- Page 1 and 2: otion control SIMOVERT MASTERDRIVES

- Page 3 and 4: 1) North American Catalog SIMOVERT

- Page 5 and 6: Motion Control Overview 1/2 Applica

- Page 7 and 8: Compact and chassis units Compact P

- Page 9: Compact and chassis units SIMOVERT

- Page 13 and 14: Motion Control Technical data 2/2 G

- Page 15 and 16: Reduction curves Permissible rated

- Page 17 and 18: Compact and chassis units Permissib

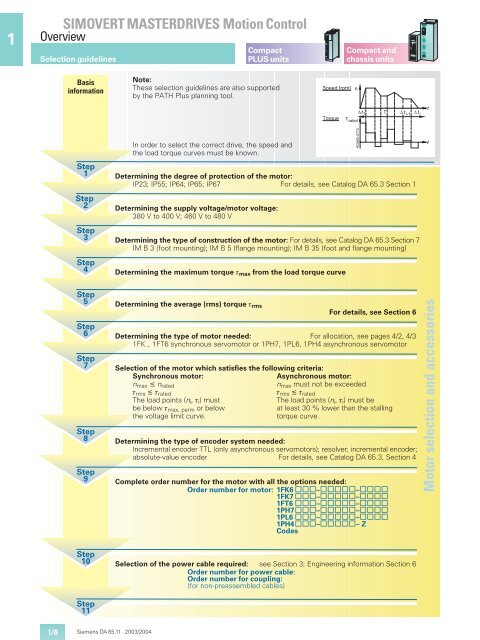

- Page 19 and 20: Motion Control Selection and orderi

- Page 21 and 22: Basic units Nominal power rating 1

- Page 23 and 24: Nominal power rating 1 ) Compact an

- Page 25 and 26: Compact and chassis units 1) See

- Page 27 and 28: Compact and chassis units Control b

- Page 29 and 30: Sound pressure level with standard

- Page 31 and 32: Sound pressure level with standard

- Page 33 and 34: Sound pressure level with standard

- Page 35 and 36: SCI1 and SCI2 interface boards (for

- Page 37 and 38: Capacitor module 1 ) DC link module

- Page 39 and 40: Nomin al power rating Compact and c

- Page 41 and 42: Rectifier units Nominal power ratin

- Page 43 and 44: Rated rectifier/ regenerative outpu

- Page 45 and 46: Nominal power rating Compact and ch

- Page 47 and 48: Inverter Nominal power rating Compa

- Page 49 and 50: Compact and chassis units SIMOVERT

- Page 51 and 52: Compact and chassis units 6FX@ 002-

- Page 53 and 54: Compact and chassis units SIMOVERT

- Page 55 and 56: Compact and chassis units SIMOVER

- Page 57 and 58: Compact and chassis units The OP1S

- Page 59 and 60: Compact and chassis units SIMOVERT

- Page 61 and 62:

Drive ES Basic Drive ES Graphic Com

- Page 63 and 64:

Compact and chassis units Software

- Page 65 and 66:

Motion Control Motor selection 4/2

- Page 67 and 68:

Compact and chassis units Motors fr

- Page 69 and 70:

Compact PLUS units Inverters with 1

- Page 71 and 72:

Compact PLUS units Inverters with a

- Page 73 and 74:

Compact and chassis units SIMOVERT

- Page 75 and 76:

Compact and chassis units SIMOVERT

- Page 77 and 78:

Compact and chassis units SIMOVERT

- Page 79 and 80:

Compact and chassis units SIMOVERT

- Page 81 and 82:

Motion Control Documentation and tr

- Page 83 and 84:

Compact and chassis units Operating

- Page 85 and 86:

Compact and chassis units SIMOVERT

- Page 87 and 88:

Compact and chassis units The start

- Page 89 and 90:

Compact and chassis units Overview

- Page 91 and 92:

Motion Control Engineering informat

- Page 93 and 94:

Compact and chassis units 3. Calcul

- Page 95 and 96:

Compact and chassis units 5. Select

- Page 97 and 98:

Compact and chassis units 8. Select

- Page 99 and 100:

Compact and chassis units 3. Max. s

- Page 101 and 102:

Thus: Compact and chassis units IMo

- Page 103 and 104:

Compact and chassis units 3. Max. s

- Page 105 and 106:

Compact and chassis units SIMOVERT

- Page 107 and 108:

Legend Compact and chassis units SI

- Page 109 and 110:

