Training Aspects of the Hazard Analysis Critical Control Point System

Training Aspects of the Hazard Analysis Critical Control Point System

Training Aspects of the Hazard Analysis Critical Control Point System

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

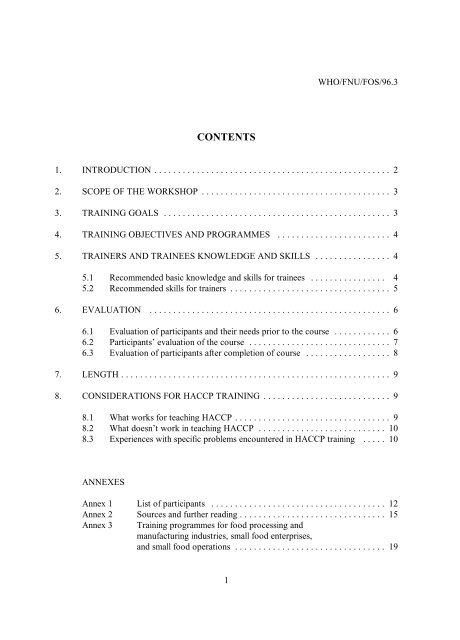

CONTENTS<br />

1<br />

WHO/FNU/FOS/96.3<br />

1. INTRODUCTION .................................................. 2<br />

2. SCOPE OF THE WORKSHOP ........................................ 3<br />

3. TRAINING GOALS ................................................ 3<br />

4. TRAINING OBJECTIVES AND PROGRAMMES ........................ 4<br />

5. TRAINERS AND TRAINEES KNOWLEDGE AND SKILLS ................ 4<br />

5.1 Recommended basic knowledge and skills for trainees ................ 4<br />

5.2 Recommended skills for trainers .................................. 5<br />

6. EVALUATION ................................................... 6<br />

6.1 Evaluation <strong>of</strong> participants and <strong>the</strong>ir needs prior to <strong>the</strong> course ............ 6<br />

6.2 Participants’ evaluation <strong>of</strong> <strong>the</strong> course .............................. 7<br />

6.3 Evaluation <strong>of</strong> participants after completion <strong>of</strong> course .................. 8<br />

7. LENGTH ......................................................... 9<br />

8. CONSIDERATIONS FOR HACCP TRAINING ........................... 9<br />

8.1 What works for teaching HACCP ................................. 9<br />

8.2 What doesn’t work in teaching HACCP ........................... 10<br />

8.3 Experiences with specific problems encountered in HACCP training ..... 10<br />

ANNEXES<br />

Annex 1 List <strong>of</strong> participants ..................................... 12<br />

Annex 2 Sources and fur<strong>the</strong>r reading ............................... 15<br />

Annex 3 <strong>Training</strong> programmes for food processing and<br />

manufacturing industries, small food enterprises,<br />

and small food operations ................................ 19

1. INTRODUCTION<br />

A WHO Workshop on <strong>Training</strong> in <strong>the</strong> <strong>Hazard</strong> <strong>Analysis</strong> <strong>Critical</strong> <strong>Control</strong> <strong>Point</strong> <strong>System</strong><br />

(HACCP) was held in Geneva from 1-2 June 1995.<br />

The Workshop was opened by Dr Motarjemi, Scientist, Food Safety Unit, WHO, on<br />

behalf <strong>of</strong> <strong>the</strong> Director-General. In welcoming <strong>the</strong> participants, Dr Motarjemi underlined <strong>the</strong><br />

importance <strong>of</strong> providing training in strategies to implement <strong>the</strong> HACCP system in food safety<br />

assurance programmes, and referred to <strong>the</strong> recommendations made on this subject by <strong>the</strong><br />

WHO Consultation on <strong>Hazard</strong> <strong>Analysis</strong> <strong>Critical</strong> <strong>Control</strong> <strong>Point</strong> <strong>System</strong>: Concept and<br />

Application, which was held with <strong>the</strong> participation <strong>of</strong> FAO in Geneva (29-31 May 1995). 1<br />

Dr Motarjemi pointed out that <strong>the</strong> application <strong>of</strong> <strong>the</strong> HACCP system has <strong>the</strong> potential to<br />

improve <strong>the</strong> working relationship between food processors and food inspectors. However, to<br />

gain <strong>the</strong> maximum benefit from this particular aspect <strong>of</strong> <strong>the</strong> HACCP system, it is important<br />

that <strong>the</strong> HACCP system is consistently interpreted and applied; o<strong>the</strong>rwise, conflicts may arise.<br />

To this end, <strong>the</strong> training <strong>of</strong> government and food industry personnel needs to be standardized.<br />

And as <strong>the</strong> HACCP system is a fairly new approach to food safety assurance, Dr Motarjemi<br />

advised that training experiences encountered to date should be reviewed and innovative<br />

approaches explored.<br />

The objective <strong>of</strong> <strong>the</strong> Workshop was to exchange information on experiences in HACCP<br />

training and to design training programmes for various target groups. The training<br />

programmes recommended by <strong>the</strong> Workshop will be subsequently used by WHO in its training<br />

activities, and WHO will promote <strong>the</strong>se through collaborating institutions and organizations<br />

which provide HACCP training courses. They can be also used as guidance for trainers who<br />

design training programmes worldwide.<br />

The Workshop elected Mr Spencer Garrett as Chairman, Dr Lahsen Ababouch as<br />

Vice-Chairman, and Dr Derek Buckland as <strong>the</strong> Rapporteur; <strong>the</strong> list <strong>of</strong> participants is given in<br />

Annex 1.<br />

In his closing remarks, Dr Käferstein, Chief, Food Safety Unit, thanked <strong>the</strong> participants for<br />

<strong>the</strong>ir impressive work and remarked that <strong>the</strong> Workshop was a first step towards <strong>the</strong><br />

development <strong>of</strong> a standardized HACCP training programme.<br />

1<br />

<strong>Hazard</strong> <strong>Analysis</strong> <strong>Critical</strong> <strong>Control</strong> <strong>Point</strong> <strong>System</strong>: Concept and Application, Report <strong>of</strong> a WHO Consultation<br />

with <strong>the</strong> participation <strong>of</strong> FAO (Geneva, May 1995). (Unpublished WHO document WHO/FNU/FOS/95.7)<br />

2

2. SCOPE OF THE WORKSHOP<br />

The Workshop recalled <strong>the</strong> recommendations made by <strong>the</strong> WHO Consultation on <strong>Training</strong><br />

Considerations for <strong>the</strong> Application <strong>of</strong> <strong>the</strong> <strong>Hazard</strong> <strong>Analysis</strong> <strong>Critical</strong> <strong>Control</strong> <strong>Point</strong> <strong>System</strong> to<br />

2<br />

Food Processing and Manufacturing (Geneva, March 1993) which had recommended, among<br />

o<strong>the</strong>rs, that training courses should be developed for both food processing and manufacturing<br />

industries as well as for o<strong>the</strong>r parts <strong>of</strong> <strong>the</strong> food chain and,<br />

inter alia, small food enterprises. The Consultation also recommended that, at least initially,<br />

joint HACCP training courses should be organized for government and industry personnel.<br />

Taking into account <strong>the</strong> needs, technical background and know-how <strong>of</strong> various target<br />

groups, and <strong>the</strong> different sizes <strong>of</strong> enterprises, <strong>the</strong> Workshop recommended that three different<br />

training programmes be developed:<br />

i) food processing and manufacturing industries and food/health inspectors<br />

ii) small food enterprises (including food service and catering establishments),<br />

retailers and <strong>the</strong> inspectors covering <strong>the</strong>se enterprises<br />

iii) street food vendors<br />

The Workshop also developed general recommendations which were based on <strong>the</strong> positive<br />

and negative experiences encountered by participants in <strong>the</strong>ir training courses.<br />

3. TRAINING GOALS<br />

The training goals are:<br />

C to promote a common approach for <strong>the</strong> identification <strong>of</strong> hazards, critical control<br />

points and critical limits<br />

C to provide a basic understanding <strong>of</strong> <strong>the</strong> principal HACCP activities and<br />

terminology<br />

C to share knowledge and practical experiences in applying <strong>the</strong> principal HACCP<br />

activities<br />

C to promote an understanding and awareness <strong>of</strong> food safety practices<br />

C to impart <strong>the</strong> skills necessary so that food safety assurance personnel and food<br />

inspectors can use <strong>the</strong> HACCP system appropriately in order to ensure food safety<br />

