r.l. Fidenza ITALY<br />

A heavy blow or vigorous push on the side of the machine could upset it. Always<br />

handle it carefully.<br />

Never leave the die fitted and pasta dough in the mix<strong>ing</strong> basin when the machine is not<br />

be<strong>ing</strong> used. Failure to take this precaution could lead to serious mechanical faults due to<br />

the dry<strong>ing</strong> out of the pasta dough.<br />

Only fit the die when the pasta dough is ready to use.<br />

Any modifications made to the machine must be authorized by the company.<br />

Always switch on the pasta cutter before the press. Never vice versa.<br />

After use, the die and filter must always be soaked in water.<br />

Do not use a jet of water to clean the machine and never immerse the die-hold<strong>ing</strong><br />

nut in water.<br />

Never fit a die or filter which has not been kept in water.<br />

For spare parts, contact “La Parmigiana S.r.l.” only original spares can guarantee<br />

the perfect work<strong>ing</strong> order and safety of the machine.<br />

The machine must only be used as described in this manual. Any other use is considered<br />

as improper.<br />

Hygiene and Clean<strong>ing</strong><br />

Clean the new machine as described on page 15.<br />

Always clean the machine carefully after use.<br />

Put the machine in a place which is suitable for the mak<strong>ing</strong> of pasta.<br />

All the dies must be kept soaked in water.<br />

Change the water twice a day.

INSTRUCTIONS<br />

D.55 DV<br />

Second Edition<br />

November 1997<br />

Technical<br />

La Parmigiana S.r.l. Fidenza ITALY<br />

Characteristics<br />

The machine has been constructed in conformity with the requirements of the<br />

follow<strong>ing</strong> EEC Machine Directives: 89/392 - 91/386 - 93/44.<br />

La Parmigiana guarantees that its machine is in conformity with the above quoted directives<br />

and hereby affixes the mark<strong>ing</strong> “CE” on the machine itself. (see plate below).<br />

9

10<br />

INSTRUCTIONS<br />

D.55 DV<br />

Second Edition<br />

November 1997<br />

La Parmigiana S.r.l. Fidenza ITALY<br />

Machine description<br />

The “La Parmigiana” machine model D.55DV is a machine for mak<strong>ing</strong> fresh pasta by<br />

extrusion.<br />

The D.55DV can make various types of pasta simply by chang<strong>ing</strong> the dies.<br />

The electrical system and the cover of the mix<strong>ing</strong> basin are constructed in conformity<br />

with EEC Directives and IEC safety standards.<br />

The machine is equipped with:<br />

Detachable electric pasta-cutter<br />

3 cutt<strong>ing</strong> knives (1 blade - 2 blades - 4 blades)<br />

2 wooden trays with nett<strong>ing</strong> base<br />

Detachable die-hold<strong>ing</strong> r<strong>ing</strong> nut<br />

Detachable worm screw<br />

Spanners (10/11 - 13/14 - <strong>16</strong>/17)<br />

Brush with plastic bristles for clean<strong>ing</strong> purposes<br />

Lever for unscrew<strong>ing</strong> r<strong>ing</strong> nut<br />

Overall dimensions (in millimetres)<br />

The machine must always work with one operator only, even when it is be<strong>ing</strong> used<br />

in combination with the ravioli maker.<br />

The operator position is in front of the electric board (see draw<strong>ing</strong> above).

INSTRUCTIONS<br />

D.55 DV<br />

Second Edition<br />

November 1997<br />

Manufacturer<br />

La Parmigiana S.r.l. Fidenza ITALY<br />

La Parmigiana S.r.l.<br />

Pasta-mak<strong>ing</strong> Machines and Systems<br />

43036 Fidenza (Parma) ITALY - Via La Bionda,33<br />

Tel. +39 524 52.86.88 - 52.90.04 - Fax + 39 524 52.44.65<br />

Machine model D55 DV Type N<br />

Year of Manufacture 1997<br />

Output per hour 30/35 Kg Upper basin capacity 8kg<br />

Lower basin capacity 6.5 Kg<br />

Dimensions<br />

Width 65 cm Length 115 cm Height 143 cm<br />

Weight 185 Kg<br />

Number of motors 3 (power per motor 380/50/3)<br />

Power of upper motor 0.55 Kw<br />

Power of lower motor 1.1 Kw<br />

Power of pasta cutter motor 0.<strong>01</strong>6 Kw<br />

Noise level 62.7 dB<br />

Voltage...........................Volt/Hertz/Phases<br />

Electrical current.............A<br />

Pack<strong>ing</strong> and transportation<br />

Please circulate these instructions to all personnel involved in the transportation<br />

and installation of the machine.<br />

The D55 DV machine is packed in wooden cases of suitable dimensions for palletiz<strong>ing</strong>.<br />

The case is stable in itself but, for safety reasons, it should be fastened to the flatbed or to<br />

the body sides of the transport vehicle to ensure against toppl<strong>ing</strong>.<br />

A packed machine weighs approx. 200 kg.<br />

Use a forklift truck to handle the machine, tak<strong>ing</strong> care not to accelerate or brake abruptly.<br />

Do not place it on top of other packages but directly on the flatbed of the transport<br />

vehicle, secur<strong>ing</strong> it with belts, or similar, to the body sides.<br />

