quality control specification clauses for the impregnation ... - Dry Treat

quality control specification clauses for the impregnation ... - Dry Treat

quality control specification clauses for the impregnation ... - Dry Treat

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

QUALITY CONTROL SPECIFICATION CLAUSES FOR THE<br />

IMPREGNATION OF POROUS MINERAL<br />

BUILDING MATERIALS WITH META CRÈME<br />

1. GENERAL<br />

1.1 Scope<br />

The material to be supplied is to be applied to <strong>the</strong> surface of a porous mineral building<br />

material to protect it from <strong>the</strong> ingress of water, water-borne salts and oil-based<br />

staining. The material is designed to impregnate <strong>the</strong> surface and permanently bond to<br />

<strong>the</strong> molecular structure of <strong>the</strong> material, thus changing its absorption characteristics<br />

whilst maintaining breathability.<br />

Impregnation shall be carried out to surfaces described in <strong>the</strong> Contract. All works to<br />

be in accordance with relevant Occupational Health and Safety requirements.<br />

2. MATERIAL<br />

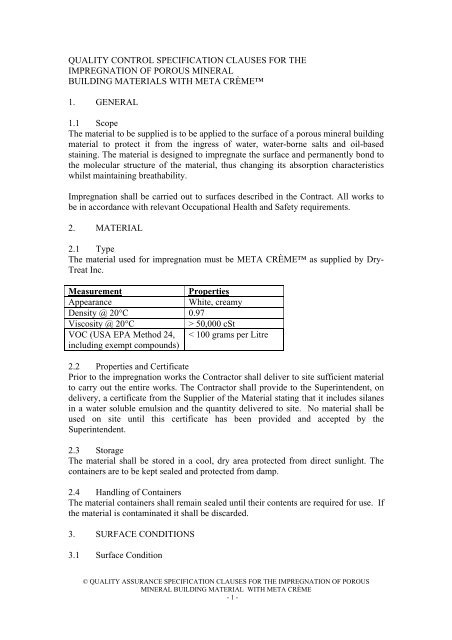

2.1 Type<br />

The material used <strong>for</strong> <strong>impregnation</strong> must be META CRÈME as supplied by <strong>Dry</strong>-<br />

<strong>Treat</strong> Inc.<br />

Measurement Properties<br />

Appearance White, creamy<br />

Density @ 20°C 0.97<br />

Viscosity @ 20°C > 50,000 cSt<br />

VOC (USA EPA Method 24,<br />

including exempt compounds)<br />

< 100 grams per Litre<br />

2.2 Properties and Certificate<br />

Prior to <strong>the</strong> <strong>impregnation</strong> works <strong>the</strong> Contractor shall deliver to site sufficient material<br />

to carry out <strong>the</strong> entire works. The Contractor shall provide to <strong>the</strong> Superintendent, on<br />

delivery, a certificate from <strong>the</strong> Supplier of <strong>the</strong> Material stating that it includes silanes<br />

in a water soluble emulsion and <strong>the</strong> quantity delivered to site. No material shall be<br />

used on site until this certificate has been provided and accepted by <strong>the</strong><br />

Superintendent.<br />

2.3 Storage<br />

The material shall be stored in a cool, dry area protected from direct sunlight. The<br />

containers are to be kept sealed and protected from damp.<br />

2.4 Handling of Containers<br />

The material containers shall remain sealed until <strong>the</strong>ir contents are required <strong>for</strong> use. If<br />

<strong>the</strong> material is contaminated it shall be discarded.<br />

3. SURFACE CONDITIONS<br />

3.1 Surface Condition<br />

© QUALITY ASSURANCE SPECIFICATION CLAUSES FOR THE IMPREGNATION OF POROUS<br />

MINERAL BUILDING MATERIAL WITH META CRÈME<br />

- 1 -

Surfaces to be impregnated must be sound, air-dry and clean. Surfaces must be free<br />

from loose or deleterious matters and residues that may prevent <strong>the</strong> sealer from<br />

penetrating. Allow newly cement-based grouted installations to cure a minimum of 72<br />

hours.<br />

3.2 Cleaning<br />

If cleaning by water methods, <strong>the</strong> surfaces must be allowed to stand <strong>for</strong> a minimum of<br />

