Gas Balanced Flue Guide - Euroheat

Gas Balanced Flue Guide - Euroheat

Gas Balanced Flue Guide - Euroheat

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

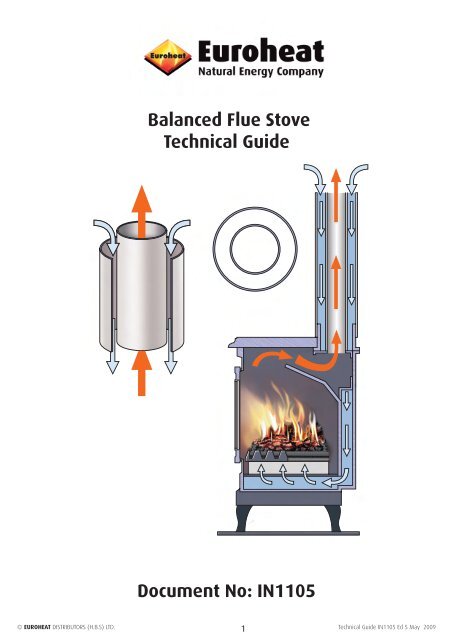

<strong>Balanced</strong> <strong>Flue</strong> Stove<br />

Technical <strong>Guide</strong><br />

Document No: IN1105<br />

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. 1<br />

Technical <strong>Guide</strong> IN1105 Ed 5 May 2009

Hearth and Fireplace Requirements<br />

Do not be tempted to fit the stove into an unsuitable fireplace. Beyond the requirements<br />

of the building regulations and access to facilitate servicing the stove, providing a<br />

setting which will complement the stove is not a luxury, it is the practicality of making<br />

the most of an investment. A good builder will be able to transform even the most<br />

utilitarian of fireplaces, whether altering its proportions to those of the “Golden Mean”<br />

ideal, exposing a wooden lintel, stone or simply removing superfluous detailing for<br />

comparatively small costs, and the result will be a pleasure for many years.<br />

Minimum clearance<br />

from combustible<br />

materials<br />

Minimum clearance<br />

from non<br />

combustible<br />

materials<br />

A 12" 300mm** 9" 230mm<br />

B 6" 150mm** 4" 100mm<br />

C 1" 25mm** N/A<br />

D 2" 50mm** 2" 50mm<br />

E 6" 150mm** 4" 100mm<br />

F<br />

F<br />

E<br />

A<br />

12mm of non<br />

combustable material.<br />

12mm of non<br />

combustable material.<br />

Curtains and furnishings should be a minimum of<br />

1m from the stove.<br />

C<br />

B<br />

D<br />

“Golden Mean”<br />

Side Profile<br />

1/3 2/3<br />

“Golden Mean”<br />

Front View<br />

The stove can be placed on a combustible<br />

floor providing it can support the weight,<br />

and providing a non combustible hearth<br />

plinth with a minimum thickness of<br />

12mm is utilized.<br />

** The measurements provided are<br />

for guidance only.<br />

In all installations any surrounding<br />

flammable materials must not be allowed<br />

to exceed 80°C or a non combustible<br />

shield provided in accordance with<br />

current regulations. The stove must<br />

always stand perfectly level and have<br />

sufficient space allowing for service<br />

work.<br />

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. 2<br />

Technical <strong>Guide</strong> IN1105 Ed 5 May 2009<br />

1<br />

2/3 2/3

<strong>Balanced</strong> <strong>Flue</strong> Systems<br />

A balanced flue system utilizes a double concentric pipe, the inner one taking away the products of combustion<br />

and the outer one bringing the air supply to the stove. This system allows a gas stove to be installed where no<br />

flue exists, and because the flue needs very little vertical height to operate, it is often possible to route the flue<br />

through the room wall to the outside.<br />

With all the air necessary for combustion being supplied through the outer pipe directly from the outside, the<br />

room in which the stove is installed needs no ventilation specifically for the stove.<br />

The balanced flue system has been designed to give a huge range of installation options, terminating either<br />

horizontally or vertically, as illustrated in the diagram below.<br />

Deciding on which form the balanced flue should take will very much be constrained by the termination of the<br />

flue. Building Regulations lay out definitive guide lines for where a flue can terminate, see the diagram later in<br />

this document, and if the building is listed there may be constraints on the position of any terminal and advice<br />

should be sort from the appropriate regulatory authority.<br />

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. 3<br />

Technical <strong>Guide</strong> IN1105 Ed 5 May 2009

No Chimney ----- No Problem<br />

This document will help you design and your qualified engineer install a suitable balanced flue system for your<br />

stove. Following the simple guide lines will allow a balanced flued stove to be fitted in most situations where<br />

a conventionally flued stove could not be fitted.<br />

Top to Horizontal High Level <strong>Flue</strong> Kit<br />

It is not necessary for the stove to be situated against the outside wall through which the<br />

flue will pass, as the versatility of the balanced flue system can allow for considerable<br />

lengths of horizontal run of the flue.<br />

Top to Vertical High Level <strong>Flue</strong> Kit<br />

The vertical balanced flue system is ideal in situations such as in a newly constructed<br />

conservatory where there are no walls through which to pass a horizontal flue. The flue will<br />

rise from the stove vertically passing through the roof where it will then terminate with a<br />

vertical terminal.<br />

Minimum height 2m maximum 30m.<br />

Rear to Horizontal Low Level<br />

The low level horizontal kit is probably the simplest method of installation and allows<br />

you to fit the stove against any suitable outside wall in any room in your property.<br />

Maximum horizontal length 440mm, minimum length 310mm.<br />

Existing Chimney Adapter Kit<br />

The flue kits are also designed to be able to utilize an existing chimney. Properties<br />

which are designed with a high thermal efficiency may not allow an air brick<br />

to be fitted to supply air to a stove over 7kW input, the balanced flue stove<br />

overcomes this requirement as it is a sealed appliance.<br />

In some cases the top section of a chimney may have been removed and the<br />

versatility of the balanced flue system allows you to use what remains of the<br />

chimney using the chimney adapter kit.<br />

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. 4<br />

Technical <strong>Guide</strong> IN1105 Ed 5 May 2009

Location of Outlets from <strong>Flue</strong>s Serving <strong>Gas</strong> <strong>Balanced</strong> <strong>Flue</strong> Stoves.<br />

