Production Part Approval Process (ppap) Submission Checklist

Production Part Approval Process (ppap) Submission Checklist

Production Part Approval Process (ppap) Submission Checklist

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

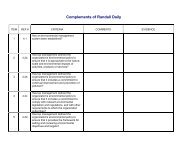

1 Suppli e rr 2 S u p p l i e r A p p r o v a l PPPP aaaa rrrr tttt NNNN uuuu mmmm bbbb eeee rrrr ::::<br />

R e q u i rr e d S u b m i t t e d R e q u i rr e d RRRReeeeaaaassssoooonnnn ffffoooorrrr SSSSuuuubbbbmmmmiiiissssssssiiiioooonnnn::::<br />

((Y/N )) (Y/N) Prri o r t o<br />

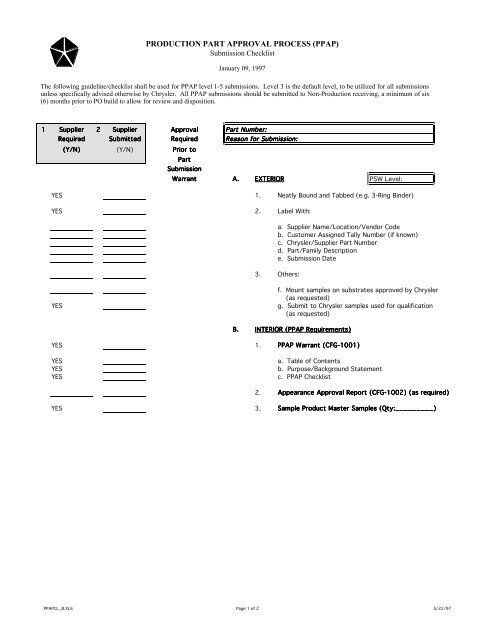

PRODUCTION PART APPROVAL PROCESS (PPAP)<br />

<strong>Submission</strong> <strong>Checklist</strong><br />

P a rr t<br />

S u b m i s s i o n<br />

January 09, 1997<br />

The following guideline/checklist shall be used for PPAP level 1-5 submissions. Level 3 is the default level, to be utilized for all submissions<br />

unless specifically advised otherwise by Chrysler. All PPAP submissions should be submitted to Non-<strong>Production</strong> receiving, a minimum of six<br />

(6) months prior to PO build to allow for review and disposition.<br />

W a r rr a n t A . E X T E R I O R PSW Level:<br />

YES 1. Neatly Bound and Tabbed (e.g. 3-Ring Binder)<br />

YES 2. Label With:<br />

a. Supplier Name/Location/Vendor Code<br />

b. Customer Assigned Tally Number (if known)<br />

c. Chrysler/Supplier <strong>Part</strong> Number<br />

d. <strong>Part</strong>/Family Description<br />

e. <strong>Submission</strong> Date<br />

3. Others:<br />

f. Mount samples on substrates approved by Chrysler<br />

(as requested)<br />

YES g. Submit to Chrysler samples used for qualification<br />

(as requested)<br />

B. I N T E R I OO R (( P P AA P R e q u i r e m e n t ss )<br />

YES 1. PPAP Warrantt ((CFG-10001))<br />

YES a. Table of Contents<br />

YES b. Purpose/Background Statement<br />

YES c. PPAP <strong>Checklist</strong><br />

2. Appearance <strong>Approval</strong> R e p o r t (( C F GG - 1 0 00 2 ) ( a s r e q u i r e d )<br />

YES 3. Sample P r o d u c t M a s t e r S a m p l e s ( QQ t y : _ __ __ _ _ _ _ _ _ )<br />

PPAPCL_B.XLS Page 1 of 2 5/22/97

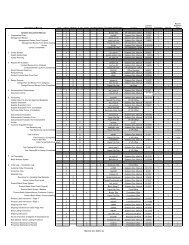

11 S u p p l i e r 2 S u p p l ii e r A p p r o v a ll<br />

R e q u i r e d S u b m i t t e d R e q u i r e d<br />

(Y/N ) (Y/N) Pri o r t oo<br />

PRODUCTIO N P A RR T A P P R O V A L P R O C E S S ( P P A P )) [[ C o n t i n u e d ]<br />

