The customer magazine of Andritz Pulp & Paper Issue 2 — 2005

The customer magazine of Andritz Pulp & Paper Issue 2 — 2005

The customer magazine of Andritz Pulp & Paper Issue 2 — 2005

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SONOCO<br />

Sonoco, founded in 1899 as the<br />

Southern Novelty Company in the<br />

USA, operates in 32 countries, producing<br />

packaging for a variety <strong>of</strong><br />

industries and for many <strong>of</strong> the most<br />

recognized global brands. With its<br />

18,000 employees today, it is the<br />

world's largest producer <strong>of</strong> engineered<br />

carriers made <strong>of</strong> fiber, plastic,<br />

and composite materials. Sonoco<br />

processes more than one million<br />

tonnes <strong>of</strong> recycled paper annually.<br />

In 1992, Sonoco purchased the Trent<br />

Valley Mill from <strong>Paper</strong>board Industries<br />

Corp. Trent Valley (near Trenton,<br />

Ontario, Canada) has been in operation<br />

since 1880 at the same site near the<br />

Trent Canal (386 km waterway linking<br />

the Bay <strong>of</strong> Quinte <strong>of</strong> Lake Ontario with<br />

the Georgian Bay <strong>of</strong> Lake Huron).<br />

<strong>The</strong> mill manufactures coreboard,<br />

canboard, and linerboard products<br />

from 100% recycled paper. All <strong>of</strong> the<br />

mill's products are produced on a<br />

Kobayashi Ultraformer, 177-inch trim<br />

at a speed <strong>of</strong> 630 fpm, purchased in<br />

1977. <strong>The</strong> machine can produce about<br />

300 t/d <strong>of</strong> up to six-ply board. In addition<br />

to base-stock, the mill has capabilities<br />

to slit its products on-site<br />

down to 2-1/8 inch widths.<br />

26 FiberSpectrum <strong>Issue</strong> 2 <strong>—</strong> <strong>2005</strong><br />

High quality,<br />

lower costs<br />

With improved refining,<br />

Trent Valley has been able<br />

to shift its attention to optimization<br />

projects. "We're<br />

working on lowering basis<br />

weight and doing all kinds<br />

<strong>of</strong> fun stuff with the kraft<br />

portion <strong>of</strong> the sheet,"<br />

exclaims Giffen.<br />

"<strong>The</strong> linerboard we produced<br />

was 83% OCC in<br />

five plies and 17% kraft in<br />

one ply," says Giffen.<br />

"However, the kraft constituted<br />

over 65% <strong>of</strong> the furnish<br />

cost. <strong>The</strong> kraft made<br />

the sheet look equivalent<br />

to what could be produced<br />

from virgin kraft. It<br />

is sold as a premium<br />

sheet. With the LemaxX<br />

Spiral TM , we've been able<br />

to cut the amount <strong>of</strong> kraft<br />

dramatically. We've made<br />

big improvements in our<br />

cost structure without<br />

having to worry about the<br />

final quality <strong>of</strong> the sheet."<br />

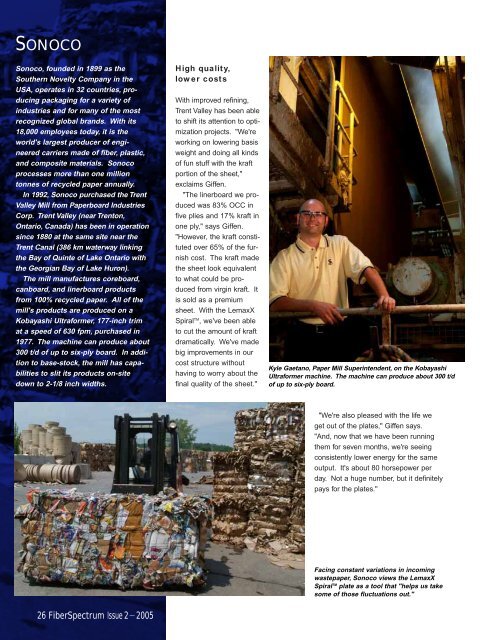

Kyle Gaetano, <strong>Paper</strong> Mill Superintendent, on the Kobayashi<br />

Ultraformer machine. <strong>The</strong> machine can produce about 300 t/d<br />

<strong>of</strong> up to six-ply board.<br />

"We're also pleased with the life we<br />

get out <strong>of</strong> the plates," Giffen says.<br />

"And, now that we have been running<br />

them for seven months, we're seeing<br />

consistently lower energy for the same<br />

output. It's about 80 horsepower per<br />

day. Not a huge number, but it definitely<br />

pays for the plates."<br />

Facing constant variations in incoming<br />

wastepaper, Sonoco views the LemaxX<br />

Spiral TM plate as a tool that "helps us take<br />

some <strong>of</strong> those fluctuations out."