simulation of residual stress in curved glulam beams - Engineered ...

simulation of residual stress in curved glulam beams - Engineered ...

simulation of residual stress in curved glulam beams - Engineered ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

e found that larger the pressure and smaller radius <strong>of</strong><br />

curvature <strong>of</strong> the neutral axis give rise larger <strong>residual</strong><br />

<strong>stress</strong> perpendicular to gra<strong>in</strong>. The effect <strong>of</strong> radius <strong>of</strong><br />

curvature is more significant than that <strong>of</strong> pressure on the<br />

<strong>stress</strong> perpendicular to gra<strong>in</strong>. For example, under the<br />

condition <strong>of</strong> µ=0.1, when p=0.5MPa, R=5.0m, the <strong>stress</strong><br />

is 0.16MPa; while when p=0.5MPa, R=4.0m, the <strong>stress</strong><br />

is 0.18MPa and when p=0.75MPa, R=5.0m, <strong>stress</strong> is<br />

0.19MPa.<br />

Residual <strong>stress</strong> perpendicular to gra<strong>in</strong> (MPa)<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

p=0.5MPa, R=3.0m<br />

p=1.0MPa, R=3.0m<br />

p=0.75MPa, R=3.0m<br />

p=0.5MPa, R=4.0m<br />

p=0.75MPa, R=4.0m p=1.0MPa, R=4.0m<br />

0.0<br />

p=0.5MPa, R=5.0m<br />

p=1.0MPa, R=5.0m<br />

p=0.75MPa, R=5.0m<br />

0.0 0.1 0.2 0.3 0.4 0.5<br />

Coefficient <strong>of</strong> friction<br />

Figure 5: Residual <strong>stress</strong> perpendicular to gra<strong>in</strong> <strong>of</strong> beam<br />

(cross-section: 90mm×180mm; lam<strong>in</strong>a: 90mm×15mm)<br />

Figure 6 shows the effect <strong>of</strong> different parameters on the<br />

longitud<strong>in</strong>al <strong>residual</strong> <strong>stress</strong> <strong>in</strong> <strong>curved</strong> Glulam <strong>beams</strong>.<br />

Only the radius <strong>of</strong> curvature affects the longitud<strong>in</strong>al<br />

<strong>residual</strong> <strong>stress</strong> <strong>in</strong> a <strong>curved</strong> beam. The smaller the radius<br />

<strong>of</strong> curvature <strong>of</strong> the neutral axis, the more severe the<br />

bend<strong>in</strong>g <strong>of</strong> the lam<strong>in</strong>as and the larger the longitud<strong>in</strong>al<br />

<strong>stress</strong> <strong>in</strong> a lam<strong>in</strong>a. While the coefficient <strong>of</strong> friction and<br />

the pressure pose little effect on the longitud<strong>in</strong>al <strong>stress</strong>.<br />

When radius <strong>of</strong> curvature R=5.0m, the longitud<strong>in</strong>al <strong>stress</strong><br />

is about 13.2MPa; while when R=4.0m and 3.0m, the<br />

<strong>stress</strong> are about 16.5MPa and 22.2MPa, respectively.<br />

Longitud<strong>in</strong>al <strong>residual</strong> <strong>stress</strong> (MPa)<br />

21<br />

18<br />

15<br />

p=0.5MPa, R=3.0m p=0.75MPa, R=3.0m<br />

p=1.0MPa, R=3.0m p=0.5MPa, R=4.0m<br />

p=0.75MPa, R=4.0m p=1.0MPa, R=4.0m<br />

p=0.5MPa, R=5.0m p=0.75MPa, R=5.0m<br />

p=1.0MPa, R=5.0m<br />

12<br />

0.0 0.1 0.2 0.3 0.4 0.5<br />

Coefficient <strong>of</strong> friction<br />

Figure 6: Longitud<strong>in</strong>al <strong>residual</strong> <strong>stress</strong> (cross-section:<br />

90mm×180mm; lam<strong>in</strong>a: 90mm×15mm)<br />

The effect <strong>of</strong> the parameters on the rebound<strong>in</strong>g<br />

deformation <strong>of</strong> <strong>curved</strong> Glulam <strong>beams</strong> is shown <strong>in</strong> Figure<br />

7. Parameters listed <strong>in</strong> Table 1 all affect the rebound<strong>in</strong>g<br />

deformation. The smaller the coefficient <strong>of</strong> friction <strong>in</strong><br />