Minimum Separation Distances for Terminals in mm<br />

Location <strong>Balanced</strong> <strong>Flue</strong><br />

A Below an opening Appliance<br />

rated heat<br />

input<br />

B Above an opening (1)<br />

0-7kw<br />

>7-14kw<br />

> 14-32kw<br />

>32<br />

0-32kw<br />

>32kw<br />

C Horizontally to an opening (1) 0-7kw<br />

>7-14kw<br />

>14kw<br />

D Below gutters, soil pipes or drain<br />

pipes<br />

300<br />

300<br />

600<br />

1500<br />

2000<br />

300<br />

600<br />

300<br />

400<br />

600<br />

E Below eaves 300<br />

Q Above the highest point of<br />

F Below balcony or car port roof<br />

600<br />

600<br />

intersection with the roof<br />

R <strong>Flue</strong> should not penetrate shaded area 600<br />

G From a vertical drain pipe or soil<br />

300<br />

pipe<br />

S <strong>Flue</strong> should not penetrate shaded area 200<br />

Note (1)<br />

An opening means an openable element, such as an openable window, or a fixed opening such as an air<br />

vent. However, in addition, the outlet should not be nearer than 300mm to an opening into the building fabric<br />

formed for the purpose of accommodating a built in element, such as a window frame.<br />

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. 5<br />

Technical <strong>Guide</strong> IN1105 Ed 5 May 2009<br />

<br />

Minimum Separation Distances for Terminals in mm<br />

Location <strong>Balanced</strong> <strong>Flue</strong><br />

H From an internal or external corner<br />

or to a boundry alongside the<br />

terminal<br />

600<br />

I Above ground,roof or balcony level 300<br />

J From a surface or a boundary facing the<br />

terminal<br />

600<br />

K From a terminal facing the terminal 600<br />

L From an opening in the car port into the<br />

building<br />

M Vertically from a terminal on the same<br />

wall<br />

N Horizontally from a terminal on the<br />

same wall<br />

1200<br />

1200<br />

300<br />

P From a structure on the roof 1500

Calculating <strong>Flue</strong> Aspect Ratios<br />

The stove operates correctly only with air flow induced by the flue system being within the defined parameters.<br />

To achieve these, the vertical elements of the flue, which induce flue draught and increase the air supply to the<br />

stove, must be balanced against the horizontal elements of the flue, which offer resistance to flue draught and<br />

reduce the air supply to the stove.<br />

The ratio of vertical to horizontal lengths must be calculated to ensure the correct flue draught will be induced<br />

by the proposed flue.<br />

The difference in height between the top of the stove and the bottom of the terminal determines the vertical<br />

height to be used in the calculation. The flue run may necessitate the vertical elements to be separated by<br />

several horizontal runs, this is not important, only the total height gain is needed.<br />

The horizontal length is often more tedious to determine, but again, it is the total length which needs to be<br />

determined, regardless of their being continuous or in stages. Any 90 degree change of direction within the<br />

flue will offer resistance to flue draught and each change of direction will offer the same resistance to the flue<br />

draught as a horizontal run of 1000mm. For every 45 degree change in direction the resistance is that of a<br />

horizontal run of 500mm.<br />

BALANCED FLUE ASPECT RATIO DYNAMICS ILLUSTRATED<br />

6.0<br />

5.5<br />

5.0<br />

4.5<br />

4.0<br />

3.5<br />

3.0<br />

2.5<br />

2.0<br />

1.5<br />

1.0<br />

0.5<br />

0<br />

.5m vertical = 3.5m horizontal max.<br />

Depending on<br />

which direction your<br />

flue configuration<br />

will take and the<br />

model of the stove,<br />

a flue reduction<br />

plate (FRP) may<br />

or may not be<br />

required.<br />

See pages 24 & 25<br />

for details.<br />

1m vertical = 7m horizontal max.<br />

For 1m vertical rise a flue may have a maximum horizontal run of 7m.<br />

For each 90 degree bend introduced the horizontal run must be reduced by 1m.<br />

For each 45 degree bend introduced the horizontal run must be reduced by 500mm.<br />

0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0<br />

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. 6<br />

Technical <strong>Guide</strong> IN1105 Ed 5 May 2009

Basic Principle of <strong>Balanced</strong> <strong>Flue</strong> Ratios Illustrated<br />

Top to Horizontal High Level<br />

1.5<br />

1.0<br />

0.5<br />

0<br />

1.5<br />

1.0<br />

0.5<br />

0<br />

0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0<br />

Example 'A'<br />

For a 1m vertical rise a flue can have a maximum of 7m horizontal length.<br />

0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0<br />

Example 'B'<br />

Rear to Horizontal Low Level<br />

Each additional 90 degree bend creates a draught resistance equal to 1m<br />

of horizontal length.<br />

Therefore in example 'B' the introduction of 2 x 90 degree bends,<br />

in a horizontal plain, reduces the maximum horizontal length by 2m.<br />

Example 'C'<br />

<strong>Flue</strong> spigot<br />

0 Min 310mm/ Max 440mm<br />

The rear exit flue may have a maximum horizontal run of 440mm<br />

from the flue spigot, the minimum length 310mm.<br />

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. 7<br />

Technical <strong>Guide</strong> IN1105 Ed 5 May 2009

Example 1: Top to Horizontal High Level Kit<br />

Using the standard top to horizontal high level flue kit only.<br />

Standard kit starter<br />

length T1<br />

Components used<br />

Standard kit 90<br />

degree long bend<br />

Description Part No.<br />

Top to 150mm 180mm<br />

HorizontalHigh<br />

Level Kit<br />

MS91102 MS91103<br />

Sleeve liner MS91065 MS91066<br />

Terminal<br />

guard<br />

FP767 FP767<br />

Closure bezel MS91033 MS91040<br />

Ceramic rope or<br />

Fraxfill sealant to<br />

prevent draughts<br />

Closure<br />

bezel<br />

<br />

Minimum<br />

50mm<br />

Cavity wall<br />

The closure<br />

bezel fits around<br />

the flue pipe<br />

covering the<br />

hole through<br />

a solid wall<br />

giving the<br />

installation<br />

a clean finish<br />

both inside and<br />

outside.<br />

12mm<br />

Standard kit<br />

terminal length T2<br />

Sleeve kit<br />

(accessory)<br />

Terminal guard<br />

(accessory)<br />

Solid wall<br />

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. 8<br />

Technical <strong>Guide</strong> IN1105 Ed 5 May 2009

Example 2: Top to Horizontal High Level Kit<br />

Taking the attached diagram as an example we can calculate the flue parameters for a top to horizontal flue<br />

