ETA110030 RB screws - ETA-Danmark

ETA110030 RB screws - ETA-Danmark

ETA110030 RB screws - ETA-Danmark

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

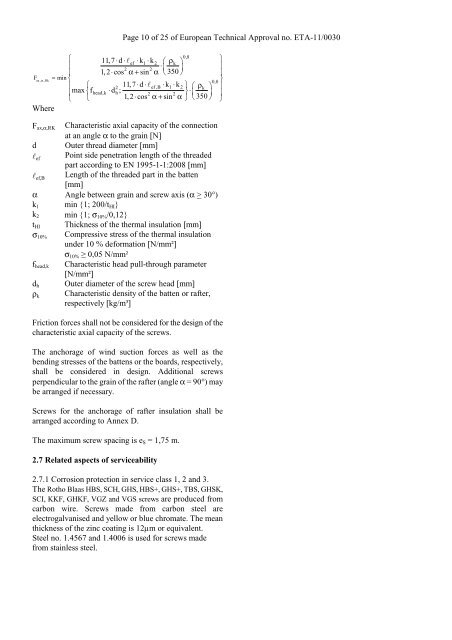

Page 10 of 25 of European Technical Approval no. <strong>ETA</strong>-11/0030<br />

0,8<br />

⎧ 11,7 ⋅d ⋅l ef ⋅ k1 ⋅ k2<br />

⎛ ρk<br />

⎞ ⎫<br />

⎪ ⋅<br />

2 2 ⎜ ⎟ ⎪<br />

⎪ 1,2 ⋅cos α + sin α ⎝ 350 ⎠ ⎪<br />

F = min<br />

ax , α ,Rk ⎨ 0,8 ⎬<br />

⎪ ⎧ 2 11,7 ⋅d ⋅l ef ,B ⋅ k1 ⋅ k2<br />

⎫ ⎛ ρk<br />

⎞ ⎪<br />

⎪max ⎨fhead,k ⋅d h ;<br />

⋅<br />

2 2 ⎬ ⎜ ⎟<br />

1,2 ⋅cos α + sin α 350<br />

⎪<br />

⎩ ⎩ ⎭ ⎝ ⎠ ⎭<br />

Where<br />

Fax,α,RK Characteristic axial capacity of the connection<br />

at an angle α to the grain [N]<br />

d Outer thread diameter [mm]<br />

Point side penetration length of the threaded<br />

lef<br />

part according to EN 1995-1-1:2008 [mm]<br />

lef,B Length of the threaded part in the batten<br />

[mm]<br />

α Angle between grain and screw axis (α > 30°)<br />

k1 min {1; 200/tHI}<br />

min {1; σ10%/0,12}<br />

k2<br />

tHI<br />

σ10%<br />

fhead,k<br />

dh<br />

ρk<br />

Thickness of the thermal insulation [mm]<br />

Compressive stress of the thermal insulation<br />

under 10 % deformation [N/mm²]<br />

σ10% ≥ 0,05 N/mm²<br />

Characteristic head pull-through parameter<br />

[N/mm²]<br />

Outer diameter of the screw head [mm]<br />

Characteristic density of the batten or rafter,<br />

respectively [kg/m³]<br />

Friction forces shall not be considered for the design of the<br />

characteristic axial capacity of the <strong>screws</strong>.<br />

The anchorage of wind suction forces as well as the<br />

bending stresses of the battens or the boards, respectively,<br />

shall be considered in design. Additional <strong>screws</strong><br />

perpendicular to the grain of the rafter (angle α = 90°) may<br />

be arranged if necessary.<br />

Screws for the anchorage of rafter insulation shall be<br />

arranged according to Annex D.<br />

The maximum screw spacing is eS = 1,75 m.<br />

2.7 Related aspects of serviceability<br />

2.7.1 Corrosion protection in service class 1, 2 and 3.<br />

The Rotho Blaas HBS, SCH, GHS, HBS+, GHS+, TBS, GHSK,<br />

SCI, KKF, GHKF, VGZ and VGS <strong>screws</strong> are produced from<br />

carbon wire. Screws made from carbon steel are<br />

electrogalvanised and yellow or blue chromate. The mean<br />

thickness of the zinc coating is 12µm or equivalent.<br />

Steel no. 1.4567 and 1.4006 is used for <strong>screws</strong> made<br />

from stainless steel.