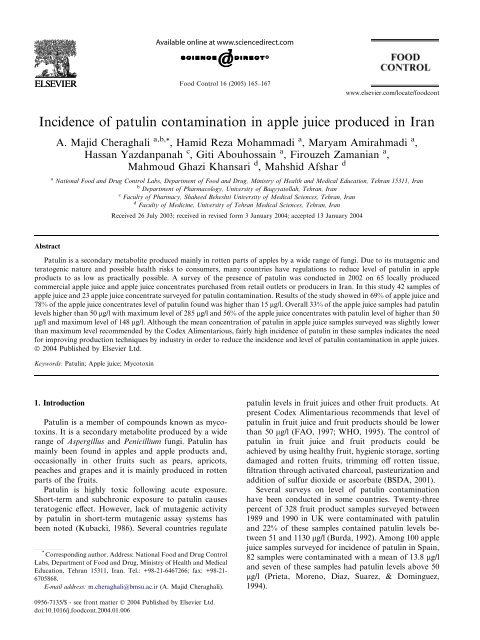

Incidence of patulin contamination in apple juice produced in Iran

Incidence of patulin contamination in apple juice produced in Iran

Incidence of patulin contamination in apple juice produced in Iran

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Incidence</strong> <strong>of</strong> <strong>patul<strong>in</strong></strong> <strong>contam<strong>in</strong>ation</strong> <strong>in</strong> <strong>apple</strong> <strong>juice</strong> <strong>produced</strong> <strong>in</strong> <strong>Iran</strong><br />

Abstract<br />

A. Majid Cheraghali a,b,* , Hamid Reza Mohammadi a , Maryam Amirahmadi a ,<br />

Hassan Yazdanpanah c , Giti Abouhossa<strong>in</strong> a , Firouzeh Zamanian a ,<br />

Mahmoud Ghazi Khansari d , Mahshid Afshar d<br />

a<br />

National Food and Drug Control Labs, Department <strong>of</strong> Food and Drug, M<strong>in</strong>istry <strong>of</strong> Health and Medical Education, Tehran 15311, <strong>Iran</strong><br />

b<br />

Department <strong>of</strong> Pharmacology, University <strong>of</strong> Baqyyatollah, Tehran, <strong>Iran</strong><br />

c<br />

Faculty <strong>of</strong> Pharmacy, Shaheed Beheshti University <strong>of</strong> Medical Sciences, Tehran, <strong>Iran</strong><br />

d<br />

Faculty <strong>of</strong> Medic<strong>in</strong>e, University <strong>of</strong> Tehran Medical Sciences, Tehran, <strong>Iran</strong><br />

Received 26 July 2003; received <strong>in</strong> revised form 3 January 2004; accepted 13 January 2004<br />

Patul<strong>in</strong> is a secondary metabolite <strong>produced</strong> ma<strong>in</strong>ly <strong>in</strong> rotten parts <strong>of</strong> <strong>apple</strong>s by a wide range <strong>of</strong> fungi. Due to its mutagenic and<br />

teratogenic nature and possible health risks to consumers, many countries have regulations to reduce level <strong>of</strong> <strong>patul<strong>in</strong></strong> <strong>in</strong> <strong>apple</strong><br />

products to as low as practically possible. A survey <strong>of</strong> the presence <strong>of</strong> <strong>patul<strong>in</strong></strong> was conducted <strong>in</strong> 2002 on 65 locally <strong>produced</strong><br />

commercial <strong>apple</strong> <strong>juice</strong> and <strong>apple</strong> <strong>juice</strong> concentrates purchased from retail outlets or producers <strong>in</strong> <strong>Iran</strong>. In this study 42 samples <strong>of</strong><br />

<strong>apple</strong> <strong>juice</strong> and 23 <strong>apple</strong> <strong>juice</strong> concentrate surveyed for <strong>patul<strong>in</strong></strong> <strong>contam<strong>in</strong>ation</strong>. Results <strong>of</strong> the study showed <strong>in</strong> 69% <strong>of</strong> <strong>apple</strong> <strong>juice</strong> and<br />