system.<br />

Total Height = A<br />

Total Horizontal = B<br />

In this example<br />

A = 2.8 Metres B = 1.75 Metres<br />

Three x 90 degree bends have been used one of which (C) is the standard supply kit bend. This bend is ignored<br />

from the calculation as it is presumed it will always be used. The two remaining 90 degree bends increase the<br />

horizontal length by two metres.<br />

(one metre extra horizontal length per additional 90 degree bend).<br />

Total Height A = 2.8 Metres<br />

Total Horizontal B = 1.0 Metres<br />

In this example there is sufficient vertical rise for the horizontal run, as shown in the graph on page 6.<br />

Components used<br />

Standard kit<br />

terminal length<br />

T2<br />

Accessory 250mm<br />

length within wall<br />

Accessory short<br />

90 O bend<br />

Accessory 1metre length<br />

Wall band<br />

Accessory short<br />

90 O bend<br />

Description Part No. Quantity<br />

Top to 150mm 180mm<br />

HorizontalHigh<br />

Level Kit<br />

MS91102 MS91103<br />

1<br />

1 metre length MS91028 MS91034 1<br />

500mm length MS91029 MS91035 2<br />

250mm length MS91030 MS91036 1<br />

90° short bend MS91031 MS91037 2<br />

Wall band MS91052 MS91053 1<br />

B<br />

B+B= Total Horizontal<br />

A Total height<br />

Standard kit<br />

long 90 O bend<br />

Accessory<br />

500mm length<br />

Standard kit<br />

starter length<br />

T1<br />

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. 9<br />

Technical <strong>Guide</strong> IN1105 Ed 5 May 2009<br />

A<br />

B

Example 3: Top to Vertical High Level Kit<br />

The ratio of vertical to horizontal lengths must be calculated to ensure the correct flue draught will be induced<br />

by the proposed flue. Taking the ratio diagram as an example we can calculate the flue parameters for a top<br />

to vertical flue system.<br />

Total Height = A<br />

Total Horizontal = B<br />

In this example<br />

A = 3.5 Metres B = 1.5 Metres<br />

Two x 90deg bends have been used. The two 90 degree bends increase the horizontal length by two metres.<br />

(One metre extra horizontal length per additional 90 degree bend).<br />

Total height A = 3.5 Metres<br />

Total Horizontal B =0.9 Metres<br />

In this example there is sufficient vertical rise for the horizontal run, as shown in the illustration on page 6.<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

(accessory)<br />

<br />

(accessory)<br />

<br />

<br />

Components used<br />

Description Part No. Quantity<br />

Top to Vertical<br />

High Level Kit<br />

150mm<br />

MS91100<br />

180mm<br />

MS91101<br />

1<br />

1 metre length MS91028 MS91034 1<br />

500mm length MS91029 MS91035 3<br />

90° short bend MS91031 MS91037 2<br />

Wall band MS91052 MS91053 2<br />

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. 10<br />

Technical <strong>Guide</strong> IN1105 Ed 5 May 2009

Example 4: Top to Vertical High Level Kit<br />

This example incorporates two 45 degree bends, a situation commonly encountered when having to route flue<br />

pipe around an obstacle such as a beam. When calculating the horizontal run the 45 degree bends equate to<br />

an additional 500mm per bend.<br />

Taking the ratio diagram as an example we can calculate the flue parameters for a top to vertical flue system.<br />

Total Height = A<br />

Total Horizontal = B<br />

In this example<br />

A = 4.5 Metres B = 1.5 Metres<br />

2 x 45deg bends have been used. The two 45 degree bends increase the horizontal length by one metre.<br />

(500mm extra horizontal length per 45 degree bend).<br />

Total height A = 4.5 Metres<br />

Total Horizontal B = 2.0 Metres<br />

In this example there is sufficient vertical rise for the horizontal run, as shown in the illustration on page 6.<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

(accessory)<br />

Components used<br />

Description Part No. Quantity<br />

Top to Vertical<br />

High Level Kit<br />

150mm<br />

MS91100<br />

180mm<br />

MS91101<br />

1<br />

1 metre length MS91028 MS91034 5<br />

Adjustable<br />

length<br />

MS91045 MS91046 1<br />

45° short bend MS91054 MS91055 2<br />

Wall band MS91052 MS91053 5<br />

Roof flashing MS91063 MS91063 1<br />

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. 11<br />

Technical <strong>Guide</strong> IN1105 Ed 5 May 2009

Example 5: Top to Vertical High Level Kit<br />

The minimum vertical height for a top to vertical flue is two meters of flue and the top to vertical kit<br />

components.<br />

Components used<br />

Description Part No. Quantity<br />

Top to Vertical<br />

High Level Kit<br />

150mm<br />

MS91100<br />

180mm<br />

MS91101<br />

1<br />

1 metre length MS91028 MS91034 2<br />

Wall band MS91052 MS91053 2<br />

Roof flashing MS91063 MS91063 1<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

(accessory)<br />

<br />

<br />

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. 12<br />

Technical <strong>Guide</strong> IN1105 Ed 5 May 2009

Example 6: Through Ceilings and Roof Spaces<br />

Fitting a Top to Vertical High Level <strong>Flue</strong> Kit Through Ceilings and Roof Spaces<br />

When installing balanced flue pipe through a ceiling the use of a ceiling support and fire stop spacer are<br />

recommended. There should be no flue joints at any point as the flue passes through a ceiling.<br />

There should a minimum clearance of 25mm from the flue pipe to any combustible material.<br />

