simulation of residual stress in curved glulam beams - Engineered ...

simulation of residual stress in curved glulam beams - Engineered ...

simulation of residual stress in curved glulam beams - Engineered ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

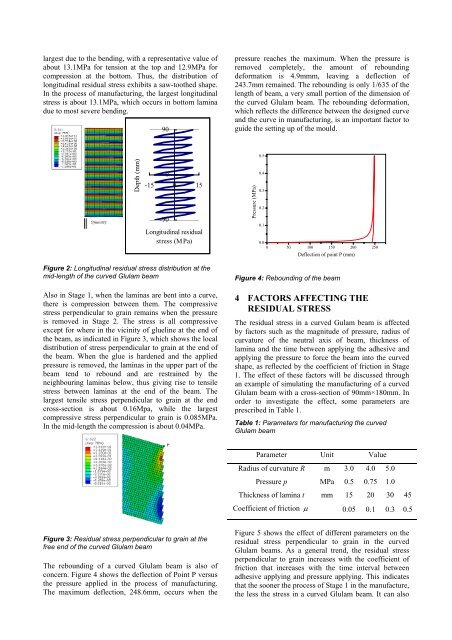

largest due to the bend<strong>in</strong>g, with a representative value <strong>of</strong><br />

about 13.1MPa for tension at the top and 12.9MPa for<br />

compression at the bottom. Thus, the distribution <strong>of</strong><br />

longitud<strong>in</strong>al <strong>residual</strong> <strong>stress</strong> exhibits a saw-toothed shape.<br />

In the process <strong>of</strong> manufactur<strong>in</strong>g, the largest longitud<strong>in</strong>al<br />

<strong>stress</strong> is about 13.1MPa, which occurs <strong>in</strong> bottom lam<strong>in</strong>a<br />

due to most severe bend<strong>in</strong>g.<br />

Depth (mm)<br />

90<br />

0<br />

-15 0 15<br />

-90<br />

Longitud<strong>in</strong>al <strong>residual</strong><br />

<strong>stress</strong> (MPa)<br />

Figure 2: Longitud<strong>in</strong>al <strong>residual</strong> <strong>stress</strong> distribution at the<br />

mid-length <strong>of</strong> the <strong>curved</strong> Glulam beam<br />

Also <strong>in</strong> Stage 1, when the lam<strong>in</strong>as are bent <strong>in</strong>to a curve,<br />

there is compression between them. The compressive<br />

<strong>stress</strong> perpendicular to gra<strong>in</strong> rema<strong>in</strong>s when the pressure<br />

is removed <strong>in</strong> Stage 2. The <strong>stress</strong> is all compressive<br />

except for where <strong>in</strong> the vic<strong>in</strong>ity <strong>of</strong> gluel<strong>in</strong>e at the end <strong>of</strong><br />

the beam, as <strong>in</strong>dicated <strong>in</strong> Figure 3, which shows the local<br />

distribution <strong>of</strong> <strong>stress</strong> perpendicular to gra<strong>in</strong> at the end <strong>of</strong><br />

the beam. When the glue is hardened and the applied<br />

pressure is removed, the lam<strong>in</strong>as <strong>in</strong> the upper part <strong>of</strong> the<br />

beam tend to rebound and are restra<strong>in</strong>ed by the<br />

neighbour<strong>in</strong>g lam<strong>in</strong>as below, thus giv<strong>in</strong>g rise to tensile<br />

<strong>stress</strong> between lam<strong>in</strong>as at the end <strong>of</strong> the beam. The<br />

largest tensile <strong>stress</strong> perpendicular to gra<strong>in</strong> at the end<br />

cross-section is about 0.16Mpa, while the largest<br />

compressive <strong>stress</strong> perpendicular to gra<strong>in</strong> is 0.085MPa.<br />