78% <strong>of</strong> the <strong>apple</strong> <strong>juice</strong> concentrates level <strong>of</strong> <strong>patul<strong>in</strong></strong> found was higher than 15 lg/l. Overall 33% <strong>of</strong> the <strong>apple</strong> <strong>juice</strong> samples had <strong>patul<strong>in</strong></strong><br />

levels higher than 50 lg/l with maximum level <strong>of</strong> 285 lg/l and 56% <strong>of</strong> the <strong>apple</strong> <strong>juice</strong> concentrates with <strong>patul<strong>in</strong></strong> level <strong>of</strong> higher than 50<br />

lg/l and maximum level <strong>of</strong> 148 lg/l. Although the mean concentration <strong>of</strong> <strong>patul<strong>in</strong></strong> <strong>in</strong> <strong>apple</strong> <strong>juice</strong> samples surveyed was slightly lower<br />

than maximum level recommended by the Codex Alimentarious, fairly high <strong>in</strong>cidence <strong>of</strong> <strong>patul<strong>in</strong></strong> <strong>in</strong> these samples <strong>in</strong>dicates the need<br />

for improv<strong>in</strong>g production techniques by <strong>in</strong>dustry <strong>in</strong> order to reduce the <strong>in</strong>cidence and level <strong>of</strong> <strong>patul<strong>in</strong></strong> <strong>contam<strong>in</strong>ation</strong> <strong>in</strong> <strong>apple</strong> <strong>juice</strong>s.<br />

Ó 2004 Published by Elsevier Ltd.<br />

Keywords: Patul<strong>in</strong>; Apple <strong>juice</strong>; Mycotox<strong>in</strong><br />

1. Introduction<br />

Patul<strong>in</strong> is a member <strong>of</strong> compounds known as mycotox<strong>in</strong>s.<br />

It is a secondary metabolite <strong>produced</strong> by a wide<br />

range <strong>of</strong> Aspergillus and Penicillium fungi. Patul<strong>in</strong> has<br />

ma<strong>in</strong>ly been found <strong>in</strong> <strong>apple</strong>s and <strong>apple</strong> products and,<br />

occasionally <strong>in</strong> other fruits such as pears, apricots,<br />

peaches and grapes and it is ma<strong>in</strong>ly <strong>produced</strong> <strong>in</strong> rotten<br />

parts <strong>of</strong> the fruits.<br />

Patul<strong>in</strong> is highly toxic follow<strong>in</strong>g acute exposure.<br />

Short-term and subchronic exposure to <strong>patul<strong>in</strong></strong> causes<br />

teratogenic effect. However, lack <strong>of</strong> mutagenic activity<br />

by <strong>patul<strong>in</strong></strong> <strong>in</strong> short-term mutagenic assay systems has<br />

been noted (Kubacki, 1986). Several countries regulate<br />

* Correspond<strong>in</strong>g author. Address: National Food and Drug Control<br />

Labs, Department <strong>of</strong> Food and Drug, M<strong>in</strong>istry <strong>of</strong> Health and Medical<br />

Education, Tehran 15311, <strong>Iran</strong>. Tel.: +98-21-6467266; fax: +98-21-<br />

6705868.<br />

E-mail address: m.cheraghali@bmsu.ac.ir (A. Majid Cheraghali).<br />

0956-7135/$ - see front matter Ó 2004 Published by Elsevier Ltd.<br />

doi:10.1016/j.foodcont.2004.01.006<br />

Food Control 16 (2005) 165–167<br />

www.elsevier.com/locate/foodcont<br />

<strong>patul<strong>in</strong></strong> levels <strong>in</strong> fruit <strong>juice</strong>s and other fruit products. At<br />

present Codex Alimentarious recommends that level <strong>of</strong><br />

<strong>patul<strong>in</strong></strong> <strong>in</strong> fruit <strong>juice</strong> and fruit products should be lower<br />