No flue joints<br />

between fire<br />

stop spacer<br />

and ceiling<br />

support.<br />

Components used<br />

Weight of flue<br />

supported here.<br />

Ceiling support<br />

Fire stop spacer<br />

Weight of flue<br />

supported here.<br />

Description 150mm 180mm<br />

Ceiling support MS91056 MS91057<br />

Fire stop spacer MS91058 MS91059<br />

Roof flashing MS91063 MS91063<br />

Wall band MS91052 MS91053<br />

Roof flashing<br />

(accessory)<br />

<br />

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. 13<br />

Technical <strong>Guide</strong> IN1105 Ed 5 May 2009

Example 7: Existing Chimney Adapter Kit Vertical Termination<br />

Fitting an Existing Chimney Adapter Kit in Conjunction with a High Level Vertical Kit<br />

There are great advantages in converting an existing chimney into a balanced flue. The existing chimney<br />

adapter kit can convert either ceramic lined chimneys or an unlined chimney into a balanced flue system. By<br />

using this system combustion air is drawn from the outside rather than from the property greatly increasing<br />

overall efficiency.<br />

In addittion many houses chimney stacks have been removed and the<br />

roof tiled over. They are usually capped off at attic floor level.<br />

We have developed a kit which can bring these chimneys back to life<br />

using a gas balanced flue stove.<br />

It can also be used in modern properties which have heat<br />

replacement systems where normal ventilation requirements<br />

cannot be applied.<br />

The system requires the use of two flexible flue liners, one to run<br />

inside the other mimicking the standard balanced flue pipe.<br />

The inside pipe is for the evacuation of the products of<br />

combustion and the outer is the air supply for combustion.<br />

It is imperative that all the joints are sealed<br />

to make them air tight.<br />

There follows two examples of the system,<br />

one is showing an existing chimney breast<br />

and the system terminating in a<br />

vertical position (through the roof).<br />

The second is showing the<br />

system terminating in a horizontal<br />

position (through a gable end of<br />

a property perhaps).<br />

Using two sizes of flue liner to<br />

mimic the balanced flue pipe.<br />

Ensure the seal is tight<br />

to the adapter kit<br />

<strong>Flue</strong> system<br />

size<br />

Inner liner Outer liner<br />

150mm 101mm / 4” 153mm / 6”<br />

180mm 125mm / 5“ 178mm / 7”<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Existing chimney<br />

top adapter<br />

Existing chimney<br />

bottom adapter<br />

Depending on which direction your flue configuration will take and the model of the stove, a reduction plate<br />

may or may not be required. See pages 24 & 25 for details.<br />

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. 14<br />

Technical <strong>Guide</strong> IN1105 Ed 5 May 2009

Example 8: Existing Chimney Adapter Kit Horizontal Termination<br />

Fitting an Existing Chimney Adapter Kit in Conjunction with a Top to Horizontal Kit<br />

If this orientation is to be used then the standard 90 degree long bend from the top to horizontal kit MUST be<br />

used so that the last union before the terminal length T2 is a female (F) end.<br />

Existing chimney top adapter<br />

Existing chimney bottom adapter<br />

<strong>Flue</strong> system<br />

size<br />

Inner liner Outer liner<br />

150mm 101mm / 4” 153mm / 6”<br />

180mm 125mm / 5“ 178mm / 7”<br />

Existing chimney top adapter<br />

350mm<br />

95mm<br />

75mm<br />

100mm<br />

Accessory 1<br />

metre length<br />

Standard kit<br />

90° long bend<br />

Standard kit<br />

starter length<br />

T1<br />

Clay<br />

liner<br />

Flexible<br />

liner<br />

Standard kit<br />

terminal length<br />

T2<br />

Existing chimney bottom adapter<br />

350mm<br />

75mm<br />

The example above is showing an existing chimney adapter kit utilizing a existing clay liner, using a flexible<br />

liner to run inside the clay liner in order to expel the products of combustion but using the clay liner for the<br />

feed of combustion air. Ensure that the seals between flexible liner and the adapter are sound and the seal<br />

between the clay liner and the adapter are also sound.<br />

It can go through the long 90° bend (in the top to horizontal kit) and terminate through the gable end of the<br />

property.<br />

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. 15<br />

Technical <strong>Guide</strong> IN1105 Ed 5 May 2009<br />

M<br />

F<br />

T1<br />

M<br />

F<br />

T2

Example 9: Through a Combustible Roof<br />

Installation of Top to Vertical High Level <strong>Balanced</strong> <strong>Flue</strong> Pipe Through a Combustible Roof<br />

A 25mm gap of non combustible material must be used when you are passing the balanced flue pipe through<br />

any combustible material.<br />

Conservatories can “come alive” with the installation of a stove, but care should be taken when installing a<br />

stove into a conservatory because the modern ones can be made entirely from plastic (or PVC). Advise from<br />

your conservatory installer/manufacturer should be sought.<br />

The flue system should be supported.<br />

600mm<br />

600mm<br />

600mm<br />

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. 16<br />

Technical <strong>Guide</strong> IN1105 Ed 5 May 2009

Frequently Asked Questions<br />

Q. Can the stove be flued directly off the back?<br />

A. Yes, using the standard low level horizontal kit.<br />

Q. Can I use a bend directly off the top of the stove?<br />

A. No, the stove adapter is only designed to fit the telescopic starter length and straight lengths, bends will not<br />

seal to the flue outlet.<br />

Q. Can I fit the stove in the corner of a room?<br />

A. Yes, there is no problem in doing this using the top to horizontal flue kit, but it must be remembered that if<br />

the corner is also the corner of the property that the termination must be 600mm from any corner. See diagram<br />

page 5.<br />

Q. Can the vertical flue be passed through a combustible roof, such as a polycarbonate roof in a conservatory?<br />

A. Yes, as long as allowances are made for the type of roofing material and suitable insulation is provided. See<br />

the section on flueing through a combustible roof.<br />

Q. Can the stove be fitted into a bedroom?<br />

A. Yes, the stoves are room sealed and below 14kW input.<br />

Q. Can I cut the lengths of flue pipe?<br />

A. Yes, however the differential between the inner and outer length has to be maintained. It would be preferable<br />

to use an adjustable length<br />

Q. Does the flue terminal need to be guarded?<br />

A. If the flue terminal is to be sited less than two meters above level ground,<br />

a balcony or a flat roof where people have access, a guard must be fitted. Local<br />

by-laws may also require a further minimum height where the terminal is sited<br />

adjoining a public footpath.<br />

Q. If I have a high level horizontal kit can I then terminate it vertically?<br />

A. Yes, there is a vertical terminal with a crimped end which will fit to the<br />

flue system.<br />

Q. Do I need an air brick or other ventilation for supplying free air to the<br />

stove?<br />

A. No, the stove is room sealed and does not have any requirement for free<br />

air.<br />

Q. Does it matter how far out of the wall the terminal is fitted on a horizontal flue kit?<br />

A. Yes, there should be 12mm of flue pipe visible before the start of the flue terminal. Any greater length can<br />

upset the balanced flues operation.<br />

Q. What colours are the flue pipe available in?<br />

A. The flue pipe is supplied in one colour, a matt grey finish, which closely matches the cast finished stoves and<br />

complements the enamel finished stove. It is possible to change the colour using heat resistant paint.<br />