Compact and chassis units Installat

- Page 111 and 112:

Compact and chassis units X7 D' C'

- Page 113 and 114:

Compact and chassis units SIMOVERT

- Page 115 and 116:

Compact and chassis units Safe Stop

- Page 117 and 118:

Compact PLUS units Compact PLUS con

- Page 119 and 120:

Compact PLUS units Compact PLUS con

- Page 121 and 122:

Compact PLUS units Compact PLUS inv

- Page 123 and 124:

Compact PLUS units Terminals of the

- Page 125 and 126:

Compact PLUS units Compact PLUS cap

- Page 127 and 128:

Compact and chassis units Compact-t

- Page 129 and 130:

Compact and chassis units Compact-t

- Page 131 and 132:

Compact and chassis units Chassis-t

- Page 133 and 134:

Compact and chassis units Chassis-t

- Page 135 and 136:

Compact and chassis units Rectifier

- Page 137 and 138:

Compact and chassis units Applicati

- Page 139 and 140:

Compact and chassis units Electroma

- Page 141 and 142:

Compact and chassis units Rectifier

- Page 143 and 144:

Compact and chassis units Technical

- Page 145 and 146:

Compact and chassis units Overload

- Page 147 and 148:

Compact and chassis units Braking u

- Page 149 and 150:

Compact and chassis units Free-whee

- Page 151 and 152:

Compact and chassis units Component

- Page 153 and 154:

Compact and chassis units The incre

- Page 155 and 156:

Compact and chassis units Note If u

- Page 157 and 158:

Compact and chassis units X424 - Te

- Page 159 and 160:

Compact and chassis units The follo

- Page 161 and 162:

Connection X490 Compact and chassis

- Page 163 and 164:

Compact and chassis units Peer-to-p

- Page 165 and 166:

Compact and chassis units SIMOVERT

- Page 167 and 168:

Compact and chassis units Integrati

- Page 169 and 170:

Compact and chassis units USS proto

- Page 171 and 172:

Technical data of the SLB Compact a

- Page 173 and 174:

Compact and chassis units Bus conne

- Page 175 and 176:

Compact and chassis units The CAN p

- Page 177 and 178:

Overview Compact and chassis units

- Page 179 and 180:

Compact and chassis units Technolog

- Page 181 and 182:

Compact and chassis units Technolog

- Page 183 and 184:

Compact and chassis units Technolog

- Page 185 and 186:

Compact and chassis units Encoders

- Page 187 and 188:

Compact and chassis units Central c

- Page 189 and 190:

Compact and chassis units USS bus v

- Page 191 and 192:

Compact and chassis units Fig. 6/10

- Page 193 and 194:

Motion Control Dimension drawings 7

- Page 195 and 196:

360 14.2 Fig. 7/3 260 10.2 220 8.6

- Page 197 and 198:

Inverters, size J 350 13.78 67 2.64

- Page 199 and 200:

200 7.87 200 7.87 27.95 710 ø9 0.3

- Page 201 and 202:

Type b 1 4EP38 4EP39 4EP40 mm (in)

- Page 203 and 204:

Type Designation acc. to DIN 41 302

- Page 205 and 206:

Power COMBICON (2 x) Fig. 7/22 Comp

- Page 207 and 208:

Compact and chassis units Busbar su

- Page 209 and 210:

Compact and chassis units SIMOVERT

- Page 211 and 212:

Compact and chassis units SIMOVERT

- Page 213 and 214:

Compact and chassis units (continue

- Page 215 and 216:

Compact and chassis units SIMOVERT

- Page 217 and 218:

Compact and chassis units u t l d 6

- Page 219 and 220:

Compact and chassis units u t l SIM

- Page 221 and 222:

Compact and chassis units For motor

- Page 223 and 224:

Compact and chassis units For motor

- Page 225 and 226:

Motion Control Appendix A/2 Certifi

- Page 227 and 228:

Compact and chassis units SIMOVERT

- Page 229 and 230:

Compact and chassis units Compact P

- Page 231 and 232:

Compact and chassis units SIMOVERT

- Page 233 and 234:

Compact and chassis units In the fa

- Page 235 and 236:

Compact and chassis units SIMOVERT

- Page 237 and 238:

Compact and chassis units Siemens A

- Page 239 and 240:

Automation & Drives Interactive cat

- Page 241:

Catalog DA 65.11 • 2003/2004 SIMO