P a rr t<br />

S u b m ii s ss i o n<br />

WW a rr r a n t<br />

4. Desi g n R e c o r d s<br />

YES a. Supplier Specification and Drawings<br />

b. Chrysler Specification and Drawings<br />

c. Other<br />

5. Change Documents<br />

YES a. SRPC (Signed Cover Sheet Only)<br />

YES b. HPF-3709 (<strong>Process</strong> Change Procedure)<br />

c. Letters Of Agreement (If applicable)<br />

YES c1. Certificate of Design and Construction<br />

YES c2. Qualification Test Plan<br />

c3. Others<br />

YES 66. Di mm e n s i o n a l R e s u l t s<br />

Tabular Summary: Spec Para No., Spec. Limits,<br />

Samples, Pass-Fail Results, Mean, Std. Dev., Min-Max<br />

Values, Normality, Histograms, Capability, formatted<br />

data.<br />

a. Raw data plusTabular Summary Format<br />

(statistical)<br />

b. Address Cpk < 1.33<br />

c. Failures: Chrysler Approved 7D Reports<br />

(as required)<br />

7. Checkii n g AA i d s ( a ss r e q u e ss t e d )<br />

YES 8. Testt Result ss<br />

Electrical Tabular Summary: Spec. Para No., Description, Spec. Limits,<br />

Number of Samples, Pass-Fail Results, Mean, Std. Dev., Min-Max Values,<br />

Normality, Histograms, formatted test.<br />

a. Test Vectors<br />

b. Specific Test Circuits, paper copy only<br />

c. Test fixtures (Mechanical and Electrically),paper copy only<br />

d. Other: ______________________________<br />

a. Tabular Summary of Reliability Test Results<br />

b. Product Electrical Tabular Summary or Parametric<br />

Verification Summary<br />

c. Address Cpk < 1.33<br />

d. Failures: Chrysler Approved 7D Reports<br />

(as required)<br />

YES YES 9. Prroccesss Flo w C h aa rr t ( t o CC h rr y s l e rr rr e cc e i v ii n g dd o c k )<br />

YES YES 10. FMEA ((DDesii g n / P rr o c e s s )<br />

YES a. Design (supplier design only)<br />

PPAPCL_B.XLS Page 2 of 2 5/22/97

11 S u p p l i e r 2 S u p p l ii e r A p p r o v a ll<br />

R e q u i r e d S u b m i t t e d R e q u i r e d<br />

(Y/N ) (Y/N) Pri o r t oo<br />

PRODUCTIO N P A RR T A P P R O V A L P R O C E S S ( P P A P )) [[ C o n t i n u e d ]<br />

P a rr t<br />

S u b m ii s ss i o n<br />

WW a rr r a n t<br />

YES b. <strong>Process</strong> (Entire process flow)<br />

YES YES 11. Control P l a n s<br />

YES a. Prototype (Prototype <strong>Process</strong> Control &<br />

Component DV Test Plans)<br />

YES b. Pre-Launch (Component PV Test Plan)<br />

YES c. <strong>Production</strong> (<strong>Production</strong> <strong>Process</strong> Control & Initial<br />

<strong>Production</strong> Test Plan)<br />

YES 1122.. PPrroocceessss PPeerfoorrmmaannccee ((PPppkk//Cppkk))<br />

a. Significant/Critical <strong>Process</strong>es identified in Control<br />

Plan<br />

b. Address Ppk/Cpk < 1.67/1.33 (AIAG PPAP<br />

Manual)<br />

YES 1133. Measuremment System Studie s ( GG a g e R & R )<br />

<strong>Approval</strong> (type name and sign) Date:<br />

Component Engineer PPAP <strong>Checklist</strong> <strong>Approval</strong><br />

Supplier PPAP <strong>Checklist</strong> <strong>Approval</strong><br />

Supplier PPAP <strong>Submission</strong> <strong>Approval</strong><br />

a. Product/<strong>Process</strong> Measuring Equipment<br />

b. Address R&R's > 10% (AIAG MSA Manual)<br />

14. Desii g n E n g ii n e e r i n g A p p r o v a ll<br />

YES a. Review Chrysler Specification (submit letter of<br />

acceptance or exceptions taken)<br />

YES b. Other:<br />

PPAPCL_B.XLS Page 3 of 2 5/22/97