500-700 cfm - APC

500-700 cfm - APC

500-700 cfm - APC

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

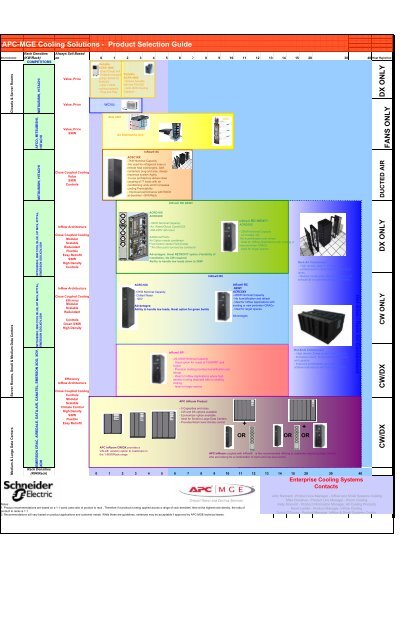

<strong>APC</strong>-MGE Cooling Solutions - Product Selection Guide<br />

Environment<br />

Closets & Server Rooms<br />

Server Rooms, Small & Medium Data Centers<br />

Medium & Large Data Centers<br />

Medium &<br />

Large Data<br />

Centers<br />

Rack Densities<br />

(KW/Rack)<br />

COMPETITORS<br />

MITSUBISHI, HITACHI<br />

AFCO, MITSUBISHI,<br />

HITACHI<br />

MITSUBISHI, HITACHI<br />

MITSUBISHI, IBM COOL BLUE, HP MCS, RITTAL,<br />

EMERSON XDO,XDV,XDH<br />

MITSUBISHI, IBM COOL BLUE, HP MCS, RITTAL,<br />

EMERSON XDO,XDV,XDH<br />

EMERSON CRAC, AIREDALE, DATA-AIR, CANATEL, EMERSON XDO, XDV,<br />

XDH<br />

Always Sell Based<br />

on 0 1 2 3 4 5 6 X - AXIS 7 8 9 10 11 12 13 14 15 20 30 40 Heat Rejection<br />

Value, Price<br />

Value, Price<br />

Value, Price<br />

$/KW<br />

Close Coupled Cooling<br />

Value<br />

$/KW<br />

Controls<br />

InRow Architecture<br />

Close Coupled Cooling<br />

Modular<br />

Scalable<br />

Redundant<br />

Flexible<br />

Easy Retrofit<br />

$/KW<br />

High Density<br />

Controls<br />

InRow Architecture<br />

Close Coupled Cooling<br />

Efficiency<br />

Modular<br />

Scalable<br />

Redundant<br />

Controls<br />

Green $/KW<br />

High Density<br />

Efficiency<br />

InRow Architecture<br />

Close Coupled Cooling<br />

Controls<br />

Modular<br />

Scalable<br />

Climate Control<br />

High Density<br />

$/KW<br />

Flexible<br />

Easy Retrofit<br />

Portable<br />

ACPA 1000<br />

- Easy Closet sell<br />

-Portable compact<br />

design allows for<br />

flexibility<br />

- Upto 1.5KW<br />

cooling capacity<br />

- Plug and Play<br />

WCVU<br />

Side ADU<br />

Side ADU<br />

Air Distribution Unit<br />

Portable<br />

ACPA 4000<br />

- Shares benefits<br />

with the PA1000<br />

- Upto 4KW Cooling<br />

Capacity<br />

Air Distribution Unit<br />

ACRC1XX<br />

<strong>APC</strong> InRoom CW/DX provides a<br />

VALUE solution option to customers in<br />

the 1-5KW/Rack range<br />

InRow® SC<br />

ACSC1XX<br />

-7KW Nominal Capacity<br />

-No need for refrigerant lines or<br />

remote heat exchangers. Selfcontained,<br />

plug-and-play, design<br />

maximize system Agility<br />

-In-row architecture allows close<br />

coupling of IT loads with air<br />

conditioning units which increases<br />

cooling Predictability<br />

- Improved performance with RACS<br />

at densities >3KW/Rack<br />

ACRD1XX<br />

ACRD2XX<br />

InRow® RD NEW!!<br />

-10KW Nominal Capacity<br />

-Air, Water/Glycol Cooled DX<br />

-208-230V 3ph input<br />

Additional Parts:<br />

Air Option needs condenser<br />

Fluid Option needs Fluid Cooler<br />

**All other parts sourced by contractor<br />

Advantages: Great RETROFIT option, Flexibility of<br />

installation, No CW required<br />

Ability to handle low loads down to 2KW<br />

-17KW Nominal Capacity<br />

- Chilled Water<br />

- 120V<br />

Advantages:<br />

Ability to handle low loads, Great option for green builds<br />

InRow® RP<br />

Rack Densities<br />

(KW/Rack) 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 20 30 40<br />

InRow® RC<br />

ARU<br />

-29-45KW Nominal Capacity<br />

- Great option for loads of 10KW/RP and<br />

higher<br />

- Precision cooling provides humidification and<br />

reheat<br />

- Ideal for InRow Applications where high<br />

density is being deployed with no existing<br />

cooling<br />

- Ideal for larger spaces<br />

<strong>APC</strong> InRoom Product<br />

- 5 Capacities and sizes<br />

- CW and DX options available<br />

- Economizer option available<br />

- Ideal for Small to Large Data Centers<br />

- Provides Room level climate control<br />

Notes:<br />

1. Product recommendations are based on a 1:1 worst case ratio of product to rack . Therefore if a product is being applied across a range of rack densities, then at the highest rack density, the ratio of<br />

product to racks is 1:1<br />

2. Recommendations will vary based on product applications and customer needs. While these are guidelines, variances may be acceptable if approved by <strong>APC</strong>-MGE technical teams.<br />

