You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

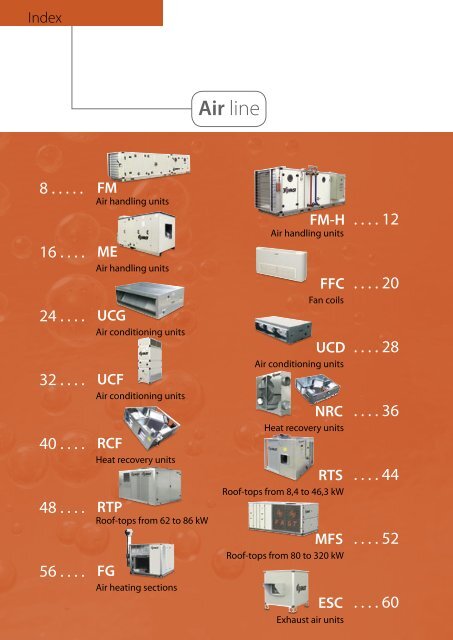

Index<br />

8 . . . . .<br />

16 . . . .<br />

24 . . . .<br />

32 . . . .<br />

40 . . . .<br />

48 . . . .<br />

56 . . . .<br />

FM<br />

Air handling units<br />

ME<br />

Air handling units<br />

UCG<br />

Air conditioning units<br />

UCF<br />

Air conditioning units<br />

RCF<br />

Heat recovery units<br />

RTP<br />

Roof-tops from 62 to 86 kW<br />

FG<br />

Air heating sections<br />

Air line<br />

FM-H<br />

Air handling units<br />

FFC<br />

Fan coils<br />

UCD<br />

Air conditioning units<br />

NRC<br />

Heat recovery units<br />

RTS<br />

Roof-tops from 8,4 to 46,3 kW<br />

MFS<br />

Roof-tops from 80 to 320 kW<br />

ESC<br />

Exhaust air units<br />

. . . . 12<br />

. . . . 20<br />

. . . . 28<br />

. . . . 36<br />

. . . . 44<br />

. . . . 52<br />

. . . . 60

www.fastaer.com<br />

Air line<br />

Air handling<br />

units<br />

Fan coils<br />

Air conditioning<br />

units<br />

Heat recovery<br />

units<br />

Roof-top units<br />

Air heating sections<br />

Exhaust units<br />

7

FM<br />

Air handling units<br />

8<br />

FM<br />

Air handling units<br />

Air flow rate from 1.000 to 100.000 m³/h<br />

The air handling units in the FM series are the blend of<br />

experience, research and testing in the specific aeraulic<br />

machines sector. The FM series adapts to all the specific needs<br />

of the system, both with regard to operation and to overall<br />

sizes allowing different air treatment requirements to be met<br />

even in specific fields such as hospitals, the food industry, the<br />

pharmaceutical industry and microelectronics..<br />

The FM series is made in full compliance with the provisions of<br />

the EN 1886 norm as far as mechanical resistance, air leakage,<br />

heat performance and soundproofing is concerned.<br />

The precise frame-panels coupling makes it possible to<br />

achieve air leakage values from the casing within the values<br />

of class B of the UNI EN 1886 standard with certification from<br />

the RWTÜV laboratories.<br />

> Versions<br />

24 sizes available.<br />

Supporting structure and<br />

modular construction<br />

which enable the<br />

components to be<br />

standardised and a high<br />

flexibility of use.<br />

50 mm thick sandwich panels<br />

available in:<br />

- galvanised steel (inside only)<br />

- pre-painted galvanised steel<br />

- stainless steel<br />

- aluminium<br />

with insulation in injected<br />

polyurethane or mineral<br />

wool of various densities.<br />

Special versions studied for<br />

particular environments.

Main technical data<br />

FM Model 13 20 28 35 42 50 57 69<br />

Air flow rate (speed 2 m/s) m³/h 910 1.450 2.000 2.510 3.060 3.610 4.300 4.970<br />

Air flow rate (speed 2,5 m/s) m³/h 1.130 1.810 2.500 3.130 3.820 4.510 5.090 6.210<br />

Air flow rate (speed 3 m/s) m³/h 1.360 2.180 3.010 3.760 4.590 5.420 6.110 7.460<br />

Air flow rate (speed 3,5 m/s) m³/h 1.590 2.540 3.510 4.390 5.350 6.320 7.460 8.700<br />

FM Model 82 105 119 154 194 237 286 342<br />

Air flow rate (speed 2 m/s) m³/h 5.870 7.580 8.580 11.080 14.000 17.060 20.610 24.620<br />

Air flow rate (speed 2,5 m/s) m³/h 7.340 9.480 10.720 13.850 17.500 21.320 25.760 30.770<br />

Air flow rate (speed 3 m/s) m³/h 8.800 11.370 12.870 16.620 21.000 25.580 30.900 36.930<br />

Air flow rate (speed 3,5 m/s) m³/h 10.270 13.280 15.010 19.390 24.490 29.850 36.070 43.080<br />

FM Model 413 480 547 614 681 749 816 883<br />

Air flow rate (speed 2 m/s) m³/h 29.710 34.560 39.390 44.230 49.060 53.900 58.740 63.580<br />

Air flow rate (speed 2,5 m/s) m³/h 37.140 43.130 49.240 55.280 61.330 67.380 73.430 79.480<br />

Air flow rate (speed 3 m/s) m³/h 44.570 51.840 59.080 66.340 73.600 80.850 88.110 95.370<br />

Air flow rate (speed 3,5 m/s) m³/h 51.990 60.440 68.930 77.400 85.860 94.330 102.780 111.280<br />

> Selection software<br />

The innovative on-line AHU configuration<br />

software allows a fast and correct scaling<br />

of the unit in real time.<br />

The choice of the components is guided<br />

and the direct access to the company<br />

database makes it possible to select them<br />

from among an extensive record.<br />

The software gives operators a complete<br />

technical data sheet, a detailed<br />

description, a detailed drawing and an<br />

economic summary that is always up to<br />

date.<br />

Speed: face velocity on the heat exchange coil.<br />

>FM<br />

Air handling units<br />

9

FM<br />

Air handling units<br />

10<br />

> Characteristics<br />

Supporting structure made<br />

of <strong>new</strong>-geometry rounded<br />

aluminium profiles with corners<br />

made of reinforced nylon. The<br />

casing is made of 50 mm thick<br />

sandwich panels fixed to the frame<br />

with exclusive panel block and<br />

complete absence of screws.<br />

Aluminium dampers with<br />

aerofoil blades. The careful<br />

construction keeps the leakage<br />

values very low.<br />

All the types of filtration<br />

systems usually used in air<br />

handling units are available,<br />

thereby ensuring compliance<br />

The exclusive fixing of the panels to<br />

the frame permits uniform pressure<br />

over the casing providing excellent air<br />

tightness (class B – EN 1886)<br />

Perfectly smooth internal surfaces to<br />

prevent dirt from accumulating<br />

with the room air-quality related<br />

regulations currently in force.<br />

Heat exchange coils all<br />

extractable on slides and supplied<br />

in different materials depending<br />

on the use and the fluid.<br />

Humidification systems chosen<br />

on the basis of special usage<br />

for which they are designed<br />

in compliance with the fluid<br />

available.<br />

Fans with forward or backward<br />

curved blades. The choice is made<br />

in accordance with the aeraulic<br />

performance required paying<br />

attention to the efficiency and<br />

noise level.<br />

Silencers available in different<br />

lengths made of rock wool<br />

protected by a polyester film and<br />

contained in a microperforated<br />

stretched sheet made of<br />

galvanised steel.<br />

Various types of heat recovery<br />

systems make it possible to<br />

comply with energy saving<br />

regulations currently in force.<br />

Extractable coils on slides for easy<br />

maintenance and cleaning<br />

Special versions for particular applications

2.405 2.085 1.765 1.445 1.125 805 645<br />

Face dimensions (mm)<br />

735 895 1.055 1.215 1.375 1.695 2.015 2.335 2.655 2.975 3.295 3.615 3.935 4.255 4.575<br />