24 hours be<strong>for</strong>e <strong>impregnation</strong> commences. Areas to be treated must, where necessary,<br />

be protected from adverse wea<strong>the</strong>r conditions and must be surface dry <strong>for</strong> a minimum<br />

of 24 hours be<strong>for</strong>e application commences. Artificial drying of <strong>the</strong> surface must not<br />

be permitted.<br />

3.3 After <strong>Treat</strong>ment<br />

The treated surface must be left undisturbed (no rain or condensation) as long as<br />

possible (a minimum 12 hours), to ensure proper curing.<br />

4. APPLICATION EQUIPMENT<br />

4.1 Method of Delivery<br />

Generously coat <strong>the</strong> surface with an even layer of META CRÈME using a foam<br />

roller, low pressure airless sprayer, brush, lambs wool applicator or similar.<br />

4.2 Application Rate<br />

Apply a minimum of one even coat, with a minimum interval between coats of at least<br />

24 hours, shall be made each at <strong>the</strong> coverage rate of at least 1 quart per 30 to 100 sq.ft.<br />

(1 litre per 3 to 10 sq.m.), depending on surface absorption and depth of penetration<br />

required.<br />

4.3 Testing of Material<br />

During application, <strong>the</strong> Contractor, when requested, provides to <strong>the</strong> Superintendent<br />

samples from <strong>the</strong> spray nozzle or roller tray. This shall be tested to confirm density<br />

value as stated in <strong>the</strong> material con<strong>for</strong>mity certificate.<br />

4.6 Temperature & Wea<strong>the</strong>r Conditions<br />

The outdoor temperature and <strong>the</strong> temperature of <strong>the</strong> substrate shall be within <strong>the</strong> range<br />

of 40 to 95 °F (5 to 35 °C).<br />

4.7 Protection<br />

Painted surfaces, plastic, exposed bituminous materials and joint sealants adjacent to<br />

surfaces to be impregnated shall be masked-off be<strong>for</strong>e <strong>the</strong> treatment. <strong>Treat</strong>ed surface<br />

shall be protected from rain and traffic spray during application and <strong>for</strong> at least twelve<br />

hours after completion. Plants in <strong>the</strong> vicinity shall be protected against contact with<br />

<strong>the</strong> material. Any residue <strong>for</strong>med by <strong>the</strong> material on glass, wood or metal by contact<br />

shall be removed immediately by an alcohol based cleaning agent.<br />

5. TRIAL APPLICATION AREA & SAMPLING<br />

5.1 Location<br />

© SPECIFICATION CLAUSES FOR THE IMPREGNATION OF POROUS MINERAL BUILDING MATERIAL WITH META CRÈME<br />

- 2 -

Test <strong>control</strong>s must be determined <strong>for</strong> each type of porous mineral building<br />

material to be treated.<br />

On completion of <strong>the</strong> application on <strong>the</strong> <strong>control</strong> area(s) test <strong>for</strong> <strong>the</strong> Depth of<br />

Penetration and Determination of Resistance to Stains. The Depth of<br />

Penetration must be determined using <strong>the</strong> method set out in Clauses 5.3. and<br />

Determination of Resistance to Stains using <strong>the</strong> method set out in Clause 5.4.<br />

5.2 Method of Sampling<br />

The method of sampling must be <strong>the</strong> same <strong>for</strong> all test procedures, and must<br />

be as follows:<br />

(a) After a minimum of 14 days following <strong>the</strong> last application of META<br />

CRÈME 2 inches (50 mm) internal diameter cores must be cut through <strong>the</strong><br />

treated surface ensuring that <strong>the</strong> core is perpendicular to <strong>the</strong> surface. The<br />

depth of cut must be 1 ½ inches +/- ¼ inch (40 mm, +/- 5 mm).<br />

(b) Whenever possible, coring must be carried out using a vacuumclamped<br />

coring machine. Where metallic fixings are used <strong>the</strong>y must be<br />

removed subsequent to coring. Fixing holes and core holes must be made<br />

good using an approved repair procedure.<br />

(c) The core must be removed, sealed in a plastic bag, labelled and sent to<br />

an approved laboratory <strong>for</strong> testing.<br />

5.3 Testing <strong>for</strong> Depth of Penetration by Dye <strong>Treat</strong>ment<br />

The following test procedure must be used to determine <strong>the</strong> actual depth of<br />

penetration of <strong>the</strong> treatment:<br />

(a) Test cores must be obtained as per <strong>the</strong> procedure in Clause 5.2.<br />

