Brett Fox - EEWeb

Brett Fox - EEWeb

Brett Fox - EEWeb

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

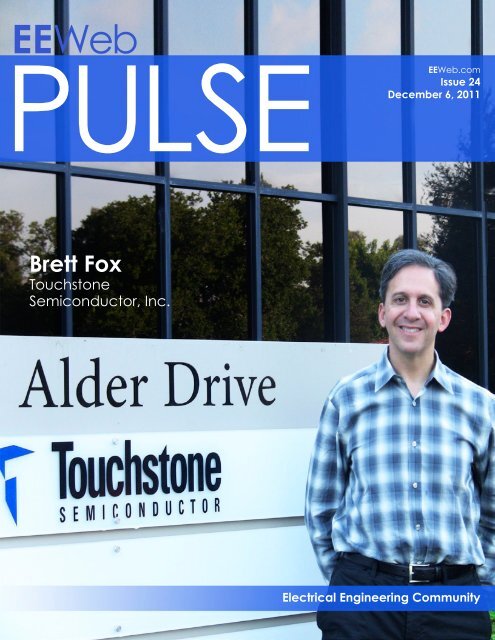

<strong>EEWeb</strong><br />

PULSE<br />

<strong>Brett</strong> <strong>Fox</strong><br />

Touchstone<br />

Semiconductor, Inc.<br />

<strong>EEWeb</strong>.com<br />

Issue 24<br />

December 6, 2011<br />

Electrical Engineering Community

It’s all about<br />

connections. <strong>EEWeb</strong><br />

Electrical Engineering Community<br />

engineers<br />

hobbyists<br />

discussions<br />

power<br />

microcontroller<br />

Digi-Key is an authorized distributor for all supplier partners. New products added daily.<br />

© 2011 Digi-Key Corporation, 701 Brooks Ave. South, Thief River Falls, MN 56701, USA<br />

Contact Us For Advertising Opportunities<br />

The user-to-user forum is for everyone, from<br />

design engineers to hobbyists, to discuss<br />

technology, products, designs and more.<br />

Join the discussions that match your interest<br />

or offer your expertise to others.<br />

Join the discussion now at:<br />

students<br />

industry experts<br />

1.800.574.2791<br />

advertising@eeweb.com<br />

www.eeweb.com/advertising<br />

community<br />

wireless<br />

www.digikey.com/techxchange<br />

technical documents<br />

lighting<br />

sensor<br />

resources<br />

application notes<br />

white papers<br />

links<br />

reference designs

TABLE OF CONTENTS<br />

<strong>Brett</strong> <strong>Fox</strong> 4<br />

Touchstone Semiconductor, Inc.<br />

Interview with <strong>Brett</strong> <strong>Fox</strong> - President and CEO<br />

Featured Products<br />

Software and Hardware Platform Enable 10<br />

Over One TeraFlop Processing Rates<br />

BY MICHAEL PARKER WITH ALTERA<br />

An introduction to a processing platform that provides the advantages of both floating point and<br />

fixed point processing.<br />

System Perspective on Specifying 14<br />

Electronic Power Supplies:Load<br />

Characterization<br />

BY BOB STOWE WITH TRUE POWER RESEARCH<br />

Learn about the effect of the load when specifying a power supply.<br />

RTZ - Return to Zero Comic 17<br />

<strong>EEWeb</strong> | Electrical Engineering Community Visit www.eeweb.com 3<br />

8<br />

TABLE OF CONTENTS

INTERVIEW<br />

<strong>Brett</strong> <strong>Fox</strong><br />

Touchstone Semiconductor, Inc.<br />

How did Touchstone come<br />

about?<br />

The idea for this company has been<br />

floating around with me for many<br />

years, actually since I left Maxim in<br />

early 2000. Back then was not the<br />

right time to start a company like<br />

Touchstone. At the time, the funding<br />

was going toward businesses that<br />

were one-product, one-customer<br />

type models. VCs could make an<br />

investment and it could quickly turn<br />

into money. We were trying to build<br />

a real company. When I left Micrel<br />

in 2005 I started to think about what<br />

I wanted to do. I was fortunate<br />

enough to know some people in<br />

venture capital. Crosslink Capital, a<br />

VC firm in San Francisco, asked me<br />

to be an Entrepreneur in Residence<br />

(EIR), which is a pretty cool job.<br />

You essentially are given a salary,<br />

an office, and a business card. You<br />

get to sit in on their meetings and<br />

see the inner workings of how a<br />

venture capital firm works. They<br />

will help you look at companies in<br />

your space, and if you want to start<br />

<strong>Brett</strong> <strong>Fox</strong> - President and CEO at Touchstone Semiconductor, Inc.<br />

a company, they will help you do<br />

that. The real genesis of Touchstone<br />

started there. I started to work on<br />

finding a team of people, flushing<br />

out the business plan more, making<br />

contacts and all those types of<br />

things. When I left Crosslink in early<br />

2008, Touchstone was formed, and<br />

I started raising money in earnest.<br />

What was the most<br />

challenging aspect of starting<br />

Touchstone?<br />

The most challenging thing was<br />

raising the money. It took us two<br />

years to raise our funding. We<br />

started in early 2008 and found the<br />

first investor, Opus Capital, within<br />

a month. Most people say if you<br />

can find one investor, you will find<br />

another one easily. In our particular<br />

case, because of the economic<br />

environment of 2008 combined with<br />

the environment of semiconductor<br />

investments (which continued to<br />

worsen throughout the year), we<br />

saw that it was unlikely we would<br />

close our funding in 2008. After<br />

2008, we really had to regroup.<br />

Opus stood with us. In the summer<br />

of 2009, the economic environment<br />

was getting better; VCs were<br />

starting to put money to work. We<br />

<strong>EEWeb</strong> | Electrical Engineering Community Visit www.eeweb.com 4<br />