11

12<br />

INSTRUCTIONS<br />

D.55 DV<br />

Second Edition<br />

November 1997<br />

La Parmigiana S.r.l. Fidenza ITALY<br />

Use<br />

The machine model D55 DV has been designed, built and protected for the mak<strong>ing</strong><br />

of pasta by extrusion obtained from raw materials such as common and durum<br />

wheat flour to which water and/or eggs are added.<br />

Any use other than that described above, is considered as improper use and can damage<br />

the machine and render the guarantee null and void.<br />

Environmental conditions<br />

The machine works correctly in the follow<strong>ing</strong> environmental conditions:<br />

Temperature rang<strong>ing</strong> from +20° to +30°C<br />

Humidity rang<strong>ing</strong> from 40% to 50%<br />

Technical assistance<br />

La Parmigiana S.r.l. places its Fidenza plant technicians at the complete disposal of its<br />

Clientele for the resolv<strong>ing</strong> of any problems which might arise regard<strong>ing</strong> the use and<br />

maintenance of the machine.<br />

For servic<strong>ing</strong>, repairs or technical instructions on premises other than those of La<br />

Parmigiana S.r.l., contact the Technical Department directly.<br />

The Technical Department, which can be reached by telephon<strong>ing</strong> +39.524/528688-529004<br />

dur<strong>ing</strong> office hours 8.30 - 12.00 and 14.00 - 17.30, can also give you the names of the<br />

authorized maintenance technicians in your area so as to ensure quicker service.<br />

Demolition<br />

Dispose of the various materials of which the machine is constructed in suitable dumps.<br />

Do not pollute the environment with the oil contained in the speed reducer.<br />

Keep yourself informed and always observe the laws in force.

INSTRUCTIONS<br />

D.55 DV<br />

Second Edition<br />

November 1997<br />

Installation<br />

standards<br />

La Parmigiana S.r.l. Fidenza ITALY<br />

13

14<br />

INSTRUCTIONS<br />

D.55 DV<br />

Second Edition<br />

November 1997<br />

La Parmigiana S.r.l. Fidenza ITALY<br />

Checks<br />

On receiv<strong>ing</strong> the machine, check that it has not been damaged<br />

dur<strong>ing</strong> transportation. Check that the microswitches on the mix<strong>ing</strong><br />

basins are work<strong>ing</strong> correctly and that the box contain<strong>ing</strong> the<br />

electrical system is undamaged. If the machine has been damaged<br />

dur<strong>ing</strong> transportation, follow the procedure laid down in the<br />

sales agreement for reimbursement. The cost of the repair is<br />

charged to the party which caused the damage. Remove any<br />

objects which have been placed in the mix<strong>ing</strong> basin for pack<strong>ing</strong><br />

purposes.<br />

Lift<strong>ing</strong> and transportation<br />

Use a mechanical lift, plac<strong>ing</strong> the machine on its supports.<br />

A heavy blow or vigorous push on the side of the machine<br />

could upset it. Always handle it carefully.<br />

After putt<strong>ing</strong> the machine in its place, always lock the front<br />

wheels by press<strong>ing</strong> down the lock<strong>ing</strong> pedal. (See Dwg. 3)<br />

The minimum space required for the machine in<br />

production is illustrated in Dwg. 4.<br />

Precautions<br />

Before start<strong>ing</strong> up the machine, check that the<br />

voltage of the electric board corresponds to<br />

that of the mains (No.3 Dwg.2).<br />

Ensure that the machine is stable.<br />

Remove the screw on the reducer inside the<br />

machine. Take off the rear hous<strong>ing</strong> first - this<br />

screw can be easily identified by its white sticker.<br />

(Photo No. 4)<br />

Please remember that the screw on the reducer<br />

prevents oil from spill<strong>ing</strong> out dur<strong>ing</strong> transportation<br />

and must be removed to stop pressure from<br />

build<strong>ing</strong> up inside the reducer while the machine<br />

is operat<strong>ing</strong>.<br />

Failure to remove this screw will cause oil to<br />

leak through the O r<strong>ing</strong>s.<br />

The screw must always be replaced when the<br />

machine is tilted or transported.<br />

Photo B<br />

Dwg.4<br />

Dwg.2<br />

3<br />

Dwg.3<br />

press

INSTRUCTIONS<br />

D.55 DV<br />

Second Edition<br />

November 1997<br />

La Parmigiana S.r.l. Fidenza ITALY<br />

Preliminary clean<strong>ing</strong><br />

The machine and, in particular, the mix<strong>ing</strong> basins and extrusion channel are dusty and<br />

dirty with various substances. La Parmigiana cleans the components which come into<br />

contact with the pasta in a preliminary manner by mak<strong>ing</strong> a test pasta dough. The worm<br />

screw and extrusion channel are then greased with protective oil.<br />

When the machine is new, the mix<strong>ing</strong> basins, extrusion channel and worm screw should<br />

be cleaned with a damp cloth; then a pasta dough with 5 kg of flour should be made and<br />