13<br />

20 28 35 42 50<br />

57<br />

69 82 105<br />

119<br />

154<br />

194<br />

237<br />

286<br />

342<br />

413<br />

> Eurovent certificate performance<br />

Casing mechanical<br />

strenght<br />

Casing air leakage with pressure<br />

test – 400 Pa<br />

Casing air leakage with pressure<br />

test +700 Pa<br />

The voluntary certification<br />

programmes established and<br />

managed by Eurovent provide<br />

for a comparison between<br />

the technical characteristics<br />

declared by the manufacturer<br />

in the documentation and in<br />

the selection software and the<br />

results of the test conducted<br />

on real products. Eurovent<br />

Fast SPA<br />

I-35044 Montagnana (PD) - Via Luppia Alberi, 170<br />

Tel. +39.0429.806311 - Fax +39.0429.806340<br />

info@fastaer.com - www.fastaer.com<br />

480 547 614 681 749 816 883<br />

purpose is to create a basis for<br />

comparison in order to ensure<br />

"healthy" and "fair" competition<br />

on the European market and<br />

constitute a benchmark for<br />

engineers, consultants and<br />

users who draw on it for the<br />

selection of air conditioning<br />

and refrigeration systems with<br />

certified performances.<br />

FAST Spa has obtained the<br />

Eurovent certification for the<br />

“Air handling unit” programme<br />

FM series units and for FM-<br />

H series units for specific<br />

sectors guaranteeing its<br />

costumers total transparency<br />

and accuracy in the declared<br />

performance.<br />

FM Series Class EN 1886 values<br />

2A Max. relative bending: 4 mm/m<br />

B Max. leakage: 0,44 l/s m 2<br />

B Max. leakage: 0,63 l/s m 2<br />

Filter by-pass leakage F9 Total leakage K: 0,5 %<br />

Thermal transmittance U T3 1 < U ≤ 1,4 W/K m 2<br />

Base unit thermal bridging factor TB3 0,45 < kb ≤ 0,6<br />

>FM<br />

Air handling units<br />

11

FM-H<br />

Air handling units<br />

12<br />

FM-H<br />

Air handling units for special sectors<br />

with patented antibacterial treatment<br />

Air flow rate from 1.000 to 30.000 m³/h<br />

The air handling unit in the FM-H series has proved to be the<br />

ideal choice to minimise the risks of the internal development of<br />

biological contaminants and therefore a totally innovative on the<br />

panorama of climate control for specific applications (hospital,<br />

food processing, chemical, pharmaceutical sectors etc.).<br />

In addition to the geometric-constructive characteristics<br />

laid down in recent standard-legislation related documents,<br />

the unit is provided with a special patented anti-bacteria<br />

treatment applied on the internal surface, the efficiency of<br />

which has been confirmed by the University of Padua.<br />

The FM-H series is made in full compliance with the provisions<br />

of the EN 1886 norm as far as mechanical resistance, air leakage,<br />

heat performance and soundproofing is concerned.<br />

The precise frame-panels coupling makes it possible to achieve<br />

air leakage values from the casing within the values of class B<br />

of the UNI EN 1886 standard with certification from the RWTÜV<br />

laboratories.<br />

> Versions<br />

15 sizes available.<br />

Supporting structure and<br />

modular construction.<br />

50 mm thick sandwich panels<br />

available in:<br />

- aluminium alloy with antibacteria<br />

treatment for the<br />

external panel;<br />

- pre-painted galvanised<br />

steel, stainless steel or<br />

aluminium for the external<br />

panel with insulation made<br />

of injected polyurethane<br />

or mineral wool of various<br />

thicknesses.

Main technical data<br />

FM Model 20 28 35 42 50 57 69 82<br />

Air flow rate (Speed 1,5 m/s) m³/h 1.100 1.500 1.900 2.300 2.700 3,100 3,700 5,700<br />

Air flow rate (Speed 2 m/s) m³/h 1.450 2.000 2.500 3.100 3.600 4,100 5,000 7,600<br />

Air flow rate (Speed 2,5 m/s) m³/h 1.800 2.500 3.100 3.800 4.500 5,100 6,200 9,500<br />

Air flow rate (Speed 3 m/s) m³/h 2.160 3.000 3.800 4.500 5.400 6,200 7,500 8,900<br />

FM Model 105 119 154 194 237 286 342<br />

Air flow rate (Speed 1,5 m/s) m³/h 5.700 6.400 8.300 10.500 12.800 15.500 18.500<br />

Air flow rate (Speed 2 m/s) m³/h 7.600 8.600 11.100 14.000 17.100 20.600 24.600<br />

Air flow rate (Speed 2,5 m/s) m³/h 9.500 10.700 13.900 17.500 21.300 25.800 30.800<br />

Air flow rate (Speed 3 m/s) m³/h 11.300 12.900 16.600 21.000 25.600 30.900 37.000<br />

> Patented antibacterial treatment<br />

The excellent results obtainined<br />

in terms of anti-bacteria action,<br />

through the use of a special<br />

treatment carried out by FAST and<br />

the application of which has been<br />

patented, are confirmed through<br />

laboratory tests. These tests<br />

guarantee the non-proliferation<br />

The laboratory tests to assess the<br />

bactericide effectiveness of the<br />

treatment were carried out by<br />

Padua University in Italy.<br />

Speed: face velocity on the heat exchange coil.<br />

and the destruction of biological<br />

pollutants harmful for human health,<br />

thereby enabling the units to meet<br />

ever more demanding standard and<br />

legislation related provisions.<br />

Tests in culture soup with humidity around 100%<br />

% destruction<br />

100<br />

75<br />

50<br />

20<br />

0<br />

- 25<br />

- 50<br />

- 75<br />

Legionella pneumophila ssp pneumophila<br />

4 8<br />

12<br />

16<br />

20<br />

24<br />

28<br />

AISI 304 INOX Zn<br />

32<br />

36<br />

40<br />

hours of exposure<br />

44<br />

48<br />

52<br />

56<br />

Antibacteria treatment<br />

The destructive power of the bactericide treatment (Legionella<br />

pneumophila in the photograph) remains constant over time.<br />

60<br />

64<br />

68<br />

72<br />

>FM-H<br />

Air handling units<br />

13

FM-H<br />

Air handling units<br />

14<br />

> Characteristics<br />

Inspection and cleaning:<br />

- access doors, draining panels<br />

and adequate lighting in each<br />

section;<br />

- internal corners connected to<br />

avoid the build up of dirt;<br />

- edges and cracks are avoided,<br />

the permanent joints are sealed.<br />

Internal panels and<br />

surfaces:<br />

- the precise frame-panels<br />

coupling makes it possible<br />

to achieve air leakage values<br />

from the casing within class B<br />

of the UNI EN 1886 standard<br />

with certification from the TÜV<br />

laboratories.<br />

- materials resistant to the<br />

formation of cracks, splinters,<br />

chipping and abrasion, which<br />

can be washed and disinfected,<br />

which do not favour the<br />

proliferation of biological agents<br />

and which reduce the microbic<br />

load (anti-bacteria treatment<br />

with certified destruction of the<br />

microbe load) are used.<br />

Fan sections, exchange coils,<br />

filters and external air intakes:<br />

- plug fans coated with<br />

antibacterial treatment for all<br />

the sizes, provided with guides<br />

and supports reduced to the<br />

minimum;<br />

- coils and heat recovery units<br />

in Cu/Cu, Stainless steel/Cu or<br />

Stainless Steel/Stainless Steel<br />

versions;<br />

- class F7 filters positioned upline<br />

on the unit intakes, F8/F9 class<br />

downline;<br />

- external air intakes scaled for<br />

speeds less than 2 m/s and<br />

provided with adequate means<br />

of protection.<br />

Panels and internal surface<br />

Inspection and cleaning Fan sections, heat exchange coils,<br />

filters and external air intakes<br />

Humidification, silencers and<br />

drop eliminators:<br />

- direct steam-type humidification<br />

or with immersed electrode<br />

producer;<br />

- adequate distances are kept<br />

between humidification and the<br />

next component;<br />

- drop eliminators subjected to<br />

anti-bacteria treatment.<br />

Performance and safety-related<br />

characteristics:<br />

- the performance of the unit has<br />

been certified as per the<br />

Eurovent programme;<br />

- the unit, when equipped with<br />

all the electrical and electronic<br />

components for its correct<br />

functioning, is CE-labelled,<br />

which confirms compliance with<br />

the safety requirements of the<br />

applicable directives.<br />

Humidification, silencers and drop<br />

eliminators

Face dimensions (mm)<br />

2.085 1.765 1.445 1.125 805<br />

> Eurovent certificate performance<br />

735 895 1.055 1.215 1.375 1.695 2.015 2.335<br />

20 28 35 42 50<br />

The voluntary certification<br />

programmes established and<br />

managed by Eurovent provide<br />

for a comparison between<br />

the technical characteristics<br />

declared by the manufacturer<br />

in the documentation and in<br />

the selection software and the<br />

results of the test conducted<br />

on real products. Eurovent<br />

Fast SPA<br />

I-35044 Montagnana (PD) - Via Luppia Alberi, 170<br />

Tel. +39.0429.806311 - Fax +39.0429.806340<br />

info@fastaer.com - www.fastaer.com<br />

57 69 82 105<br />

119 154<br />

194 237<br />

purpose is to create a basis for<br />

comparison in order to ensure<br />

"healthy" and "fair" competition<br />

on the European market and<br />

constitute a benchmark for<br />

engineers, consultants and<br />

users who draw on it for the<br />

selection of air conditioning<br />

and refrigeration systems with<br />

certified performances.<br />

286 342<br />

FAST Spa has obtained the<br />

Eurovent certification for the<br />

“Air handling unit” programme<br />

FM series units and for FM-<br />

H series units for specific<br />

sectors guaranteeing its<br />

costumers total transparency<br />

and accuracy in the declared<br />

performance.<br />

Classified characteristic FM-H Series Class EN 1886 values<br />

Casing mechanical<br />

strenght<br />

Casing air leakage with pressure<br />

test –400 Pa<br />

Casing air leakage with pressure<br />

test +700 Pa<br />

2A Max. relative bending: 4 mm/m<br />

B Max. leakage: 0.44 l/s m 2<br />

B Max. leakage: 0.63 l/s m 2<br />

Filter by-pass leakage F9 Total leakage K: 0,5 %<br />

Thermal transmittance U T3 1 < U ≤ 1,4 W/K m 2<br />

Base unit thermal bridging factor TB3 0,45 < kb ≤ 0,6<br />

>FM-H<br />

Air handling units<br />

15

ME<br />

Air handling units<br />

16<br />

ME<br />

Air handling units<br />

Air flow rate from 1.000 to 20.000 m 3 /h<br />

The air handling units in the ME series combine outstanding<br />

technical and performance characteristics able to meet all the<br />

requirements that are typical in civil and industrial conditioning<br />

systems.<br />

The high quality of the components used grants a high<br />

performances of the product. A large number of accessories and<br />

configurations make the unit perfectly adaptable to the most<br />

different systems-related requirements.<br />

The precise frame-panels coupling makes it possible to achieve<br />

air leakage values from the casing within the values of class B<br />

of the UNI EN 1886 standard with certification from the RWTÜV<br />

laboratories.<br />

> Versions<br />

12 sizes available.<br />

Self-bearing structure and<br />

modular construction<br />

enable the components<br />

to be standardised and<br />

guarantee very flexible use.<br />

Sandwich panels with top and<br />

bottom panels 50 mm thick,<br />

side panels 25 mm thick<br />

available in:<br />

- galvanised steel (inside)<br />

- pre-painted galvanised<br />

steel (outside)<br />

with injected polyurethane<br />

insulation.

