New Technologies - APV

New Technologies - APV

New Technologies - APV

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Micronised APIs in direct compression<br />

aggregation of API particles predominates over binding to the carrier surface.<br />

This is not a surprising observation which can be applied to allexcipients.<br />

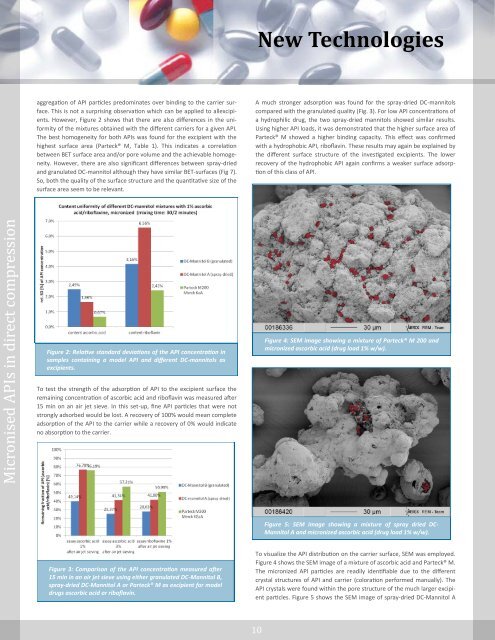

However, Figure 2 shows that there are also differences in the uniformity<br />

of the mixtures obtained with the different carriers for a given API.<br />

The best homogeneity for both APIs was found for the excipient with the<br />

highest surface area (Parteck® M, Table 1). This indicates a correlation<br />

between BET surface area and/or pore volume and the achievable homogeneity.<br />

However, there are also significant differences between spray-dried<br />

and granulated DC-mannitol although they have similar BET-surfaces (Fig 7).<br />

So, both the quality of the surface structure and the quantitative size of the<br />

surface area seem to be relevant.<br />

Figure 2: Relative standard deviations of the API concentration in<br />

samples containing a model API and different DC-mannitols as<br />

excipients.<br />

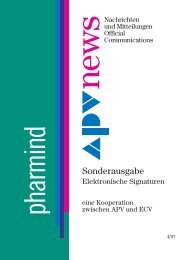

To test the strength of the adsorption of API to the excipient surface the<br />

remaining concentration of ascorbic acid and riboflavin was measured after<br />

15 min on an air jet sieve. In this set-up, fine API particles that were not<br />

strongly adsorbed would be lost. A recovery of 100% would mean complete<br />

adsorption of the API to the carrier while a recovery of 0% would indicate<br />

no absorption to the carrier.<br />

Figure 3: Comparison of the API concentration measured after<br />

15 min in an air jet sieve using either granulated DC-Mannitol B,<br />

spray-dried DC-Mannitol A or Parteck® M as excipient for model<br />

drugs ascorbic acid or riboflavin.<br />

12 10<br />

<strong>New</strong> <strong>Technologies</strong><br />

A much stronger adsorption was found for the spray-dried DC-mannitols<br />

compared with the granulated quality (Fig. 3). For low API concentrations of<br />

a hydrophilic drug, the two spray-dried mannitols showed similar results.<br />

Using higher API loads, it was demonstrated that the higher surface area of<br />

Parteck® M showed a higher binding capacity. This effect was confirmed<br />

with a hydrophobic API, riboflavin. These results may again be explained by<br />

the different surface structure of the investigated excipients. The lower<br />

recovery of the hydrophobic API again confirms a weaker surface adsorption<br />

of this class of API.<br />

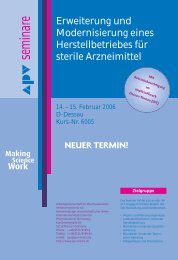

Figure 4: SEM image showing a mixture of Parteck® M 200 and<br />

micronized ascorbic acid (drug load 1% w/w).<br />

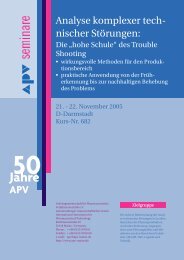

Figure 5: SEM image showing a mixture of spray dried DC-<br />

Mannitol A and micronized ascorbic acid (drug load 1% w/w).<br />

To visualize the API distribution on the carrier surface, SEM was employed.<br />

Figure 4 shows the SEM image of a mixture of ascorbic acid and Parteck® M.<br />

The micronized API particles are readily identifiable due to the different<br />

crystal structures of API and carrier (coloration performed manually). The<br />

API crystals were found within the pore structure of the much larger excipient<br />

particles. Figure 5 shows the SEM image of spray-dried DC-Mannitol A