extruded through all the dies<br />

purchased. (The pasta produced<br />

is not suitable for human<br />

consumption and must<br />

Photo D<br />

therefore be used for other<br />

purposes). For safety reasons,<br />

it is advisable to repeat<br />

this operation twice over.<br />

Start<strong>ing</strong> up<br />

The machine does not have a<br />

plug for connect<strong>ing</strong> it to the<br />

mains socket. It is therefore<br />

the responsibility of the user<br />

to fit a plug suitable for his particular<br />

electrical system.<br />

(La Parmigiana S.r.l. refuses<br />

to accept responsibility for<br />

faulty connections or plugs<br />

which are not suitable for the<br />

electrical system).<br />

Connect the plug to the<br />

mains socket, ensur<strong>ing</strong> that<br />

the safety covers (No.2<br />

Photo C) of the basins are<br />

well closed.<br />

Start up the machine by<br />

turn<strong>ing</strong> the main switch to<br />

position 1(No.7 Photo D) and<br />

by press<strong>ing</strong> the green pushbutton<br />

which starts the<br />

hopper (No.9 Photo D) or<br />

that of the press (No.8 Photo<br />

D).<br />

Photo C<br />

15

<strong>16</strong><br />

INSTRUCTIONS<br />

D.55 DV<br />

Second Edition<br />

November 1997<br />

After start<strong>ing</strong> up the machine, ensure<br />

that the blades (No.11 Photo<br />

R page <strong>16</strong>) fitted inside the basins<br />

are turn<strong>ing</strong> in the direction shown<br />

by the arrow (No.12 Photo R page<br />

<strong>16</strong>) on the front of the mix<strong>ing</strong> basin<br />

and on the side of the hopper<br />

(No.12 Photo C).<br />

If they are not turn<strong>ing</strong> in the right<br />

direction, it is sufficient (for threephase<br />

motors) to change the position<br />

of two of the three phase<br />

wires in the electrical plug (as illustrated<br />

in the diagram on the<br />

right) leav<strong>ing</strong> the yellow-green<br />

earth wire in the same position.<br />

In the case of s<strong>ing</strong>le-phase motors,<br />

the adjustment requires an<br />

electrician.<br />

To stop the machine, press the<br />

red button on the electric board.<br />

In the event of emergency, turn<br />

off the main safety switch (No.7<br />

Photo D).<br />

La Parmigiana S.r.l. Fidenza ITALY<br />

Photo R<br />

Photo D

INSTRUCTIONS<br />

D.55 DV<br />

Second Edition<br />

November1997<br />

Production<br />

La Parmigiana S.r.l. Fidenza ITALY<br />

For maximum safety in the use of the machine, the operator must stand in the<br />

position described on page 10.<br />

17

18<br />

INSTRUCTIONS<br />

D.55 DV La Parmigiana S.r.l. Fidenza ITALY<br />

Second Edition<br />

November1997<br />

Ingredients<br />

The machine can operate with any kind of flour: common wheat, durum wheat, graded,<br />

special, wholemeal etc. flour. The last type of flour must, however, be sieved in order to<br />

eliminate any bran flakes.<br />

The quantity of flour poured into the basin must always be weighed so as to be able to<br />

gauge exactly how much liquid is to be added in order to obtain the correct consistency<br />

of the pasta dough.<br />

The eggs must be broken in a separate container so that the die does not become<br />

clogged with fragments of eggshell.<br />

The eggs, moreover, must be beaten so that the yolks and the whites are well mixed.<br />

Recipes<br />

Unfilled durum wheat pasta<br />

100% durum wheat flour<br />

310-350 cl. water per kilogram.<br />

Unfilled egg pasta<br />

Pasta dough -a-<br />

100% “00” type common wheat flour<br />

4/6 eggs per kilogram of flour<br />

Water until 310-350 cl. of total liquid per kilogram of flour is reached<br />

Pasta dough -b-<br />

50/70% “00” type common wheat flour<br />

30/50% durum wheat flour<br />

3/5 eggs per kilogram of flour<br />

Water until 310-350 cl. of total liquid per kilogram of flour is reached<br />

Sheets for filled pasta (such as ravioli)<br />

Pasta dough -a-<br />

100% “00” type common wheat flour.<br />

3/4 eggs per kilogram of flour (it is advisable not to add all the egg whites, so that the<br />

pasta sheet is more elastic and hence easier to work with).<br />

Slightly more water than that used for the normal pasta dough, so that the consistency is<br />

crumbly but with larger granules.<br />

Pasta dough -b-<br />

70/80% “00” type common wheat flour.<br />

20/30% durum wheat flour.<br />

2-3 eggs per kilogram of flour (better without the whites).<br />

Slightly more water than that used for the normal pasta dough, so that the consistency is<br />

crumbly but with larger granules.

INSTRUCTIONS<br />

D.55 DV<br />

Second Edition<br />

November1997<br />

La Parmigiana S.r.l. Fidenza ITALY<br />

Pasta with wholemeal flour<br />

100% sieved wholemeal flour.<br />

33% water.<br />

If the consistency of the product is not satisfactory, a small amount of “00” type common<br />

wheat flour (10/20%) can be added and/or<br />

2-3 eggs so that it maintains a firm consistency when cooked.<br />

Suggestions<br />

The percentage of liquid might have to be varied depend<strong>ing</strong> on the type of flour used.<br />

The pasta dough can also be affected by atmospheric conditions.<br />

Avoid work<strong>ing</strong> in:<br />

- strong draughts<br />

- temperatures below or above 20-30°C<br />

- humidity below or above 40-50%.<br />

If a lot of eggs are used, the pasta will have a better consistency when cooked, but the<br />

dough will be less elastic (and hence more difficult to work with).<br />

Prepar<strong>ing</strong> the pasta dough<br />

Preliminary steps<br />

Immerse the die chosen in hot water (40-50°C). Keep the filter (No.18 Photo K) and the<br />

die-hold<strong>ing</strong> r<strong>ing</strong> nut (No.<strong>16</strong> Photo K), already clean and dry, to hand.<br />

Do not fit any of these components onto the machine before mak<strong>ing</strong> the pasta<br />

dough.<br />

Handle them with care to avoid dropp<strong>ing</strong> them on your feet.<br />