Main technical data<br />

ME model 13 20 28 35 42 50 57 69 82 119 154 194<br />

Air flow rate (speed 2 m/s) m³/h 900 1.500 2.000 2.500 3.100 3.600 4.100 5.000 5.900 8.600 11.100 14.000<br />

Air flow rate (speed 2,5 m/s) m³/h 1.100 1.800 2.500 3.100 3.800 4.500 5.100 6.200 7.300 10.700 13.900 17.500<br />

Air flow rate (speed 3 m/s) m³/h 1.400 2.200 3.000 3.800 4.600 5.400 6.100 7.500 8.800 12.900 16.600 21.000<br />

Air flow rate (speed 3,5 m/s) m³/h 1.600 2.500 3.500 4.400 5.400 6.300 7.100 8.700 10.300 15.000 19.400 24.400<br />

> Face dimensions (mm)<br />

630<br />

510<br />

790<br />

670<br />

1.110<br />

990<br />

1.430<br />

1.310<br />

1.750<br />

1.630<br />

670 830 990 1.150 1.310 1.630<br />

13<br />

Speed: face velocity on the heat exchange coil.<br />

20 28 35 42 50<br />

57 69 82<br />

119 154<br />

194<br />

>ME<br />

Air handling units<br />

17

ME<br />

Air handling units<br />

18<br />

> Characteristics<br />

Self-bearing structure with<br />

sandwich panels fixed with<br />

screws on threaded inserts.<br />

The conformation of the edge<br />

of the panel makes it possible<br />

to have internal surfaces that<br />

are completely smooth with<br />

reduction of the accumulation of<br />

dust, thereby guaranteeing easy<br />

cleaning and maintenance of the<br />

unit.<br />

Aluminium dampers with<br />

aerofoil blades. The careful<br />

construction keeps the leakage<br />

value very low.<br />

The high degree of modularity make it possible<br />

to standardise the components giving greater<br />

flexibility in the production of the unit<br />

Internal smooth surfaces for a<br />

reduction in the accumulation of dirt<br />

Panel filters, bag filters and<br />

absolute filters with different<br />

efficiencies to guarantee the<br />

quality of the air treated can be<br />

installed in accordance with the<br />

regulations currently in force.<br />

Heat exchange coils all<br />

extractable on slides and supplied<br />

in different materials depending<br />

on the use and the feed fluid.<br />

Humidification systems chosen<br />

on the basis of special usage<br />

for which they are designed<br />

in compliance with the fluid<br />

available.<br />

Extensive choice of the components to meet<br />

all the system-related needs (the photo shows<br />

compressed air-water humidification)<br />

Fans with forward or backward<br />

curved blades, selected in<br />

accordance with the aeraulic<br />

performance required paying<br />

attention to the efficiency and<br />

noise level.<br />

Silencers available in different<br />

lengths made of rock wool<br />

protected by a polyester film and<br />

contained in a microperforated<br />

stretched galvanised steel sheet.<br />

Cross-flow or run-aroundcoils<br />

heat recovery systems<br />

complying with energy-saving<br />

related legislation in force.

Certified performance<br />

Classified characteristic ME Series Class EN 1886 values<br />

Casing mechanical<br />

strenght<br />

Casing air leakage with pressure<br />

test –400 Pa<br />

Casing air leakage with pressure<br />

test +700 Pa<br />

Fast SPA<br />

I-35044 Montagnana (PD) - Via Luppia Alberi, 170<br />

Tel. +39.0429.806311 - Fax +39.0429.806340<br />

info@fastaer.com - www.fastaer.com<br />

The ME series is made in full compliance with<br />

the provisions of the EN 1886 norm as far<br />

as mechanical resistance, air leakage, heat<br />

performance and soundproofing<br />

are concerned.<br />

The precise frame-panels coupling makes it<br />

possible to achieve air leakage values from<br />

the casing that come within the values of<br />

class B of the UNI EN 1886 standard with<br />

certification from the RWTÜV laboratories.<br />

2A Max. relative bending: 4 mm/m<br />

B Max. leakage: 0,44 l/s m 2<br />

B Max. leakage: 0,63 l/s m 2<br />

Filter by-pass leakage F9 Total leakage K: 0,5 %<br />

Thermal transmittance U T3 1 < U ≤ 1,4 W/K m 2<br />

Base unit thermal bridging factor TB3 0,45 < kb ≤ 0,6<br />

>ME<br />

Air handling units<br />

19

FFC<br />

Fan coils<br />

20<br />

FFC<br />

Fan coils<br />

Heating capacity from 3.510 to 17.430 W<br />

Cooling capacity from 1.550 to 7.810 W<br />

The fanc oils in the FFC series are elegantly designed products<br />

that are very reliable and easy to install.<br />

The wide range of models, the extensive availability of<br />

accessories and the possibility to have units in versions both<br />

with cabinets and ductable make it possible to meet the many<br />

requirements that might be encountered in system design in the<br />

civil sector.<br />

The version with cabinet (F) features frontal air intake and can<br />

be installed both vertically on the wall or from the ceiling,<br />

horizontally, while version (C), without cover and with air-intake<br />

from below is ideal for ducted installations both vertically and<br />

horizontally.<br />

> Versions<br />

FFC F version with covering<br />

cabinet.<br />

FFC F version without covering<br />

cabinet.<br />

> Accessories<br />

PXF multi-function command<br />

panel.<br />

BA 1 row water heating coil.<br />

EH electric coil.<br />

BAC auxiliary condensate drain<br />

pan.<br />

FD straight flange for air supply.<br />

FP 90° flange for air supply.<br />

DP supply plenum.<br />

PCP rear closure panel.<br />

SIP hanging installation support.<br />

KV three-way valve set.<br />

SMT minimum water temperature<br />

probe.<br />

Z feet for version without<br />

covering cabinet.

Main technical data<br />

FFC-F, FFC-C model (3 rows) 02 03 04 05 06 08 10<br />

max. W 3.510 5.120 7.550 8.750 13.310 15.540 17.430<br />

Heating capacity med. W 2.770 4.200 6.570 7.610 11.310 13.675 15.685<br />

min. W 1.965 3.480 5.210 5.510 8.520 11.030 12.900<br />

Water flow rate l/h 302 440 649 753 1.145 1.336 1.499<br />

Water side pressure drop kPa 5,7 13,7 12,7 16,5 15,0 19,8 24,4<br />

Heating capacity 1R (BA) max. W 1.820 2.930 3.530 4.450 5,650 6.570 6.970<br />

Water flow rate 1R (BA) l/h 157 252 304 383 486 565 599<br />

Water side pressure drop 1R (BA) kPa 6,7 15,7 22,0 33,3 16,5 21,7 24,1<br />

Electric heating coil capacity W 950 1.300 1.650 1.950 2.200 2.200 2.200<br />

Total cooling capacity max. W 1.550 2.470 3.470 4.260 5.010 7.090 7.810<br />

Sensible cooling capacity max. W 1.280 1.960 2.820 3.050 4.370 5.130 5.670<br />

Water flow rate l/h 267 425 597 733 862 1.219 1.343<br />

Water side pressure drop kPa 6,2 17,5 14,8 24,1 12,3 22,9 27,2<br />

max. m³/h 290 450 600 720 920 1.140 1.300<br />

Air flow rate med. m³/h 220 350 460 600 720 930 1.120<br />

min. m³/h 140 260 330 400 520 700 900<br />

max. dB(A) 42,5 40,0 43,5 48,0 47,5 43,5 57,5<br />

Sound pressure level med. dB(A) 37,5 32,5 36,0 43,5 42,5 48,5 52,5<br />

min. dB(A) 26,5 27,5 29,0 34,5 33,5 42,5 47,5<br />

Max. motor power W 25 44 57 67 82 106 131<br />

Max. input current A 0,12 0,21 0,28 0,35 0,40 0,49 0,58<br />

cooling<br />

heating<br />

Fast SPA<br />

I-35044 Montagnana (PD) - Via Luppia Alberi, 170<br />

Tel. +39.0429.806311 - Fax +39.0429.806340<br />

info@fastaer.com - www.fastaer.com<br />

Supply voltage 230V (+/- 10%) – 1 – 50 Hz.<br />

Heating performance: Water inlet 70°C, air outlet 20°C,<br />

Dt water 10°C at maximum fan speed;<br />

for the average and minimum fan speeds, water flow is as per the maximum speed.<br />

Cooling performance: air inlet 27°C bs - 19°C bu, water inlet 7°C,<br />

Dt water 5°C at maximum fan speed;<br />

for the average and minimum fan speeds, water flow is as per the maximum speed.<br />