Stage 1, the more the slippage and the less the composite<br />

action, thus the rebound<strong>in</strong>g deformation is smaller. A<br />

smaller radius <strong>of</strong> curvature and the larger pressure mean<br />

more severe bend<strong>in</strong>g <strong>of</strong> lam<strong>in</strong>a, result<strong>in</strong>g <strong>in</strong> larger<br />

rebound<strong>in</strong>g deformation.<br />

Rebound<strong>in</strong>g deflection (mm)<br />

18<br />

15<br />

12<br />

9<br />

6<br />

3<br />

p=0.5MPa, R=3.0m p=0.75MPa, R=3.0m<br />

p=1.0MPa, R=3.0m p=0.5MPa, R=4.0m<br />

p=0.75MPa, R=4.0m p=1.0MPa, R=4.0m<br />

p=0.5MPa, R=5.0m p=0.75MPa, R=5.0m<br />

p=1.0MPa, R=5.0m<br />

0<br />

0.0 0.1 0.2 0.3 0.4 0.5<br />

Coefficient <strong>of</strong> friction<br />

Figure 7: Rebound<strong>in</strong>g deflection <strong>of</strong> <strong>curved</strong> Glulam beam<br />

(cross-section: 90mm×180mm; lam<strong>in</strong>a: 90mm×15mm)<br />

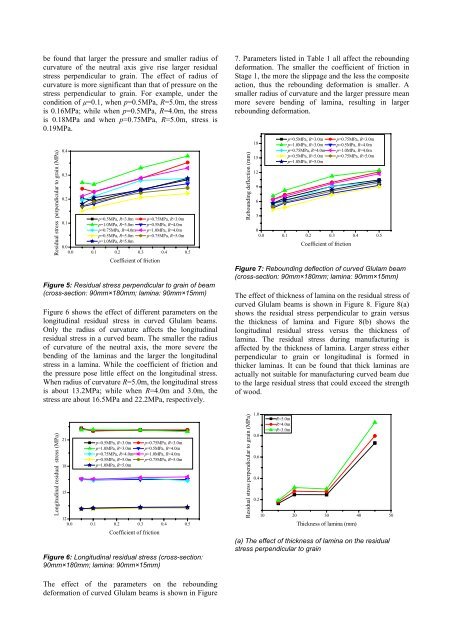

The effect <strong>of</strong> thickness <strong>of</strong> lam<strong>in</strong>a on the <strong>residual</strong> <strong>stress</strong> <strong>of</strong><br />

<strong>curved</strong> Glulam <strong>beams</strong> is shown <strong>in</strong> Figure 8. Figure 8(a)<br />

shows the <strong>residual</strong> <strong>stress</strong> perpendicular to gra<strong>in</strong> versus<br />

the thickness <strong>of</strong> lam<strong>in</strong>a and Figure 8(b) shows the<br />

longitud<strong>in</strong>al <strong>residual</strong> <strong>stress</strong> versus the thickness <strong>of</strong><br />

lam<strong>in</strong>a. The <strong>residual</strong> <strong>stress</strong> dur<strong>in</strong>g manufactur<strong>in</strong>g is<br />

affected by the thickness <strong>of</strong> lam<strong>in</strong>a. Larger <strong>stress</strong> either<br />

perpendicular to gra<strong>in</strong> or longitud<strong>in</strong>al is formed <strong>in</strong><br />

thicker lam<strong>in</strong>as. It can be found that thick lam<strong>in</strong>as are<br />

actually not suitable for manufactur<strong>in</strong>g <strong>curved</strong> beam due<br />

to the large <strong>residual</strong> <strong>stress</strong> that could exceed the strength<br />

<strong>of</strong> wood.<br />

Residual <strong>stress</strong> perpendicular to gra<strong>in</strong> (MPa)<br />

1.0<br />

0.8<br />

0.6<br />

0.4<br />

0.2<br />

R=5.0m<br />

R=4.0m<br />

R=3.0m<br />

10 20 30 40 50<br />

Thickness <strong>of</strong> lam<strong>in</strong>a (mm)<br />

(a) The effect <strong>of</strong> thickness <strong>of</strong> lam<strong>in</strong>a on the <strong>residual</strong><br />

<strong>stress</strong> perpendicular to gra<strong>in</strong>