The weight of the components is<br />

as follows:<br />

Worm screw (No.14) 1.8 Kg<br />

Die (No.17) 1.6 Kg<br />

R<strong>ing</strong> nut (No.<strong>16</strong>) 2.5 Kg<br />

Photo K<br />

19

20<br />

INSTRUCTIONS<br />

D.55 DV La Parmigiana S.r.l. Fidenza ITALY<br />

Second Edition<br />

November1997<br />

Start<strong>ing</strong> production<br />

The pasta dough is always made, and can<br />

only be made, in the upper basin (hopper).<br />

Do not pour common or durum wheat flour<br />

in the lower basin (press).<br />

If this should happen accidentally, empty the<br />

basin carefully (take off the die if it has already<br />

been fitted) and remove all traces of dry flour<br />

which can interfere with the knead<strong>ing</strong> of the<br />

pasta dough).<br />

Open the cover (No.2 Photo F), pour in the<br />

required quantity of the common or durum<br />

wheat flour, close the cover and start the<br />

machine.<br />

Pour the liquid through the grid on the cover<br />

(Photo G) in the quantity indicated accord<strong>ing</strong><br />

to the recipe be<strong>ing</strong> followed; pour it slowly to<br />

allow the flour to absorb it.<br />

The pasta dough must be kneaded for 10/15<br />

minutes, until it becomes granulous (No. 6<br />

Photo C1), the granules be<strong>ing</strong> approximately<br />

the size of coffee beans.<br />

It must be crumbly to the touch (and easy to<br />

compact when you press it between your<br />

hands) but must not leave traces of flour on<br />

your palms.<br />

When the pasta dough is ready, insert the<br />

worm screw (No. 14 Photo K page 21) into the<br />

pasta outlet channel (No. 37 Photo K) and fit it<br />

into place at the end of the channel. The worm<br />

screw is correctly engaged if it rotates when<br />

the machine is started.<br />

Open the basin covers (No. 2 Photo C page<br />

19), pull the lock<strong>ing</strong> knob (No. 15 Photo C page<br />

21) and turn the hopper over.<br />

Transfer the pasta dough manually to the basin<br />

below.<br />

Lift the hopper, br<strong>ing</strong><strong>ing</strong> it back to its original<br />

position and close the press cover. Start the<br />

motor so that the first handful of pasta comes<br />

out of the channel (Photo L page 21) in order<br />

to remove any dry traces of dough from<br />

previous operations, which could interfere with<br />

procedures.<br />

Photo F<br />

Photo G<br />

Photo C1

INSTRUCTIONS<br />

D.55 DV<br />

Second Edition<br />

November1997<br />

Stop the motor, then fit the dry die<br />

(No. 17 Photo K) and the filter (No.<br />

18 Photo K), in this order, into the<br />

die-hold<strong>ing</strong> r<strong>ing</strong> nut (No. <strong>16</strong> Photo<br />