than 50 lg/l (FAO, 1997; WHO, 1995). The control <strong>of</strong><br />

<strong>patul<strong>in</strong></strong> <strong>in</strong> fruit <strong>juice</strong> and fruit products could be<br />

achieved by us<strong>in</strong>g healthy fruit, hygienic storage, sort<strong>in</strong>g<br />

damaged and rotten fruits, trimm<strong>in</strong>g <strong>of</strong>f rotten tissue,<br />

filtration through activated charcoal, pasteurization and<br />

addition <strong>of</strong> sulfur dioxide or ascorbate (BSDA, 2001).<br />

Several surveys on level <strong>of</strong> <strong>patul<strong>in</strong></strong> <strong>contam<strong>in</strong>ation</strong><br />

have been conducted <strong>in</strong> some countries. Twenty-three<br />

percent <strong>of</strong> 328 fruit product samples surveyed between<br />

1989 and 1990 <strong>in</strong> UK were contam<strong>in</strong>ated with <strong>patul<strong>in</strong></strong><br />

and 22% <strong>of</strong> these samples conta<strong>in</strong>ed <strong>patul<strong>in</strong></strong> levels between<br />

51 and 1130 lg/l (Burda, 1992). Among 100 <strong>apple</strong><br />

<strong>juice</strong> samples surveyed for <strong>in</strong>cidence <strong>of</strong> <strong>patul<strong>in</strong></strong> <strong>in</strong> Spa<strong>in</strong>,<br />

82 samples were contam<strong>in</strong>ated with a mean <strong>of</strong> 13.8 lg/l<br />

and seven <strong>of</strong> these samples had <strong>patul<strong>in</strong></strong> levels above 50<br />

lg/l (Prieta, Moreno, Diaz, Suarez, & Dom<strong>in</strong>guez,<br />

1994).

166 A. Majid Cheraghali et al. / Food Control 16 (2005) 165–167<br />

All <strong>of</strong> the 215 samples <strong>of</strong> <strong>apple</strong> <strong>juice</strong> concentrates<br />

were analyzed <strong>in</strong> Turkey for <strong>patul<strong>in</strong></strong> <strong>in</strong> 1994 were contam<strong>in</strong>ated<br />

rang<strong>in</strong>g from 7 to 376 lg/l and 98 <strong>of</strong> these<br />

samples conta<strong>in</strong>ed <strong>patul<strong>in</strong></strong> level above 50 lg/l (Gokmen<br />

& Acar, 1998). In Brazil 111 samples <strong>of</strong> processed fruit<br />

<strong>juice</strong>s and 38 samples <strong>of</strong> sound fruits were analyzed for<br />

<strong>patul<strong>in</strong></strong>. Only one out <strong>of</strong> 30 samples <strong>of</strong> <strong>apple</strong> <strong>juice</strong> was<br />

found positive at 17 lg/l. However, 150–267 lg/kg <strong>of</strong><br />

<strong>patul<strong>in</strong></strong> was found <strong>in</strong> 14 spoiled <strong>apple</strong> samples (De Sylos<br />

& Rodriguez-Amaya, 1999).<br />

2. Materials and methods<br />

Sixty five samples <strong>of</strong> <strong>apple</strong> <strong>juice</strong> and <strong>apple</strong> <strong>juice</strong><br />

concentrate randomly sampled at various retail outlets<br />

and producers <strong>in</strong> <strong>Iran</strong> between 2001 and 2002. Samples<br />

stored below 4 °C before analysis.<br />

For analysis <strong>of</strong> the samples th<strong>in</strong> layer chromatography<br />

(TLC) method reported by the Association <strong>of</strong><br />

Official Analytical Chemists (AOAC, 1984) has been<br />

used. However, a densitometry method us<strong>in</strong>g TLC<br />

scanner was used for quantification <strong>of</strong> <strong>patul<strong>in</strong></strong> <strong>in</strong> samples.<br />