Q. To what wind speed are the terminals tested to?<br />

A. The maximum wind used is 12.5 m/s with 10% error. (28mph).<br />

Vertical terminal with<br />

crimped end<br />

Size Part No:<br />

150mm MS91047<br />

180MM MS91048<br />

Q. What is the maximum length the flue can travel horizontaly from the rear outlet of the stove?<br />

A. The standard low level horizontal flue kit gives a maximum extension of 440mm. No additional lengths or<br />

bends should be fitted.<br />

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. 17<br />

Technical <strong>Guide</strong> IN1105 Ed 5 May 2009

Components of Top to Horizontal High Level Kit<br />

150mm kit MS91102<br />

180mm kit MS91103<br />

This is a high level horizontal flue kit. Other sections may be added to achieve the desired termination. For<br />

additional lengths and accessories see pages 21 to 23.<br />

<br />

Telescopic terminal length<br />

(T2)<br />

<br />

<br />

<br />

<br />

<br />

T2<br />

<br />

<br />

<br />

<br />

<br />

<br />

Clamp band<br />

Telescopic starter length (T1)<br />

which must be used as the<br />

first length of flue pipe from<br />

the stoves flue collar<br />

Dimensions of standard 150mm flue kit<br />

90° Long bend<br />

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. 18<br />

Technical <strong>Guide</strong> IN1105 Ed 5 May 2009<br />

T1<br />

T1<br />

Dimensions of standard 180mm flue kit<br />

Max: 555mm<br />

Min: 470mm<br />

The min can be reduced further by cutting 40mm<br />

off the T2 section<br />

T2<br />

12mm<br />

Max 555mm<br />

Min 445mm<br />

The min can be reduced<br />

further by cutting 40mm<br />

off the T1 section

Components of Top to Vertical High Level Kit<br />

150mm kit MS91100<br />

180mm kit MS91101<br />

This kit is used when the installation requires the termination to be through a roof. Further components will<br />

be required with this kit. For additional lengths and accessories see pages 21 to 24.<br />

200mm<br />

250mm<br />

T1<br />

Adjustable Starter Pipe<br />

Toatal length Minimum Length<br />

for Calculations<br />

Vertical Terminal<br />

Locking Band<br />

Adjustable Starter Pipe<br />

Maximum Length<br />

For Calculations<br />

250mm 30mm 170mm<br />

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. 19<br />

Technical <strong>Guide</strong> IN1105 Ed 5 May 2009

Components of Rear to Horizontal Low Level Kit<br />

150mm kit MS91097<br />

180mm kit MS91098<br />

Only the standard kit may be used, additional bends and lengths MUST not be used as they will adversely<br />

effect the performance of the balanced flue and could be dangerous.<br />

Telescopic Module<br />

(horizontal adjustable)<br />

T1<br />

Maximum<br />

Length 440 mm<br />

Minimum<br />

Length 310 mm<br />

Spacers and self tapping<br />

screws for wind shield<br />

Horizontal<br />

Terminal<br />

Terminal Guard<br />

Wind shield<br />

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. 20<br />

Technical <strong>Guide</strong> IN1105 Ed 5 May 2009

Additional <strong>Flue</strong> Pipe System Accessories<br />

Each section of additional flue pipe is<br />

supplied with a locking band.<br />

1 metre pipe<br />

500mm pipe<br />

250mm pipe<br />

90 degree short bend<br />

45 degree short bend<br />

Adjustable length 250mm<br />

Wall Band<br />

When calculating the amount of flue pipe required the usable length and not the overall length should be<br />

used, see the table below.<br />

Description 150mm 180mm Over all length Useable length<br />

1 metre pipe MS91028 MS91034 1m 960mm<br />

500mm pipe MS91029 MS91035 500mm 460mm<br />

250mm pipe MS91030 MS91036 250mm 210mm<br />

90 Degree bend MS91031 120mm vertical 170mm horizontal<br />

90 Degree bend MS91037 246mm vertical 186mm horizontal<br />

Adjustable pipe MS91045 MS91046 195 max length 85 min length<br />

45 Degree bend MS91054 MS91055 170mm vertical 75mm horizontal<br />

2 x 45 Degree bend<br />

off set<br />

MS91054 x 2 MS91055 x 2 340mm 150mm off set<br />

Wall band MS91052 MS91053<br />

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. 21<br />

Technical <strong>Guide</strong> IN1105 Ed 5 May 2009

Additional <strong>Flue</strong> System Accessories<br />

Ceiling Support & Fire Stop Spacers<br />

Required when a balanced flue kit passes through a ceiling.<br />

Fire Stop<br />

Description Part No. 150mm Part No. 180mm<br />

Ceiling Support MS91056 MS91057<br />

Fire Stop MS91058 MS91059<br />

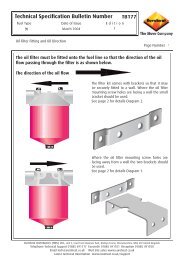

Existing Chimney Adapter Kit<br />

Allows an existing sound chimney to be used as part of the balanced flue.<br />

Description Part No. 150mm Part No. 180mm<br />

Existing Chimney Adapter Kit MS91085 MS91086<br />

Sleeve Liner<br />

Required when flue pipe passes through a cavity wall. It can be cut down to size or an extender sleeve added.<br />