2<br />

<strong>Training</strong> Considerations for <strong>the</strong> Application <strong>of</strong> <strong>the</strong> <strong>Hazard</strong> <strong>Analysis</strong> <strong>Critical</strong> <strong>Control</strong> <strong>Point</strong> <strong>System</strong> to Food<br />

Processing and Manufacturing. Report <strong>of</strong> a WHO Consultation on <strong>Hazard</strong> <strong>Analysis</strong> <strong>Critical</strong> <strong>Control</strong> <strong>Point</strong> <strong>System</strong><br />

(Geneva, March 1993). (Unpublished WHO document WHO/FNU/FOS/93.3)<br />

3

4. TRAINING OBJECTIVES AND PROGRAMMES<br />

The principles <strong>of</strong> HACCP can be applied across <strong>the</strong> food chain. However, <strong>the</strong> application<br />

<strong>of</strong> <strong>the</strong>se principles can vary depending on <strong>the</strong> type <strong>of</strong> industry or business. Therefore, <strong>the</strong><br />

objectives and training programmes should be adapted to <strong>the</strong> targets and <strong>the</strong>ir particular<br />

needs.<br />

Two approaches for training food inspectors and personnel in food businesses are<br />

presented in Annex 3; one is a proposal for a training course geared for food manufacturing<br />

and processing industries, and <strong>the</strong> o<strong>the</strong>r is intended for small food enterprises. These training<br />

programmes are designed for personnel in food industries/enterprises as well as for<br />

government <strong>of</strong>ficials, e.g. food/health inspectors. Additional training in auditing (e.g. 2 days)<br />

is also recommended for government <strong>of</strong>ficials. An example <strong>of</strong> a course outline for additional<br />

training <strong>of</strong> food/health inspectors carrying out auditing <strong>of</strong> small food enterprises is also given<br />

in Annex 3.<br />

In addition, a third training programme is suggested for very small food operations or<br />

those which carry out simple activities, at <strong>the</strong> operator level, in food service establishments<br />

producing more complex ready-to-eat foods. Street food vendors and small kiosk-type<br />

operators are regarded as falling within this category (Annex 3).<br />

It can be noted that as one moves from <strong>the</strong> large food industry to <strong>the</strong> smaller enterprise <strong>the</strong><br />

training programme becomes less detailed and more simplified, reflecting a certain degree <strong>of</strong><br />

flexibility in <strong>the</strong> application <strong>of</strong> <strong>the</strong> HACCP system, and depending on <strong>the</strong> size and resources <strong>of</strong><br />

<strong>the</strong> establishment in question. The third training programme for very small food operations,<br />

which is fundamentally based on <strong>the</strong> concept <strong>of</strong> <strong>the</strong> HACCP system, illustrates how it can be<br />

used to train food operators, such as street food vendors, in <strong>the</strong> basic issues <strong>of</strong> food safety.<br />

5. TRAINERS AND TRAINEES KNOWLEDGE AND SKILLS<br />

5.1 Recommended basic knowledge and skills for trainees<br />

The trainees’ basic qualifications should include:<br />

C reading, comprehension and ability to write in a technical language<br />

C some technical knowledge <strong>of</strong> <strong>the</strong> commodity or <strong>the</strong> process being used in <strong>the</strong><br />

HACCP training sessions<br />

C a basic knowledge in<br />

4

i) food safety commensurate to <strong>the</strong>ir responsibilities at work, including<br />

government requirements 3<br />

ii) general principles <strong>of</strong> food hygiene, as recommended by <strong>the</strong> Codex Alimentarius<br />

Commission<br />

iii) biological, chemical and physical hazards, and methods for <strong>the</strong>ir control to<br />

ensure basic food safety<br />

iv) basic sanitation requirements, and control methods<br />

C <strong>the</strong> desire to produce/ensure safe food and a willingness to undergo training in<br />

food safety<br />

C where trainees are also <strong>the</strong> owners <strong>of</strong> a business (as in <strong>the</strong> case <strong>of</strong> small food<br />

enterprises), a knowledge <strong>of</strong> <strong>the</strong> possible long-term economic gains using this<br />

concept<br />

5.2 Recommended skills for trainers<br />

The recommended skills required for trainers are:<br />

C knowledge <strong>of</strong> <strong>the</strong> local language, or provision <strong>of</strong> interpretation facilities and<br />

translation, when necessary<br />

C suitable technical background<br />

C good communication skills, including interactive skills and experience in<br />

coordinating interactive exercises<br />

C expert knowledge <strong>of</strong> hazards associated with foods and experience in how to<br />

conduct a hazard analysis<br />

C experience in developing HACCP plans and implementing <strong>the</strong>m<br />

C access to a resource person with expert knowledge about <strong>the</strong> product/process<br />

being dealt with<br />

C flexibility and responsiveness to trainees’ needs with respect to <strong>the</strong>ir skills<br />

3<br />

FAO. Summary <strong>of</strong> proceedings <strong>of</strong> <strong>the</strong> HACCP working group <strong>of</strong> experts convened by FAO to plan a training<br />

<strong>of</strong> trainers course in HACCP for developing countries, Rome, 13-17 February 1995. Food and Agriculture Organization<br />

<strong>of</strong> <strong>the</strong> United Nations, Rome, 1995.<br />

5

6. EVALUATION<br />

For <strong>the</strong> most productive utilization <strong>of</strong> resources and smooth running <strong>of</strong> <strong>the</strong> course, three<br />

main types <strong>of</strong> evaluation will be necessary:<br />

- an evaluation <strong>of</strong> individual participants and <strong>the</strong>ir needs, prior to <strong>the</strong> course<br />

- an evaluation <strong>of</strong> <strong>the</strong> course by <strong>the</strong> individual participants<br />

- an evaluation <strong>of</strong> <strong>the</strong> participants once <strong>the</strong>y have completed <strong>the</strong> course<br />

Such evaluations do not need to be carried out in a formal classroom/<strong>of</strong>fice setting. Any<br />

suitable place can be used, so long as <strong>the</strong> evaluation is carried out in a relaxed manner.<br />

Open-ended and/or multiple choice questions can be put to <strong>the</strong> participants, preferably by<br />

local course organizers ra<strong>the</strong>r than <strong>the</strong> trainers <strong>the</strong>mselves. The trainers would, <strong>of</strong> course,<br />

need feedback from this exercise in order to tailor <strong>the</strong> course to specific needs.<br />

6.1 Evaluation <strong>of</strong> participants and <strong>the</strong>ir needs prior to <strong>the</strong> course<br />

a) Assessment <strong>of</strong> education and background information: Some background information<br />

and an indication as to <strong>the</strong> trainee’s level <strong>of</strong> education may be obtained by asking<br />

simple, non-intrusive questions such as name, current and previous jobs, type <strong>of</strong> food<br />

operations carried out and responsibilities, availability to attend course, etc.<br />

For some target groups such as street food vendors, an assessment <strong>of</strong> basic literacy<br />

skills in <strong>the</strong> language <strong>of</strong> <strong>the</strong> course may be necessary, because when this is missing,<br />

specially-designed course material will be necessary. When candidates are illiterate,<br />

<strong>the</strong>se questions may be answered verbally.<br />

b) Knowledge <strong>of</strong> food safety: In addition to basic education, an assessment <strong>of</strong> each<br />

participant’s knowledge in food safety is necessary. To this end, simple questions<br />

which can be answered by yes/no, or multiple choice answers, could be posed (see<br />

examples given in Box 1).<br />

c) Present attitudes and practices in food handling/inspection: Information on <strong>the</strong><br />

attitudes and current practices in food handling, processing or inspection is essential to<br />

achieve an effective and properly designed course, and this information can also be<br />

used to determine <strong>the</strong> effect <strong>of</strong> <strong>the</strong> course on subsequent knowledge, attitudes and<br />

practices. Such information could be obtained by<br />

C interviewing prospective participants<br />

C observing <strong>the</strong>ir food operations (using a HACCP approach)<br />

C interviewing local authorities<br />

C reviewing existing studies<br />

Inspectors could be asked to give a summary <strong>of</strong> <strong>the</strong>ir current inspection procedures.<br />

6

Examples <strong>of</strong> questions answered by yes/no<br />

C Is it safe to eat food that has been dropped on <strong>the</strong> ground? (Yes/No)<br />