K).<br />

Screw the r<strong>ing</strong> nut right down onto<br />

the channel in a clockwise direction<br />

(No. 37 Photo K) ensur<strong>ing</strong> that<br />

the rods (No. 22 Photo V) are kept<br />

horizontal.<br />

Fit the two trays (No.23 Photo V)<br />

into the guides located on the<br />

machine cas<strong>ing</strong>. The base of the<br />

trays is made of net to allow the<br />

pasta to be continuously ventilated.<br />

If this feature is not required,<br />

fit the air protection (supplied with<br />

the ravioli mak<strong>ing</strong> machine) immediately<br />

under the lower tray.<br />

Start the machine up again and<br />

throw away the first pasta produced,<br />

which serves to clean the<br />

die.<br />

Now production can begin.<br />

Long pasta (Photo V)<br />

Spaghetti, tagliatelle, bucatini<br />

The above described machine can<br />

produce long pasta.<br />

Let the pasta fall onto the trays<br />

(No. 23 Photo V) and cut it to<br />

the required length, keep<strong>ing</strong> a<br />

distance of 30-40 cm between<br />

the cutt<strong>ing</strong> point and the die<br />

so that the pasta can be wellventilated<br />

by the fan incorporated<br />

in the machine.<br />

La Parmigiana S.r.l. Fidenza ITALY<br />

Photo K<br />

Photo C<br />

Photo L<br />

Photo V<br />

21

22<br />

INSTRUCTIONS<br />

D.55 DV La Parmigiana S.r.l. Fidenza ITALY<br />

Second Edition<br />

November1997<br />

Short pasta (Photo T)<br />

Short pasta is produced by us<strong>ing</strong><br />

an electric dough- cutter with an<br />

electronic speed variator (No.25<br />

Photo T).<br />

Insert the knife (No. 21 Photo Q)<br />

into the pin of the pasta cutter<br />

motor until it strikes home, fitt<strong>ing</strong> it<br />

into the groove.<br />

Check that the cutt<strong>ing</strong> side of<br />

the blade is fac<strong>ing</strong> the die.<br />

Insert the pasta-cutter unit (blade<br />

and motor) on the rods (No.22<br />

Photo Q) of the die-hold<strong>ing</strong> nut,<br />

center<strong>ing</strong> the two washers with<br />

your f<strong>ing</strong>ers (No. 26 Photo Q).<br />

When the pasta-cutter comes into<br />

contact with the rod striker, release<br />

the washers, which will automatically<br />

fit into the notches, thus<br />

lock<strong>ing</strong> the pasta-cutter.<br />

Fit the motor plug into the socket<br />

located on the side of the cas<strong>ing</strong><br />

(No. 28 Photo Q) and turn on the<br />

switch (No. 29 Photo D).<br />

The cutt<strong>ing</strong> speed, and therefore<br />

the pasta length, can be adjusted<br />

by us<strong>ing</strong> the potentiometer knob<br />

(No. 30 Photo D) or by chang<strong>ing</strong><br />

the three knives provided.<br />

Always start the pasta-cutter<br />

first and then the press, never<br />

viceversa, as the knife could get<br />

damaged.<br />

Always turn the pasta-cutter<br />

motor off before remov<strong>ing</strong> it<br />

from the rods of the die-hold<strong>ing</strong><br />

nut.<br />

Photo T<br />

Photo Q<br />

Photo D

INSTRUCTIONS<br />

D.55 DV<br />

Second Edition<br />

November1997<br />

Die substitution<br />

Stop the machine by press<strong>ing</strong> the push-button<br />

(No.8 Photo D page 14).<br />

Switch the pasta-cutter motor off and remove<br />

it. Then place it on the special supports located<br />

on the left side of the machine (Photo J).<br />

To unscrew the die-hold<strong>ing</strong> r<strong>ing</strong> nut, insert the<br />

special lever provided (No. 32 Photo S) into<br />

the holes (No. 33 Photo S) located on the diehold<strong>ing</strong><br />

r<strong>ing</strong> nut.<br />

After remov<strong>ing</strong> the die and the filter, clean the<br />

threads of the r<strong>ing</strong> nut (No. <strong>16</strong> Photo U) and<br />

the channel (No. 37 Photo U) by means of the<br />

special brush (No. 34 Photo U).<br />

Then fit another die.<br />

After use, always keep the dies soaked in<br />

water.<br />

Cool<strong>ing</strong> (see draw<strong>ing</strong>)<br />

After the machine has been operat<strong>ing</strong> for 25-<br />

30 minutes, cool<strong>ing</strong> is necessary to maintain<br />

the right dough extrusion temperature and<br />

increase the output by 20-30%.<br />

Connect a suitably-sized hose to the water<br />

mains and the water inlet and a second hose<br />

to the outlet and the clarified water discharge.<br />

Open the mains tap to let out a trickle of water.<br />

La Parmigiana S.r.l. Fidenza ITALY<br />

Photo J<br />

Photo S<br />

Photo U<br />

23

INSTRUCTIONS<br />

D.55 DV<br />

Second Edition<br />

November1997<br />

La Parmigiana S.r.l. Fidenza ITALY<br />

Clean<strong>ing</strong> and<br />

Maintenance<br />

All clean<strong>ing</strong> and maintenance operations must be carried out with the main<br />

switch off.<br />

25

26<br />

INSTRUCTIONS<br />

D.55 DV La Parmigiana S.r.l. Fidenza ITALY<br />

Second Edition<br />

November1997<br />

Clean<strong>ing</strong><br />

Turn the main switch off (No. 7 Photo D page<br />

15).<br />

Remove the die-hold<strong>ing</strong> r<strong>ing</strong> nut (No. <strong>16</strong> Photo<br />