FEATURED INTERVIEW

INTERVIEW<br />

started to raise money in earnest<br />

again. In early fall, we found Khosla<br />

Ventures as our second investor. I<br />

am thrilled at how it worked out; we<br />

found two really good investors who<br />

know our space. Opus’ Managing<br />

Partner, Gill Cogan, was actually<br />

an original investor in Maxim, and<br />

when you look at our business<br />

model, we knew he would be a<br />

fantastic resource. Pierre Lamond<br />

led the deal for Khosla Ventures.<br />

Pierre is a co-founder of National<br />

Semiconductor and was involved<br />

with Linear Technology and many<br />

other successful semiconductor<br />

companies. He was very familiar<br />

with what we were doing, and was<br />

looking for a company like ours to<br />

invest in. Our funding (money in<br />

the bank) came on March 8, 2010,<br />

and since that time it has been a<br />

relatively straightforward ride for<br />

the company. I am not saying there<br />

have not been bumps along the way,<br />

because indeed there are always<br />

unforeseen things.<br />

Can you tell us about the<br />

Founders of Touchstone<br />

Semiconductor, Inc.?<br />

All of us either come from Maxim,<br />

Linear, or Analog Devices. Most of<br />

the team has worked together in<br />

one way, shape, or form.<br />

I have my BSEE from the University<br />

of California, San Diego, and<br />

my MBA from the University of<br />

Southern California. In 1989 I joined<br />

Maxim, and before that I was a<br />

designer for about five years. When<br />

I joined Maxim, it was a roughly<br />

$40 million company, and when I<br />

left in 2000, they were making over<br />

a billion dollars in revenue. I was<br />

very fortunate—right place, right<br />

time, and right set of skills. I ended<br />

up setting the strategic direction<br />

for most areas of the company.<br />

After Maxim I worked at a start-up<br />

for about nine months. Then I went<br />

to Micrel for about four years and<br />

ran the high bandwidth division. I<br />

ended up turning that around from<br />

being the least profitable division of<br />

the company to the most profitable<br />

when I left. From there I went to<br />

Crosslink Capital for about a year,<br />

and then started working full time<br />

on Touchstone.<br />

The thing that we really<br />

want customers to think<br />

about Touchstone is that<br />

the company is doing<br />

cool and unique things.<br />

Hopefully, as time goes<br />

on, we will achieve<br />

that reputation, and<br />

customers will look to<br />

us for those types of cool<br />

and unique products.<br />

Jeroen Fonderie, the Vice President<br />

of Engineering, has a PhD from Delft<br />

University in the Netherlands. That is<br />

one of the best engineering schools<br />

for analog designers in Europe.<br />

When he was there he wrote a book<br />

on op amp design. He has written<br />

over 20 scientific publications, and<br />

he holds seven patents. Beyond<br />

that, he is a fantastic manager, and<br />

a very good business man. In the<br />

Analog world, that is a very rare<br />

combination. When you put all three<br />

of those factors together, you have<br />

a great VP of Engineering for a<br />

company like Touchstone.<br />

Adolfo Garcia, our VP of Marketing<br />

and Applications, started out also as<br />

a designer. He went from being in<br />

the design world to joining Analog<br />

Devices, and worked there for<br />

several years before moving on to<br />

Linear Technology and continuing in<br />

applications for several more years.<br />

He then worked at Micrel, which is<br />

where we crossed paths. He was<br />

running part of that business on the<br />

analog side. He then worked at a<br />

couple of other analog companies,<br />

and when I was looking to start<br />

Touchstone, he was the ideal guy to<br />

run marketing and applications. You<br />

want someone who is technically<br />

very strong and who can cover a lot<br />

of different products.<br />

The design team is mostly from<br />

Maxim, Linear, Analog Devices,<br />

National, or MPS. All of the designers<br />

in the company have also worked<br />

together in some way, shape, or<br />

form. Some of the designers and I<br />

go back 20 years; they all average<br />

about 20 years of experience and<br />

about 10 patents per designer. So<br />

this is a group that can hit the ground<br />

running, can work independently,<br />

and will be able to get things done<br />

in a reasonable time period. We<br />

also wanted people that fit in our<br />

company culture, you want people<br />

that work well together. It does not<br />

mean that everyone has to be best<br />

friends or see eye to eye on every<br />

issue, but they have to be able to<br />

work well together and understand<br />

<strong>EEWeb</strong> | Electrical Engineering Community Visit www.eeweb.com 5<br />