C Is it important to wash hands after using <strong>the</strong> toilet? (Yes/No)<br />

C Is it important to keep flies <strong>of</strong>f food? (Yes/No)<br />

C Is pasteurized or boiled milk safer than raw milk? (Yes/No)<br />

Examples <strong>of</strong> questions with multiple choice answers<br />

C If cooked food has to be kept for more than 5 hours, it should not be kept:<br />

- above 60 °C<br />

- below 10 °C<br />

- at room temperature<br />

C Which <strong>of</strong> <strong>the</strong> following actions will reduce <strong>the</strong> number <strong>of</strong> germs in food?<br />

- washing in clean water<br />

- cooking, boiling<br />

- washing in dirty water<br />

- leaving at room temperature<br />

- wrapping<br />

- cutting in small pieces<br />

C Which surface is <strong>the</strong> most difficult to keep clean?<br />

- plastic<br />

- wood<br />

- metal<br />

Box 1 Examples <strong>of</strong> questions used to evaluate <strong>the</strong> food safety knowledge <strong>of</strong> trainees<br />

participating in a course for small food enterprises<br />

6.2 Participants’ evaluation <strong>of</strong> <strong>the</strong> course<br />

This could be done in group discussion or by completion <strong>of</strong> an anonymous course<br />

evaluation sheet. Participants will probably be less inhibited if <strong>the</strong> latter is used.<br />

Individual units, e.g. lectures, practical exercises, should be assessed on <strong>the</strong> basis <strong>of</strong> a<br />

number <strong>of</strong> factors: clarity, presentation, time allowed, visual aids, relevance, etc., in order to<br />

arrive at an overall numerical score.<br />

as:<br />

Some form <strong>of</strong> overall course assessment may also be carried out, through questions such<br />

- Do you feel you have benefitted from <strong>the</strong> course?<br />

- Would you recommend <strong>the</strong> course to your friends?<br />

In some cases, open-ended questions requiring a definite response may be useful, e.g.:<br />

- How could <strong>the</strong> course be changed to make it more useful to you?<br />

7

6.3 Evaluation <strong>of</strong> participants after completion <strong>of</strong> course<br />

To assess improvement in <strong>the</strong> participants’ awareness, attitude and practices, some <strong>of</strong> <strong>the</strong><br />

questions/observations included in <strong>the</strong> pre-course evaluation could be repeated to monitor <strong>the</strong><br />

impact and effectiveness <strong>of</strong> <strong>the</strong> course.<br />

In addition, evaluation may be carried out with regard to :<br />

- impact <strong>of</strong> <strong>the</strong> course for identification <strong>of</strong> current unsafe food handling or<br />

processing practices, and changes in <strong>the</strong> practices<br />

- practical feasibility <strong>of</strong> improved food handling/processing or inspection<br />

- improved communication/understanding between food inspectors and food<br />

processors, food handlers, or street food vendors<br />

- improved focusing <strong>of</strong> inspection techniques and procedures<br />

- improved inspection function, i.e. education ra<strong>the</strong>r than enforcement<br />

- identification <strong>of</strong> future training needs, and suggestions to meet <strong>the</strong>m<br />

In addition, it is suggested that <strong>the</strong> participants should be contacted some six to nine<br />

months after completing <strong>the</strong> course in order to survey <strong>the</strong>ir long-term reactions (see Box 2).<br />

Surveying participants after 6-9 months with regard to:<br />

- what worked and what didn't; how should <strong>the</strong> course be changed; were participants<br />

able to implement HACCP after <strong>the</strong> course as planned?<br />

- evaluating attitude and commitment to change for industry and food control authorities<br />

- finding out if <strong>the</strong> trainees have a better focus on enhancing food safety<br />

- determining <strong>the</strong> degree <strong>of</strong> acceptance <strong>of</strong> <strong>the</strong>ir changing role by food control authorities<br />

Box 2 Examples <strong>of</strong> questions which can be put to participants from food processing and<br />

manufacturing industries when evaluating <strong>the</strong> course<br />

8

7. LENGTH<br />

The length <strong>of</strong> <strong>the</strong> course will vary depending on whe<strong>the</strong>r or not <strong>the</strong>re are visits to plants or<br />

o<strong>the</strong>r forms <strong>of</strong> food operations as well as on <strong>the</strong> instructors' evaluation <strong>of</strong> <strong>the</strong> individual course<br />

participants. It is recommended that approximately 10-15% <strong>of</strong> <strong>the</strong> course be devoted to basic<br />

principles, 30-40% on hazard identification and determination <strong>of</strong> CCPs, and<br />

45-60% on remaining topics, including auditing. Additional and separate training in auditing is<br />

also recommended for food control authorities.<br />

8. CONSIDERATIONS FOR HACCP TRAINING<br />

The following considerations are useful in teaching <strong>the</strong> HACCP system. It should be<br />

remembered, though, that all <strong>of</strong> <strong>the</strong>m may not apply in every case.<br />

8.1 What works for teaching HACCP<br />

C Knowing <strong>the</strong> audience (e.g. <strong>the</strong> size <strong>of</strong> <strong>the</strong> company or <strong>the</strong> food produced, inspection<br />

responsibilities, sectors <strong>of</strong> industry covered, skill level, etc.). This can be done by<br />

carrying out a survey prior to <strong>the</strong> training course<br />

C Use <strong>of</strong> case studies appropriate to <strong>the</strong> country, product range, and technology<br />

C <strong>Training</strong> materials in local languages, when possible<br />

C Keeping <strong>the</strong> instructor / participant ratio low (l : 5) during exercises, when possible<br />

C Using a participatory training approach, especially one that encourages team work; for<br />

example, by using defective plans or developing a HACCP plan with emphasis on<br />

identification <strong>of</strong> hazards and determination <strong>of</strong> critical control points<br />

C When possible, field visits (e.g. visits to plants or pilot plants, or o<strong>the</strong>r food<br />

operations). Alternatively, video or o<strong>the</strong>r visuals aids to assist in understanding<br />

HACCP<br />

C Experienced tutor who is flexible, and has knowledge <strong>of</strong> <strong>the</strong> commodity and successful<br />

HACCP implementation<br />

C Calling upon services <strong>of</strong> o<strong>the</strong>r experts when working on unfamiliar products<br />

C Testimonials from individuals who have been successful in implementing HACCP<br />

C Minimizing <strong>the</strong> effect <strong>of</strong> supervisory reporting relationships, for example by careful<br />

seating arrangements, and avoiding placing representatives from <strong>the</strong> same company in<br />

<strong>the</strong> same working group<br />

9

C Keeping it simple<br />

C Relating HACCP to current experience (de-mystify)<br />

C Using examples <strong>of</strong> available HACCP plans, as references<br />

C Understanding and taking into consideration local cultures<br />

C Encouraging networking by participants<br />

8.2 What doesn't work in teaching HACCP<br />

C Poor advance planning<br />

C Poor balance in <strong>the</strong> programme (lecture / <strong>the</strong>ory / practical exercises)<br />

C Environmental and business distractions (e.g. telephone calls)<br />

C Pace <strong>of</strong> <strong>the</strong> course, in particular when <strong>the</strong>re are language differences<br />

C Trainees who don't want to learn<br />

C Long days<br />

C Dominant participants<br />

C Audience too diverse in product lines or experience<br />

8.3 Experiences with specific problems encountered in HACCP training 4<br />

C Communication problems - not enough qualified instructors in some geographic<br />

locations<br />

C <strong>Training</strong> and material costs too high<br />

C Insufficient training materials in local languages and not adapted to local situations,<br />

e.g. inapplicable examples - not useful for small enterprises; poorly translated<br />

materials<br />

4<br />

Some <strong>of</strong> <strong>the</strong>se are <strong>of</strong> particular significance for training in developing countries<br />

10

C Confusion over various concepts, e.g. ISO and HACCP, verification, GMP, GHP,<br />

5<br />

generic HACCP plans, etc.<br />

C Cultural sensitivities, e.g. interactive approach not appropriate in all cultures<br />