K) by insert<strong>ing</strong> the special lever (No. 32 Photo<br />

S) in the holes (No. 33 Photo S) and lever<strong>ing</strong><br />

upwards. Remove the die and the filter (Nos.<br />

17-18 Photo K), leav<strong>ing</strong> the worm screw fitted.<br />

The two basins, the hopper (Photo T1) and the<br />

press (Photo R page 27) are equipped with<br />

detachable mix<strong>ing</strong> shafts (No. 11 Photo R-T1)<br />

to enable thorough clean<strong>ing</strong> of the parts in<br />

contact with the pasta dough.<br />

In order to facilitate the disassembl<strong>ing</strong> of the<br />

lower basin shaft, check that the knife blade near<br />

the front wall of the basin is fac<strong>ing</strong> upwards.<br />

If it is not, switch the machine on and let the<br />

blade-hold<strong>ing</strong> shaft rotate until it is in position.<br />

In order to disassemble the various shafts,<br />

loosen the lock nuts (No. 40 Photo T1) and<br />

unscrew the r<strong>ing</strong> nuts (No. 38 Photo T1) until<br />

the blade-hold<strong>ing</strong> shafts are completely free.<br />

Clean the hopper inside with a sponge or a<br />

damp cloth; if necessary, rotate it to remove any<br />

traces of dry pasta.<br />

Clean the press in the same way and push all<br />

the scraps through the pasta outlet.<br />

Turn the main switch on and rotate the worm<br />

screw for a few seconds so that all the scraps<br />

area discharged.<br />

Turn the main switch off again.<br />

Remove the worm screw (No. 14 Photo W page<br />

27) and clean inside the channel (No. 37 Photo<br />

W) with a sponge or a damp cloth; particular<br />

care must be taken in clean<strong>ing</strong> the grooves,<br />

us<strong>ing</strong> a special tool (No. 32 Photo W) in order<br />

to remove all pasta scraps.<br />

Photo K<br />

PhotoS<br />

Photo T1

INSTRUCTIONS<br />

D.55 DV<br />

Second Edition<br />

November1997<br />

Wash the worm screw and fit it back<br />

into the channel.<br />

The worm screw might become<br />

scratched dur<strong>ing</strong> operation; this<br />

does not cause any damage in itself,<br />

but it is however advisable to<br />

smooth the surface as much as<br />

possible by us<strong>ing</strong> sand paper or a<br />

fine file.<br />

Re-assemble both mix<strong>ing</strong> shafts,<br />

tighten the r<strong>ing</strong>-nut (No.38 Photo T1<br />

page 26) but not too much, then<br />

secure it with the lock nut (No. 40<br />

Photo T1).<br />

Clean the external thread of the<br />

channel (No. 37 Photo U) and the<br />

internal thread of the die-hold<strong>ing</strong> r<strong>ing</strong><br />

nut (No. <strong>16</strong> Photo U), and lubricate<br />

them with vaseline oil.<br />

After use, keep the die and the filter<br />

soaked in water in order to prevent<br />

the dough remain<strong>ing</strong> in the holes<br />

from dry<strong>ing</strong>.<br />

Keep all dies, even those which<br />

are seldom used, soaked in water<br />

and remember to change it at<br />

least twice a day.<br />

Precautions<br />

Do not use a jet of water to clean<br />

the machine and never immerse<br />

the die-hold<strong>ing</strong> r<strong>ing</strong> nut (No. <strong>16</strong><br />

Photo U) in water.<br />

Never fit a die or a filter that have<br />

not been soaked in water, because<br />

they might contain dried pasta<br />

dough.<br />

If this occurs, boil them before use<br />

until the dough softens again.<br />

La Parmigiana S.r.l. Fidenza ITALY<br />

Photo F<br />

Photo W<br />

Photo U<br />

27

28<br />

INSTRUCTIONS<br />

D.55 DV La Parmigiana S.r.l. Fidenza ITALY<br />

Second Edition<br />

November1997<br />

Periodical check-ups<br />

Check daily that the safety system<br />

connected to the mix<strong>ing</strong> basin covers,<br />

the microswitch and the control wheel<br />

(Draw<strong>ing</strong> E 143, page 29) is operat<strong>ing</strong><br />

correctly.<br />

Periodically check (every 100 work<strong>ing</strong> hours)<br />

the motor belt (No. 6 Photo X) tension<strong>ing</strong> and,<br />

should they be loose, adjust the screw<br />

located under the motor base (No. 35 Photo<br />

X).<br />

Every 2/3 months disconnect the electric<br />

plug, remove the rear cover and grease the<br />

chain (No. 5 Photo B).<br />

Check monthly or every 200 hours of work the<br />

bolts lock<strong>ing</strong> that fix the reducer to the<br />

structure of the machine.<br />

The concerned bolts ane indicated in the picture<br />

B1, two of them are on the right side and the other<br />

two on the left side of the structure.<br />

Check that there are no oil leaks between the<br />

extrusion channel flange and the cas<strong>ing</strong> or<br />

inside the extrusion channel itself.<br />

If an oil leak is detected, replace the seal<strong>ing</strong><br />

r<strong>ing</strong> (No. 28 draw<strong>ing</strong> 6).<br />

CAUTION: This operation should be<br />

carried out by a skilled technician.<br />

To replace the seal r<strong>ing</strong>, remove the screws<br />

secur<strong>ing</strong> the extrusion channel to the mix<strong>ing</strong><br />

basin.<br />

Remove the nuts secur<strong>ing</strong> the extrusion<br />

channel to the cas<strong>ing</strong>, then extract the<br />

extrusion channel.<br />

At this point, remove the seal<strong>ing</strong> r<strong>ing</strong> from<br />

the reduction gear flange (No. 32 draw<strong>ing</strong> 6)<br />

by lever<strong>ing</strong> it off with a screwdriver.<br />

Put a new r<strong>ing</strong> on, then fit on the extrusion<br />

channel firmly tighten<strong>ing</strong> the screws and nuts.<br />

Dwg. 6<br />

Photo X<br />

Photo B<br />

Photo B1

INSTRUCTIONS<br />

D.55 DV<br />

Second Edition<br />

November1997<br />

La Parmigiana S.r.l. Fidenza ITALY<br />

Safety cover<br />

Draw<strong>ing</strong> E143 shows in detail the safety system which comes into operation whenever<br />

one of the mix<strong>ing</strong> basin covers moves.<br />

This system must always be in perfect work<strong>ing</strong> order, it therefore requires daily<br />

checks.<br />

Check that disc 2 is firmly secured by nut 5 and washer 4 and that rotates at the same<br />

time as the cover.<br />

Check that the contact pin of limit switch 7 is operat<strong>ing</strong> correctly (it must slide smoothly<br />

and a “click” must be heard when it makes contact).<br />

Check that the disc is aligned with the contact pin of limit switch 7 (draw<strong>ing</strong> 1).<br />

Do not tamper with the safety system.<br />

Never operate the machine if the safety system is not in perfect work<strong>ing</strong> order.<br />