FEATURED INTERVIEW

INTERVIEW<br />

the focus of the company. Everyone<br />

here believes in our model and is<br />

moving forward to implement our<br />

strategy.<br />

How do you choose the<br />

products to manufacture?<br />

We have two strategies we are<br />

working in parallel. The primary<br />

focus at the beginning was<br />

alternative source products. We<br />

did this because it solves a big<br />

problem that our customers face<br />

today. Most of the parts in the High<br />

Performance Analog segment are<br />

sole-sourced. That means that there<br />

is one source, and if customers have<br />

a problem obtaining a product from<br />

the primary source, they are out<br />

of luck. We provide an alternative<br />

source, and an assurance of supply<br />

they cannot have using only Maxim.<br />

In parallel with that, we are working<br />

on proprietary parts, which is the<br />

long-term future of the company.<br />

We want customers to think of us as<br />

a very different company. We want<br />

to develop things that are really<br />

different, unique, and cool to solve<br />

problems that are not being solved<br />

today. That is our basic product<br />

choosing methodology.<br />

Our philosophy follows the words<br />

of Hall of Fame baseball player<br />

Willie Keeler: “Hit ‘em where they<br />

ain’t.” To us, this means don’t create<br />

the obvious products because<br />

customers will naturally gravitate<br />

toward the big companies. We are<br />

pursuing a niche strategy where<br />

we focus on markets that are big<br />

enough for us to make money but<br />

not so big that the larger companies<br />

would be interested in pursuing<br />

them.<br />

What industry sectors are you<br />

looking at?<br />

We are pretty flexible in terms of<br />

what we do. The initial focus of the<br />

company is toward industrial types<br />

of companies. We have naturally<br />

evolved to low power applications.<br />

We are combining those two things<br />

together and it seems to be working.<br />

As you target single-source<br />

applications components, is<br />

there any concern with IP as<br />

you design this part?<br />

We are designing in a different<br />

technology from the primary source,<br />

so almost by definition we have to<br />

use different architectures. We look<br />

at patents before we start. We do not<br />

want to infringe on someone else’s<br />

patents. We do not want to cause<br />

any unneeded issues.<br />

We want to fill niches<br />

in the marketplace,<br />

build our business up,<br />

and show engineers<br />

that we can solve<br />

problems that have not<br />

been solved before.<br />

Can you tell us more about<br />

the manufacturing and<br />

testing?<br />

We are using TSMC as our primary<br />

foundry. They are a great partner<br />

and have been very supportive<br />

along the way. We do most of<br />

our development in their 0.18µ<br />

technology but we are not limited to<br />

just that. We can use any technology<br />

that they have. That is the nice thing<br />

about our business model; we are<br />

flexible. We are able to pick the<br />

right technology for the product.<br />

We are old school with regard to<br />

testing. We test everything that we<br />

develop. If we are guaranteeing our<br />

specifications over temperature,<br />

we test and make sure that it will<br />

perform exactly what we say it will.<br />

How do you keep up with<br />

inventory?<br />

That is one of the big advantages<br />

for us. Because everything we are<br />

developing is on 8-inch wafers and<br />

we hold a lot of stuff in die banks, it<br />

does not cost us a huge amount of<br />

money to manufacture. If someone<br />

comes in with a huge order, we are<br />

able to manufacture, test, and ship<br />

it pretty fast.<br />

Can you tell us about your low<br />

power op amp?<br />

Customers seem to love the<br />

TS1001 600nA, 0.8V Op Amp. Even<br />

customers who cannot use it seem<br />

to love it, which is really nice for us.<br />

It has been a great door opener for<br />

the company. Where we are seeing<br />

a lot of use for this part is in lowpower<br />

applications. If someone<br />

needs bandwidth less than a<br />

kilohertz, and you want to reduce<br />

power consumption, it is perfect.<br />

Customers are getting really excited<br />

about it in those specific types of<br />

applications.<br />

What can we expect to see<br />

from Touchstone in the future?<br />

We have a couple of different<br />

<strong>EEWeb</strong> | Electrical Engineering Community Visit www.eeweb.com 6<br />

FEATURED INTERVIEW

INTERVIEW<br />

product families coming out at the<br />

end of September and October<br />

2011. I am a little bit hesitant to<br />

say anything until they come out<br />

because the scary thing in our<br />

business is until you see it and know<br />

it works, it’s not a sure thing.<br />

The thing that we really want<br />

customers to think about Touchstone<br />

is that the company is doing cool<br />

and unique things. Hopefully, as<br />

time goes on we will achieve that<br />

reputation, and customers will look<br />

to us for those types of cool and<br />

unique products. We want to fill<br />

niches in the marketplace, build our<br />

business up, and show engineers<br />

that we can solve problems that<br />

have not been solved before.<br />

How many products would<br />

you like to see Touchstone<br />

having in five years?<br />

Our minimum goal is 200, and it<br />

looks like we will easily be able<br />

to achieve that. We will continue<br />

<strong>EEWeb</strong><br />

Electrical Engineering Community<br />

Contact Us For Advertising Opportunities<br />

1.800.574.2791<br />

advertising@eeweb.com<br />

www.eeweb.com/advertising<br />

expanding our support staff around<br />

those products. Right now we have<br />

25 people in the company, and<br />

we are always looking for good<br />

designers. We have a very high bar<br />

regarding who we hire. We have an<br />

extremely talented and cohesive<br />

team, so it is an elite group that<br />

people will be joining. ■<br />

<strong>EEWeb</strong> | Electrical Engineering Community Visit www.eeweb.com 7<br />

