SAC Clutch tool set SAC KupplungswerkzeugSatz Outil de ... - Unior

SAC Clutch tool set SAC KupplungswerkzeugSatz Outil de ... - Unior

SAC Clutch tool set SAC KupplungswerkzeugSatz Outil de ... - Unior

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

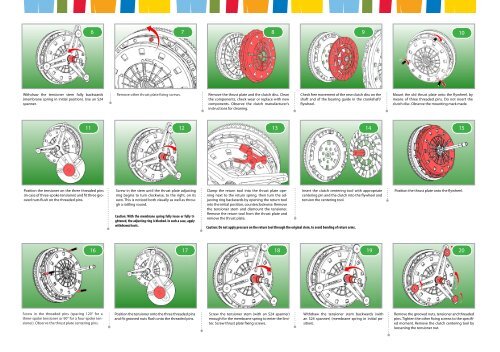

Withdraw the tensioner stem fully backwards<br />

(membrane spring in initial position). Use an S24<br />

spanner.<br />

11<br />

Position the tensioner on the three threa<strong>de</strong>d pins<br />

(in case of three-spoke tensioner) and fit three grooved<br />

nuts flush on the threa<strong>de</strong>d pins.<br />

Screw in the threa<strong>de</strong>d pins (spacing 120° for a<br />

three-spoke tensioner or 90° for a four-spoke tensioner).<br />

Observe the thrust plate centering pins.<br />

6 7 8 9 10<br />

Remove other thrust plate fixing screws. Remove the thrust plate and the clutch disc. Clean Check free movement of the new clutch disc on the<br />

the components, check wear or replace with new shaft and of the bearing gui<strong>de</strong> in the crankshaft/<br />

components. Observe the clutch manufacturer's<br />

instructions for cleaning.<br />

flywheel.<br />

12<br />

Screw in the stem until the thrust plate adjusting<br />

ring begins to turn clockwise, to the right, on its<br />

own. This is noticed both visually as well as through<br />

a rattling sound.<br />

Caution: With the membrane spring fully loose or fully tightened,<br />

the adjusting ring is blocked. In such a case, apply<br />

withdrawal <strong>tool</strong>s.<br />

Position the tensioner onto the three threa<strong>de</strong>d pins<br />

and fit grooved nuts flush onto the threa<strong>de</strong>d pins.<br />

Clamp the return <strong>tool</strong> into the thrust plate opening<br />

next to the return spring, then turn the adjusting<br />

ring backwards by opening the return <strong>tool</strong><br />

into the initial position, counterclockwise. Remove<br />

the tensioner stem and dismount the tensioner.<br />

Remove the return <strong>tool</strong> from the thrust plate and<br />

remove the thrust plate.<br />

Caution: Do not apply pressure on the return <strong>tool</strong> through the original stem, to avoid bending of return arms.<br />

Screw the tensioner stem (with an S24 spanner)<br />

enough for the membrane spring to enter the limiter.<br />

Screw thrust plate fixing screws.<br />

Withdraw the tensioner stem backwards (with<br />

an S24 spanner) (membrane spring in initial position).<br />

Mount the old thrust plate onto the flywheel, by<br />

means of three threa<strong>de</strong>d pins. Do not insert the<br />

clutch disc. Observe the mounting mark ma<strong>de</strong>.<br />

13 14<br />

15<br />

Insert the clutch centering <strong>tool</strong> with appropriate<br />

centering pin and the clutch into the flywheel and<br />

tension the centering <strong>tool</strong>.<br />

16 17 18 19<br />

Position the thrust plate onto the flywheel.<br />

20<br />

Remove the grooved nuts, tensioner and threa<strong>de</strong>d<br />

pins. Tighten the other fixing screws to the specified<br />

moment. Remove the clutch centering <strong>tool</strong> by<br />

loosening the tensioner nut.