Hydraulic Control Systems in Gas and Steam ... - Bosch Rexroth

Hydraulic Control Systems in Gas and Steam ... - Bosch Rexroth

Hydraulic Control Systems in Gas and Steam ... - Bosch Rexroth

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Hydraulic</strong> <strong>Control</strong> System | Industrial <strong>Hydraulic</strong>s<br />

As can be seen from the preced<strong>in</strong>g descriptions, <strong>Bosch</strong> <strong>Rexroth</strong> is <strong>in</strong> a position,<br />

via its modular system, to supply the complete hydraulic functions required <strong>in</strong><br />

gas <strong>and</strong> steam turb<strong>in</strong>es, the closed-loop control, <strong>and</strong> safety functions for the<br />

power range 25 – 1600 MW. A wide range of relevant reference projects,<br />

together with experience, are available <strong>and</strong> on h<strong>and</strong> if required.<br />

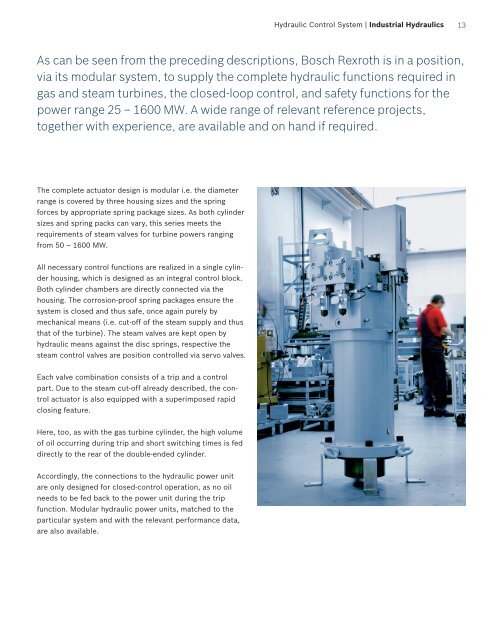

The complete actuator design is modular i.e. the diameter<br />

range is covered by three hous<strong>in</strong>g sizes <strong>and</strong> the spr<strong>in</strong>g<br />

forces by appropriate spr<strong>in</strong>g package sizes. As both cyl<strong>in</strong>der<br />

sizes <strong>and</strong> spr<strong>in</strong>g packs can vary, this series meets the<br />

requirements of steam valves for turb<strong>in</strong>e powers rang<strong>in</strong>g<br />

from 50 – 1600 MW.<br />

All necessary control functions are realized <strong>in</strong> a s<strong>in</strong>gle cyl<strong>in</strong>der<br />

hous<strong>in</strong>g, which is designed as an <strong>in</strong>tegral control block.<br />

Both cyl<strong>in</strong>der chambers are directly connected via the<br />

hous<strong>in</strong>g. The corrosion-proof spr<strong>in</strong>g packages ensure the<br />

system is closed <strong>and</strong> thus safe, once aga<strong>in</strong> purely by<br />

mechanical means (i.e. cut-off of the steam supply <strong>and</strong> thus<br />

that of the turb<strong>in</strong>e). The steam valves are kept open by<br />

hydraulic means aga<strong>in</strong>st the disc spr<strong>in</strong>gs, respective the<br />

steam control valves are position controlled via servo valves.<br />

Each valve comb<strong>in</strong>ation consists of a trip <strong>and</strong> a control<br />

part. Due to the steam cut-off already described, the control<br />

actuator is also equipped with a superimposed rapid<br />

clos<strong>in</strong>g feature.<br />

Here, too, as with the gas turb<strong>in</strong>e cyl<strong>in</strong>der, the high volume<br />

of oil occurr<strong>in</strong>g dur<strong>in</strong>g trip <strong>and</strong> short switch<strong>in</strong>g times is fed<br />

directly to the rear of the double-ended cyl<strong>in</strong>der.<br />

Accord<strong>in</strong>gly, the connections to the hydraulic power unit<br />

are only designed for closed-control operation, as no oil<br />

needs to be fed back to the power unit dur<strong>in</strong>g the trip<br />

function. Modular hydraulic power units, matched to the<br />

particular system <strong>and</strong> with the relevant performance data,<br />

are also available.<br />

13