FEATURED INTERVIEW

FEATURED PRODUCTS<br />

Fastest 14-bit Sample-and-Hold Amplifier<br />

Datel, a business unit of Murata Power Solutions has announced what it<br />

claims is the world’s fastest stand alone 14bit sample and hold amplifier.<br />

According to the company, the SHM-14 amplifier has a 70MHz full power<br />

bandwidth and 250MHz small signal bandwidth that achieves 12 and<br />

14bit acquisitions within 25ns (/-0.012%) and 35ns (/-0.003%) respectively.<br />

Datel adds that the low power device has an aperture jitter within 1ps<br />

and a low output noise of 65uV rms. Output linearity is within +/-0.0023%,<br />

while digital sample/hold inputs are differential and compatible with all<br />

logic families including TTL, CMOS and ECL. For more information,<br />

please click here.<br />

3-GHz, 10-Output Level Translator<br />

The LMK00301 is a 3-GHz, 10-output differential fanout buffer intended<br />

for high-frequency, low-jitter clock/data distribution and level translation.<br />

The input clock can be selected from two differential inputs or one<br />

crystal input. The selected input clock is distributed to two banks of 5<br />

differential outputs and one LVCMOS output. Each output bank can be<br />

configured as LVPECL, LVDS, or HCSL drivers, or disabled to reduce<br />

power. The LVCMOS output has a synchronous enable input for runtpulse-free<br />

operation when enabled or disabled. The LMK00301 can<br />

be powered from a single 3.3 V supply, or dual 3.3 V/2.5 V supplies for<br />

lower power operation. The LMK00301 provides high performance,<br />

versatility, and power efficiency, making it ideal for replacing fixedoutput<br />

buffer devices while increasing timing margin in the system. For<br />

more information, please click here.<br />

Tightest Offset Current-Sense Amplifiers<br />

Touchstone Semiconductor, a developer of high-performance analog<br />

integrated circuit solutions, announced the TS1100 family of 1µA currentsense<br />

amplifiers that cut offset to 30µV, over 3X tighter than the closest<br />

competitor. The tight offset allows users to not have to increase power<br />

consumption in order to achieve improved accuracy. This is something<br />

that cannot be done with any other low power current sense amplifier.<br />

The TS1100 is available in four gain options from 25V/V to 200V/V, so<br />

customers can choose the ideal gain option for their unique application.<br />

For more information, please click here.<br />

<strong>EEWeb</strong> | Electrical Engineering Community Visit www.eeweb.com 8<br />