(b) The cores must be oven dried <strong>for</strong> 24 hours at 100 °F (40°C).<br />

(c) The core must be split diametrically and <strong>the</strong> split face sprayed with a<br />

water-based fugitive dye.<br />

(d) The area not absorbing dye indicates <strong>the</strong> zone of treatment. The<br />

minimum distance from <strong>the</strong> interface of <strong>the</strong> dyed concrete must be recorded.<br />

This distance must be deemed to be <strong>the</strong> depth of penetration of <strong>the</strong> applied<br />

treatment. Should difficulty be encountered in distinguishing this interface a<br />

petrographic microscope must be used.<br />

5.4 Testing <strong>for</strong> Determination of Resistance to Stains<br />

The following test procedure must be used to determine <strong>the</strong> resistance to<br />

staining of <strong>the</strong> treatment:<br />

© QUALITY ASSURANCE SPECIFICATION CLAUSES FOR THE IMPREGNATION OF POROUS<br />

MINERAL BUILDING MATERIAL WITH META CRÈME<br />

- 3 -

(a) Test cores must be obtained as per <strong>the</strong> procedure in Clause 5.2.<br />

(b) The cores must be oven dried <strong>for</strong> 24 hours at 230 °F (110°C).<br />

(c) The cores must have three to 4 drop of olive oil placed on <strong>the</strong> surface<br />

and leave in place <strong>for</strong> 24 hours.<br />

(d) Subject <strong>the</strong> test specimens, successively to <strong>the</strong> following cleaning<br />

procedures:<br />

Procedure A – Class 5<br />

Clean <strong>the</strong> test specimen with running hot water <strong>for</strong> 5 minutes, and <strong>the</strong>n wipe<br />

<strong>the</strong> surface with a damp cloth.<br />

Procedure B – Class 4<br />

Clean <strong>the</strong> test specimen manually with weak cleaning agent (a commercial<br />

agent not containing abrasive, with a pH of 6.5 to 7.5), using a natural, nonabrasive<br />

sponge or a cloth, <strong>the</strong>n rinse <strong>the</strong> surface with running water, and<br />

finally wipe it with a damp cloth.<br />

Procedure C – Class 3<br />

Clean <strong>the</strong> test specimen mechanically with <strong>the</strong> strong cleaning agent (a<br />

commercial cleaning agent, containing abrasive, with a pH of 9 to 10).<br />

Example of apparatus: Rotating brush, with hard bristles, having a 3 inch (8<br />

cm) diameter, rotational frequency approximately 500 r/min. Tank <strong>for</strong><br />

cleaning agent, equipped with a suitable feeder, and connected to <strong>the</strong> brush.<br />

Carry out cleaning <strong>for</strong> 2 minutes, <strong>the</strong>n rinse <strong>the</strong> surface with running water<br />

and finally wipe it with a damp cloth.<br />

Procedure D – Class 2<br />

Immerse <strong>the</strong> test specimen <strong>for</strong> 24 hours in a suitable solvent (e.g. hydrochloric<br />

acid diluted 3 + 97, potassium hydroxide, 7 oz. / quart (200 g/L) solution,<br />

acetone), <strong>the</strong>n thoroughly rinse <strong>the</strong> surface with running water and finally<br />

wipe it with a damp cloth.<br />

Stain not removed – Class 1<br />

Cleaning is considered to be accomplished if any one of <strong>the</strong> solvents removed<br />

<strong>the</strong> stain.<br />

After each cleaning procedure, dry <strong>the</strong> test specimen in <strong>the</strong> oven adjusted to<br />

230 °F (110 °C) and subjects <strong>the</strong>m to a visual examination. Examine <strong>the</strong><br />

surface with <strong>the</strong> naked eye or with spectacles if usually worn, at a distance of<br />