Fifty ml <strong>of</strong> fruit <strong>juice</strong> or concentrate extracted three<br />

times with 50 ml ethyl acetate. Pooled organic phase<br />

dried over 20 g anhydrous sodium sulphate and evaporated<br />

to about 25 ml. The solution cleaned up us<strong>in</strong>g a<br />

silica gel column runn<strong>in</strong>g with 200 ml benzene/ethyl<br />

acetate (25:75). Effluent was collected and evaporated<br />

under stream <strong>of</strong> nitrogen gas.<br />

Residue was dissolved <strong>in</strong> 500 ll <strong>of</strong> chlor<strong>of</strong>orm and 20<br />

ll spotted on TLC plate. Thirty microliters <strong>of</strong> work<strong>in</strong>g<br />

standard <strong>of</strong> 10 lg/ml <strong>of</strong> <strong>patul<strong>in</strong></strong> was also spotted on the<br />

TLC plate. Plates were developed us<strong>in</strong>g toluene/ethyl<br />

acetate/formic acid 90% (50:40:10). After dry<strong>in</strong>g, plates<br />

have been scanned us<strong>in</strong>g TLC scanner (model E3, CA-<br />

MAG equipped with mercury lamp) at 278 nm. Concentration<br />

<strong>of</strong> <strong>patul<strong>in</strong></strong> was calculated after correct<strong>in</strong>g for<br />

recovery which was calculated between 80% and 115%.<br />

3. Results<br />

Results from the survey <strong>of</strong> commercial <strong>apple</strong> <strong>juice</strong>/<br />

concentrate for <strong>patul<strong>in</strong></strong> <strong>contam<strong>in</strong>ation</strong> are presented <strong>in</strong><br />

Table 1.<br />

Table 1<br />

Results <strong>of</strong> survey for <strong>patul<strong>in</strong></strong> <strong>contam<strong>in</strong>ation</strong>s <strong>of</strong> <strong>apple</strong> <strong>juice</strong> and concentrates<br />

Sample type No. Patul<strong>in</strong> concentration<br />

50 lg/ml<br />

Max. (lg/l) Mean ± SD<br />

Apple <strong>juice</strong> 42 13 (31%) 15 (36%) 14 (33%) 285.3 48.1 ± 9.5<br />

Apple <strong>juice</strong><br />

concentrate 23 5 (22%) 5 (22%) 13 (56%) 148.8 61.7 ± 41.6<br />

Total 65 18 (28%) 20 (31%) 27 (41%) 285.3 54.9 ± 25.6

Published surveys <strong>in</strong> 1994 reported <strong>in</strong>cidence <strong>of</strong> <strong>patul<strong>in</strong></strong> <strong>in</strong><br />

fruit <strong>juice</strong>s sampled <strong>in</strong> Spa<strong>in</strong> and Austria between 43%<br />

and 85% with <strong>patul<strong>in</strong></strong> levels <strong>of</strong> 10–185 lg/l (Pittet, 1998).<br />

In present study 42 samples <strong>of</strong> <strong>apple</strong> <strong>juice</strong> and 23<br />

<strong>apple</strong> <strong>juice</strong> concentrate surveyed for <strong>patul<strong>in</strong></strong> <strong>contam<strong>in</strong>ation</strong>.<br />

Results <strong>of</strong> the study showed <strong>in</strong> 69% <strong>of</strong> <strong>apple</strong><br />

<strong>juice</strong>s and 78% <strong>of</strong> the <strong>apple</strong> <strong>juice</strong> concentrates level <strong>of</strong><br />

<strong>patul<strong>in</strong></strong> was found to be higher than 15 lg/l. Overall 33%<br />

<strong>of</strong> the <strong>apple</strong> <strong>juice</strong> samples had <strong>patul<strong>in</strong></strong> levels higher than<br />

50 lg/l with maximum level <strong>of</strong> 285 lg/l and 56% <strong>of</strong> the<br />

<strong>apple</strong> <strong>juice</strong> concentrate with <strong>patul<strong>in</strong></strong> level <strong>of</strong> higher than<br />

