Mast climbers and hoists Mast climbers and hoists - Vertikal.net

Mast climbers and hoists Mast climbers and hoists - Vertikal.net

Mast climbers and hoists Mast climbers and hoists - Vertikal.net

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Modular <strong>and</strong> commonality are the<br />

latest buzzwords in the industry.<br />

AS Climbers of Italy pitched this<br />

feature strongly when it opened for<br />

business a couple of years ago <strong>and</strong><br />

has already built up a significant<br />

business on both sides of the<br />

Atlantic. More recently Hek has<br />

announced that it will launch its<br />

new modular system range of<br />

light, medium <strong>and</strong> heavy duty<br />

mast climbing products at Bauma.<br />

Meanwhile Alimak is promising to<br />

unveil some new electronics <strong>and</strong><br />

remote access features that might<br />

just change the face of the rack<br />

<strong>and</strong> pinion business?<br />

Is this the age of<br />

the mast climber?<br />

With an increasing number of<br />

producers coming into the mainstream<br />

market with ever wider <strong>and</strong> more<br />

versatile product ranges, the market<br />

for mast <strong>climbers</strong> is likely to continue<br />

to grow at an increasing pace.<br />

House builders throughout Europe<br />

rarely think twice about the access<br />

they use for new builds - they<br />

typically call in their regular<br />

scaffold company <strong>and</strong> have them<br />

erect façade scaffold. In the UK <strong>and</strong><br />

Irel<strong>and</strong> this has typically been tube<br />

<strong>and</strong> coupler, due to its cheap purchase<br />

cost <strong>and</strong> almost unlimited versatility.<br />

However tube <strong>and</strong> coupler requires<br />

a high level of expertise to both<br />

design <strong>and</strong> erect <strong>and</strong> it is also<br />

becoming increasingly difficult to<br />

find young people who are prepared<br />

to put up with the manual labour<br />

involved, not to mention the challenges<br />

of erecting it safely without breaking<br />

manual h<strong>and</strong>ling rules.<br />

<strong>Mast</strong> <strong>climbers</strong> are in comparison<br />

relatively easy to erect or install,<br />

do not require the same degree of<br />

reconfiguring <strong>and</strong> those using them<br />

can work at the absolute ideal<br />

height. There is no climbing up<br />

<strong>and</strong> down on ladders <strong>and</strong> of course<br />

materials can be loaded at ground<br />

level, which is far safer than in the<br />

air. With such benefits it is certain<br />

that the mast climber is set to<br />

go mainstream <strong>and</strong> grab a far<br />

great slice of the market than it<br />

currently enjoys.<br />

The heaviest Fraco mast<strong>climbers</strong><br />

can incorporate a variety of<br />

craneage. Note the hoist<br />

access to the crane.<br />

Scanclimber<br />

follows slip<br />

form tower<br />

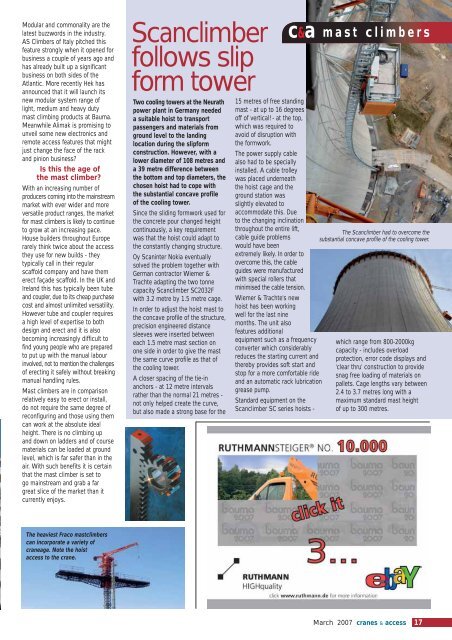

Two cooling towers at the Neurath<br />

power plant in Germany needed<br />

a suitable hoist to transport<br />

passengers <strong>and</strong> materials from<br />

ground level to the l<strong>and</strong>ing<br />

location during the slipform<br />

construction. However, with a<br />

lower diameter of 108 metres <strong>and</strong><br />

a 39 metre difference between<br />

the bottom <strong>and</strong> top diameters, the<br />

chosen hoist had to cope with<br />

the substantial concave profile<br />

of the cooling tower.<br />

Since the sliding formwork used for<br />

the concrete pour changed height<br />

continuously, a key requirement<br />

was that the hoist could adapt to<br />

the constantly changing structure.<br />

Oy Scaninter Nokia eventually<br />

solved the problem together with<br />

German contractor Wiemer &<br />

Trachte adapting the two tonne<br />

capacity Scanclimber SC2032F<br />

with 3.2 metre by 1.5 metre cage.<br />

In order to adjust the hoist mast to<br />

the concave profile of the structure,<br />

precision engineered distance<br />

sleeves were inserted between<br />

each 1.5 metre mast section on<br />

one side in order to give the mast<br />

the same curve profile as that of<br />

the cooling tower.<br />

A closer spacing of the tie-in<br />

anchors - at 12 metre intervals<br />

rather than the normal 21 metres -<br />

not only helped create the curve,<br />

but also made a strong base for the<br />

c&a<br />

15 metres of free st<strong>and</strong>ing<br />

mast - at up to 16 degrees<br />

off of vertical! - at the top,<br />

which was required to<br />

avoid of disruption with<br />

the formwork.<br />

The power supply cable<br />

also had to be specially<br />

installed. A cable trolley<br />

was placed underneath<br />

the hoist cage <strong>and</strong> the<br />

ground station was<br />

slightly elevated to<br />

accommodate this. Due<br />

to the changing inclination<br />

throughout the entire lift,<br />

cable guide problems<br />

would have been<br />

extremely likely. In order to<br />

overcome this, the cable<br />

guides were manufactured<br />

with special rollers that<br />

minimised the cable tension.<br />

Wiemer & Trachte's new<br />

hoist has been working<br />

well for the last nine<br />

months. The unit also<br />

features additional<br />

equipment such as a frequency<br />

converter which considerably<br />

reduces the starting current <strong>and</strong><br />

thereby provides soft start <strong>and</strong><br />

stop for a more comfortable ride<br />

<strong>and</strong> an automatic rack lubrication<br />

grease pump.<br />

St<strong>and</strong>ard equipment on the<br />

Scanclimber SC series <strong>hoists</strong> -<br />

mast <strong>climbers</strong><br />

The Scanclimber had to overcome the<br />

substantial concave profile of the cooling tower.<br />

which range from 800-2000kg<br />

capacity - includes overload<br />

protection, error code displays <strong>and</strong><br />

'clear thru' construction to provide<br />

snag free loading of materials on<br />

pallets. Cage lengths vary between<br />

2.4 to 3.7 metres long with a<br />

maximum st<strong>and</strong>ard mast height<br />

of up to 300 metres.<br />

March 2007 cranes & access<br />

17