C Educational level <strong>of</strong> line workers in developing countries makes it more difficult for<br />

trainers to transfer information to actual production operations<br />

C Rapid turnover in work force<br />

5 Generic HACCP plans refer to examples <strong>of</strong> HACCP plans developed for a food commodity or process in<br />

which flow charts, CCPs, critical limits and/or o<strong>the</strong>r aspects <strong>of</strong> a HACCP plan have been defined as guidance for<br />

food business operators producing such commodities or using such processes. Plans derived during HACCP<br />

training workshops could also be considered as generic. Generic plans are not appropriate for use until validated for<br />

a specific food and food process.<br />

11

ANNEX 1<br />

LIST OF PARTICIPANTS<br />

Pr<strong>of</strong>. Lahsen Ababouch, Institut Agronomique et Vétérinaire Hassan II, Rabat, Morocco<br />

(Vice-Chairman)<br />

Dr Martin Adams, Department <strong>of</strong> Microbiology, School <strong>of</strong> Biological Sciences, University <strong>of</strong><br />

Surrey, Guildford, U.K.<br />

Dr Leslie Bluhm (also representing Dr J. Kvenberg, Chairman <strong>of</strong> <strong>the</strong> Codex Committee on<br />

Food Hygiene) Strategic Manager, Food Processing and Packaging, Planning & Strategic<br />

Initiatives, Center for Food Safety and Applied Nutrition, Food and Drug Administration,<br />

Washington, D.C., U.S.A.<br />

Dr Derek Buckland, Senior Adviser (Food Safety), Ministry <strong>of</strong> Health, Wellington,<br />

New Zealand (Rapporteur)<br />

Dr Victor Daghie, Institute <strong>of</strong> Hygiene, Public Health, Health Services and Management,<br />

Ministry <strong>of</strong> Health, Bucharest, Romania<br />

Mr Bertrand Gagnon, Chief, Food Preservation <strong>System</strong>s, Science and Technology Services,<br />

Agriculture and Agri-Food Canada, Nepean, Ontario, Canada<br />

Mr E. Spencer Garret, Laboratory Director, National Seafood Inspection Laboratory,<br />

U.S. Department <strong>of</strong> Commerce, Pascagoula, MS., U.S.A. (Chairman)<br />

Ms Poonsri Jirathana, Senior Scientist, Centre <strong>of</strong> Export Inspection and Certification for<br />

Agricultural Products, Division <strong>of</strong> Agricultural Chemistry, Department <strong>of</strong> Agriculture,<br />

Ministry <strong>of</strong> Agriculture and Cooperatives, Chatuchak, Bangkok, Thailand<br />

Pr<strong>of</strong>. Jean-Louis Jouve, Hygiène et Industrie des Denrées Alimentaires d’Origine Animale,<br />

Ecole Nationale Vétérinaire, Nantes, France<br />

Dr Su Leaper, Food Science New Business Manager, Campden and Chorleywood Food<br />

Research Association, Chipping Campden, Gloucestershire, U.K.<br />

Dr Anthony Mayes, Senior Microbiologist, Unilever Research Laboratory, Bedford, U.K.<br />

Ms Zahara Merican, Senior Research Officer, Food Technology Research Center, Malaysian<br />

Agricultural Research and Development Institute, Kuala Lumpur, Malaysia<br />

Mr Christian Perrier, Institut Pasteur de Lille, Villeneuve d’Ascq, France<br />

Mr Stuart B. Petitt, Head, Department <strong>of</strong> Food Microbiology, Lea<strong>the</strong>rhead Food RA, Surrey,<br />

12

U.K.<br />

Pr<strong>of</strong>. Fernando Quevedo, Executive Director, Food Quality and Safety Assurance<br />

International, Lima, Peru<br />

Mr Stephen Rooke, Senior Principal Environmental Health Officer, Department <strong>of</strong> Health,<br />

London, U.K.<br />

Pr<strong>of</strong>. Saad Mahmoud Saad, Head, Department <strong>of</strong> Food Hygiene and <strong>Control</strong>, Faculty <strong>of</strong><br />

Veterinary Medicine, Banha University, Moshtohor, Egypt<br />

Dr Rudolf Schmitt, Ecole d’Ingénieurs du Valais, Sion, Switzerland<br />

Dr Robert Bruce Tompkin, Vice-President Product Safety, Armour Swift-Eckrich Inc.,<br />

Downers Grove, Illinois, U.S.A.<br />

Dr Michiel van Schothorst, Vice-President, Food Safety Affairs, Nestlé, S.A., Vevey,<br />

Switzerland<br />

Pr<strong>of</strong>. Alexander von Holy, Department <strong>of</strong> Microbiology, University <strong>of</strong> <strong>the</strong> Witwatersrand,<br />

Johannesburg, South Africa<br />

Representatives <strong>of</strong> O<strong>the</strong>r Organizations<br />

European Commission: Dr Christine Majewski, Directorate Industrial Affairs III: Consumer<br />

Goods Industries, Brussels, Belgium<br />

Food and Agriculture Organization <strong>of</strong> <strong>the</strong> United Nations, Rome, Italy:<br />

Mr Carlos Lima dos Santos, Senior Fishery Industry Officer (Inspection and Quality<br />

Assurance), Fish Utilization and Marketing Service, Fisheries Department;<br />

Mr Anthony Whitehead, Senior Officer, Food Quality and Standards Service, Food and<br />

Nutrition Division<br />

Industry Council for Development: Mrs Avita A. Usfar, SEAMEO/ICD Cooperative<br />

Programme, SEAMEO TROPMED Regional Center for Community Nutrition, University <strong>of</strong><br />

Indonesia, Jakarta, Indonesia<br />

International Commission on Microbiological Specifications for Foods:<br />

Dr Michiel van Schothorst, Vice-President, Food Safety Affairs, Nestlé, S.A., Vevey,<br />

Switzerland<br />

International Life Sciences Institute: Dr Servé Notermans, Food Microbiologist, National<br />

Institute <strong>of</strong> Public Health and Environmental Protection, Bilthoven, The Ne<strong>the</strong>rlands<br />

International Union <strong>of</strong> Food Science and Technology: Dr D. Edward Hood, President,<br />

13

Dublin, Ireland<br />

National Food Processors Association: Mr Dane Bernard, Vice-President, Food Safety and<br />

Strategic Programs, Washington, D.C., U.S.A.<br />

United Nations Industrial Development Organization, Vienna, Austria<br />

[invited but unable to attend]<br />

U.S. Agency for International Development, Washington, D.C., U.S.A.<br />

[invited but unable to attend]<br />

Observers<br />

Mr Oscar do Porto, Consultant, Prevessin, France<br />

Secretariat<br />

Dr Bruno de Benoist, Regional Adviser for Nutrition and Food Safety, WHO Regional Office<br />

for Africa, Brazzaville, Congo<br />

Dr Anthony Hazzard, Acting Food Safety Specialist, WHO Western Pacific Regional<br />

Environmental Health Centre, Kuala Lumpur, Malaysia<br />

Dr F. K. Käferstein, Chief, Food Safety Unit, WHO, Geneva, Switzerland<br />

Dr Robert T. Mitchell, Head, Food Microbiology Branch, Ministry <strong>of</strong> Agriculture, Fisheries<br />

and Food, London, U.K. (Temporary Adviser)<br />

Dr Shoji Miyagawa, Scientist, Food Safety Unit, WHO, Geneva, Switzerland<br />

Dr Kazuaki Miyagishima, Scientist, Food Safety Unit, WHO, Geneva, Switzerland<br />

Dr Yasmine Motarjemi, Scientist, Food Safety Unit, WHO, Geneva, Switzerland (Secretary)<br />

Dr Kenneth E. Mott, Chief, Schistosomiasis and o<strong>the</strong>r Trematode Infections Unit, WHO,<br />

Geneva, Switzerland<br />

Dr Gerald G. Moy, Scientist, Food Safety Unit, WHO, Geneva, Switzerland<br />

Dr Klaus Stöhr, Scientist, Veterinary Public Health Unit, WHO, Geneva, Switzerland<br />

Dr Anna Verster, Regional Adviser for Nutrition and Food Safety, WHO Regional Office for<br />

<strong>the</strong> Eastern Mediterranean, Alexandria, Egypt<br />

14

ANNEX 2<br />

SOURCES AND FURTHER READING<br />

The following list <strong>of</strong> documents and tools is not exhaustive: it is intended as a guide to <strong>the</strong><br />

reader and lists some <strong>of</strong> <strong>the</strong> basic material and sources <strong>of</strong> information which may be helpful for<br />

training in HACCP. This list partly uses <strong>the</strong> material presented at <strong>the</strong> Workshop. Use <strong>of</strong> some<br />

<strong>of</strong> this material or information sources may require a fee.<br />