50 lg/l and maximum level <strong>of</strong> 148 lg/l (Table 1).<br />

Although the mean concentration <strong>of</strong> <strong>patul<strong>in</strong></strong> <strong>in</strong> <strong>apple</strong><br />

<strong>juice</strong> samples surveyed was slightly lower than maximum<br />

level recommended by the Codex Alimentarious, fairly<br />

high <strong>in</strong>cidence <strong>of</strong> the <strong>patul<strong>in</strong></strong> <strong>in</strong> <strong>apple</strong> <strong>juice</strong> marketed <strong>in</strong><br />

<strong>Iran</strong> <strong>in</strong>dicates the need for awareness <strong>of</strong> the <strong>apple</strong><br />

<strong>in</strong>dustry to <strong>patul<strong>in</strong></strong> <strong>contam<strong>in</strong>ation</strong> <strong>in</strong> fruit and the<br />

implementation <strong>of</strong> improved techniques for the production<br />

<strong>of</strong> <strong>apple</strong> products <strong>in</strong> order to reduce the <strong>in</strong>cidence<br />

and level <strong>of</strong> <strong>patul<strong>in</strong></strong> <strong>contam<strong>in</strong>ation</strong> <strong>in</strong> <strong>apple</strong> <strong>juice</strong>s. It was<br />

also previously reported that it is possible, even when<br />

process<strong>in</strong>g <strong>apple</strong>s that may be pre-disposed to fungal<br />

<strong>contam<strong>in</strong>ation</strong>, to reduce significantly <strong>patul<strong>in</strong></strong> concentrations<br />

to an acceptable level. It has been reported that<br />

the mean <strong>patul<strong>in</strong></strong> level <strong>in</strong> the non-processed fruit was 920<br />

ng/g follow<strong>in</strong>g an <strong>in</strong>itial water treatment step. Additional<br />

removal <strong>of</strong> rotten and damaged fruit prior to further<br />

process<strong>in</strong>g, significantly reduced the mean <strong>patul<strong>in</strong></strong> level<br />

<strong>in</strong> the <strong>juice</strong> to 55 ng/g (Sydenham et al., 1995).<br />

References<br />

AOAC (1984). In S. Williams (Ed.), Official Methods <strong>of</strong> Analysis (pp.<br />

496–497). Virg<strong>in</strong>ia, USA: Association <strong>of</strong> Official Analytical Chemists.<br />

BSDA (2001). Code <strong>of</strong> practice to m<strong>in</strong>imize the occurrence <strong>of</strong> <strong>patul<strong>in</strong></strong> <strong>in</strong><br />

<strong>apple</strong> <strong>juice</strong> (2nd ed.). London: British S<strong>of</strong>t dr<strong>in</strong>k Association.<br />

A. Majid Cheraghali et al. / Food Control 16 (2005) 165–167 167<br />

Brackett, R. E., & Marth, E. H. (1979). Ascorbic acid and ascorbate<br />

cause disappearance <strong>of</strong> <strong>patul<strong>in</strong></strong> from buffer solutions and <strong>apple</strong><br />

<strong>juice</strong>. Journal <strong>of</strong> Food Protection, 42, 864–866.<br />

Bolger, M. (2002). Integration <strong>of</strong> risk assessment and management. In<br />

Jo<strong>in</strong>t FAO/WHO sem<strong>in</strong>ar on the safety/risk analysis <strong>of</strong> contam<strong>in</strong>ants:<br />

genotoxic carc<strong>in</strong>ogens, Rotterdam, The Netherlands.<br />

Burda, K. (1992). <strong>Incidence</strong> <strong>of</strong> <strong>patul<strong>in</strong></strong> <strong>in</strong> <strong>apple</strong>, pear and mixed fruit<br />

products marketed <strong>in</strong> New South Wales. Journal <strong>of</strong> Food Protection,<br />

55, 796–798.<br />

De Sylos, C. M., & Rodriguez-Amaya, D. B. (1999). <strong>Incidence</strong> <strong>of</strong><br />