Dwg 1 Dwg E143<br />

29

30<br />

INSTRUCTIONS<br />

D.55 DV La Parmigiana S.r.l. Fidenza ITALY<br />

Second Edition<br />

November1997

INSTRUCTIONS<br />

D.55 DV<br />

Second Edition<br />

November1997<br />

Spares<br />

La Parmigiana S.r.l. Fidenza ITALY<br />

For piece replacement always use Original Spares.<br />

Do not wait for the pieces to be worn out.<br />

Replac<strong>ing</strong> a piece at the right time means improv<strong>ing</strong> machine performance and avoid<strong>ing</strong><br />

worse damage.<br />

31

32<br />

INSTRUCTIONS<br />

D.55 DV La Parmigiana S.r.l. Fidenza ITALY<br />

Second Edition<br />

November1997<br />

Table E143<br />

Safety cover<br />

2 Camme in alluminio<br />

3 Rosetta 8x24<br />

4 Rosetta 6x18<br />

5 Dado cieco M6<br />

6 Vite M4x20<br />

7 Fine corsa<br />

8 Raccordo<br />

9 Guaina 10x14<br />

10 Raccordo<br />

11 Ghiera 1/4 Gas<br />

12 Dado autobloccante M8<br />

13 Rosetta 8,4x17<br />

14 Vite M8x15

INSTRUCTIONS<br />

D.55 DV<br />

Second Edition<br />

November1997<br />

QS1 Sezionatore<br />

TC Trasformatore<br />

KM1 Contattore pressa<br />

KM2 Contattore tramoggia<br />

FR1 Relè Termico Pressa<br />

FR2 Relè Termico Tramoggia<br />

SB0 Pulsante Emergenza<br />

SA1 Selettore<br />

SB2 Pulsan. arresto pressa<br />

SB4 Pulsan. arresto tramoggia<br />

SB1-HL1 Pulsan. luminoso marcia pressa<br />

La Parmigiana S.r.l. Fidenza ITALY<br />

Diagram E 171<br />

SB3-HL2 Pulsan. luminoso marcia tramoggia<br />

HLO Segnale Luminoso Bianco<br />

UF1 Regolatore Velocità<br />

UF1 Manopola<br />

XA Morsettiera<br />

XP Connettore<br />

SQ1 Finecorsa Vasca Inferiore<br />

SQ2 Finecorsa Vasca Superiore<br />

M1 Motore Pressa<br />

M2 Motore Tramoggia<br />

M3 Motore Tagliapasta<br />

33

34<br />

INSTRUCTIONS<br />

D.55 DV La Parmigiana S.r.l. Fidenza ITALY<br />

Second Edition<br />

November1997<br />

QS1 Sezionatore<br />

TC Trasformatore<br />

KM1 Contattore pressa<br />

KM2 Contattore tramoggia<br />

FR1 Relè Termico Pressa<br />

FR2 Relè Termico Tramoggia<br />

SB0 Pulsante Emergenza<br />

SA1 Selettore<br />

SB2 Pulsan. arresto pressa<br />

SB4 Pulsan. arresto tramoggia<br />

SB1-HL1 Pulsan. luminoso marcia pressa<br />

Diagram E 171<br />

SB3-HL2 Pulsan. luminoso marcia tramoggia<br />

HLO Segnale Luminoso Bianco<br />

UF1 Regolatore Velocità<br />

UF1 Manopola<br />

XA Morsettiera<br />

XP Connettore<br />

SQ1 Finecorsa Vasca Inferiore<br />

SQ2 Finecorsa Vasca Superiore<br />

M1 Motore Pressa<br />

M2 Motore Tramoggia<br />

M3 Motore Tagliapasta

INSTRUCTIONS<br />

D.55 DV<br />

Second Edition<br />

November1997<br />

1 Telaio per Pasta<br />

5 Perno fissaggio Vasca<br />

6 Sostegni Tagliapasta<br />

7 Carcassa<br />

10 Ventola<br />

12 Motore<br />

15 Puleggia Motore<br />

19 C<strong>ing</strong>hia A53<br />

20 Coperchio posteriore<br />

26 Vite M8x90<br />

27 Perno Piano Motore<br />

Table E49 Frame<br />

La Parmigiana S.r.l. Fidenza ITALY<br />

28 Ruota normale<br />

29 Piano Motore<br />

33 Ruota con Freno<br />

35 Pomolo bloccaggio Vasca<br />

40 Coperchio superiore<br />

52 Presa di Corrente<br />

35

36<br />

INSTRUCTIONS<br />

D.55 DV La Parmigiana S.r.l. Fidenza ITALY<br />

Second Edition<br />

November1997<br />

Table E66 Reductor<br />

3 Coperchio<br />

4 Guarnizione<br />

5 Ruota dentata z=174<br />

6 Chiavetta 6x6x18<br />

7 Vite M4x6<br />

8 Ghiera<br />

9 Cuscinetto 6004<br />

10 Flangia Alluminio<br />

11 Tendicatena<br />

13 Puleggia D=267<br />

<strong>16</strong> Pignone z=12<br />

17 Paraolio 22x38x7<br />

18 Chiavetta 6x5x18<br />

19 Flangia forata<br />

20 Cuscinetto 62/22 2RS<br />

21 Ingranaggio elicoidale z=19<br />

22 Scatola Riduttore<br />

24 Cuscinetto 7204 BEP<br />

25 Flangia ghisa<br />

28 Paraolio 50x65x8<br />

29 Perno con Innesto<br />

30 Cuscinetto 51306<br />

32 Flangia reggispinta<br />

33 Cuscinetto 6006<br />

42 Anello di guida

INSTRUCTIONS<br />

D.55 DV<br />

Second Edition<br />

November1997<br />

Table E37/51<br />

Extruder and Lower Basin<br />

1 Cavo completo<br />

2 Copritaglierino<br />

4 Motore Taglierino<br />

5 Supporto Motore<br />

6 Cuscinetto 6004<br />

7 Anello<br />

8 Perno curvo<br />

10 Perno scorrevole<br />

11 Molla<br />

12 Ghiera<br />

14 Rosetta di blocco<br />

17 Coltello 1 lama<br />

18 Coltello 4 lame<br />

20 Dado portatrafile<br />

21 Coltello 2 lame<br />

22 Vite coclea<br />

23 Vite prigioniera<br />

24 Canale di estrusione<br />

27 Bocchettone per acqua<br />

28 Copriflangia<br />

30 Salvatrafile<br />

La Parmigiana S.r.l. Fidenza ITALY<br />

31 Trafila<br />

38 Flangia tagliapasta<br />

40 Coperchio carter<br />

104 Coperchio<br />

106 Ghiera<br />

107 Controghiera<br />

108 Albero con pale<br />

109 Paraolio 30x52x7<br />

110 Perno con Innesto<br />

112 Corona z=75<br />

113 Cuscinetto 6205-2RS<br />

114 Boccola<br />