InRow® RD NEW!!!<br />

ACRD5XX<br />

- 29KW Nominal Capacity<br />

- Air Cooled DX<br />

-No humidification and reheat<br />

- Ideal for InRow Applications with existing or<br />

new perimeter CRACs<br />

- Ideal for larger spaces<br />

InRow® RC<br />

NEW!!<br />

ACRC5XX<br />

- 47KW Nominal Capacity<br />

- No humidification and reheat<br />

- Ideal for InRow Applications with<br />

existing or new perimeter CRACs<br />

- Ideal for larger spaces<br />

Advantages:<br />

B TCO l b ild<br />

+<br />

OR<br />

+<br />

OR OR<br />

Rack Air Containment<br />

- High density racks 1-10 racks<br />

- containment for indval racks and multipule<br />

racks.<br />

- Modular construction allows for supply and<br />

exhaust air or just exhaust air containment<br />

Hot Ailse Containment<br />

Hot Aisle Containment<br />

- High density Zones greater than 10 racks<br />

- Increases retuen temperature and cooling<br />

unit capacity<br />

- Improves predictability and ability to<br />

achieve redundacny with less cooling units.<br />

<strong>APC</strong> InRoom coupled with InRow® is the recommended offering to customers deploying High Density<br />

who are looking for a combination of room and row level control<br />

Hot Ailse / Rack Air Containment<br />

Enterprise Cooling Systems<br />

Contacts<br />

DX ONLY<br />

CW/DX<br />

FANS ONLY<br />

DUCTED AIR<br />

DX ONLY<br />

CW ONLY<br />

CW/DX<br />

John Niemann -Product Line Manager - InRow and Small Systems Cooling<br />

Mike Donahue - Product Line Manager - Room Cooling<br />

Kelly Sinovich - Product Information Manager, All Cooling Products<br />

Kevin Lemke - Product Manager, InRow Cooling<br />

Zurica D'Souza - Product Manager, InRow & Small Systems Cooling

<strong>APC</strong>-MGE Cooling Solutions - Product Selection Guide<br />

Cooling<br />

Configs<br />

InRow<br />

vs.<br />

Room<br />

Cooling<br />

Fast<br />

Facts<br />

DID YOU KNOW?<br />

Performance<br />

Limitations of Legacy Architecture<br />

with raised floor air distribution Upper limits of raised<br />

KW (Sensible Heat) = Delta T x CFM / 3145<br />

Rack<br />

Power<br />

(kW)<br />

that can be<br />

cooled by one<br />

tile with this<br />

airflow<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

Typical<br />

Capability<br />

Perf tile<br />

With<br />

Effort<br />

<strong>500</strong>-<strong>700</strong> <strong>cfm</strong><br />

Grate tile<br />

Extreme<br />

Blade Servers<br />

4.5 - 6.5 kW<br />

per Rack<br />

2.5 - 4 kW<br />

per Rack<br />

Standard IT<br />

Equipment<br />

1. 1Kilowatt = 3412 BTU/Hr = 0.28 Ton and 1 Ton = 3.517 Kilowatts = 12,000 BTU/Hr<br />

floor<br />

Impractical<br />

0 0 100 200 300 400 <strong>500</strong> 600 <strong>700</strong> 800 900 1000<br />

[47.2] [94.4] [141.6] [188.8] [236.0] [283.2] [330.4] [377.6] [424.8] [471.9]<br />

Average Per-Rack Power Density = (kW)<br />

2. Heat pumps, refrigerators, and air conditioners, move heat, rather than convert it. The common measures are the coefficient of performance (COP), energy efficiency ratio<br />

(EER), and seasonal energy efficiency ratio (SEER).<br />

3. The concept of air conditioning is known to have been applied in Ancient Rome, where aqueduct water was circulated through the walls of certain houses to cool them.<br />

Similar techniques in medieval Persia involved the use of cisterns and wind towers to cool buildings during the hot season. Modern air conditioning emerged from advances<br />

in chemistry during the 19th century, and the first large-scale electrical air conditioning was invented and used in 1902 by Willis Haviland Carrier.<br />

4. Containment options including RACS and HACS on CW products provide higher ride through capabilities than comparable DX units due to minimum copressor restart<br />

times, and therefore are more widely recommended together in high density applications<br />

5. In The InRow RP DX , during HACS mode, the VFD speed is controlled by the supply temperature in the front of the rack. Therefore, it is independant control loop from the<br />

fan speed. The fan speed is controlled by return air temperature. In the scenario where a load is added to the rack, the return air temperature is affected much quicker than<br />

the supply which is why the fan speed reacts first.<br />

Usable CRAC Capacity<br />

100%<br />

80%<br />

60%<br />

40%<br />

20%<br />

0%<br />

rooom-oriented cooling<br />

row-oriented cooling<br />

rack-oriented cooling<br />

1 2 3 4 5 6 7 8 9 10111213141516171819202122232425<br />

Perimeter Cooling units alone can cool upto 5KW/Rack in IT loads and lose<br />

efficiencies as well as effectiveness beyond this threshold. At loads beyond<br />

this threshold InRow as well as Hybrid (Permeter + InRow) should be<br />

For More Information Read <strong>APC</strong>-MGE WP - 130