The Siemens answer: Complete mobility. - Virtual Vehicle

The Siemens answer: Complete mobility. - Virtual Vehicle

The Siemens answer: Complete mobility. - Virtual Vehicle

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

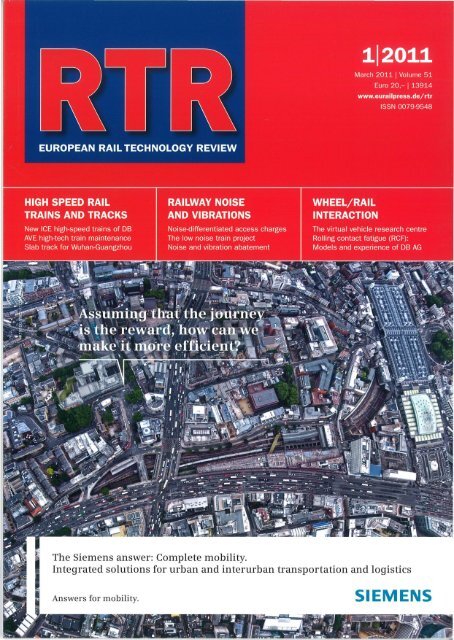

<strong>The</strong> <strong>Siemens</strong> <strong>answer</strong>: <strong>Complete</strong> <strong>mobility</strong>.<br />

Integrated solutions for urban and interurban transportation and logistics<br />

Answers für mübility. SIEMENS

Front cover:<br />

<strong>Complete</strong> <strong>mobility</strong>.<br />

Ensuring <strong>mobility</strong> is the number-one challenge in our<br />

society. We need networked traffic and information<br />

systems to remain mobile in future - for safe, costeffective<br />

and environmentally friendly passenger and<br />

cargo traffic. That is why, with "<strong>Complete</strong> <strong>mobility</strong>",<br />

<strong>Siemens</strong> creates integrated efficient transport and<br />

logistics solutions, from infrastructure equipment for<br />

rail and road traffic, rail vehicles through to airport<br />

logistics and postal automation. (Foto: <strong>Siemens</strong>)<br />

Superior quality, reliability, and a long life span - these are<br />

the high standards you can expect from ZF's cutting-edge<br />

technology for all types of rall vehicle: the optimized weight<br />

of the ZF-Highspeed transmission, complete driveline<br />

systems, damping components and modules, and vibration<br />

isolation for greater comfort and safety.<br />

Driveline and Chassis Technology

Research into vehiclejtrack interactions<br />

Knowledge of the interactions between rai/way vehicles and their track is a<br />

precondition for further optimisation of the wheeljrail system. <strong>The</strong> "<strong>Vehicle</strong><br />

Oynamics - Rail Applications" group within in the <strong>Virtual</strong> <strong>Vehicle</strong> Research Centre<br />

in Graz (Austria) is involved in a project to establish the influences of various<br />

parameters on the dynamic interactions between vehicles and railway tracks and<br />

their consequential effects, making use of vehicles, which, although only virtual,<br />

are very close to reality.<br />

Rg. 1: Computer graphie ofa "virtual rai/way vehiele"<br />

Sourees: <strong>Siemens</strong> (photo) and <strong>Virtual</strong> Vehiele (multiple-body simulation. graphie)<br />

<strong>The</strong> decisive factor in optimising the railway<br />

as a system is to apply a holistic, systematic<br />

view of that system, along with the subsystems<br />

"vehicle" and "track", and the way<br />

they interact through the wheeljrail contact.<br />

<strong>The</strong> kernel of the wheeljrail contact can be<br />

studied by looking into four facets: "contact<br />

geometry", "adhesion", "wear" and "damage".<br />

In addition to this, the structural dynamic<br />

properties of the wheel sets as weil<br />

as the dynamic properties of the track are<br />

of importance. Allofthis is also associated<br />

with questions regarding the quality of the<br />

track's geometry and the condition of the<br />

track.<br />

By fitting together the specific simulation<br />

Dipl.-Ing.<br />

Bernd Luber<br />

Team Leader <br />

Rail Applications<br />

Area Mechanics<br />

<strong>Virtual</strong> <strong>Vehicle</strong> Competence Centre, Graz<br />

bemd.luber@V2c2.at<br />

32 RTR 1/2011<br />

models in the area of "rail systems", as<br />

the Graz centre is doing, it becomes possible<br />

to produce conclusions closely reflecting<br />

the reality of the railway as a complete<br />

system. <strong>The</strong>se results can then be applied<br />

right fram the early phase of product development<br />

thraugh to maintenance (Fig. 1).<br />

1 Wheeljrail contact<br />

Effects occur at the point of adhesion between<br />

the wheel and the rail that are relevant<br />

not only for the dynamics of vehicle<br />

movement and the track andjor the damage<br />

phenomena but also for making adjust-<br />

Dr. techno<br />

Martin Rosenberger<br />

Co-Head of<br />

Area Mechanics<br />

<strong>Virtual</strong> <strong>Vehicle</strong> Competence Centre, Graz<br />

martin.rosenberger@v2c2.at<br />

ments to traction and braking. <strong>The</strong> "rail systems"<br />

group in Graz is developing models<br />

for the purpose of recording relevant influences<br />

and visualising them reliably.<br />

It is a fair general statement that the mechanisms<br />

regarded as responsible for the occurrence<br />

of many of the forms of damage<br />

affecting wheels and rails have not yet been<br />

adequately researched. It is possible that<br />

a better understanding of the processes at<br />

play in wheeljrail contact may lead to a reduction<br />

in wear and rolling contact fatigue<br />

(RCF) affecting both wheels and rails. If so,<br />

it will then be possible to lengthen maintenance<br />

intervals and bring down maintenance<br />

costs. At the same time, there will<br />

be improvements in operational safety and<br />

passenger comfort.<br />

1.1 Damage mechanisms<br />

In order to understand the underlying<br />

mechanisms that lead to wear (profile wear,<br />

short-pitched rail corrugations and eccentricities)<br />

and RCF (head checks and herringbone<br />

patterns), it is necessary to know<br />

about the friction processes occurring at<br />

the point of contact, on the one hand, and<br />

the structural dynamics of the vehicle and<br />

the track, on the other hand (Fig. 2).<br />

<strong>The</strong> effects occurring at the point of adhesion<br />

between wheels and rails are, however,<br />

also of significance for adjusting traction<br />

and breaking. <strong>The</strong> models already in<br />

use today do not take sufficient account<br />

of them. <strong>The</strong> adhesion characteristics are<br />

affected by temperature influences, rough-<br />

Dr. techno<br />

Michael Schmeja<br />

Area Manager System<br />

..,o;:",.lYI'•• Design & Optimisation<br />

Head of Interdepartmental<br />

Function RAIL<br />

<strong>Virtual</strong> <strong>Vehicle</strong> Competence Centre, Graz<br />

Michael.Schmeja@V2c2.at