Fur<strong>the</strong>r reading<br />

Ababouch, L. Considerations for <strong>Training</strong> in HACCP. Background papers presented at <strong>the</strong><br />

Workshop on <strong>Training</strong> aspects <strong>of</strong> HACCP (1-2 June 1995), Geneva, World Health<br />

Organization.<br />

Agriculture Canada. HACCP Curriculum Guidelines. Agriculture and Agri-Food,<br />

59 Camelot Drive, Nepean, Ontario, Canada, K1A 0Y9, 1995.<br />

Agriculture Canada. Food Safety Enhancement Programme - For Processing Establishments<br />

and Shell Egg Grading Stations (including video film). Agriculture and Agri-Food,<br />

59 Camelot Drive, Nepean, Ontario, Canada, K1A 0Y9, 1995.<br />

AMI. HACCP: The <strong>Hazard</strong> <strong>Analysis</strong> and <strong>Critical</strong> <strong>Control</strong> <strong>Point</strong> <strong>System</strong> in <strong>the</strong> Meat and<br />

Poultry Industry. American Meat Institute Foundation, POB 3556, Washington, D.C. 20007,<br />

U.S.A., 1994.<br />

Bryan, F. L. Teaching HACCP Techniques to Food Processors and Regulatory Officials.<br />

Dairy, Food and Environmental Sanitation, 11(10):562-568, 1991.<br />

Bryan, F. L. <strong>Hazard</strong> <strong>Analysis</strong> <strong>Critical</strong> <strong>Control</strong> <strong>Point</strong> Evaluations: A Guide to identifying<br />

<strong>Hazard</strong>s and Assessing Risks associated with Food Preparation and Storage. World Health<br />

Organization, 1992.<br />

Campden Food and Drink Research Association. HACCP: A practical guide. Technical<br />

Manual No 38. Campden & Chorleywood Food Research Association, Chipping Campden,<br />

Gloucestershire, GL55 6LD, U.K.<br />

Dillon, M. and Griffith, C. How to HACCP. An Illustrated Guide. 2nd Edition.<br />

M.D. Associates, Cleethorpes Enterprise Centre, Unit 43, Jackson Place, Wilton Road<br />

Industrial Estate, Humberston, Grimsby, North East Lincolnshire DN 36 4AS, U.K., 1996.<br />

ICMSF. Microorganisms in Foods, 4. Application <strong>of</strong> <strong>the</strong> <strong>Hazard</strong> <strong>Analysis</strong> <strong>Critical</strong> <strong>Control</strong><br />

<strong>Point</strong> (HACCP) <strong>System</strong> to ensure microbiological safety and quality. Blackwell Scientific<br />

Publications, Ltd., Oxford, 1988.<br />

15

ILSI. A Simple Guide to Understanding and Applying <strong>the</strong> <strong>Hazard</strong> <strong>Analysis</strong> <strong>Critical</strong> <strong>Control</strong><br />

<strong>Point</strong> Concept. ILSI Press, ILSI Europe, Avenue E. Mounier, 83, Box 6, 1200 Brussels,<br />

Belgium.<br />

Jouve, J.-L. La Qualité microbiologique des Aliments: Maîtrise et Critères. Polytechnica,<br />

Paris, France, 1993.<br />

FAO. Summary <strong>of</strong> Proceedings <strong>of</strong> <strong>the</strong> HACCP Working Group <strong>of</strong> Experts Convened by FAO<br />

to Plan a <strong>Training</strong> <strong>of</strong> Trainers Course in HACCP for Developing Countries, Rome, 13-17<br />

February 1995. Food and Agriculture Organization <strong>of</strong> <strong>the</strong> United Nations, Rome, 1995.<br />

FAO. The Use <strong>of</strong> <strong>Hazard</strong> <strong>Analysis</strong> <strong>Critical</strong> <strong>Control</strong> <strong>Point</strong> (HACCP) Principles in Food<br />

<strong>Control</strong>. FAO Food and Nutrition Paper No. 58, December 1994.<br />

Lima dos Santos, C.A. and Lupin, H.M. Impact <strong>of</strong> FAO <strong>Training</strong> on <strong>the</strong> quality and<br />

marketability <strong>of</strong> seafood. Paper presented at <strong>the</strong> 37th Annual Conference <strong>of</strong> <strong>the</strong> Canadian<br />

Institute <strong>of</strong> Food Science and Technology, Vancouver, BC, Canada, 15-18 May 1994.<br />

Food and Agriculture Organization <strong>of</strong> <strong>the</strong> United Nations, Rome, 1994.<br />

Mayes, T. HACCP training. Food <strong>Control</strong>. 5(3):190-195,. 1994.<br />

Mitchell, B. How to HACCP. British Food J.( 94) 1: 16-20, 1992.<br />

Mortimore, S. and Wallace, C. HACCP - A Practical Approach. Chapman and Hall, London,<br />

1995.<br />

NACMCF. The Role <strong>of</strong> Regulatory Agencies and Industry in HACCP. International Journal<br />

<strong>of</strong> Food Microbiology, 2:187-195, 1994.<br />

NMFS. Industry HACCP. Student Workbook. National Marine Fishery Service, National<br />

<strong>Training</strong> Branch, 1 Blackburn Drive, Gloucester, MA 01930, U.S.A.<br />

NMFS. Omani International Scientific <strong>Training</strong> Workshop. National Marine Fishery Service,<br />

National Seafood Inspection Laboratory <strong>Training</strong>. Pascagoula, MS. U.S.A.<br />

Saad, M. HACCP: Comprehensive <strong>Training</strong> Guidelines (in Arabic). Department <strong>of</strong> Food<br />

Hygiene and <strong>Control</strong> Faculty <strong>of</strong> Veterinary Medicine, Banha University, Egypt.<br />

U.K. Department <strong>of</strong> Health. Assured Safe Catering: A Management <strong>System</strong> for <strong>Hazard</strong><br />

<strong>Analysis</strong>. HMSO Bookshops, 49 High Holburn, London WC1V 6HB, U.K.,1993.<br />

USFDA. Core and Seafood HACCP training. Food and Drug Administration,<br />

Washington, D.C., U.S.A.<br />

USFDA. HACCP - Regulatory Applications in Retail Food Service Establishments,<br />

16

Department <strong>of</strong> Health and Human Services, Maryland 2057, U.S.A.<br />

RIPHH <strong>Training</strong> Standard: HACCP principles and <strong>the</strong>ir Application in Food Safety<br />

(introductory course). The Royal Institute <strong>of</strong> Public Health and Hygiene, 28 Portland Place,<br />

London WIN 4DE, U.K.<br />

WHO. <strong>Hazard</strong> <strong>Analysis</strong> <strong>Critical</strong> <strong>Control</strong> <strong>Point</strong> <strong>System</strong>: Concept and Application, Report <strong>of</strong> a<br />

WHO Consultation with <strong>the</strong> participation <strong>of</strong> FAO (Geneva, May 1995). Unpublished WHO<br />

document (WHO/FNU/FOS/95.7).<br />

WHO. <strong>Training</strong> Considerations for <strong>the</strong> Application <strong>of</strong> <strong>the</strong> <strong>Hazard</strong> <strong>Analysis</strong> <strong>Critical</strong> <strong>Control</strong><br />

<strong>Point</strong> <strong>System</strong> to Food Processing and Manufacturing. Report <strong>of</strong> a WHO Consultation on<br />

<strong>Hazard</strong> <strong>Analysis</strong> <strong>Critical</strong> <strong>Control</strong> <strong>Point</strong> <strong>System</strong> (Geneva, March 1993). Unpublished WHO<br />

document (WHO/FNU/FOS/93.3).<br />

WHO. Application <strong>of</strong> <strong>the</strong> <strong>Hazard</strong> <strong>Analysis</strong> <strong>Critical</strong> <strong>Control</strong> <strong>Point</strong> system for <strong>the</strong> improvement<br />

<strong>of</strong> food safety. WHO-supported case studies on food prepared in Homes, at Street Vending<br />

Operations, and in Cottage Industries. Unpublished WHO document (WHO/FNU/FOS/93.1).<br />

WHO. Street-vended food: a HACCP-based food safety strategy for governments.<br />

Unpublished WHO document (WHO/FNU/FOS/95.5).<br />

Computer s<strong>of</strong>tware<br />

Application <strong>of</strong> HACCP-computer Program, Institute <strong>of</strong> Hygiene, Public Health Services and<br />