Sound pressure level (weighted A) measured in the room<br />

with volume of 85 m 3 and reverberation time of 0,5 s.<br />

>FFC<br />

Fan coils<br />

21

FFC<br />

Fan coils<br />

22<br />

> Characteristics<br />

The supporting structure is<br />

made of galvanised steel of an<br />

adequate thickness. Each unit<br />

is equipped with a reversable<br />

condensate drain pan. In the<br />

case of ceiling installations, the<br />

assembly can be made easier by<br />

the use of the bracket accessory.<br />

The covering cabinet (RAL 7040)<br />

is made of steel sheet that has<br />

been suitably treated to ensure<br />

high-level resistance to rust and<br />

corrosion.<br />

The filtering cells, made of<br />

materials that can be regenerated,<br />

can be easily extracted and<br />

washed.<br />

The coils' hydraulic connections can be<br />

reversed during installation<br />

A wide range of accessories, such as<br />

the three-way valve kit that complete<br />

the functions of the fan coil, is available<br />

The heat exchange coil is been<br />

made from copper pipes and<br />

aluminium fins that are blocked<br />

through the mechanical expansion<br />

of the pipes. The manifolds are<br />

provided with reversable female<br />

connections and easily accessible<br />

air relief valves. The number of heat<br />

exchanger rows is three while in the<br />

case of four-pipe systems, a onerow<br />

heating coil can be added.<br />

The PXF control panel<br />

(accessory) controls fancoil<br />

functioning as per the mode set,<br />

the room temperature and the<br />

temperature of the water in the<br />

circuit in such a way as to keep the<br />

set temperature in the room.<br />

The fan-motor assembly<br />

consists of double intake radial<br />

fans with lengthwise blades to<br />

get a high flow rate with a low<br />

number of rpms. The electrical<br />

motor, protected against<br />

overloading, has three speeds with<br />

the running capacitor always on,<br />

directly coupled to the fans and<br />

dampened with flexible supports.<br />

The thermoplastic supply grille<br />

for air diffusion is flat and fixed.<br />

A sturdy filter, that can easily be removed<br />

and cleaned, is responsible for the filtering<br />

The high performance levels of the<br />

units are achieved through heat<br />

exchange coils with low pressure<br />

drops and fans that ensure adequate<br />

pressures even for ducts, if any

Sizes and weights<br />

FFC - F model 02 03 04 05 06 08 10<br />

Length L mm 750 980 1.200 1.200 1.320 1.320 1.320<br />

Width W mm 220 220 220 220 220 220 220<br />

Height H mm 503 503 503 503 608 608 608<br />

Weight kg 15 20 24 24 34 34 34<br />

FFC - C Model 02 03 04 05 06 08 10<br />

Length L1 * mm 522 753 973 973 1.122 1.122 1.122<br />

Width W1 mm 453 453 453 453 558 558 558<br />

Height H1 mm 216 216 216 216 216 216 216<br />

Weight kg 13 18 22 22 33 33 33<br />

L<br />

> Accessories compatibility<br />

BA, EH<br />

BAC<br />

DP, FD, FP<br />

Fast SPA<br />

I-35044 Montagnana (PD) - Via Luppia Alberi, 170<br />

Tel. +39.0429.806311 - Fax +39.0429.806340<br />

info@fastaer.com - www.fastaer.com<br />

H<br />

W<br />

H 1<br />

02 03 04 05 06 08 10 Vers.<br />

02 – – – – – – C-F<br />

03 – – – – – – C-F<br />

04 – – – – – C-F<br />

06 – – – – C-F<br />

4 C-F<br />

5 – – – C-F<br />

6 – – – – C-F<br />

02 – – – – – – C<br />

03 – – – – – – C<br />

04 – – – – – C<br />

06 – – – – C<br />

1 – – – – – C-F<br />

2 – – – – – C-F<br />

KV 3 – – – – C-F<br />

PCP<br />

4 – – – C-F<br />

5 – – – – C-F<br />

02 – – – – – – F<br />

03 – – – – – – F<br />

04 – – – – – F<br />

06 – – – – F<br />

PXF, SIP, SMT C-F<br />

Z<br />

* Without electrical box.<br />

02 – – – C<br />

06 – – – – C<br />

Standard, Optional, – Not available.<br />

L 1<br />

W 1<br />

>FFC<br />

Fan coils<br />

23

UCG<br />

Air conditioning units<br />

24<br />

UCG<br />

Air conditioning units<br />

Air flow rate from 800 to 4.900 m 3 /h<br />

The units in the UCG series have been designed for the creation<br />

of both centralised systems and individual installations for<br />

buildings with a civil or commercial use such as shops, offices,<br />

restaurants and communities.<br />

These climate control units which have a cooling function<br />

in summer and simple heating in winter can be installed<br />

horizontally or vertically and contribute to the creation of<br />

systems that are either the all-air type or the primary air and fan<br />

coil type.<br />

The units in the UCG series can be easily hidden in suspended<br />

ceilings and can serve more than one room through a<br />

distribution plenum or ducts. The extensive range of accessories<br />

provided then make it possible to circulate the air inside the<br />

rooms, to mix with fresh air, to take in exclusively fresh air for a<br />

full change or operate in “free-cooling” mode.<br />

> Versions<br />

7 sizes available.<br />

Horizontal or vertical installation<br />

possible.<br />

> Accessories<br />

UxGA intake grille.<br />

UxSR damper on intake with<br />

manual actuator.<br />

UxSM mixing box provided with<br />

plenum, two dampers with<br />

manual actuator and class<br />

G2 filters.<br />

UxBP one-row water-type reheating<br />

coil applied outside<br />

the unit.<br />

UxBR electrical re-heating coil<br />

applied outside the unit<br />

provided with a double<br />

safety thermostat.<br />

UxPM panel with multiple circular<br />

supplies.<br />

UxGM supply outlet.<br />

UxSL module with silencers.<br />

UUV steam humidifying<br />

distributor ramp.<br />

PX control panel for wall<br />

installation with ON/OFF<br />

switch and motor speed<br />

selection.<br />

PCT2 control panel for wall<br />

installation with thermostat,<br />

season change, electrical<br />

heating coil management<br />

and fan speed selection.