FEATURED PRODUCTS

Avago Technologies Motion Control Solutions<br />

World’s Smallest Miniature<br />

Reflective 3-channel Encoder<br />

Features Advantages Benefits<br />

3-channel encoding<br />

(AB and I)<br />

Index Signal “I” No need for separate<br />

components to generate<br />

the index signal<br />

Miniature size Surface mount leadless<br />

package: 3.95 mm (L) x<br />

3.4mm (W) x 0.95mm H)<br />

Ability to fit into<br />

miniature motor designs<br />

304 LPI High encoding resolution Various CPR capable<br />

by adjusting to the<br />

matching ROP of the<br />

codewheel<br />

Built in Interpolator of<br />

1x, 2x, and 4x<br />

High operating<br />

frequencies: 55 kHz<br />

at 1x interpolation<br />

1x, 2x and 4x via external<br />

pinouts<br />

Operating frequencies can<br />

be increased by external<br />

interpolator pinouts by<br />

maximum of 4x<br />

Index gating Options available for both<br />

gated and ungated versions<br />

-20°C to 85°C Industrial application<br />

capable<br />

Base CPR resolution can<br />

be interpolated by end<br />

user<br />

Corresponding high<br />

RPM performance with<br />

increased frequencies<br />

Catering for various user<br />

gating requirements<br />

Covering consumer,<br />

commercial and<br />

industrial applications<br />

Avago Technologies AEDR-850x three<br />

channel reflective encoders integrate<br />

an LED light source, photo detector<br />

and interpolator circuitry.<br />

It is best suited to applications where<br />

small size and space matters!<br />

Applications include medical hand<br />

held devices, camera phones, wheel<br />

chairs, actuator, vending machine<br />

applications, just to name a few.<br />

To request a free sample go to:<br />

www.avagotech.com/motioncontrol

1Processing Rates<br />

Software and Hardware<br />

Platforms Enable Over<br />

TERAFLOP<br />

Computing applications have long used floating<br />

point numerical processing, including many in CPU<br />

architectures, which are mathematically superior<br />

and support wide dynamic ranges. However, most<br />

embedded applications have traditionally used fixed<br />

point processing. Despite significantly increasing<br />

development complexity (often three times the time of<br />

floating point development), fixed point microprocessors,<br />

DSPs, and FPGAs can generally provide lower power<br />

consumption, lower costs, and in the case of FPGAs,<br />

much higher processing rates.<br />

A new FPGA-based floating point flow is available that<br />

allows for the same high processing rate as enjoyed<br />

by fixed point applications to be achieved in floating<br />

point applications. A floating point co-processor which<br />

can be tightly coupled to FPGA hardware is also newly<br />

available, allowing both hardware and software floating<br />

point data processing to be leveraged. In addition, both<br />

of these new capabilities still support high throughput,<br />

fixed point processing for the parts of the DSP datapath<br />

that do not need the dynamic range of floating point<br />

processing. The result is a processing platform that<br />

Michael Parker<br />

Sr Technical Manager<br />

provides the advantages of both floating point and<br />

fixed point processing, while providing the flexibility to<br />

seamlessly partition and optimize the implementation<br />

between hardware and software.<br />

Parallelism is a key advantage of a hardware solution<br />

like FPGAs, but it is often not applied to floating point<br />

signal processing because long latencies make the<br />

data dependencies in algorithms, such as matrix<br />

decomposition, difficult to manage. Therefore, the<br />

resultant systems offered poor performance levels and<br />

were uncompetitive with other platforms such as GPU or<br />

multi-core CPU architectures.<br />

Altera has developed a floating point design flow<br />

that overcomes these issues. Rather than building a<br />

datapath from individual operators, the entire datapath<br />

is considered as a single function, with inter-operator<br />

redundancy factored out. Mantissa representation can<br />

be converted to hardware-friendly twos complement,<br />

and mantissa widths extended to reduce the frequency<br />

of normalizations. Elementary functions can be<br />

implemented as much as possible using hard multipliers,<br />

<strong>EEWeb</strong> | Electrical Engineering Community Visit www.eeweb.com 10

TECHNICAL ARTICLE<br />

which offer guaranteed internal routing and timing, as<br />

well as low power and latency. New techniques can be<br />

applied for matrix decompositions, with the algorithms<br />

restructured to remove most of the data dependencies,<br />

so that parallel—and therefore high latency—datapaths<br />

can be used for these computations.<br />

This approach is known as “Fused Datapath,” and when<br />

combined with a new 28nm Variable Precision DSP<br />

block architecture, offers extremely high data processing<br />

capabilities, in excess of one TeraFLOPS on a single<br />

FPGA die. The Fused Datapath technology has been<br />

embedded in Altera’s DSPBuilder design suite, which<br />

allows the full simulation and system design capabilities<br />

of Mathworks’ Matlab and Simulink to be utilized. This<br />

FPGA innovation in high-performance floating point<br />

enables the parallel hardware architecture advantages<br />

to be used in the very highest performance applications<br />

where the dynamic range of floating point is required.<br />

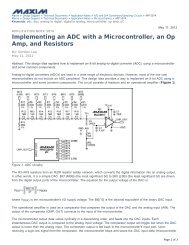

An example of the matrix inversion processing capability<br />

with the latest floating point Cholesky matrix processing<br />

design is shown in Figure 1.<br />

Multi-Channel Cholesky Inversion Core<br />

Matrix Size Vector Size Throughput (matrices/sec) Latency (us)<br />

100x100<br />

50x50<br />

75x75<br />

50x50<br />

25x25<br />

20x20<br />

50<br />

50<br />

25<br />

25<br />

25<br />

20<br />

29,900<br />

128,000<br />

42,700<br />

118,000<br />

256,000<br />

1,000,000<br />

380<br />

270<br />

392<br />

304<br />

71<br />

96<br />

Multiple single precision Cholesky cores may be implemented with a single FPGA<br />