Management, Str. Dr Leonte 1-3, 76256 Bucharest, Romania<br />

CCFRA HACCP Documentation S<strong>of</strong>tware. Campden & Chorleywood Food Research<br />

Association, Chipping Campden, Gloucestershire, GL55 6LD, U.K.<br />

Food MicroModel. Lea<strong>the</strong>rhead Food RA, Randalls Road, Lea<strong>the</strong>rhead, Surrey KT22 7RY,<br />

U.K.<br />

FIST - HACCP for Windows. A s<strong>of</strong>tware package for <strong>the</strong> management <strong>of</strong> HACCP system.<br />

TNO Nutrition and Food Research Institute, BGT Division, PO Box 360, 3700 AJ Zeist,<br />

The Ne<strong>the</strong>rlands<br />

Databases<br />

Dialog Information Service. DIALOG, POB 188, Oxford OX1 5AX, U.K.;<br />

3460 Hillview Av., Palo Alto, CA 94304, U.S.A.; POB 123, Sydney, NSW 2007, Australia;<br />

Malleswaram 11th Cross (provides access to o<strong>the</strong>r major databases in Food Science,<br />

Agriculture and Biochemistry)<br />

Reference Databases for <strong>Hazard</strong> Identification, Agriculture and Agri-Food, 59 Camelot Drive,<br />

17

Nepean, Ontario, Canada, K1A 0Y9, 1995.<br />

Foodline, Lea<strong>the</strong>rhead Food RA, Lea<strong>the</strong>rhead, Surrey KT 22 7 RY, U.K.<br />

Food Science and Technology Abstracts, International Food Information Service (IFIS)<br />

Publishing, Lane End House, Shinfield, Reading RG2 9BB, U.K.<br />

Medline. U.S. National Library <strong>of</strong> Medicine, Library Operations, 8600 Rockville Pike,<br />

Be<strong>the</strong>sda, Maryland 20894, U.S.A.<br />

USFDA Prime connection, Center for Food Safety and Applied Nutrition, Food and Drug<br />

Administration, Washington, D.C. 20204, U.S.A.<br />

IPCS Intox <strong>System</strong>. World Health Organization, Geneva, Switzerland<br />

Joint FAO/WHO Codex Alimentarius Database, Maximum Residue Limits (MRLs),<br />

Chief, Joint FAO/WHO Food Standards Programme, FAO. Rome, Italy<br />

Video films<br />

<strong>Hazard</strong> <strong>Analysis</strong> <strong>Critical</strong> <strong>Control</strong> <strong>Point</strong>. Food Quality Management n.v., Lakenmakersstraat<br />

170, 2800 Mechelen, Belgium.<br />

HACCP video film. Agriculture and Agri-Food, 59 Camelot Drive, Nepean, Ontario, Canada,<br />

K1A 0Y9, 1995.<br />

Food Safety: An Educational Video for Institutional Food Service Workers. Center for Food<br />

Safety and Applied Nutrition, Food and Drug Administration, Washington, D.C. 20204,<br />

U.S.A.<br />

Food Safe, Food Smart: HACCP and its Application to Food Industry. Agriculture, Food and<br />

Rural Development, Food Quality Branch, Edmonton Alberta T6H 4P2, Canada<br />

HACCP A Retail Seafood Safety Program. New England Fisheries Development Association,<br />

Inc., 309 World Trade Center, Boston, Mass. 02210-2001, U.S.A.<br />

ICD/WHO. Food safety: An international directory <strong>of</strong> audiovisual material. Unpublished<br />

WHO document (WHO/FNU/FOS/95.4). World Health Organization, Geneva Switzerland,<br />

1995.<br />

O<strong>the</strong>r sources<br />

The First Certificate in Food Safety : Examination syllabus. The Royal Institute <strong>of</strong> Public<br />

Health and Hygiene, 28 Portland Place, London WIN 4DE, U.K.<br />

18

ANNEX 3<br />

TRAINING PROGRAMME FOR<br />

FOOD PROCESSING AND MANUFACTURING INDUSTRIES<br />

The proposed training course is designed for a minimum <strong>of</strong> four days for personnel in food<br />

industries as well as government <strong>of</strong>ficials, e.g. food/health inspectors. Additional training<br />

(approximately 2 days) in auditing is also recommended for government <strong>of</strong>ficials.<br />

Course objectives<br />

The course objectives are to:<br />

C develop an understanding <strong>of</strong> <strong>the</strong> need to improve food safety and to develop a common<br />

understanding <strong>of</strong> <strong>the</strong> application <strong>of</strong> <strong>the</strong> principal activities <strong>of</strong> <strong>the</strong> HACCP system to<br />

food processing and manufacturing to ensure <strong>the</strong> production <strong>of</strong> safe food<br />

C provide a sound basis to enable effective assessment <strong>of</strong> HACCP plans and <strong>the</strong>ir<br />

implementation<br />

Course outline<br />

Module Learning objectives<br />

1. Introduction a. Course logistics<br />

2. Relationship <strong>of</strong><br />

GMPs/GHPs to<br />

HACCP<br />

b. Objectives<br />

a. Understanding that prior to implementing HACCP, effective<br />

GMPs/GHPs, as defined in <strong>the</strong> Codex General Principles <strong>of</strong> Food<br />

Hygiene, must be in place<br />

b. Understanding consequences for HACCP implementation, if<br />

GMPs/GHPs are not in place<br />

19

3. Overview <strong>of</strong> HACCP a. Understanding <strong>the</strong> HACCP approach to food safety and that it<br />

differs from traditional approaches<br />

4. Discussion <strong>of</strong><br />

foodborne hazards<br />

5. Preliminary steps to<br />

develop a HACCP<br />

plan<br />

6. Conducting a hazard<br />

analysis<br />

b. Learning about <strong>the</strong> advantages <strong>of</strong> <strong>the</strong> HACCP system<br />

c. Understanding that without management commitment, HACCP<br />

cannot be effectively implemented on a sustained basis<br />

d. Understanding that <strong>the</strong>re are seven principles to HACCP and that<br />

<strong>the</strong>y are easy to comprehend<br />

a. Understanding that <strong>the</strong>re are hazards associated with foods which, if<br />

left uncontrolled, can injure consumers<br />

b. Learning what a hazard is and <strong>the</strong> three different categories <strong>of</strong><br />

hazards, i.e. biological, chemical or physical<br />

c. Understanding that <strong>the</strong>re are ways <strong>of</strong> addressing hazards (control<br />

measures) to prevent, reduce or minimize hazards associated with<br />

foods<br />

a. Understanding <strong>the</strong> importance <strong>of</strong> forming a HACCP team<br />

b. Describing products to be covered by HACCP and <strong>the</strong>ir intended<br />

use<br />

c. Understanding <strong>the</strong> importance and use <strong>of</strong> process flow diagrams and<br />

<strong>the</strong>ir verification for accuracy<br />

a. Identifying all potential hazards and points where <strong>the</strong>y enter <strong>the</strong><br />

process/food or can be enhanced during <strong>the</strong> process<br />

b. Identifying significant hazards relative to severity and likelihood <strong>of</strong><br />

occurrence<br />

c. Documenting <strong>the</strong> rationale for hazard selection for future use<br />

7. Identifying CCPs a. Understanding a CP and a CCP and <strong>the</strong>ir difference<br />

b. Understanding relationship between an identified hazard and a CCP<br />

c. Utilizing a decision tree to identify CCPs and to address all<br />

significant hazards<br />

20

8. Determining<br />

critical limits<br />

9. Establishing<br />

monitoring system<br />

10. Establishing<br />

corrective actions<br />

11. Establishing<br />

verification<br />

procedures<br />

12. Establishing record<br />

keeping and<br />

documentation<br />

a. Understanding critical limits and operational limits and determining<br />

each one<br />

b. Selecting critical limits which have relevance to <strong>the</strong> safety <strong>of</strong> a<br />

product but which are not unnecessarily restrictive<br />

c. Documenting <strong>the</strong> rationale for <strong>the</strong> selection <strong>of</strong> critical limits for<br />

future use<br />

a. Identifying how monitoring is to be conducted<br />

b. Identifying who will be responsible for monitoring activities<br />

c. Determining necessary frequency for taking measurements<br />

d. Identifying where measurements will be taken<br />

e. Understanding <strong>the</strong> importance <strong>of</strong> monitoring for control purposes<br />

a. Learning to devise effective corrective actions<br />

b. Understanding <strong>the</strong> need for appropriate documentation <strong>of</strong> corrective<br />

actions<br />

a. Learning <strong>the</strong> importance <strong>of</strong> verification to support HACCP and help<br />

assure its long-term viability in an establishment<br />

b. Learning different activities which can be conducted as part <strong>of</strong><br />

verification<br />

a. Learning <strong>the</strong> type <strong>of</strong> records needed to document HACCP activities<br />

b. Learning <strong>the</strong> importance <strong>of</strong> record keeping for determining <strong>the</strong><br />

effectiveness <strong>of</strong> <strong>the</strong> HACCP system<br />

c. Learning what information should be included in records<br />

d. Learning <strong>the</strong> importance <strong>of</strong> reviewing and signing records<br />