<strong>patul<strong>in</strong></strong> <strong>in</strong> fruits and fruit <strong>juice</strong>s marketed <strong>in</strong> Camp<strong>in</strong>as, Brazil.<br />

Food Additive and Contam<strong>in</strong>ants, 16, 71–74.<br />

FAO (1997). Worldwide regulations for mycotox<strong>in</strong>s 1995. Food and<br />

Agriculture Organization Food and Nutrition Paper 64 (pp. 7–28).<br />

Rome: FAO.<br />

Gokmen, V., & Acar, J. (1998). <strong>Incidence</strong> <strong>of</strong> <strong>patul<strong>in</strong></strong> <strong>in</strong> <strong>apple</strong> <strong>juice</strong><br />

concentrates <strong>produced</strong> <strong>in</strong> Turkey. Journal <strong>of</strong> Chromatography A,<br />

815, 99–102.<br />

Kubacki, S. J. (1986). The analysis and occurrence <strong>of</strong> <strong>patul<strong>in</strong></strong> <strong>in</strong> <strong>apple</strong><br />

<strong>juice</strong>. In P.S. Steyn & R. Vleggaar (Eds.), Mycotox<strong>in</strong>s and<br />

phycotox<strong>in</strong>s––a collection <strong>of</strong> <strong>in</strong>vited papers presented at the sixth<br />

<strong>in</strong>ternational IUPAC symposium on mycotox<strong>in</strong>s and phycotox<strong>in</strong>s,<br />

Pretoria, South Africa, 1985 (pp. 293–304). Amsterdam: Elsevier.<br />

Leggott, N. L., & Shephard, G. S. (2001). Patul<strong>in</strong> <strong>in</strong> South Africa<br />

commercial <strong>apple</strong> products. Food Control, 12, 73–76.<br />

MAFF (1993). Mycotox<strong>in</strong>s: third report. In Food surveillance paper no.<br />

36 (pp. 46–50). M<strong>in</strong>istry <strong>of</strong> Agriculture, Fisheries and Food.<br />

London: HMSO.<br />

Pittet, A. (1998). Natural occurrence <strong>of</strong> mycotox<strong>in</strong>s <strong>in</strong> foods and<br />

feeds––an updated review. Revue de Medec<strong>in</strong>e Veter<strong>in</strong>aire, 149,<br />

479–492.<br />

Prieta, J., Moreno, M. A., Diaz, S., Suarez, G., & Dom<strong>in</strong>guez, L.<br />

(1994). Survey <strong>of</strong> <strong>patul<strong>in</strong></strong> <strong>in</strong> <strong>apple</strong> <strong>juice</strong> and children’s <strong>apple</strong> food by<br />

the biphasic dialysis membrane procedure. Journal <strong>of</strong> Agricultural<br />

and Food Chemistry, 42, 1701–1703.<br />

Sydenham, E. W., Vismer, H. F., Marasas, W. F. O, Brown, N.,<br />

Schlechter, M., Westhuizen, L., & Rheeder, J. P. (1995). Reduction<br />

<strong>of</strong> <strong>patul<strong>in</strong></strong> <strong>in</strong> <strong>apple</strong> <strong>juice</strong> samples––<strong>in</strong>fluence <strong>of</strong> <strong>in</strong>itial process<strong>in</strong>g.<br />

Food Control, 6, 195–200.<br />

Wilson, D. M., & Nuovo, G. J. (1973). Patul<strong>in</strong> production <strong>in</strong> <strong>apple</strong>s<br />

decayed by Penicillium expansum. Applied Microbiology, 26, 124–<br />

125.<br />

WHO (1995). Evaluation <strong>of</strong> certa<strong>in</strong> food additives and contam<strong>in</strong>ants.<br />

In 44th report <strong>of</strong> the jo<strong>in</strong>t Food and Agriculture Additives/World<br />

Health Organization Expert Committee on Food Additives, Technical<br />

Report Series 859 (pp. 36–39), Geneva, Switzerland: World<br />

Health Organization.