Max 360mm<br />

Min 240mm<br />

Outer diameter<br />

150mm kit 165mm<br />

180mm kit 195mm<br />

Extender sleeve<br />

Ceiling Support<br />

Description Part No. 150mm Part No. 180mm<br />

Sleeve Liner MS91065 MS91066<br />

Extender sleeve MS91067 MS91068<br />

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. 22<br />

Technical <strong>Guide</strong> IN1105 Ed 5 May 2009<br />

Cavity

Additional <strong>Flue</strong> System Accessories<br />

Roof Flashing<br />

Required when a balanced flue kit passes through the surface of a roof,<br />

flat or pitched.<br />

Roof Flashing<br />

Description Part No. 150mm kits Part No. 180mm kits<br />

Roof Flashing MS91063 MS91063<br />

Terminal Guard<br />

The terminal guard is suitable for High-Level Top to Horizontal kits only. The flue outlet should be protected<br />

with a guard if persons could come into contact with it or if it could become damaged. If a flue outlet is in a<br />

vunerable position, such as where the flue discharges within reach of the ground (less than 2m), or a balcony,<br />

veranda or an opening window.<br />

Terminal Guard Closure Bezel<br />

Closure Bezel<br />

The closure bezel fits around the flue pipe covering the hole through the wall and gives the installation a clean<br />

finish.<br />

Description Part No. 150mm kits Part No. 180mm kits<br />

Closure Bezel MS91033 MS91040<br />

Terminal Guard FP767 FP767<br />

Fraxfill<br />

Fraxfill is a pliable (tacky putty)<br />

white ceramic fibre gap fill supplied<br />

in a 300g cartridge for use with a<br />

sealant gun. Fraxfill is recommended<br />

for applications with operating<br />

temperatures of up to 1200°C.<br />

<br />

Description Part No. 150mm kits Part No. 180mm kits<br />

Fraxfill MS9045 MS9045<br />

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. 23<br />

Technical <strong>Guide</strong> IN1105 Ed 5 May 2009

<strong>Flue</strong> Reduction Plate (FRP)<br />

Before Installation<br />

Depending on which direction your flue configuration will take, a reduction plate may or may not be<br />

required.<br />

The choke plate is a circular plate which fits under the inner flue connection.<br />