Main technical data<br />

UCG model 09 11 15 19 24 33 50<br />

Nominal air flow rate m³/h 800 1.100 1.450 1.870 2.400 3.200 4.900<br />

Static pressure available<br />

on supply 1 Pa 50 50 50 50 50 50 50<br />

Total 4R coil cooling capacity 2 kW 5,3 6,2 10,1 10,4 16,0 20,6 33,6<br />

Sensible cooling capacity<br />

4R coil 2 kW 3,9 4,6 7,0 7,8 11,0 14,6 23,1<br />

Total 6R coil cooling capacity 2 kW 6,7 8,3 11,7 14 16,7 23,0 35,3<br />

Sensible cooling capacity<br />

6R coil 2 kW 4,7 5,7 7,9 9,6 11,8 16,2 24,6<br />

4R coil heating capacity 3 kW 11,9 14,5 19,9 24,3 31,6 43,1 65,8<br />

Total cooling capacity<br />

direct expansion coil 4 kW 4,6 5,5 7,4 9,4 11,8 16,0 25,0<br />

Re-heating water coil<br />

capacity 5 kW 4,9 5,9 7,9 10,0 12,9 17,5 25,9<br />

Max. total input power W 300 450 500 550 800 1,100 1,600<br />

Max. total input current A 1,35 2,2 2,5 2,7 3,9 4,3 7,8<br />

> Accessories compatibility<br />

1 At the nominal flow rate with three-row coils and air filter.<br />

2 Performances referring to: inlet air 27°C, 50% RH; water temperature 7-12°C.<br />

3 Performances referring to: inlet air 20°C; water temperature 70-60°C.<br />

4 Performances referring to: R407C refrigerant, evaporation temperature 5°C;<br />

inlet air 27°C, 50% RH;<br />

5 Performances referring to: inlet air 15°C; water temperature 70-60°C.<br />

09 11 15 19 24 33 50<br />

UxGA U1GA U2GA U3GA U4GA U5GA U6GA U7GA<br />

UxSR U1SR U2SR U3SR U4SR U5SR U6SR U7SR<br />

UxSM U1SM U2SM U3SM U4SM U5SM U6SM U7SM<br />

UxBP U1BP U2BP U3BP U4BP U5BP U6BP U7BP<br />

UxBR U1BR U2BR U3BR U4BR U5BR U6BR U7BR<br />

UxPM U1PM U2PM U3PM U4PM U5PM U6PM U7PM<br />

UxGM U1GM U2GM U3GM U4GM U5GM U6GM U7GM<br />

UxSL U1SL U2SL U3SL U4SL U5SL U6SL U7SL<br />

UUV UUV<br />

PX PX<br />

PCT2 PCT2<br />

>UCG<br />

Air conditioning units<br />

25

UCG<br />

Air conditioning units<br />

26<br />

> Characteristics<br />

Structure made of 15 mm thick<br />

galvanised steel sandwich panels<br />

with injected polyurethane<br />

insulation (density 40 kg/m 3 ) for<br />

the side walls; single wall type with<br />

10 mm thick closed cell insulation<br />

for the remaining walls.<br />

Air filtering performed by<br />

class G2 filters as a standard, in<br />

accordance with the EN 779<br />

standard on the air intake panel<br />

Standard class G2 EN 779 intake filters<br />

The sandwich panels guarantee<br />

excellent thermo-acoustic insulation<br />

Double-intake radial fans<br />

with forward-curved blades with<br />

directly coupled motor. The single<br />

phase 230V-50Hz motor has five<br />

speeds, three of which can be<br />

selected through the control<br />

panel.<br />

Internal, insulated condensate<br />

collection pan adapted for<br />

both vertical and horizontal unit<br />

installation.<br />

Coils with 4 or 6 rows that can<br />

be fed with hot or chilled water<br />

made of copper pipes with fins<br />

made of aluminium held in place<br />

by the mechanical expansion of<br />

the pipes. They are equipped with<br />

threaded sleeves for the hydraulic<br />

connections and the air relief<br />

valve. The coils can be rotated on<br />

site. A three-row direct expansion<br />

coil made of copper pipe with<br />

aluminium fins held in place by<br />

the mechanical expansion of the<br />

pipes, is available.<br />

Reduced height for installations that<br />

are typical of suspended ceilings<br />

Various types of heat exchange coils<br />

are available

Sizes and weights<br />

UCG model 09 11 15 19 24 33 50<br />

Length L mm 710 710 710 950 950 950 950<br />

Width W mm 750 850 1.050 850 1.050 1.350 2.000<br />

Height H mm 330 330 330 450 450 450 450<br />

Weight (base version) kg 37 42 50 55 68 86 120<br />

Fast SPA<br />

I-35044 Montagnana (PD) - Via Luppia Alberi, 170<br />

Tel. +39.0429.806311 - Fax +39.0429.806340<br />

info@fastaer.com - www.fastaer.com<br />

L<br />

W<br />

H<br />

>UCG<br />

Air conditioning units<br />

27

UCD<br />

Air conditioning units<br />

28<br />

UCD<br />

Air conditioning units<br />

Air flow rate from 800 to 3.500 m 3 /h<br />

The conditioning units in the UCD series have been designed for<br />

civil, commercial and hotel systems for small and medium sized<br />

rooms.<br />

The units are suitable for vertical and horizontal installation<br />

for greater versatility of use and they have been made with<br />

galvanised, prepainted steel sandwich panels with injected<br />

polyurethane to guarantee high thermal insulation and<br />

extremely quiet running.<br />

The outstanding aesthetic finish of the product makes it fit for<br />

installation in box rooms, bathrooms, suspended ceilings or in<br />

the room itself.<br />

The wide range makes it possible to select the precise model to<br />

use.<br />

> Versions<br />

5 sizes available.<br />

Horizontal or vertical installation<br />

possible.<br />

Version P: with three-row coil.<br />

Version E: with two-row direct<br />

expansion coil.<br />

Version X: exhaust air unit.<br />

> Accessories<br />

FAF air filter.<br />

SM mixing box with filter and<br />

dampers.<br />

SR antifreeze damper.<br />

GM supply grille.<br />

GA intake grille.<br />

CMA counterframe.<br />

BP one-row water-type reheating<br />

coil applied outside<br />

the unit.<br />

BR electric re-heating coil<br />

applied outside the unit.<br />

PM panel with multiple circular<br />

supplies.<br />

PX control panel for wall<br />

installation with ON/OFF<br />

switch and motor speed<br />

selection.<br />

PCT2 control panel for wall<br />

installation with thermostat,<br />

season change, electrical<br />

heating element<br />

management and fan speed<br />

selection.

Main technical data<br />

UCD Model 09 15 21 28 37<br />

Nominal air flow rate m³/h 800 1.400 2.000 2.700 3.500<br />

Max. static pressure available<br />

on supply 1 Pa 87 106 91 143 130<br />

Total cooling capacity<br />

3R water coil 2<br />

Sensible cooling capacity<br />

3R water coil 2<br />

> Accessories compatibility<br />

kW 4,9 7,2 10,8 14,3 17,3<br />

kW 3,8 5,9 8,7 11,6 14,1<br />

Total cooling capacity<br />

direct exp. coil 3 kW 5,1 7,4 10,7 13,9 16,6<br />

Sensible cooling capacity<br />

direct exp. coil 3 kW 3,2 4,8 6,9 9,0 11,2<br />

3R coil heating capacity 4 kW 10,9 17,5 25,4 33,6 43,3<br />

Max. total input power kW 0,12 0,12 0,2 0,4 0,7<br />

Max. total input current A 1,1 1,1 1,6 2,7 4,3<br />

1 Nominal flow rate type with three-row coil.<br />

2 Performances referring to: inlet air 27°C, 50% RH; water temperature 7-12°C.<br />

3 Performances referring to: R407C refrigerant; evap. 5°C;<br />

inlet air 26°C, 50% RH;<br />

4 Performances referring to: inlet air 20°C; water temperature 70-60°C.<br />

09 15 21 28 37<br />

FAF FAF1 FAF2 FAF3 FAF4 FAF4<br />

SM SM1 SM2 SM3 SM4 SM5<br />

SR SR1 SR2 SR3 SR4 SR4<br />

GM GM5 GM6 GM7 GM8 GM8<br />

GA GA5 GA6 GA7 GA8 GA8<br />

CMA CMA5 CMA6 CMA7 CMA8 CMA8<br />

BP BP1 BP2 BP3 BP4 BP5<br />

BR BR1 BR2 BR3 BR4 BR5<br />

PM PM1 PM2 PM3 PM4 PM4<br />

PX PX<br />

PCT2 PCT2<br />

>UCD<br />

Air conditioning units<br />

29

UCD<br />

Air conditioning units<br />

30<br />

> Characteristics<br />

Structure made with 15 mm thick<br />

sandwich panels with injected<br />

polyurethane (density 40 kg/m 3 ).<br />

The supply and suction panels<br />

are equipped with flanges to<br />

connect to any air duct and can be<br />

moved to create different air flow<br />

configurations. The horizontal or<br />

vertical installation of the unit on<br />

the walls is made possible by the<br />

appropriate brackets.<br />

The sandwich panels guarantee<br />

excellent thermo-acoustic insulation<br />

Various types of heat exchange coils<br />

and accessories are available<br />

Double-intake radial fans<br />

with forward-curved blades with<br />

directly coupled motor. The single<br />

phase 230V-50Hz motor has five<br />

speeds, three of which can be<br />

selected through the control<br />

panel.<br />

Internal, insulated condensate<br />

collection pan adapted for<br />

both vertical and horizontal unit<br />

installation.<br />

3 rows coils that can be fed with<br />

hot or chilled water made of<br />

copper pipes with aluminium fins<br />

held in place by the mechanical<br />

expansion of the pipes. They are<br />

equipped with threaded sleeves<br />

for the hydraulic connections<br />

and the air relief valve. The coils<br />

can be rotated on site. A two-row<br />

direct expansion coil made of<br />

copper pipes with aluminium fins,<br />

held in place by the mechanical<br />

expansion of the pipes, is available.<br />

Reduced height for installations that<br />

are typical of suspended ceilings<br />

The fan-motor assemblies are able to<br />

guarantee high available pressure

Sizes and weights<br />

UCD Model 09 15 21 28 37<br />

Length L mm 630 670 670 790 790<br />

Width W mm 920 1.000 1.400 1.400 1.400<br />

Height H mm 300 320 320 380 380<br />

Weight (P version) kg 42 53 71 88 91<br />

Fast SPA<br />

I-35044 Montagnana (PD) - Via Luppia Alberi, 170<br />

Tel. +39.0429.806311 - Fax +39.0429.806340<br />

info@fastaer.com - www.fastaer.com<br />

L<br />

W<br />

H<br />

>UCD<br />

Air conditioning units<br />

31

UCF<br />

Air conditioning units<br />

32<br />

UCF<br />

Air conditioning units<br />

Air flow rate from 3.000 to 20.000 m³/h<br />

The UCF series air conditioning units are machines designed<br />

for commercial and industrial systems. The series comprises<br />

seven models with rated air flow from 3.000 m³/h to 20.000 m³/h<br />

permitting air filtering, cooling and/or heating treatment. The<br />

performances are provided by high-efficiency heat exchange<br />

coils and fans coupled to the motor shafts by means of variable<br />

pulleys and belts giving high available pressures for long ducts.<br />

The modularity of the various sections, the possibility for vertical<br />

and horizontal installation in a version that can be ducted or not<br />

and the availability of several accessories makes the use of these<br />

machines extremely versatile.<br />

> Versions<br />

Horizontal or vertical installation<br />

possible.<br />

Bearing frame type casing and 25<br />

mm thick sandwich panels.<br />

Modularity of the sections<br />

provided with heating coils,<br />

cooling coils, filters, supply<br />

and recovery plenum.<br />

> Accessories<br />

GC, GR air intake grilles.<br />

SC, SR dampers.<br />

RT, RS, EG, TC, ME, LC, RC, RV, RF,<br />

RP, M0, M1, MV, PC, FL,<br />

MC, AC, AL intake plenum.<br />

M, C supply plenum.<br />

Superheated water coils.<br />

Direct expansion coils.<br />

P support feet kit.