© SPECIFICATION CLAUSES FOR THE IMPREGNATION OF POROUS MINERAL BUILDING MATERIAL WITH META CRÈME<br />

- 4 -

1 foot (25 to 30 cm) in daylight or artificial illumination of approximately 300<br />

lx, but avoid direct sunlight.<br />

Staining must only be reported when oil is visible, if <strong>the</strong>re is no visible effect<br />

i.e. if <strong>the</strong> stain has been removed record <strong>the</strong> “cleanability” Class according <strong>the</strong><br />

Procedure; if <strong>the</strong> stain is not removed, proceed to <strong>the</strong> next cleaning procedure.<br />

5.5 Acceptability of Tests<br />

The sample cores must be taken at <strong>the</strong> rate stated below and sample cores to<br />

be tested <strong>for</strong> <strong>the</strong> Depth of Penetration and Determination of Resistance to<br />

Stains. In any area where <strong>the</strong> treatment falls below <strong>the</strong> <strong>control</strong> standard, that<br />

area is to be retreated.<br />

The minium standard frequency <strong>for</strong> testing and acceptance limits must be:<br />

i. Frequency of test cores: Per 3,000 sq. ft. (300 sq.m.) treated<br />

ii. Depth of Penetration: > 1/10 th inch (3 mm)*<br />

iii. Determination of Resistance to Stains: Class 5<br />

*varies depending on type of material being treated<br />

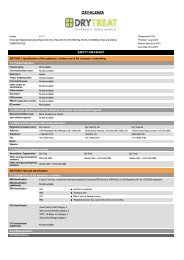

6. SAFETY ASPECTS<br />

6.1 Precautions, Safety Directions and Storage<br />

Do not take internally. Avoid contact with eyes and skin. Ethanol is liberated<br />

during curing so use a chemical respirator where vapours occur and, where ventilation<br />

is inadequate. Avoid inhaling vapors. Wear latex gloves and safety goggles<br />

during application. No smoking, keep away from naked lights or ignition<br />

sources. Keep container tightly sealed in a cool, well ventilated place. Use<br />

product be<strong>for</strong>e expiry date.<br />

6.2 First Aid<br />

If swallowed, give a glass of water and contact a physician. If skin contact<br />

occurs remove contaminated clothing and wash skin thoroughly. If irritation<br />

persists, contact a physician. If in eyes, hold open, flood with water <strong>for</strong> at least<br />

15 minutes and contact a physician. If vapours are inhaled, relocate to fresh<br />

air. If symptoms persist contact a physician. The material is of low acute toxicity<br />

but may irritate <strong>the</strong> skin. Contact with <strong>the</strong> skin and eyes are to be avoided. The<br />

material is safe <strong>for</strong> <strong>the</strong> treatment of concrete in contact with potable water.<br />

6.3 Accidents<br />

Spillage – Take up mechanically or with absorbent material such as sand,<br />

earth or vermiculite. Remove all ignition sources.<br />

© QUALITY ASSURANCE SPECIFICATION CLAUSES FOR THE IMPREGNATION OF POROUS<br />

MINERAL BUILDING MATERIAL WITH META CRÈME<br />

- 5 -

6.4 Transport<br />

Not regulated <strong>for</strong> transport of dangerous goods: DOT (Road), IMDG (Ocean),<br />

IATA (Air) Transport.<br />

6.5 Volatile Organic Content (VOC)<br />

VOC (US EPA Method 24, including exempt compounds) is less than 100<br />

g/litre, excluding water and except solvents.<br />

7. WARRANTY<br />

7.1 Requirement<br />

Per<strong>for</strong>mance warranty to 15 years is offered when <strong>the</strong> treated porous mineral<br />

building material meets <strong>the</strong> above Acceptable Results is applied by a <strong>Dry</strong>-<br />

<strong>Treat</strong> Accredited Applicator and.<br />

8. LIMITATION<br />

8.1 Limitation<br />

Product will not prevent surface etching, scuffing or wear. All stains should<br />

be cleaned-up immediately to minimise absorption.<br />

June 2009<br />

© SPECIFICATION CLAUSES FOR THE IMPREGNATION OF POROUS MINERAL BUILDING MATERIAL WITH META CRÈME<br />

- 6 -