Figure 1: FPGA-based Floating Point Processing Throughput<br />

Example<br />

For more information on Altera’s FPGA floating point<br />

design flow using Altera’s DSPBuilder Advanced<br />

Blockset and Mathworks’ Simulink, please refer to the<br />

recent BDTI whitepaper and toolflow evaluation available<br />

here.<br />

Most floating point applications are currently<br />

implemented in software. With this new FPGA design<br />

flow now offering extremely high processing rates, a<br />

new architecture can be conceived that uses a tightly<br />

coupled C-programmable engine as a co-processor to<br />

the FPGA, rather than just the reverse. The FPGA can<br />

implement the repetitive, high GFLOPS portions of the<br />

algorithm, while the co-processor can deal with the<br />

more complicated and data-dependent algorithms. This<br />

approach would combine the performance advantages of<br />

hardware implementations with the ease of development<br />

of software implementations.<br />

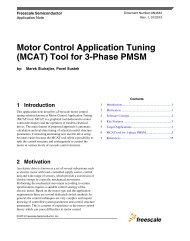

The new Anemone floating point processor from<br />

BittWare connects to the FPGA via high-rate, low latency<br />

link ports. All access to off-chip memory is through<br />

the FPGA, as are off-board interfaces, such as PCIe<br />

backplanes or Ethernet ports. The Anemone processor<br />

is a multi-core design, currently offering 16 cores<br />

per chip, all interconnected in a mesh network with a<br />

shared memory model. Each core has 32 Kbytes of local<br />

memory, supports IEEE-754 floating point processing,<br />

and is individually programmable using ANSI-C. The 16core<br />

Anemone chip offers 32 GFLOPS, while consuming<br />

only two watts of total power. Four Anemone chips,<br />

providing 128 GFLOPS, are available on an FMC (VITA<br />

57) standard daughter card for use on FPGA host boards<br />

such as AMC, PCIe, and VPX. These are available today<br />

with Altera high end Stratix IV FPGAs, as shown in Figure<br />

2, and will be offered later this year with Stratix V FPGAs.<br />

The Anemone-to-FPGA interface is made transparent<br />

to the application using BittWare’s ATLANTiS<br />

FrameWork, which can bolt up seamlessly to Altera’s<br />

QSys FPGA system interconnect tool. This facilitates<br />

optimal partitioning of processing tasks between the<br />

Anemone and FPGA. With up to one TeraFLOPS of<br />

hardware floating point processing on Stratix V FPGAs,<br />

and 128 GLOPS of software floating point processing<br />

on Anemone, extremely high computational rate<br />

applications can be implemented in a low form factor,<br />

low power consumption platform.<br />

An example application might be high-performance<br />

airborne radar systems. The FPGA can implement the<br />

digital downconversion, beamforming, MTI filtering,<br />

Doppler FFT processing, pulse compression, and<br />

matrix inversions needed in space-time adaptive<br />

processing (STAP). The Anemone processor is ideal<br />

for lower GFLOPs but more complex tasks. Examples<br />

of this are CFAR detection processing, computing beam<br />

forming coefficients, adapting and controlling radar<br />

modes, and transmit waveform generation. Low latency<br />

between the processing sub-systems is essential, and<br />

<strong>EEWeb</strong> | Electrical Engineering Community Visit www.eeweb.com 11<br />

TECHNICAL ARTICLE

TECHNICAL ARTICLE<br />

LEDs<br />

ANENOME<br />

Floating Point<br />

Co-Processor<br />

ANENOME<br />

Floating Point<br />

Co-Processor<br />

ANENOME<br />

Floating Point<br />

Co-Processor<br />

ANENOME<br />

Floating Point<br />

Co-Processor<br />

DDR3 SDRAM<br />

(up to 1 GB) 32<br />

DDR3 SDRAM<br />

(up to 1 GB) 32<br />

Link Ports<br />

Clocks, I2C, JTAG, Reset<br />

Figure 2: Anemone-Stratix High Performance Floating Point Processing System featuring an AAFM co-processing mezzanine on an S4-3U-<br />

VPX.<br />

these requirements are not easily met with GPU or CPU<br />

architectures. The combination of Anemone and Stratix<br />

FPGAs offer an ideal balance of TeraFlops processing<br />

power, flexibility to partition across hardware and<br />

software implementation, high GLOPS/Watt, and a very<br />

compact form factor.<br />

This combination can also be ideal for any embedded<br />

application requiring high-performance computing<br />

power in military, medical imaging, wireless, or test<br />

equipment applications. Through the choice of FPGA<br />

and number of Anemone chips, the design can easily<br />

scale the level of processing power. The availability of<br />

Anemone-Stratix systems on BittWare’s COTS boards<br />

and systems supports rapid product development<br />

cycles.<br />

RS-232<br />

JTAG<br />

Header<br />

About the Author<br />

Michael Parker received his MSEE from Santa Clara<br />

University in California, and his BSEE from Rensselaer<br />

Polytechnic Institute in New York. He has over 20 years<br />

of DSP wireless engineering design experience with<br />

companies such as Alvarion, Soma Networks, TCSI,<br />

Stanford Telecom, and numerous startup companies.<br />

Michael joined Altera in January 2007, and is responsible<br />

for Altera’s entire digital signal processing (DSP) product<br />

planning.<br />

Michael authored a book entitled Digital Signal<br />

Processing 101, published in 2010 and has written and<br />

published over 20 technical articles on DSP, floating<br />

point, and various other technology subjects. ■<br />

<strong>EEWeb</strong> | Electrical Engineering Community Visit www.eeweb.com 12<br />

