Tensile Test of Steel for Stress vs. Strain Diagram - MyWeb at WIT

Tensile Test of Steel for Stress vs. Strain Diagram - MyWeb at WIT

Tensile Test of Steel for Stress vs. Strain Diagram - MyWeb at WIT

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

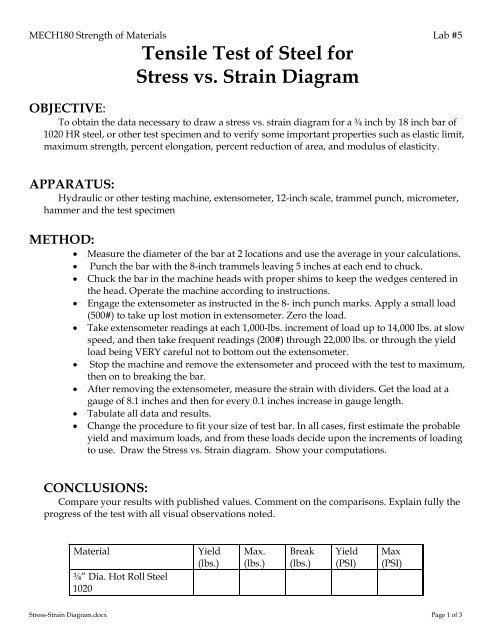

MECH180 Strength <strong>of</strong> M<strong>at</strong>erials Lab #5<br />

<strong>Tensile</strong> <strong>Test</strong> <strong>of</strong> <strong>Steel</strong> <strong>for</strong><br />

<strong>Stress</strong> <strong>vs</strong>. <strong>Strain</strong> <strong>Diagram</strong><br />

OBJECTIVE:<br />

To obtain the d<strong>at</strong>a necessary to draw a stress <strong>vs</strong>. strain diagram <strong>for</strong> a ¾ inch by 18 inch bar <strong>of</strong><br />

1020 HR steel, or other test specimen and to verify some important properties such as elastic limit,<br />

maximum strength, percent elong<strong>at</strong>ion, percent reduction <strong>of</strong> area, and modulus <strong>of</strong> elasticity.<br />

APPARATUS:<br />

Hydraulic or other testing machine, extensometer, 12-inch scale, trammel punch, micrometer,<br />

hammer and the test specimen<br />

METHOD:<br />

Measure the diameter <strong>of</strong> the bar <strong>at</strong> 2 loc<strong>at</strong>ions and use the average in your calcul<strong>at</strong>ions.<br />

Punch the bar with the 8-inch trammels leaving 5 inches <strong>at</strong> each end to chuck.<br />

Chuck the bar in the machine heads with proper shims to keep the wedges centered in<br />

the head. Oper<strong>at</strong>e the machine according to instructions.<br />

Engage the extensometer as instructed in the 8- inch punch marks. Apply a small load<br />

(500#) to take up lost motion in extensometer. Zero the load.<br />

Take extensometer readings <strong>at</strong> each 1,000-lbs. increment <strong>of</strong> load up to 14,000 lbs. <strong>at</strong> slow<br />

speed, and then take frequent readings (200#) through 22,000 lbs. or through the yield<br />

load being VERY careful not to bottom out the extensometer.<br />

Stop the machine and remove the extensometer and proceed with the test to maximum,<br />

then on to breaking the bar.<br />

After removing the extensometer, measure the strain with dividers. Get the load <strong>at</strong> a<br />

gauge <strong>of</strong> 8.1 inches and then <strong>for</strong> every 0.1 inches increase in gauge length.<br />

Tabul<strong>at</strong>e all d<strong>at</strong>a and results.<br />

Change the procedure to fit your size <strong>of</strong> test bar. In all cases, first estim<strong>at</strong>e the probable<br />

yield and maximum loads, and from these loads decide upon the increments <strong>of</strong> loading<br />

to use. Draw the <strong>Stress</strong> <strong>vs</strong>. <strong>Strain</strong> diagram. Show your comput<strong>at</strong>ions.<br />