Main technical data<br />

UCF model<br />

> Accessories<br />

30 40 56 76 107 139 203<br />

Nominal air flow rate<br />

with standard motors<br />

m³/h 3.000 4.000 5.600 7.600 10.800 14.000 20.400<br />

2 row coil cooling capacity kW 7,6 11,0 15,3 20,5 29,2 32,3 61,0<br />

2 row coil heating capacity kW 24,9 33,4 46,9 63,1 89,3 123,1 186,2<br />

3 row coil cooling capacity kW 11,0 15,0 21,4 28,5 39,9 45,3 70,1<br />

3 row coil heating capacity kW 33,2 44,1 62,3 3,8 118,4 161,7 237,4<br />

4 row coil cooling capacity kW 13,7 18,1 26,7 35,0 46,9 58,8 84,3<br />

4 row coil heating capacity kW 39,5 52,2 74,0 99,5 140,9 191,5 278,3<br />

6 row coil cooling capacity kW 17,8 22,7 33,8 47,2 66,8 84,3 121,8<br />

6 row coil heating capacity kW 47,8 63,2 89,5 122,0 172,6 231,8 337,2<br />

Standard motor electrical power kW 0,55 0,75 1,1 1,5 2,2 3,0 4,0<br />

Accessory<br />

GC front intake grille for cooling coil section<br />

Performances referring to:<br />

Cooling capacity: air temperature 26°C, RH 50%; water temperature 7/12°C.<br />

Heating power: air temperature 20°C; water temperature 80/70°C.<br />

Vertical<br />

version<br />

Horizontal<br />

version<br />

GR front intake grill for heating coil section –<br />

SC damper on the front panel of the cooling coil section<br />

SC damper on the front panel of the heating coil section<br />

RT intake plenum provided with front opening for the connection to the intake duct<br />

RS recovery plenum with grille for the air recirculation and full size external air damper<br />

EG recovery plenum with damper and a grille opposite –<br />

TC recovery plenum fully closed –<br />

ME recovery plenum with full size external damper –<br />

LC recovery plenum with 2 external dampers, one on the long side and one on the short one –<br />

RC intake plenum with front anodized aluminium grille<br />

RV intake plenum with front grille and full-size lateral opening<br />

RF intake plenum with front grille and partial lateral opening<br />

RF intake plenum with front grille and partial lateral damper<br />

M0 intake plenum with two dampers (for recirculation and intake of external air) –<br />

M1 intake plenum with two dampers (for recirculation and lower intake of external air) –<br />

MV intake plenum with two dampers (for recirculation and intake of external air) –<br />

PC recovery plenum with an external damper on the short side –<br />

FL recovery plenum with two dampers, one on the front and one on the side –<br />

MC recovery plenum with two external dampers on the short side –<br />

AC recovery plenum opened on the short sides –<br />

AL recovery plenum opened on the long sides –<br />

M supply plenum provided with outlet and adjustable supply lover made of anodized<br />

aluminium. The plenum is further internally insulated with enclosed mineral wool protected<br />

with a sheet of PVC and contained in microstretched sheet steel<br />

C supply plenum closed. The plenum is further internally insulated with enclosed mineral<br />

wool protected with a sheet of PVC and contained in microstretched sheet steel<br />

P support feet kit made of galvanised steel –<br />

Standard, Optional, – Not available.<br />

>UCF<br />

Air conditioning units<br />

33

UCF<br />

Air conditioning units<br />

34<br />

> Characteristics<br />

The structure is made of a<br />

load-bearing frame made of<br />

aluminium alloy and corners made<br />

of reinforced nylon. The 25mm<br />

thick sandwich panels are made of<br />

prepainted galvanised steel sheet<br />

on the outside and galvanised<br />

steel sheet inside with injected<br />

polyurethane insulation (density<br />

40 kg/m 3 ).<br />

The 48 mm thick filters are of<br />

the synthetic undulated G3 class<br />

type (classification according to<br />

The modular construction ensures that<br />

the unit can be adapted to the needs<br />

of the system<br />

Different types of heat exchange coils<br />

can be provided<br />

the EN 779 standard) positioned<br />

before the coils. They can be<br />

extracted from the unit side.<br />

The heat exchange coils are<br />

made of Cu/Al and come in 2, 3, 4<br />

and 6 row versions that can be fed<br />

with hot and chilled water. Their<br />

geometry is P2519 for the UCF 30-<br />

40-56-76-107 models and P6030<br />

for the other models.<br />

The fan section is provided<br />

with radial type fans with double<br />

intake and forward curved<br />

blades (the 139 and 203 models<br />

have twin fans). The motors, of<br />

the asynchronous three-phase<br />

type with cage rotor, closed<br />

construction, external ventilation<br />

with IP55 electrical protection<br />

and F class of insulation rest on<br />

elastomer shock absorbers and<br />

are provided with a variable pulley<br />

and SPZ or SPA belts according to<br />

the models.<br />

The 25 mm thick sandwich panels<br />

guarantee excellent heat and sound<br />

insulation<br />

Synthetic undulated filters with<br />

efficiency class G3 (EN779) as standard

Sizes<br />

UCF model 30 40 56 76 107 139 203<br />

Length L mm 650 650 740 740 870 870 1.130<br />

Width W mm 1.100 1.350 1.500 1.900 1.900 2.560 2.560<br />

Fan section height mm 650 650 740 740 870 870 1.130<br />

H 1<br />

Cooling section height mm 650 650 740 740 870 870 1.130<br />

H 2<br />

Heating section height mm 350 350 350 350 350 460 460<br />

H 3<br />

Supply plenum height mm 390 390 460 460 600 600 600<br />

H 4<br />

H 4<br />

H 1<br />

H 3<br />

H 2<br />

Fast SPA<br />

I-35044 Montagnana (PD) - Via Luppia Alberi, 170<br />

Tel. +39.0429.806311 - Fax +39.0429.806340<br />

info@fastaer.com - www.fastaer.com<br />

L<br />

W<br />

>UCF<br />

Air conditioning units<br />

35

NRC<br />

Heat recovery units<br />

36<br />

NRC<br />

Heat recovery units<br />

Air flow rates from 350 to 3.300 m 3 /h<br />

The NRC series units have been designed to meet the<br />

requirements of thermohygrometric well-being and air<br />

replacement and quality. They make it possible to extract a<br />

certain quantity of air from the rooms and replace it with fresh<br />

air. An aluminium plate type heat recuperator makes an effective<br />

heat exchange between the exhaust air flow and the fresh air<br />

possible. The fresh air is thus preheated or pre-cooled according<br />

to the season by the exhaust air. The fresh air is filtered before<br />

going through the recuperator which is protected from getting<br />

dirty by a filter of the same type on the expulsion side too.<br />

The high degree of flexibility in the installation (suspended<br />

ceiling type and vertical) and in the possibility of ducting the<br />

unit makes the supply and expulsion of air homogeneous to and<br />

from the rooms.<br />

The NRC series unit has been expressly designed to comply with<br />

the recent legal instructions regarding the protection of nonsmokers'<br />

health.<br />

> Versions<br />

Standard configuration horizontal<br />

or vertical.<br />

Standard horizontal or vertical<br />

configuration with water<br />

heating coil downline from<br />

the heat recuperator.<br />

Standard horizontal or vertical<br />

configuration with electric<br />

heating coil downline from<br />

the heat recuperator.<br />

> Accessories<br />

BF module with water cooling<br />

coil.<br />

MPW module with water cooling<br />

and re-heating coil.<br />

MPX module with cooling and<br />

re-heating electric coil.<br />

BFD module with direct<br />

expansion coil.<br />

BFDW module with direct<br />

expansion and water reheating<br />

coil.<br />

BFDX module with direct<br />

expansion and electric reheating<br />

coil.<br />

G4 G4 efficiency filters.<br />

SU module with silencers.<br />

FGC circular flanges.<br />

SE dampers.<br />

RG control kit.