Control<br />

Port<br />

FINe<br />

Bridge<br />

Data<br />

Port<br />

FPGA<br />

Stratix IV GX<br />

(4SGX230/530)<br />

FLASH<br />

Supported by:<br />

ATLANTiS Framework<br />

Serdes<br />

GigE<br />

10/100 Ethernet (Build Option)<br />

32<br />

32<br />

4x<br />

4x<br />

4x<br />

3x<br />

DDR3 SDRAM<br />

(up to 1 GB)<br />

DDR3 SDRAM<br />

(up to 1 GB)<br />

32 LVDS pairs<br />

4 bits DIO or RS 232/RS422<br />

(Build Options)<br />

4 bits DIO<br />

(Build Option without 10/100 Eth.)<br />

(sRIO, PCIexp, 10GigE)<br />

P0<br />

P1<br />

P2<br />

TECHNICAL ARTICLE

System Perspective<br />

on Specifying Electronic<br />

Power Supplies:<br />

Bob Stowe<br />

Power Supply Design Consultant<br />

Load<br />

Characterization<br />

In a previous issue (Issue 19) we introduced the topic of<br />

“A System Perspective on Specifying Electronic Power<br />

Supplies.” In this article we will learn about the effect of<br />

the load on specifying a power supply.<br />

The following drawing shows a power supply in a<br />

very simplified form, connected to a simplified load.<br />

The feedback and control circuit measures the output<br />

voltage, compares it to a reference (not shown), and<br />

adjusts the source voltage to maintain the load voltage<br />

constant. This process is not perfect, and the power<br />

supply specifications describe the deviation from<br />

perfection. The deviation from perfection must be within<br />

the requirements demanded by the load for the load to<br />

operate satisfactorily.<br />

The Importance of<br />

Understanding the Load<br />

The load imposes a major portion of the performance<br />

requirements on the power supply. The power supply is<br />

never a perfect black box and it is extremely important<br />

to treat it as a vital and integral part of your system. It<br />

must meet the demands placed upon it by the load in<br />

several key performance measures. The most common<br />

measures are discussed below:<br />

Static Requirements<br />

Typically, the load requires one of the following<br />

parameters to be provided and controlled to within<br />

a certain tolerance band: voltage, current, or power.<br />

The other two parameters which are not controlled<br />

would be called compliance parameters. For example,<br />

a subassembly might be designed to operate with a<br />

controlled input voltage of 5 volts. When excited with<br />

a controlled input voltage of 5 volts, the subassembly<br />

responds by drawing up to 10 amperes, and consuming<br />

up to 50 watts of power. This means that the power supply<br />

must maintain the output voltage at 5 volts and be able<br />

to provide up to 10 amperes of current, since up to 10<br />

amperes is what the load draws when excited by 5 volts.<br />

In this case, power is an alternate way of expressing<br />

compliance because power is the same as voltage times<br />

current.<br />

<strong>EEWeb</strong> | Electrical Engineering Community Visit www.eeweb.com 13

TECHNICAL ARTICLE<br />

Some loads may require different controlled parameters<br />

at different times. Such an example is a battery charger<br />

which might require constant current for battery charge<br />

mode and constant voltage for battery maintenance<br />

mode.<br />

Loads will require the controlled parameter to be within a<br />

certain tolerance band for proper operation. The power<br />

supply must maintain the controlled parameter within<br />

the tolerance band.<br />

These parameters may be expressed in terms of average,<br />

RMS, or a peak value with a duration qualifier.<br />

Dynamic Requirements<br />

Loads also exhibit dynamic characteristics which change<br />

over time.<br />

Time Transients<br />

Many types of loads frequently change their effective<br />

impedance. Such an example might be a computer<br />

printer which exhibits rapid step changes in effective<br />

impedance. For such a device to function properly, the<br />

power supply must be able to rapidly source spurts<br />

of output current while maintaining the output voltage<br />

within a specified band. This means that the power<br />

supply must have enough output capacitance and high<br />

enough control loop bandwidth to maintain the output<br />

Vsource<br />

Power Supply<br />

Zout<br />

Feedback<br />

and<br />

Control<br />

Figure 1: Simplified representation of power supply and load.<br />

voltage within the prescribed limits. Loads which have<br />

this type of behavior must have power supplies specified<br />

to limit the droop on the leading edge of the pulse, and<br />

recover to within a certain band of the steady state output<br />

in a prescribed time interval.<br />

Voltage Dependence<br />

Non-linear loads change impedance as voltage is<br />

increased. One example is a typical solid-state circuit<br />

which might draw very little current at low voltages,<br />

and then begin to draw current with a very rapid and<br />

nonlinear increase as voltage is increased.<br />

A more problematic configuration is cascading a power<br />

supply with a second power supply of a switching<br />

converter design. A switching converter has a nonlinear<br />

negative resistance characteristic. At very low input<br />

voltages, below the turn-on threshold, the current may<br />

be miniscule. When the input voltage is increased to<br />

the turn-on threshold, the input current suddenly draws<br />

very high current. As the input voltage is increased, the<br />

input current decreases, following a constant power<br />

characteristic. If care is not taken in the first power<br />

supply design and cable length, the load (the switching<br />

converter) will cycle on and off because of the voltage<br />

drop in the cable length and/or the output impedance of<br />

the power supply.<br />

<strong>EEWeb</strong> | Electrical Engineering Community Visit www.eeweb.com 14<br />

Iload<br />

Zload<br />

+<br />

Vload<br />

_<br />

TECHNICAL ARTICLE

TECHNICAL ARTICLE<br />

Frequency Dependence<br />

<strong>EEWeb</strong><br />

Electrical Engineering Community<br />

Loads can create a frequency dependence which<br />

is not obvious to the untrained user. This frequency<br />

dependence is of at least two forms:<br />

1. Resonant behavior can occur due to inductance and<br />

capacitance in both the power supply and the load.<br />

It is possible for power supplies to resonate with<br />

load capacitance or inductance if the power supply<br />

is not designed well for the load. This resonance<br />

will usually take place at frequencies determined<br />

by the reactive elements in the system. This effect is<br />

usually undesirable unless the system is designed to<br />

be resonant.<br />

2. The power supply control loop behavior can be<br />

adversely influenced due to load capacitance and<br />

inductance. The presence of substantial capacitance<br />

or inductance can move the control loop poles and<br />

zeros, substantially changing the transient response<br />

and ripple rejection capability of the power supply<br />

by decreasing or possibll increasing the bandwidth<br />

of the power supply.<br />

Join Today<br />

www.eeweb.com/register<br />

Temperature Dependence<br />

Loads must operate in their intended environment. More<br />

often than not, the power supplies for these loads must<br />

operate in the same environment. These environments<br />

may be benign, such as a test laboratory, or severe,<br />

as in down-hole oil and natural gas exploration. The<br />

power supply must be able to work in the environment<br />

of the load, or the power supply environment must be<br />

separated from the load to allow satisfactory operation.<br />

About the Author<br />

Bob Stowe has over 21 years of experience in various<br />

disciplines related to electronic energy conversion,<br />

possesses a master’s degree in power electronics,<br />

and is a member of IEEE in good standing. He also<br />

has obtained his certification in power electronics from<br />

the University of Colorado (COPEC). Additionally, he<br />

graduated from the United States Naval Academy in 1984<br />

with a bachelor’s degree in electrical engineering, and<br />

served for five subsequent years as a United States Naval<br />

Officer. As a former military officer, he is familiar with<br />

military project requirements. Bob now works for True<br />

Power Research as a Power Supply Design consultant. ■<br />

<strong>EEWeb</strong> | Electrical Engineering Community Visit www.eeweb.com 15<br />