The list below will advise which FRP will or will not be needed.<br />

Harmony 15 Stanford 15 (H15 & S15)<br />

Description Fuel Type FRP<br />

Top to horizontal high level kit with<br />

standard flue kit<br />

Top to vertical high level kit<br />

Rear to horizontal low level kit<br />

Natural<br />

<strong>Gas</strong><br />

58mm<br />

LPG 58mm<br />

Natural<br />

<strong>Gas</strong><br />

40mm<br />

LPG 45mm<br />

Natural<br />

<strong>Gas</strong><br />

No FRP<br />

LPG No FRP<br />

Harmony 25 Stanford 25 (H25 & S25)<br />

Description Fuel Type FRP<br />

Top to horizontal high level kit with<br />

standard flue kit<br />

Top to vertical high level kit<br />

Rear to horizontal low level kit<br />

Natural<br />

<strong>Gas</strong><br />

66mm<br />

LPG 66mm<br />

Natural<br />

<strong>Gas</strong><br />

50mm<br />

LPG 50mm<br />

Natural<br />

<strong>Gas</strong><br />

No FRP<br />

LPG No FRP<br />

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. 24<br />

Technical <strong>Guide</strong> IN1105 Ed 5 May 2009

Top flue connection for top to horizontal<br />

high level kit and top to vertical kit<br />

Harmony 35 (H35)<br />

Description Fuel Type FRP<br />

Top to horizontal high level kit with<br />

standard flue kit<br />

Top to vertical high level kit<br />

Rear to horizontal low level kit<br />

Natural<br />

<strong>Gas</strong><br />

76mm<br />

LPG No FRP<br />

Natural<br />

<strong>Gas</strong><br />

55mm<br />

LPG 55mm<br />

Natural<br />

<strong>Gas</strong><br />

No FRP<br />

LPG No FRP<br />

Harmony 45 (H45)<br />

Description Fuel Type FRP<br />

Top to horizontal high level kit with<br />

standard flue kit<br />

Top to vertical high level kit<br />

Rear to horizontal low level kit<br />

Natural<br />

<strong>Gas</strong><br />

70mm<br />

LPG 70mm<br />

Natural<br />

<strong>Gas</strong><br />

70mm<br />

LPG 70mm<br />

Natural<br />

<strong>Gas</strong><br />

No FRP<br />

LPG No FRP<br />

Rear flue connection for rear to<br />

horizontal low level kit<br />

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. 25<br />

Technical <strong>Guide</strong> IN1105 Ed 5 May 2009

Stove Technical Data<br />

Harmony 15<br />

150mm <strong>Flue</strong> kit system<br />

and accessories<br />

Harmony 25<br />

150mm <strong>Flue</strong> kit system<br />

and accessories<br />

Harmony 35<br />

180mm <strong>Flue</strong> kit system<br />

and accessories<br />

Harmony 45<br />

180mm <strong>Flue</strong> kit system<br />

and accessories<br />

Stanford 15<br />

150mm <strong>Flue</strong> kit system<br />

and accessories<br />

Stanford 25<br />

150mm <strong>Flue</strong> kit system<br />

and accessories<br />

<br />

<br />

<br />

<br />

435<br />

455<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

240<br />

<br />

150 ID<br />

<br />

<br />

<br />

160<br />

270<br />

120<br />

150ID<br />

150mm <strong>Flue</strong> kit Part No.<br />

Top to horizontal<br />

high level kit<br />

MS91102<br />

Top to vertical high<br />

level kit<br />

MS91100<br />

Rear to horizontal<br />

low level kit<br />

MS91097<br />

180mm <strong>Flue</strong> kit Part No.<br />

Top to horizontal<br />

high level kit<br />

MS91103<br />

Top to vertical high<br />

level kit<br />

MS91101<br />

Rear to horizontal<br />

low level kit<br />

MS91098<br />

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. 26<br />

Technical <strong>Guide</strong> IN1105 Ed 5 May 2009<br />

495<br />

600<br />

565<br />

<br />

<br />

<br />

670<br />

682<br />

<br />

750<br />

150mm <strong>Flue</strong> kit Part No.<br />

Top to horizontal<br />

high level kit<br />

MS91102<br />

Top to vertical high<br />

level kit<br />

MS91100<br />

Rear to horizontal<br />

low level kit<br />

MS91097<br />

180mm <strong>Flue</strong> kit Part No.<br />

Top to horizontal<br />

high level kit<br />

MS91103<br />

Top to vertical high<br />

level kit<br />

MS91101<br />

Rear to horizontal<br />

low level kit<br />

MS91098<br />

150mm <strong>Flue</strong> kit Part No.<br />

Top to horizontal<br />

high level kit<br />

MS91102<br />

Top to vertical high<br />

level kit<br />

MS91100<br />

Rear to horizontal<br />

low level kit<br />

MS91097<br />

150mm <strong>Flue</strong> kit Part No.<br />

Top to horizontal<br />

high level kit<br />

MS91102<br />

Top to vertical high<br />

level kit<br />

MS91100<br />

Rear to horizontal<br />

low level kit<br />

MS91097

Fitting High Level Horizontal <strong>Flue</strong> Kit<br />

The flue system starter length should be sealed to the stove’s flue spigot with a heat proof sealant, (we<br />

suggest “fraxfill”, part number MS9045). Apply a bead of heat resistant sealant to the inner face of the outer<br />

flue spigot and the outer face of the inner flue pipe. The clamp should be used to secure the first elbow or<br />

additional length and the appropriate heat proof tape used to secure the telescopic fitting.<br />

Heat proof<br />

sealant<br />

Heat proof<br />

sealant<br />

<br />

Where the flue passes through<br />

a cavity wall, the hole must be<br />

sleeved for its entire length.<br />

Accessory 90°<br />

short bend<br />

<br />

<br />

<br />

Standard kit<br />

90° long bend<br />

<br />

<br />

Wall band<br />

The guide giving the permitted flue configurations must<br />

be consulted to verify that a proposed flue is possible. The<br />

“long 90° bend” supplied as standard with the stove must be<br />

incorporated into the system to ensure a non crimped end at<br />

the last fitting before the termination length T2.<br />

All joints between the fixed lengths of flue must<br />

be secured with locking bands, and every meter in<br />

length horizontally or vertically must be supported.<br />

It is your responsibility to ensure that no part of the<br />

flue installation contravenes any gas or building<br />

regulations.<br />

<br />

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. 27<br />

Technical <strong>Guide</strong> IN1105 Ed 5 May 2009<br />

<br />

<br />

<br />

Standard kit<br />

90° long bend<br />

Accessory 90°<br />

short bend<br />

Locking band

Position of <strong>Flue</strong> Terminal on Outside Wall<br />

The position of the terminal on the outside wall should be 12mm from<br />

the edge of the terminal mesh to the face of the outside wall.<br />

If it protrudes further than 12mm it may be adversely affected by wind<br />

blowing across the terminal so upsetting the balanced flue operation.<br />

If it is fitted with less than 12mm clearance then the vented exhaust<br />

gases may be drawn back into the balanced flue primary air inlet so<br />

adversely effecting the operation of the balanced flue.<br />

The flue pipe passing through the wall should be angled slightly<br />

downwards (1 degree) towards the terminal so as to stop rain water<br />

entering and passing along the flue.<br />

Horizontal <strong>Flue</strong> Passing Through a Combustible or Cavity Wall<br />

Ceramic rope or<br />

Fraxfill sealant to<br />

prevent draughts<br />

25mm air gap<br />

incorporated as part<br />

of the <strong>Flue</strong> System<br />

Sleeve liner<br />

T1<br />

50mm<br />

minimum<br />

12mm<br />

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. 28<br />

Technical <strong>Guide</strong> IN1105 Ed 5 May 2009<br />

T2<br />

1° incline<br />

Seal the bezel part of sleeve liner<br />

to the outer face of the wall using<br />

a suitable sealant<br />

Sleeve liner<br />

12mm<br />

Ceramic rope or<br />

Fraxfill sealant to<br />

prevent draughts

Fitting the High Level Vertical <strong>Flue</strong> Kit<br />

The flue system starter length should be sealed to the stove’s flue spigot with a heat proof sealant,(we suggest<br />

“fraxfill”, part number MS9045). Apply a bead of heat resistant sealant to the inner face of the outer flue spigot<br />

and the outer face of the inner flue pipe. The clamp should be used to secure the first elbow or additional<br />

length and the appropriate heat proof tape used to secure the telescopic fitting.<br />

Heat proof<br />

sealant<br />

Wall bands should be fitted<br />

to support the flue pipe.<br />

The telescopic starter length<br />

must be used so that the<br />

male end of the flue pipe<br />

connects to the vertical flue<br />

terminal.<br />

Accessory 90°<br />

short bend<br />

The vertical terminal will only fit<br />

the male end of the flue pipe.<br />

<br />

<br />

<br />

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. 29<br />

Technical <strong>Guide</strong> IN1105 Ed 5 May 2009<br />

<br />

Heat proof<br />

sealant<br />

Accessory 90°<br />

short bend<br />

<br />

<br />

<br />

All joints between the fixed lengths of flue<br />

must be secured with locking bands, and<br />

every meter in length horizontally or vertically<br />

must be supported. It is your responsibility to<br />

ensure that no part of the flue installation<br />

contravenes any gas or building regulations.