Main technical data<br />

NRC Model 03 05 07 10 15 21 33<br />

Nominal air flow rate 1 m³/h 350 550 750 1.000 1.500 2.100 3.300<br />

Static pressure available (base vers.) 1 Pa 125 140 170 150 120 120 150<br />

Heating capacity recovered 2 kW 1,5 2,5 3,4 4,6 6,7 9,3 14,3<br />

Cooling capacity recovered 3 kW 0,4 0,7 1,0 1,3 1,9 2,6 4,3<br />

Heat recovery unit efficiency 2 % 52,1 55,0 54,3 54,4 53,1 52,7 52,0<br />

Internal heating coil capacity H 2 O (air 8°C;<br />

H 2 O 70/60°C)<br />

Internal heating coil capacity H 2 O (air 8°C;<br />

H 2 O 45/40°C)<br />

Internal electric coil heating capacity<br />

(electrical power supply 400V-3-50Hz)<br />

Cooling coil capacity H O (air 30°C, 60% RH;<br />

2<br />

H O 7/12°C) BF<br />

2<br />

Direct expansion coil cooling capacity (air<br />

30°C, 60% RH; Tev 5°C; Tcond 47°C; R407C) BFD<br />

Re-heating coil capacity H O (air 17°C; H O<br />

2 2<br />

70/60°C) MPW-BFDW<br />

Re-heating coil capacity H 2 O (air 17°C; H 2 O<br />

45/40°C) MPW-BFDW<br />

Electric re-heating coil capacity (electrical<br />

power supply 400V-3-50Hz) MPX-BFDX<br />

Total input power of the fans (elect. power<br />

supply 230V-1-50Hz)<br />

> Accessories compatibility<br />

kW 4,1 6,7 8,8 13 18,7 25,9 36,6<br />

kW 2,4 4,0 5,2 7,7 11,2 15,4 22,0<br />

kW 3 3 6 6 10 15 25<br />

kW 3,4 4,9 6,5 10,2 13,8 18,5 28,0<br />

kW 3,8 5,1 7,2 10,9 14,8 19,2 27,0<br />

kW 1,5 2,4 3,4 4,8 5,7 7,4 10,2<br />

kW 0,8 1,2 1,7 2,5 3,0 3,8 5,2<br />

kW 1,5 2 3 4 6 8 13<br />

kW 0,27 0,44 0,65 1,12 1,12 2 4<br />

1 At maximum fan speed.<br />

2 Performance related to: fresh air flow equal to the exhaust air flow;<br />

external air temperature –5°C, RH 80%;<br />

room air temperature 20°C, 50% RH.<br />

3 Performances referring to: fresh air flow equal to the exhaust air flow;<br />

external air temperature 34°C, RH 50%;<br />

room air temperature 26°C, 50% RH.<br />

Horizontal configuration<br />

NRC Model 03 05 07 10 15 21 33<br />

BF BF35 BF55 BF75 BF100 BF150 BF210 BF330<br />

MPW MPW35 MPW55 MPW75 MPW100 MPW150 MPW210 MPW330<br />

MPX MPX35 MPX55 MPX75 MPX100 MPX150 MPX210 MPX330<br />

BFD BFD35 BFD55 BFD75 BFD100 BFD150 BFD210 BFD330<br />

BFDW BFDW35 BFDW55 BFDW75 BFDW100 BFDW150 BFDW210 BFDW330<br />

BFDX BFDX35 BFDX55 BFDX75 BFDX100 BFDX150 BFDX210 BFDX330<br />

SU SU1 SU1 SU2 SU3 SU3 SU4 SU5<br />

FGC FGC1 FGC1 FGC1 FGC2 FGC2 – –<br />

G4 G435 G455 G475 G4100 G4150 G4210 G4330<br />

SE SE1 SE1 SE2 SE3 SE3 SE4 SE5<br />

RG RG35 RG55 RG75 RG100 RG150 RG210 RG330<br />

Vertical configuration<br />

NRC V Model 03 05 07 10 15 21 33<br />

FGC FGC1 FGC1 FGC1 FGC2 FGC2 – –<br />

G4 G435 G455 G475 G4100 G4150 G4210 G4330<br />

SE SE1 SE1 SE2 SE3 SE3 SE4 SE5<br />

RG RG35 RG55 RG75 RG100 RG150 RG210 RG330<br />

– Not available.<br />

>NRC<br />

Heat recovery units<br />

37

NRC<br />

Heat recovery unit<br />

38<br />

> Characteristics<br />

Self-bearing 20 mm thick<br />

sandwich panels made of<br />

galvanised steel sheet for the<br />

external and internal surfaces<br />

and with injected polyurethane<br />

insulation (density 40 kg/m 3 ).<br />

Undulated filters class G3<br />

gravimetric efficiency 80% in<br />

accordance with EN 779, 48 mm<br />

thick, positioned before the heat<br />

recuperator on both air supply and<br />

exhaust.<br />

Reduced height for installations typical<br />

of suspended ceilings<br />

Standard electronic regulators for the<br />

variation of the fan speed<br />

Heat recuperators of the crossflow<br />

type with aluminium plates<br />

with performances above 50% in<br />

winter operation.<br />

Double-intake radial fans<br />

with forward-curved blades<br />

with directly coupled motor. The<br />

motor, single phase 230V-50Hz,<br />

is at single speed. The air flow is<br />

controlled by means of standard<br />

electronic regulators.<br />

Class G3 EN 779 filters on supply and<br />

return<br />

Condensate drain pan made of<br />

galvanised steel.<br />

Inspection from below, from<br />

above and sideways according to<br />

the chosen configuration.<br />

Internal hot water or electric coil for<br />

the heating of the rooms (accessory)<br />

Pre-sheared panels to create the by<br />

pass for the free cooling<br />

Many accessories are available, such as<br />

the circular flanges

Sizes and weights<br />

NRC Model 03 05 07 10 15 21 33<br />

Height H mm 300 300 330 390 390 390 390<br />

Width W mm 900 900 1,000 1.250 1.250 1.400 1.750<br />

Length L mm 1.090 1.090 1.190 1.500 1.500 1.750 2.500<br />

Weight (base version) kg 61 65 74 115 140 180 330<br />

Accessory<br />

BF, MPW, BFD, BFDW, BFDX, MPX<br />

Height H1 mm 300 300 330 390 390 390 390<br />

Width W1 mm 460 460 510 635 635 710 860<br />

Length L1 mm 800 800 850 950 950 950 950<br />

L<br />

Fast SPA<br />

I-35044 Montagnana (PD) - Via Luppia Alberi, 170<br />

Tel. +39.0429.806311 - Fax +39.0429.806340<br />

info@fastaer.com - www.fastaer.com<br />

W<br />

35 55 75 100 150 210 330<br />

Accessory weight 35 55 75 100 150 210 330<br />

BF kg 40 40 50 60 60 70 75<br />

MPW kg 43 43 54 65 65 76 85<br />

MPX kg 45 45 57 68 68 79 90<br />

BFD kg 40 40 50 60 60 70 75<br />

BFDW kg 43 43 54 65 65 76 85<br />

BFDX kg 45 45 57 68 68 79 90<br />

SU kg 25 25 30 36 36 45 60<br />

H<br />

L 1<br />

W 1<br />

H 1<br />

>NRC<br />

Heat recovery unit<br />

39

RCF<br />

Heat recovery units<br />

40<br />

RCF<br />

Heat recovery units with cooling circuit<br />

without external unit.<br />

Air flow rates from 750 to 3.300 m 3 /h<br />

The RCF series is a one block answer to the system requirements<br />

typical of civil rooms such as bars, restaurants, offices and<br />

meeting rooms.<br />

The RCF units group together in a single block unit in addition<br />

to the ventilation sections, filtration, heat recovery, a cooling<br />

circuit in heat pump version with high-performance low-noise<br />

scroll compressors. The fresh air is heated or cooled according to<br />

the season thanks to the heat pump refrigeration circuit charged<br />

with R407C refrigerant installed inside the unit. All this means<br />

it is possible to have a complete machine with autonomous<br />

operation in every season and able to combine the necessary<br />

re<strong>new</strong>al of air for the rooms with efficient heat recovery.<br />

The precise design of the machine combines very small<br />

dimensions that permit easy installation in suspended ceilings<br />

with excellent accessibility for all the internal components.<br />

The RCF series unit has been expressly designed to comply with<br />

the recent legal instructions regarding the protection of nonsmokers'<br />

health.<br />

> Versions<br />

5 sizes available in horizontal<br />

configuration for<br />

suspended ceiling<br />

installation.<br />

Unit with heat regulation and<br />

ready for installation.<br />

> Accessories<br />

MBC module with two-row hot<br />

water coil.<br />

MBX module with electric<br />

coil with double safety<br />

thermostat.<br />

G4F G4 efficiency filters.<br />

SUF module with silencers.<br />

FGC circular flanges.<br />

FC free-cooling set.