1<strong>16</strong> Cuscinetto 7205-2RS<br />

117 Testa di Perno<br />

122 Flangia anteriore<br />

123 Vasca<br />

125 Perno filettato<br />

126 Bussola di guida<br />

128 Supporto interno<br />

129 Maglia di giunzione<br />

130 Catena 3/8 “<br />

37

38<br />

INSTRUCTIONS<br />

D.55 DV La Parmigiana S.r.l. Fidenza ITALY<br />

Second Edition<br />

November1997<br />

Table E46-02 Upper Basin<br />

1 Perno filettato<br />

4 Motore<br />

5 Motoriduttore 1:28<br />

9 Antiurto per Vasca<br />

11 Maniglia Ribaltamento<br />

12 Cuscinetto 6205<br />

14 Paraolio 30x42x7<br />

15 Supporto Motoriduttore<br />

<strong>16</strong> Perno trasmissione<br />

17 Bussola di guida<br />

18 Ghiera<br />

19 Controghiera<br />

20 Albero impastatore<br />

21 Vasca impastatrice<br />

24 Pomolo di chiusura Coperchio<br />

29 Coperchio Vasca<br />

30 Boccola<br />

32 Molla ribaltamento<br />

33 Flangia sinistra<br />

34 Testa bloccaperno

INSTRUCTIONS<br />

D.55 DV<br />

Second Edition<br />

November1997<br />

Spare parts request form (module M1-e)<br />

Photocopy this, fill out and send it by Post of Fax to:<br />

La Parmigiana S.r.l. Fidenza ITALY<br />

Customer..........................................................................E.G. Reg. no...........................................<br />

street........................................................... no........ City..............................................................<br />

Postal code....................... Country...................................Tel.............................Fax......................<br />

e-mail............................................................................................................................................<br />

Machine Model ......<strong>D55dv</strong>...... Type ......N........... Date acquisition of year ...................<br />

..<br />

Serial number (on one side of the machine)......................................................................................<br />

Voltage........................Volt Frequency..............Hz No. of Phases............................<br />

(Refer to the relevant draw<strong>ing</strong>s and diagrams)<br />

No<br />

Draw<strong>ing</strong><br />

Position<br />

cod. Article<br />

Description<br />

LA PARMIGIANA s.r.l.<br />

Technical assistance service<br />

Via La Bionda, 33<br />

43036 Fidenza (PR) ITALY<br />

Tel.0524/528688-529004 Fax 0524/524465<br />

laparmigiana@laparmigiana.com<br />

Quantity<br />

Date (Stamp and Signature)<br />

................................... ...................................................................<br />

Under<br />

Guarantee<br />

(Yes/No)<br />

XII-03<br />

39

40<br />

INSTRUCTIONS<br />

D.55 DV La Parmigiana S.r.l. Fidenza ITALY<br />

Second Edition<br />

November1997<br />

GUARANTEE CERTIFICATE “LA PARMIGIANA”<br />

La Parmigiana s.r.l. guarantees the product from eventual manufactur<strong>ing</strong> defects<br />

of all parts for a period of 1 (one) year from the date shown on the purchas<strong>ing</strong><br />

receipt.<br />

The guarantee applies only for the replacements of the defective parts.<br />

The guarantee can be applied when the defective part is handed over to<br />

La Parmigiana s.r.l.<br />

Via La Bionda,33 43036<br />

Fidenza (PR) ITALY<br />

together with a copy of the purchas<strong>ing</strong> receipt of the machine and the declaration<br />

form (last page of the instruction manual) which has to be completed by the buyer.<br />

La Parmigiana reserves the right to replace the part or repair it.<br />

The guarantee does not cover the follow<strong>ing</strong> :<br />

- eventual defects result<strong>ing</strong> from operations carried out on the machine by the<br />

client without prior authorisation by La Parmigiana;<br />

- periodic maintenance and repairs or replacements of parts used normally or<br />

which are worn out;<br />

- transportation costs of the part from the client to La Parmigiana and vice versa,<br />

and the relative risks;<br />

- labour costs related to the defective part;<br />

- coverage of any damages, direct or indirect, due to breakdown of the machine<br />

itself (inclusive but not limited to the fact if the machine is used for other purposes<br />

than those foreseen: incorrect handl<strong>ing</strong> and disregard<strong>ing</strong> instructions in the<br />

manual of La Parmigiana relat<strong>ing</strong> to its use and maintenance, installation and<br />

non-adherence to technical and safety instructions, incorrect installation of<br />

software), and repairs carried out by the client to defective plants or equipment<br />

to which the machine has been connected, and other conditions and causes<br />

not attributed to La Parmigiana;<br />

- in any case the guarantee is not valid if the machine is handled by persons not<br />

authorised by La Parmigiana.<br />

La Parmigiana s.r.l. Fidenza