21

13. Management <strong>of</strong><br />

HACCP plan<br />

14. Implementation<br />

strategies<br />

15. Maintenance <strong>of</strong><br />

HACCP plans<br />

a. Understanding <strong>the</strong> importance <strong>of</strong> management support<br />

b. Understanding <strong>the</strong> importance <strong>of</strong> operational units in supporting a<br />

HACCP system, e.g. supervisors, quality control/quality assurance,<br />

technical<br />

c. Understanding <strong>the</strong> importance <strong>of</strong> standard operating procedures and<br />

how <strong>the</strong>y are used<br />

d. Understanding how to assemble and maintain a HACCP plan<br />

e. Understanding composition, role and importance <strong>of</strong> <strong>the</strong> HACCP<br />

team<br />

a. <strong>Training</strong> Programmes (GMPs - HACCP plan support)<br />

b. Preparation <strong>of</strong> standard operating procedure<br />

c. Transfer <strong>of</strong> ownership (responsibility for food safety)<br />

d. Gaining management support<br />

a. Understanding <strong>the</strong> importance <strong>of</strong> HACCP team formation and<br />

activities: i.e. <strong>the</strong> advantages <strong>of</strong> a multidisciplinary team including -<br />

but not limited to - <strong>the</strong> following skills: food technologist,<br />

microbiologist, personnel in production, quality assurance<br />

b. Understanding that plant management is responsible for safety <strong>of</strong><br />

food, implementation, and management <strong>of</strong> <strong>the</strong> HACCP plan<br />

c. Understanding <strong>the</strong> need for a person, trained in HACCP, to lead <strong>the</strong><br />

HACCP team and to be skilled in meeting management<br />

d. Learning to review <strong>the</strong> HACCP plan<br />

16. HACCP Plan a. Learning constituents <strong>of</strong> <strong>the</strong> HACCP plan and supporting<br />

documents<br />

b. Standard operating procedures (sample record forms, sampling<br />

plans, monitoring procedures, calibration procedures)<br />

c. Overview <strong>of</strong> HACCP master planning sheet<br />

22

17. Auditing a. Understanding <strong>the</strong> objective <strong>of</strong> auditing<br />

b. Learning about those who may perform auditing (food industries,<br />

third parties, and/or government <strong>of</strong>ficials) and <strong>the</strong>ir role<br />

c. Learning what is audited: records, procedures, and products<br />

d. Learning how to plan <strong>the</strong> frequency <strong>of</strong> auditing (i.e. considering <strong>the</strong><br />

risk factor, compliance, etc.)<br />

e. Learning how to audit in order to ensure ongoing support for<br />

HACCP, document compliance with <strong>the</strong> HACCP plan, and to<br />

determine if plan needs to be changed<br />

23

TRAINING PROGRAMME FOR<br />

SMALL FOOD ENTERPRISES<br />

The proposed training course is designed for both food inspectors and managers <strong>of</strong> small<br />

food enterprises, such as managers <strong>of</strong> food service establishments. The first part <strong>of</strong> <strong>the</strong> course<br />

covers requirements for inspectors and personnel in small food enterprises, whereas <strong>the</strong> second<br />

part <strong>of</strong> <strong>the</strong> course is for food inspectors only.<br />

Course objectives<br />

Part 1<br />

(Course for personnel in small food enterprises and for inspectors)<br />

A period <strong>of</strong> 2-3 days could be considered for this course<br />

The course objectives are to:<br />

C increase understanding <strong>of</strong> <strong>the</strong> necessity to improve food safety, and develop a common<br />

perception about <strong>the</strong> application <strong>of</strong> <strong>the</strong> principal activities <strong>of</strong> <strong>the</strong> HACCP system to small<br />

food enterprises for preparation and production <strong>of</strong> safe food<br />

C provide a sound basis to enable effective assessment <strong>of</strong> implementation <strong>of</strong> <strong>the</strong> HACCP<br />

system<br />

Course outline<br />

Module Learning objectives<br />

1. Introduction a. Course logistics<br />

2. The need for<br />

control <strong>of</strong> hazards<br />

b. Objectives<br />

a. Understanding <strong>the</strong> need for HACCP (explaining <strong>the</strong> nature and extent<br />

<strong>of</strong> food safety problems, e.g., by providing statistics on foodborne<br />

diseases)<br />

b. Learning about traditional methods <strong>of</strong> control <strong>of</strong> foodborne diseases<br />

and <strong>the</strong>ir limitations (legislation and inspection, end-product testing)<br />

c. Understanding why HACCP concept was developed<br />

d. Learning about <strong>the</strong> international status <strong>of</strong> HACCP<br />

e. Reviewing <strong>the</strong> advantages and benefits <strong>of</strong> <strong>the</strong> system, as well as <strong>the</strong><br />

difficulties and problems faced by food inspectors and personnel <strong>of</strong><br />

small food enterprises<br />

24

3. Introduction to<br />

HACCP<br />

6<br />

4. Application <strong>of</strong><br />

HACCP principles:<br />

<strong>Hazard</strong> <strong>Analysis</strong><br />

5. Application <strong>of</strong><br />

HACCP principles:<br />

from determination<br />

<strong>of</strong> CCPs to<br />

verification<br />

6. Relationship<br />

between GMP,<br />

GHP and HACCP<br />

7. HACCP<br />

implementation<br />

a. Understanding <strong>the</strong> meaning <strong>of</strong> terms such as hazard, risk, <strong>Hazard</strong><br />

<strong>Analysis</strong> <strong>Critical</strong> <strong>Control</strong> <strong>Point</strong> system<br />

b. Learning basic concept and principles <strong>of</strong> <strong>the</strong> HACCP system<br />

c. Learning about Codex principles and guidelines for <strong>the</strong>ir application<br />

d. Learning about <strong>the</strong> importance <strong>of</strong> a HACCP team<br />

a. Identifying food safety hazards<br />

b. Conducting hazard analysis<br />

a. Learning to determine control measures and critical control points,<br />

and to apply <strong>the</strong> o<strong>the</strong>r HACCP principles<br />

b. Learning to design and apply a HACCP plan<br />

a. Recognizing <strong>the</strong> elements <strong>of</strong> GMP and GHP<br />

b. Recognizing <strong>the</strong> importance <strong>of</strong> GMP and GHP as prerequisite<br />

programmes to <strong>the</strong> implementation <strong>of</strong> HACCP systems<br />

c. Recognizing <strong>the</strong> importance <strong>of</strong> applying <strong>the</strong> HACCP principles in <strong>the</strong><br />

identification <strong>of</strong> food safety interventions where GMP and GHP are<br />

limited<br />

d. Understanding <strong>the</strong> difference between ISO 9000 and <strong>the</strong> HACCP<br />

system<br />

a. Understanding <strong>the</strong> role <strong>of</strong> food enterprises and governments in<br />

implementing HACCP<br />

b. Learning about <strong>the</strong> importance <strong>of</strong> commitment by senior management,<br />

<strong>the</strong> need for resources and capacity building, training, and an<br />

appropriate time-scale<br />

6<br />

A practical exercise could be included in this lecture to help <strong>the</strong> lecturer evaluate <strong>the</strong> trainees’ level <strong>of</strong><br />

knowledge and to guide <strong>the</strong> lecturer in selecting <strong>the</strong> type <strong>of</strong> information which <strong>the</strong> trainees may need. For this purpose<br />

<strong>the</strong> trainees should be divided into small groups (e.g. 5-7 persons). If possible <strong>the</strong> group should be multisectorial.<br />