Main technical data<br />

RCF Model 07 10 15 21 33<br />

Supply and return nominal<br />

air flow rates<br />

m³/h 750 1.000 1.500 2.100 3.300<br />

Minimum air flow rates m³/h 640 850 1.275 1.785 2.800<br />

Static pressure available<br />

on supply 1 Pa 256 211 223 146 267<br />

Total heating capacity<br />

(recov. + compress.) 2 kW 8,5 11,4 16,1 23,9 31,5<br />

Total cooling capacity<br />

(recov. + compress.) 3 kW 5,5 7,7 10,3 16,9 19,7<br />

Heat recovery unit efficiency 3 % 51 56,4 52,8 55,6 53,9<br />

Total fan input power kW 0,6 0,6 1,1 1,1 2,2<br />

Total maximum fan<br />

input current<br />

A 5,0 5,0 8,6 8,6 13,2<br />

Winter operation compressor<br />

input power 3 kW 1,2 1,7 2,6 3,4 3,8<br />

Summer operation compressor<br />

input power 2 kW 2,4 3,0 4,0 5,6 5,8<br />

Maximum compressor<br />

input current<br />

A 10,9 14,0 6,7 9,7 11,1<br />

Total input power<br />

on heating 3 kW 1,8 2,3 3,7 4,5 5,0<br />

Total input power<br />

on cooling 2 kW 3,0 3,6 5,1 6,7 8,0<br />

Unit power supply ph-V-Hz 1-230-50 1-230-50<br />

3+N<br />

400-50<br />

3+N<br />

400-50<br />

Sound pressure level at 1 m dB(A) 53 55 57 59 62<br />

1 Fan power supply 230V; nominal air flow rate without accessories.<br />

2 Performances referring to: fresh air flow equal to the exhaust air flow;<br />

external air temperature 34°C, RH 50%;<br />

room air temperature 26°C, 50% RH.<br />

3 Performances referring to: fresh air flow equal to the exhaust air flow;<br />

external air temperature -5°C, RH 80%;<br />

room air temperature 20°C, 50% RH.<br />

4 Performances referring to: inlet/outlet water temperature 70/60°C<br />

under conditions 3) with compressor operating.<br />

5 Performances referring to: inlet/outlet water temperature 45/40°C<br />

under conditions 3) with compressor operating.<br />

at 1 m in free field with ducted vents.<br />

3+N<br />

400-50<br />

Refrigerant R407C R407C R407C R407C R407C<br />

MBC water heating coil 07 10 15 21 33<br />

Heating capacity 4 kW 4,5 5,5 8,4 11,0 15,6<br />

Heating capacity 5 kW 1,4 1,7 2,7 3,5 5,0<br />

MBX Electrical heating coil 07 10 15 21 33<br />

Heating capacity kW 3,0 4,5 6,0 9,0 12,0<br />

Electrical heating coil current A 4,6 6,8 9,1 13,7 18,2<br />

Heat recovery units<br />

>RCF<br />

41

RCF<br />

Heat recovery units<br />

42<br />

> Characteristics<br />

Self-bearing 20 mm thick<br />

sandwich panels made of<br />

galvanised steel sheet for the<br />

external and internal surfaces with<br />

injected polyurethane insulation<br />

(density 40kg/m 3 ).<br />

Undulated filters class G3<br />

gravimetric efficiency 80% in<br />

accordance with EN 779, 48 mm<br />

thick, positioned before the heat<br />

recuperator on both airflow supply<br />

and exhaust.<br />

Heat recuperator of the cross-flow<br />

type with aluminium plates with<br />

performances above 50% in winter<br />

operation.<br />

Double-intake radial fans with<br />

forward-curved blades with directly<br />

coupled motor. The motor, single<br />

phase 230V-50Hz, is at single speed.<br />

The air flow rate is controlled<br />

Class G3 EN 779 filters on<br />

supply and exhaust<br />

Reduced height for installations typical<br />

of suspended ceilings<br />

within the limit of +/- 15% on the<br />

nominal flow rate through standard<br />

electronic controllers.<br />

Condensate drain pan made of<br />

aluminium.<br />

Cooling circuit in heat pump<br />

version complete with efficient<br />

and very quiet scroll compressors,<br />

four-way valve for cycle inversion,<br />

evaporating coil, condensing coil,<br />

liquid receiver, liquid separator,<br />

double thermostatic valve, sight<br />

glass (only for models 15, 21, 33),<br />

drier filter, high/low pressure<br />

switches.<br />

The unit is provided with electrical<br />

panel complete with power<br />

section and regulators (threeway<br />

valves for the supplementary<br />

hot water coil and the relative<br />

actuators are included), able<br />

to guarantee the control of all<br />

the cooling circuit functions.<br />

The following components are<br />

available: NTC temperature probe<br />

on the exhaust duct, external air<br />

temperature probe with dampers<br />

and relative actuators in the freecooling<br />

version, pressure switch on<br />

the filter in the supply. A control<br />

terminal that can be operated<br />

remotely is supplied for the<br />

automatic control of the unit and<br />

an outlet for the power supply and<br />

control of a light in compliance with<br />

the legislation currently in force for<br />

premises for smokers.<br />

Inspection from underneath for<br />

the heat recuperator, the filters, the<br />

condensate drain pan and the fans.<br />

Cooling circuit in high-efficiency heat<br />

pump version with scroll compressors<br />

Units provided with heat<br />

regulation with electrical<br />

panel on the machine<br />

Standard electronic regulators for the<br />

variation of the fan speed

Sizes and weights<br />

RCF Model 07 10 15 21 33<br />

Length mm 1.500 1.500 1.800 1.800 1.800<br />

> Accessories compatibility<br />

L<br />

Width mm 1.300 1.300 1.500 1.500 1.600<br />

W<br />

Height mm 450 450 550 550 600<br />

H<br />

Weight kg 215 220 350 400 500<br />

W L<br />

Fast SPA<br />

I-35044 Montagnana (PD) - Via Luppia Alberi, 170<br />

Tel. +39.0429.806311 - Fax +39.0429.806340<br />

info@fastaer.com - www.fastaer.com<br />

07 10 15 21 33<br />

MBC MBC07 MBC10 MBC15 MBC21 MBC33<br />

MBX MBX07 MBX10 MBX15 MBX21 MBX33<br />

G4F G4F07 G4F10 G4F15 G4F21 G4F33<br />

SUF SUF07 SUF10 SUF15 SUF21 SUF33<br />

FGC FGC07 FGC10 FGC15 FGC21 –<br />

FC FC07 FC10 FC15 FC21 FC33<br />

– Not available.<br />

H<br />

>RCF<br />

Heat recovery units<br />

43

RTS<br />

Rooftop units<br />

44<br />

RTS<br />

Small roof-top units<br />

Cooling capacity from 8,4 to 47,7 kW<br />

The small rooftop units in the RTS series represent the ideal<br />

solution for the climate control of small to medium size rooms<br />

for residential, commercial and industrial use such as offices,<br />

restaurants, supermarkets etc.<br />

The units offer considerable advantages in terms of high air<br />

quality and comfort, easy installation and quiet operation.<br />

The availability of many accessories also provides considerable<br />

versatility and makes the RTS series perfectly adaptable to the<br />

various plant requirements.<br />

> Versions<br />

R407C<br />

ECOLOGICAL<br />

REFRIGERANT<br />

RTS F cooling only version.<br />

RTS H heat pump version.<br />

> Accessories<br />

SM, SCSM two-way mixing box.<br />

SM3P, SM3I, SCSM3P, SCSM3I<br />

three-way mixing box.<br />

P filter differential pressure<br />

switch.<br />

BRT two or three row water coils.<br />

BRE electric battery.<br />

TP pressure transducer<br />

(only RTS F).<br />

DCPR device for low temperatures.<br />

DP dehumidification and reheating<br />

control kit.<br />

FCH enthalpic free-cooling<br />

control.<br />

PUC ON/OFF humidification<br />

contact.<br />

SQA air quality probe.<br />

PR2 remote panel.<br />

SSV supervision card.<br />

GP coil protection grille.<br />

BSP, BSR, BSS coils with special<br />

treatment.<br />

VT rubber anti vibration<br />

mounts.<br />

AVX spring anti-vibration<br />

mounts.<br />

RC roof-curb.

Main technical data<br />

> Accessories compatibility<br />

nuevo<br />

<strong>new</strong> neu<br />

nuovo<br />

RTS<br />

Rooftop units<br />

46<br />

> Characteristics<br />

Structure for the sizes 008,<br />

010, 012, 015 is self-bearing<br />

with simple panels in aluminium<br />

with insulation of the air<br />

handling section with closed-cell<br />

polyethylene foam (density 30<br />

kg/m 3 ). For sizes 018, 022, 029,<br />

035 and 046 it is self-bearing<br />

with sandwich type panels in<br />

aluminium inside and outside,<br />

25 mm thick, with injected<br />

polyurethane insulation (density<br />

42 kg/m 3 ) for perimeter panels<br />

and the roof of the air handling<br />

section.<br />

Air-handling section fans: for<br />

the sizes 008, 010, 012, 015 the<br />

fans are radial double intake type<br />

Several available accessories (like for<br />

example three-way mixing boxes)<br />

making the unit versatile<br />

The possibility for varying speed of<br />

the air treatment fans, by means of<br />

electronic controllers or with variable<br />

pulley, permits the setting of the<br />

machine and the system, guaranteeing<br />

proper unit operation<br />

directly coupled with electronic<br />

devices for the speed control.<br />

For the sizes 018, 022, 029, 035<br />

and 046 the fans are radial with<br />

double intake coupled by means<br />

of belts and pulleys with variable<br />

pitch. The orientation of supply air<br />

flows can be frontal, upwards and<br />

downwards.<br />

Condensing section axial<br />

fans balanced statically and<br />

dynamically, protected electrically<br />

with thermomagnetic switches<br />

and mechanically with grilles.<br />

Cooling circuit equipped with<br />

scroll compressors, provided<br />

with cranckcase heater, that<br />

ensure quiet operation and high<br />

efficiency, internal and external<br />

coil with copper pipes and highefficiency<br />

aluminium fins<br />

Air filtering made by undulated<br />

synthetic filters with G4 (EN779)<br />

efficiency.<br />

Microprocessor control<br />

complete with electrical panel,<br />

probes and actuators for all the<br />

components.<br />

The units are complete with controls<br />

and are ready for installation, easy to<br />

maintain and highly reliable

Sizes and weights<br />

nuevo<br />

<strong>new</strong> neu<br />

nuovo<br />

RTP<br />

Rooftop units<br />

48<br />

RTP<br />

Packaged roof-top units<br />

Cooling capacity from 62 to 86 kW<br />

The rooftop units in the RTP series represent the ideal solution<br />

for the climate control of small to medium size rooms for<br />

residential, commercial and industrial use such as offices,<br />

restaurants, supermarkets etc.<br />

The units offer considerable advantages in terms of high air<br />

quality and environmental comfort, ease of installation and quiet<br />

operation.<br />

The availability of many accessories like the cross-flow heat<br />

recovery unit or the condensation air heater section, also<br />

gives considerable versatility making the RTP series perfectly<br />

adaptable to the most various system requirements.<br />

> Versions<br />

> Versions<br />

R407C<br />

ECOLOGICAL<br />

REFRIGERANT<br />

RTP F cooling only version.<br />

RTP H heat pump version.<br />

High temperature operation (A).<br />

Low-noise operation (L).<br />

SMP two-way mixing box with rear<br />

exhaust intake.<br />

SM2 two-way mixing box with side/<br />

lower exhaust intake.<br />

SM3 three-way mixing box with free<br />

cooling.<br />

FT7 F7 efficiency (EN 779) rigid bag<br />

filters.<br />

REC cross-flow heat recovery unit<br />

with exhaust fan.<br />

Gxx condensation air heater section<br />