In the mid-length the compression is about 0.04MPa.<br />

Figure 3: Residual <strong>stress</strong> perpendicular to gra<strong>in</strong> at the<br />

free end <strong>of</strong> the <strong>curved</strong> Glulam beam<br />

The rebound<strong>in</strong>g <strong>of</strong> a <strong>curved</strong> Glulam beam is also <strong>of</strong><br />

concern. Figure 4 shows the deflection <strong>of</strong> Po<strong>in</strong>t P versus<br />

the pressure applied <strong>in</strong> the process <strong>of</strong> manufactur<strong>in</strong>g.<br />

The maximum deflection, 248.6mm, occurs when the<br />

pressure reaches the maximum. When the pressure is<br />

removed completely, the amount <strong>of</strong> rebound<strong>in</strong>g<br />

deformation is 4.9mmm, leav<strong>in</strong>g a deflection <strong>of</strong><br />

243.7mm rema<strong>in</strong>ed. The rebound<strong>in</strong>g is only 1/635 <strong>of</strong> the<br />

length <strong>of</strong> beam, a very small portion <strong>of</strong> the dimension <strong>of</strong><br />

the <strong>curved</strong> Glulam beam. The rebound<strong>in</strong>g deformation,<br />

which reflects the difference between the designed curve<br />

and the curve <strong>in</strong> manufactur<strong>in</strong>g, is an important factor to<br />

guide the sett<strong>in</strong>g up <strong>of</strong> the mould.<br />

Pressure (MPa)<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

0.0<br />

0 50 100 150 200 250<br />

Deflection <strong>of</strong> po<strong>in</strong>t P (mm)<br />

Figure 4: Rebound<strong>in</strong>g <strong>of</strong> the beam<br />

4 FACTORS AFFECTING THE<br />

RESIDUAL STRESS<br />

The <strong>residual</strong> <strong>stress</strong> <strong>in</strong> a <strong>curved</strong> Gulam beam is affected<br />

by factors such as the magnitude <strong>of</strong> pressure, radius <strong>of</strong><br />

curvature <strong>of</strong> the neutral axis <strong>of</strong> beam, thickness <strong>of</strong><br />

lam<strong>in</strong>a and the time between apply<strong>in</strong>g the adhesive and<br />

apply<strong>in</strong>g the pressure to force the beam <strong>in</strong>to the <strong>curved</strong><br />

shape, as reflected by the coefficient <strong>of</strong> friction <strong>in</strong> Stage<br />

1. The effect <strong>of</strong> these factors will be discussed through<br />

an example <strong>of</strong> simulat<strong>in</strong>g the manufactur<strong>in</strong>g <strong>of</strong> a <strong>curved</strong><br />

Glulam beam with a cross-section <strong>of</strong> 90mm×180mm. In<br />

order to <strong>in</strong>vestigate the effect, some parameters are<br />

prescribed <strong>in</strong> Table 1.<br />

Table 1: Parameters for manufactur<strong>in</strong>g the <strong>curved</strong><br />

Glulam beam<br />

Parameter Unit Value<br />

Radius <strong>of</strong> curvature R m 3.0 4.0 5.0<br />

Pressure p MPa 0.5 0.75 1.0<br />

Thickness <strong>of</strong> lam<strong>in</strong>a t mm 15 20 30 45<br />

Coefficient <strong>of</strong> friction µ 0.05 0.1 0.3 0.5<br />

Figure 5 shows the effect <strong>of</strong> different parameters on the<br />

<strong>residual</strong> <strong>stress</strong> perpendicular to gra<strong>in</strong> <strong>in</strong> the <strong>curved</strong><br />

Glulam <strong>beams</strong>. As a general trend, the <strong>residual</strong> <strong>stress</strong><br />

perpendicular to gra<strong>in</strong> <strong>in</strong>creases with the coefficient <strong>of</strong><br />

friction that <strong>in</strong>creases with the time <strong>in</strong>terval between<br />

adhesive apply<strong>in</strong>g and pressure apply<strong>in</strong>g. This <strong>in</strong>dicates<br />

that the sooner the process <strong>of</strong> Stage 1 <strong>in</strong> the manufacture,<br />

the less the <strong>stress</strong> <strong>in</strong> a <strong>curved</strong> Glulam beam. It can also