<strong>Hazard</strong> analysis is conducted using a practical example <strong>of</strong> food preparation/production, drawn from a visit to a food<br />

handling/processing enterprise, a case study, a video film, or a situation familiar to most <strong>of</strong> <strong>the</strong> trainees. The work <strong>of</strong><br />

each group may be discussed in plenary session under <strong>the</strong> guidance <strong>of</strong> <strong>the</strong> lecturer.<br />

25

Course objectives<br />

The course objectives are to:<br />

Part 2<br />

(Course for inspectors only )<br />

C show food inspectors how <strong>the</strong>y can best use <strong>the</strong>ir knowledge to adapt inspection techniques<br />

to <strong>the</strong> needs <strong>of</strong> <strong>the</strong> business<br />

C increase understanding <strong>of</strong> <strong>the</strong> problems faced by small food enterprises<br />

Course outline<br />

Lecture Learning objectives<br />

1. Addressing problems <strong>of</strong> small<br />

food enterprises<br />

a. Sensitizing <strong>the</strong> food inspectors to particular problems<br />

<strong>of</strong> small food enterprises (e.g. low level <strong>of</strong> knowledge,<br />

high volume <strong>of</strong> food and restricted operating space,<br />

varying demand for food product, production beyond<br />

operational capacity) and addressing <strong>the</strong>se issues,<br />

absence <strong>of</strong> equipment or facilities available to monitor<br />

CCPs<br />

b. Learning to focus on process operations ra<strong>the</strong>r than<br />

on individual products<br />

2. Setting priorities a. Learning to prioritize problems based on risk<br />

assessment and adapting resources to <strong>the</strong> risks<br />

3. Adapting inspection techniques a. Learning to adapt inspection techniques, i.e.<br />

- where HACCP is in place, confirm that <strong>the</strong><br />

principles are being appropriately applied<br />

- in <strong>the</strong> absence <strong>of</strong> HACCP-based systems, <strong>the</strong><br />

inspector needs to assist in <strong>the</strong> transition to <strong>the</strong>se<br />

b. Learning to adapt and to use an educative role ra<strong>the</strong>r<br />

than a policing one<br />

26

4. Uses and mis-uses <strong>of</strong> generic<br />

HACCP plans<br />

a. Learning to understand and use correctly <strong>the</strong> generic<br />

plans 7<br />

b. Understanding <strong>the</strong> reason why generic plans should<br />

not be used without re-evaluation and revalidation<br />

5. Communication skills a. Changing <strong>the</strong> attitude <strong>of</strong> inspectors from that <strong>of</strong><br />

enforcing a prescriptive legislation to an educative and<br />

advisory role<br />

b. Developing skills to give advice on HACCP and make<br />

sure that <strong>the</strong> enterprises understand <strong>the</strong> principles and<br />

<strong>the</strong> rationale <strong>of</strong> <strong>the</strong> HACCP system, while retaining<br />

<strong>the</strong> ownership <strong>of</strong> <strong>the</strong> HACCP plan<br />

c. Developing skills for receptiveness, and listening to<br />

<strong>the</strong> explanations and rationale <strong>of</strong> <strong>the</strong> HACCP plan<br />

d. Developing skills to build a relationship with<br />

enterprises based on mutual confidence<br />

e. Developing skills to influence <strong>the</strong> actions <strong>of</strong> food<br />

enterprises so that <strong>the</strong>y achieve an acceptable solution<br />

when <strong>the</strong>re is disagreement<br />

7<br />

Generic HACCP plans refer to examples <strong>of</strong> HACCP plans developed for a food commodity or process in<br />

which flow charts, CCPs, critical limits and or o<strong>the</strong>r aspects <strong>of</strong> a HACCP plan have been defined as guidance for food<br />

business operators producing such commodities or using such processes. Plans derived during HACCP training<br />

workshops could also be considered as generic. Generic plans are not appropriate for use until validated for a specific<br />

food and food process.<br />

27

TRAINING PROGRAMME FOR<br />

SMALL FOOD OPERATIONS<br />

This course is designed for those who are in charge <strong>of</strong> very small food operations and those<br />

who carry out simple activities, at operator level, in food service establishments producing<br />

more complex ready-to-eat-foods. Street food vendors and small kiosk-type operators are<br />

regarded as falling under this category.<br />

A pre-course evaluation <strong>of</strong> course material with <strong>the</strong> direct involvement <strong>of</strong> participants in <strong>the</strong><br />

course’s development, as for o<strong>the</strong>r training programmes, should be considered. The<br />

recommended length <strong>of</strong> <strong>the</strong> course is 3-4 hours, or as may be appropriate for those attending.<br />

However, it is important that <strong>the</strong> timing as well as <strong>the</strong> length is acceptable to <strong>the</strong> participants.<br />

Cultural acceptability, <strong>the</strong> use <strong>of</strong> examples and terminology that <strong>the</strong> participants can relate<br />

to, and <strong>the</strong> presentation <strong>of</strong> information are all important factors. The course outline suggested<br />

in this report is fundamentally based on <strong>the</strong> concept <strong>of</strong> <strong>the</strong> HACCP system. It is written in<br />

simple language, avoiding as far as possible terminology usually used in HACCP, to<br />

demonstrate how <strong>the</strong> language needs <strong>of</strong> <strong>the</strong> target group in question can be met.<br />

Course objectives<br />

The course objectives are to:<br />

C increase <strong>the</strong> understanding <strong>of</strong> food operators regarding basic food safety issues and<br />

hence <strong>the</strong>ir desire for improvement<br />

C train food operators in <strong>the</strong> basic issues <strong>of</strong> food safety, according to <strong>the</strong> HACCP approach<br />

Course outline<br />

Lecture Learning objectives<br />

1.What is food? Learning what people eat and drink<br />

2.What should<br />

food do for<br />

people?<br />

3.What should<br />

food not do to<br />

people?<br />

Learning that:<br />

- food makes people strong and healthy<br />

- eating can be a pleasurable experience<br />

- food should satisfy customers and provides an income<br />

Learning that food should not<br />

- make people sick<br />

- make customers unhappy (sick) and stay away from eating places<br />

- cause food operations to go out <strong>of</strong> business<br />

28

4.What causes<br />

food to make<br />

people sick or die?<br />

5.What are<br />

microbes?<br />

6.Where do<br />

microbes come<br />

from?<br />

7. How can you<br />

stop microbes<br />

from making<br />

people sick?<br />

8.How is <strong>the</strong> food<br />

made?<br />

9.What are <strong>the</strong><br />

dangers in <strong>the</strong><br />

operation?<br />

10. How can <strong>the</strong><br />

danger be<br />

removed?<br />

11. How to be sure<br />

that <strong>the</strong><br />

prepared food<br />

is safe?<br />

a. Learning that <strong>the</strong> following make people sick or die:<br />

- chemicals<br />

- foreign bodies<br />

- bugs (microbes and parasites)<br />

b. Learning that <strong>the</strong> above are called hazards and that microbes are <strong>the</strong> most<br />

important cause <strong>of</strong> illness<br />

Learning that microbes:<br />

- are small living things, invisible to <strong>the</strong> naked eye<br />

- can grow extremely quickly<br />

- in order to grow and multiply, need food, water, time, and a warm<br />

temperature<br />

Learning that <strong>the</strong>y come from<br />

- water<br />

- raw or uncooked food<br />

- animals, pests and people<br />

- dirty surfaces and unhygienic behaviour<br />

Learning that one can stop microbes from making people sick, by<br />

C killing <strong>the</strong>m, for instance by cooking food thoroughly<br />

C stopping <strong>the</strong>m from growing, for instance by<br />

- chilling foods<br />

- not giving <strong>the</strong>m time to grow and multiply<br />

- by serving food straight after it is cooked<br />

C preventing contamination, for instance through<br />

- using clean chopping boards, knives, plates, utensils and cloths<br />

- practising good personal hygiene<br />

- keeping flies, rats, mice, cockroaches and o<strong>the</strong>r animals away from food<br />

- storing food in closed containers<br />

Describing <strong>the</strong> procedures for a food operation<br />

Learning what can lead to hazards in <strong>the</strong> specific operation under consideration<br />

Learning <strong>the</strong> practices that control <strong>the</strong> hazards<br />

a.Learning to demonstrate how you have ensured safety<br />

b. Learning what to do when things go wrong<br />

c. Learning how to make a proper record <strong>of</strong> procedures<br />

29