TECHNICAL ARTICLE

High Efficiency 5V, 10A Buck Regulator<br />

ISL95210<br />

The ISL95210 is a high-efficiency step-down regulator that can<br />

deliver 10A of output current from a 5V input. The small<br />

4mmx6mm QFN package and only four external components<br />

provide a very small total solution size. Low resistance internal<br />

MOSFETs deliver excellent efficiency and permit full power<br />

operation in a +90°C ambient without airflow.<br />

The regulator operates from an input voltage of 2.97V to 5.5V,<br />

and provides a 0.6% accurate output voltage over the full<br />

operating temperature range. Intersil's patented R4 control<br />

architecture provides exceptional transient response with no<br />

external compensation components. The output voltage may be<br />

programmed by an internal DAC or by an external resistor divider<br />

(see “Output Voltage Programming” on page 11 for more<br />

details).<br />

Several digital control signals provide flexibility for users that<br />

want additional features. Switching frequency, switching mode,<br />

output voltage margining and daisy-chained power-good<br />

functions are all programmed by these pins. The ISL95210 also<br />

includes comprehensive internal protection for overvoltage,<br />

undervoltage, overcurrent and over-temperature conditions.<br />

Related Literature<br />

• See AN1485, “ISL95210 10A Integrated FET Regulator<br />

Evaluation Board Setup Procedure”<br />

VIN = 5V<br />

CONTROL<br />

SIGNALS<br />

CIN<br />

10µF<br />

VCC<br />

VIN<br />

PVCC<br />

EN<br />

PG_IN<br />

FSET<br />

VSEL1<br />

MPCT<br />

MSEL<br />

VSEL0<br />

FCCM<br />

PGOOD<br />

PHASE<br />

VOUT<br />

VCC<br />

AGND<br />

PGND<br />

T-PAD<br />

LOUT<br />

420nH<br />

VOUT = 1.2V<br />

COUT<br />

220µF<br />

FIGURE 1. 10A DC/DC CONVERTER USING ONLY 4 EXTERNAL<br />

COMPONENTS<br />

November 17, 2011<br />

FN6938.3<br />

ISL95210<br />

FSW= 800kHz<br />

1µF<br />

+<br />

POWER GOOD<br />

LOUT = MPC0740LR42C (NEC/TOKIN)<br />

COUT = 2TPLF220M5 (SANYO)<br />

Features<br />

• 10A Continuous Output Current<br />

• 2.97V to 5.5V Input Voltage Range<br />

• Up to 95% Efficiency<br />

• Full Power Operation in +90°C Ambient without Airflow<br />

• R4 Control Architecture Delivers Excellent Transient<br />

Response Without Compensation<br />

• Pin Selectable Output Voltage Programming<br />

• ±0.6% Output Voltage Accuracy Over Full Operating<br />

Temperature Range<br />

• Programmable Enhanced Light-Load Efficiency Operation<br />

• Output Voltage Margining and Power-good Monitor<br />

• Small 6mmx4mm QFN Package<br />

Applications<br />

• Point-of-Load Power Supplies<br />

• Notebook Computer Power<br />

• General Purpose Power Rail Generation<br />

EFFICIENCY (%)<br />

100<br />

95<br />

90<br />

85<br />

80<br />

75<br />

70<br />

65<br />

Get the Datasheet and Order Samples<br />

http://www.intersil.com<br />

60<br />

55<br />

50<br />

VIN = 5V<br />

VOUT = 1.2V<br />

FSW = 800kHz<br />

0 1 2 3 4 5<br />

IOUT (A)<br />

6 7 8 9 10<br />

FIGURE 2. EFFICIENCY OF CIRCUIT SHOWN IN FIGURE 1<br />

(INCLUDES INDUCTOR LOSSES)<br />

Intersil (and design) is a registered trademark of Intersil Americas Inc. Copyright Intersil Americas Inc. 2011<br />

All Rights Reserved. All other trademarks mentioned are the property of their respective owners.

RETURN TO ZERO<br />

<strong>EEWeb</strong> | Electrical Engineering Community Visit www.eeweb.com 17<br />

RETURN TO ZERO

RETURN TO ZERO<br />

<strong>EEWeb</strong><br />

Electrical Engineering Community<br />

Contact Us For Advertising Opportunities<br />

1.800.574.2791<br />

advertising@eeweb.com<br />

www.eeweb.com/advertising<br />

<strong>EEWeb</strong> | Electrical Engineering Community Visit www.eeweb.com 18<br />

RETURN TO ZERO