CONCLUSIONS:<br />

Compare your results with published values. Comment on the comparisons. Explain fully the<br />

progress <strong>of</strong> the test with all visual observ<strong>at</strong>ions noted.<br />

M<strong>at</strong>erial Yield<br />

(lbs.)<br />

¾” Dia. Hot Roll <strong>Steel</strong><br />

1020<br />

Max.<br />

(lbs.)<br />

Break<br />

(lbs.)<br />

Yield<br />

(PSI)<br />

Max<br />

(PSI)<br />

<strong>Stress</strong>-<strong>Strain</strong> <strong>Diagram</strong>.docx Page 1 <strong>of</strong> 3

MECH180 Strength <strong>of</strong> M<strong>at</strong>erials Lab #5<br />

DATA:<br />

M<strong>at</strong>erial________ Initial diameter________ Initial Gage Length_________<br />

Rdng Load Elong<strong>at</strong>ion Rdng Load Elong<strong>at</strong>ion Rdng Load Elong<strong>at</strong>ion<br />

1 41 81<br />

2 42 82<br />

3 43 83<br />

4 44 84<br />

5 45 85<br />

6 46 86<br />

7 47 86<br />

8 48 88<br />

9 49 89<br />

10 50 90<br />

11 51 91<br />

12 52 92<br />

13 53 93<br />

14 54 94<br />

15 55 95<br />

16 56 96<br />

17 57 97<br />

18 58 98<br />

19 59 99<br />

20 60 100<br />

21 61 101<br />

22 62 102<br />

23 63 103<br />

24 64 104<br />

25 65 105<br />

26 66 106<br />

27 67 107<br />

28 68 108<br />

29 69 109<br />

30 70 110<br />

31 71 111<br />

32 72 112<br />

33 73 113<br />

34 74 114<br />

35 75 115<br />

36 76 116<br />

37 77 117<br />

38 78 118<br />

39 79 119<br />

40 80 120<br />

RESULTS:<br />

<strong>Stress</strong>-<strong>Strain</strong> <strong>Diagram</strong>.docx Page 2 <strong>of</strong> 3

MECH180 Strength <strong>of</strong> M<strong>at</strong>erials Lab #5<br />

Proportional Limit__________ Modulus <strong>of</strong> Elasticity__________<br />

Yield <strong>Stress</strong>__________ Modulus <strong>of</strong> Resilience__________<br />

Ultim<strong>at</strong>e <strong>Tensile</strong> <strong>Stress</strong>__________ Modulus <strong>of</strong> Toughness__________<br />

Rdng <strong>Stress</strong> <strong>Strain</strong> Rdng <strong>Stress</strong> <strong>Strain</strong> Rdng <strong>Stress</strong> <strong>Strain</strong><br />

1 41 81<br />

2 42 82<br />

3 43 83<br />

4 44 84<br />

5 45 85<br />

6 46 86<br />

7 47 86<br />

8 48 88<br />

9 49 89<br />

10 50 90<br />

11 51 91<br />

12 52 92<br />

13 53 93<br />

14 54 94<br />

15 55 95<br />

16 56 96<br />

17 57 97<br />

18 58 98<br />

19 59 99<br />

20 60 100<br />

21 61 101<br />

22 62 102<br />

23 63 103<br />

24 64 104<br />

25 65 105<br />

26 66 106<br />

27 67 107<br />

28 68 108<br />

29 69 109<br />

30 70 110<br />

31 71 111<br />

32 72 112<br />

33 73 113<br />

34 74 114<br />

35 75 115<br />

36 76 116<br />

37 77 117<br />

38 78 118<br />

39 79 119<br />

40 80 120<br />

<strong>Stress</strong>-<strong>Strain</strong> <strong>Diagram</strong>.docx Page 3 <strong>of</strong> 3