Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

with a maximal difference of 4 %. The trend line is in<br />

accordance with Mikheyev’s regression: the maximal<br />

difference <strong>be</strong>tween both is 5 %. To verify the metal foam<br />

height’s influence for the 10 PPI metal foam, measurements<br />

have <strong>be</strong>en performed for five different metal foam heights.<br />

The metal foam height’s influence on the heat transfer is<br />

clearly distinguishable. As the metal foam height increases,<br />

the heat transfer improves. The increase is affected by raising<br />

Rayleigh num<strong>be</strong>rs. The increase however diminishes as the<br />

metal foam height increases. Comparing the measurements<br />

for different metal foam heights to the results obtained for a<br />

flat surface, one notices that the latter curve is flatter. Finally<br />

the obtained results are compared to the trend line obtained<br />

by Phanikumar et al. Extrapolating the Nusselt num<strong>be</strong>r as a<br />

power function of metal foam height using the test results,<br />

one <strong>be</strong>comes the values as expected using Phanikumar’s trend<br />

line.<br />

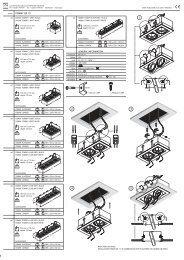

To verify the influence of the metal foam height for the 20 PPI<br />

metal foam, measurements have <strong>be</strong>en performed for three<br />

different heights. The metal foam height’s effect is clearly<br />

visible. The convection coefficient and the corresponding<br />

Nusselt num<strong>be</strong>r increase as the metal foam height increases.<br />

The increase is affected by raising Rayleigh num<strong>be</strong>rs.<br />

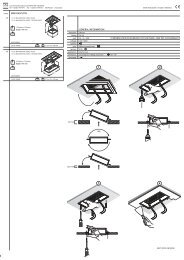

Figure 1 measurements 20 PPI sample, different foam heights<br />

The conclusion is valid for all trend lines. Moreover Nusselt<br />

num<strong>be</strong>r augments as the metal foam height increases.<br />

Finally the results are compared with the Phanikumar’s and<br />

Hetseroni’s trend lines. Surprisingly the heat transfer for<br />

Hetseroni’s 10 mm trend line is higher than the heat transfer<br />

measured at a metal foam height of 12 mm. This can <strong>be</strong><br />

explained by the fact that in Hetseroni’s experiments the foam<br />

was not attached to the base plate, it was clamped on both<br />

sides instead . The sample was heated by sending a current<br />

through the metal foam. Therefore the transferred power<br />

was distributed more uniform over the metal foam, moreover<br />

the air could move more freely through the metal foam.<br />

Phanikumar’s trend line corresponds very well to the obtained<br />

test results.<br />

33<br />

2012 • 01<br />

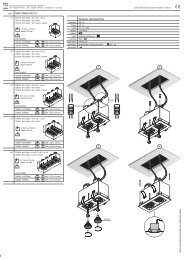

Figure 2 measurements brazed test sample vs epoxy glued<br />

The metal foam can <strong>be</strong> connected to the base plate in<br />

different ways, two of these are investigated in this work: the<br />

first is called ‘brazing the metal foam to the base plate’, while<br />

the second one is called ‘gluing the metal foam to the base<br />

plate using epoxy glue’. The average improvement obtained<br />

by brazing is around 11 % Finally Bhattacharya’s trend line<br />

is compared to the obtained results. The trend line almost<br />

depicts the same increase as does the 12 mm epoxy glued<br />

metal foam trend line.<br />

The influence of the pore density has also <strong>be</strong>en examined. For<br />

each metal foam height the heat transfer is less in the 20 PPI<br />

metal foam. On average the Nusselt num<strong>be</strong>r increases with<br />

about 20 % using the 10 PPI metal foam in comparison with<br />

the 20 PPI metal foam.<br />

The two metal foam types have also <strong>be</strong>en compared to a<br />

classical heatsink with a height of 18 mm. One can conclude<br />

that at identical metal foam height 10 PPI metal foam causes<br />

the greatest heat transfer, while the classical heatsink causes<br />

the smallest heat transfer. In the 4,000 – 6,000 interval of<br />

Rayleigh num<strong>be</strong>rs, 10 PPI metal foam gives rise to Nusselt<br />

num<strong>be</strong>rs that are on average 70 % higher than those<br />

corresponding to a classical heatsink. For 20 PPI metal<br />

foam the effect diminishes to about 45 %.<br />

In order to verify the influence of the box’s geometry,<br />

18 experiments have <strong>be</strong>en conducted. To perform these<br />

experiments, metal foam height, box width, box height and<br />

base plate temperature have <strong>be</strong>en varied.<br />

The obtained regression equation was:<br />

© Robin Reynders