Fitting the Low Level Horizontal <strong>Flue</strong> Kit<br />

The horizontal flue kit starter length should be secured by means of a self tapping screw. If it is to pass through<br />

a cavity wall then a sleeve liner (150mm part No. MS91065. 180mm part No. MS91066) should be fitted.<br />

The terminal section should be fitted with the snorkel pointing upwards and the wind shield to protect the<br />

terminal outlet. Only the standard kit may be used from the rear flue outlet.<br />

Secure starter length with<br />

a self tapping screw<br />

<strong>Flue</strong> should be sleeved if passing<br />

through a cavity wall<br />

Apply a bead of heat resistant sealant (we<br />

suggest “fraxfill”, part number MS9045) to the<br />

inner face of the outer flue spigot and the outer<br />

face of the inner flue pipe.<br />

Wind Shield<br />

The wind shield should be fitted using the spacers so that it baffles<br />

the top holes in the horizontal terminal to protect it from the<br />

effects of the wind. The top holes are pre-drilled into the terminal<br />

however in some cases the lower holes may need to be drilled to<br />

complete the installation.<br />

Terminal snorkle<br />

Sleeve kit<br />

150mm part No. MS91065<br />

180mm part No. MS91066<br />

The terminal length should be<br />

fitted with the snorkle pointing<br />

upwards.<br />

Fitting of <strong>Flue</strong> Spigot to Rear of the Stove<br />

Remove the inner and outer spigot from the top of the stove. Remove the rear blanking plate and fit the inner<br />

and outer spigots and the flue reduction plate (FRP) if required, see pages 23 and 24, to the rear of the stove.<br />

Fit the blanking plate onto the top plate.<br />

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. 30<br />

Technical <strong>Guide</strong> IN1105 Ed 5 May 2009

Glossary of Terms<br />

Term Description<br />

Top to horizontal high level<br />

The flue kit rises from the top of the stove, it includes a long sweeping 90°<br />

bend and terminates through the side wall of a property.<br />

Top to vertical high level<br />

The flue kit rises from the top of the stove and terminates vertically through<br />

a roof.<br />

Low level horizontal<br />

The flue runs horizontally from the back of the stove and terminates through<br />

the side wall of a property.<br />

T1<br />

Telescopic starter length. The first section of the flue kit which can telescope<br />

into the section of flue to follow it. Top connection only.<br />

T2<br />

Telescopic terminal length. The last section of the top to horizontal flue kit<br />

which can telescope into the section of flue before it.<br />

FRP<br />

<strong>Flue</strong> reduction plate. A choke plate fitted into the outlet of the stove to<br />

reduce the velocity of the flue gases.<br />

Sleeve liner<br />

Telescopic sleeve, required when a flue passes through a combustible or<br />

cavity wall.<br />

Outlet<br />

Position of the flue terminal, which is governed by Building Regulations, see<br />

diagram on page 6.<br />

Terminal Fitted to the end of the flue system, supplied with the flue kits.<br />

Wall band Required to support every 1m in length vertically or horizontally of flue.<br />

Locking band<br />

Supplied in the kits and with every additional length of flue pipe to secure<br />

the joints between sections.<br />

Closure bezel<br />

The closure bezel fits around the flue pipe covering the hole through the<br />

wall and giving the installation a clean finish.<br />

A wire mesh guard required when the outlet is in a vulnerable position,<br />

Terminal guard such as where the flue discharges within reach of the ground (less than<br />

2m), or a balcony, verandah or a opening window.<br />

Required when a vertical flue passes through a roof. A vulcanised rubber<br />

Roof flashing gaiter through which the flue pipe passes allowing a water tight seal to be<br />

made.<br />

A metal plate with locking band required when a flue passes through a<br />

Ceiling support ceiling. Fitting onto the floor above the ceiling through which it passes with<br />

a clamp to secure it to the flue pipe and support the weight of the flue.<br />

Fire stop spacer<br />

A metal plate which fits on the ceiling through which the stove passes which<br />

is required to conform to Building Regulations.<br />

The existing chimney adapter kit can convert either ceramic lined chimneys<br />

Existing chimney adapter kit<br />

or an unlined chimney into a balanced flue system. By using this system<br />

combustion air is drawn from the outside rather than from within the<br />

property.<br />

Terminal snorkle<br />

The upturned inner pipe within the low level horizontal flue kit, that when<br />

fitted should be pointing upwards.<br />

This fits on the outside of the low level horizontal terminal, standing away<br />

Wind guard from the body of the terminal guard, with spacers, so protecting the top<br />

holes of the terminal from the effects of wind blowing directly on them.<br />

Fraxfill is a pliable (tacky putty) white ceramic fibre gap fill supplied in<br />

Fraxfill (MS9045) a 300g cartridge for use with a sealant gun. Fraxfill is recommended for<br />

applications with operating temperatures of up to 1200°C.<br />

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. 31<br />

Technical <strong>Guide</strong> IN1105 Ed 5 May 2009

When installing the stove this documnet should be used in<br />

conjunction with <strong>Euroheat</strong>s Installation Instructions specific to the<br />

stove supplied.<br />

The gas stoves in the <strong>Euroheat</strong> range may only be installed by a<br />

suitably qualified <strong>Gas</strong> Safe technician using the appropriate fittings<br />

for the gas type being installed, and the stove must not be modified<br />

in anyway.<br />

Important<br />

The installer is responsible under the Health and Safety at Work Act 1974 vi the caustic nature of fire cement<br />

and the possibility of disturbing asbestos and other materials such as ceramic in existing installations and<br />

to suggest appropriate protection to be given to the person (s) carrying out the installation. The complete<br />

installation must be carried out with due reference to the British Standards, Codes of Practice and Building<br />

Regulations relevant to the fuel type being installed, and the manufacturers installation instructions.<br />

This document is a General Installation <strong>Guide</strong> only. It does not replace the installation instructions or building<br />

regulations. No installation should be undertaken unless the installer is suitably qualified.<br />

Information from the <strong>Euroheat</strong> Technical Team<br />

<strong>Euroheat</strong> and Nestor Martin have a policy of continual research and development and reserve the right to<br />

modify its appliances without prior notice.<br />

We make every effort to ensure that the information provided in this document is correct and accurate at<br />

the time of printing. Continued updates occur to adapt documents to customer requirements and appliance<br />

changes. For the latest editions of all <strong>Euroheat</strong> documentation visit our web site<br />

www.euroheat.co.uk.<br />

We would request that you inform <strong>Euroheat</strong> of information which you feel is not provided in this document<br />

which would assist other users in the future.<br />

The <strong>Euroheat</strong> Technical Team<br />

www.euroheat.co.uk<br />

<strong>Euroheat</strong> Distributors (H.B.S.). Ltd.,<br />

Unit 2, Court Farm Business Park,<br />

Bishops Frome, Reception: 01885 491100<br />

Worcestershire, Technical Support: 01885 491117<br />

WR6 5AYY. Email: tech@euroheat.co.uk<br />

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. 32<br />

Technical <strong>Guide</strong> IN1105 Ed 5 May 2009