Anthony Catalano - EEWeb

Anthony Catalano - EEWeb

Anthony Catalano - EEWeb

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

PROJECT<br />

mathematical description might be possible for one or<br />

two of these processes, the complex overlapping and<br />

interdependence of the processes makes it impossible<br />

at this time.<br />

Standards: LM-80 and TM-21<br />

The Illumination Engineering Society (IES) has<br />

developed standards for testing LEDs so performance<br />

and reliability can be characterized in a consistent<br />

fashion to assess their practical life. One standard,<br />

LM-80, provides a description of the method to be used<br />

in determining the “Lumen Maintenance” of LEDs, that<br />

is the light output as a function of time. The essential<br />

features specified by the testing protocol are:<br />

• Ambient and LED Case Temperature and Orientation<br />

• Drive Voltage, Current and Waveform<br />

• Instrumentation<br />

The standard calls for measurement of light output<br />

at an ambient air temperature of 25 o C, but LED case<br />

temperatures of 55 o C, 85 o C and another temperature<br />

selected by the manufacturer. The drive current is<br />

specified by the manufacturer as this varies with the<br />

die area of the LED. Measurements take place over a<br />

minimum of 6000 hrs of operation (10,000 hrs is preferred)<br />

and at intervals of at most 1000 hrs. It is common practice<br />

among first-tier manufacturers to employ several different<br />

drive currents. As we shall see later this is very important<br />

to our method of ensuring LED lifetime.<br />

Although LM-80 provides a uniform method for measuring<br />

light output over time under standardized conditions, in<br />

practice LEDs may be used at temperatures that differ<br />

substantially from the LM-80 values. Moreover, because<br />

this is not an accelerated testing method, very long times<br />

are needed to reach a conclusion on reliability. Another<br />

more recent IES Standard, TM-21 helps solve this<br />

dilemma. The standard is effectively an “ad hoc” model<br />

of LED degradation that allows the interpolation of timetemperature<br />

data between temperatures and formalizes<br />

the extrapolation of data into the future to predict output<br />

over extended times. The major points of the standard<br />

are:<br />

• Exponential Decrease in Light Output (LOP) is<br />

assumed<br />

• LOP May be Extrapolated Maximum of 6x in Time<br />

• Interpolation Between Temperatures Are Based on<br />

“Activation Energy”<br />

In mathematical terms the decrease in light output can<br />

be stated as,<br />

L(t) B[e ]<br />

t -a<br />

=<br />

where L(t) is the Lumen output at time t, B is the<br />

normalized light output at 0 or 1 hours, and α is the<br />

decay rate, which is a function of temperature. The value<br />

of α varies with temperature according to the Arrehenius<br />

expression,<br />

a(T)<br />

= Ce<br />

<strong>EEWeb</strong> | Electrical Engineering Community Visit www.eeweb.com 12<br />

E /kT a -<br />

where Ea is the activation energy, k is Boltzmann’s<br />

constant and T is the temperature in degrees Kelvin, and<br />

C is a constant. The TM-21 standard only allows for the<br />

interpolation of temperature data, so for two temperatures<br />

T 1 and T 2 we can calculate the activation factor, E a /k as,<br />

a1<br />

ln[ a2<br />

] Ea<br />

= ( )<br />

1 1 k<br />

[ - ]<br />

T2<br />

T1<br />

Once the activation factor is known then it is<br />

straightforward to calculate the decay rate from the<br />

Arrehenius expression for the intermediate temperature<br />

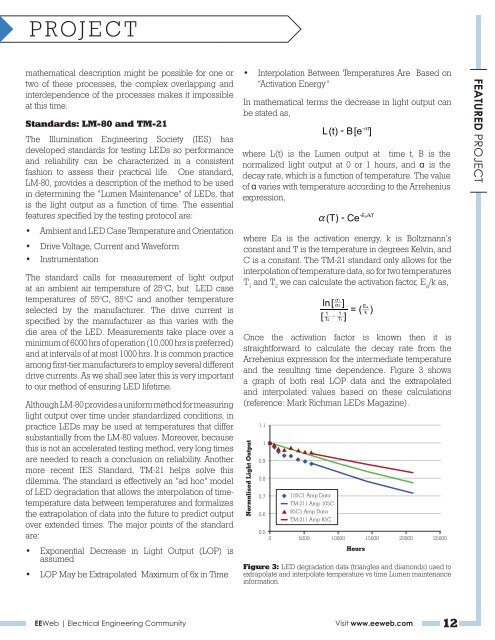

and the resulting time dependence. Figure 3 shows<br />

a graph of both real LOP data and the extrapolated<br />

and interpolated values based on these calculations<br />

(reference: Mark Richman LEDs Magazine).<br />

Normalised Light Output<br />

1.1<br />

1<br />

0.9<br />

0.8<br />

0.7<br />

0.6<br />

105C1 Amp Data<br />

TM-211 Amp 105C<br />

85C1 Amp Data<br />

TM-211 Amp 85C<br />

0.5<br />

0 5000 10000 15000 20000 25000<br />

Hours<br />

Figure 3: LED degradation data (triangles and diamonds) used to<br />

extrapolate and interpolate temperature vs time Lumen maintenance<br />

information.<br />

FEATURED PROJECT