Eco-Roofs Brochure and Specifications PDF - Eco-Roofs Green ...

Eco-Roofs Brochure and Specifications PDF - Eco-Roofs Green ...

Eco-Roofs Brochure and Specifications PDF - Eco-Roofs Green ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Eco</strong>-<strong>Roofs</strong>’<br />

<strong>Eco</strong>-<strong>Roofs</strong>’<br />

<strong>Eco</strong>-<strong>Roofs</strong>’<br />

<strong>Eco</strong>-<strong>Roofs</strong><br />

45 years of quality<br />

<strong>Eco</strong>-<strong>Roofs</strong><br />

<strong>Eco</strong>-<strong>Roofs</strong>, LLC<br />

BY ECO-ROOFS, LLC

Benefits of a <strong>Green</strong> Roof<br />

Ø Storm Water Management<br />

Ø Reduction of Heat Isl<strong>and</strong> Effect<br />

Ø Air Purification<br />

Ø Reduction in Energy Usage<br />

Ø Noise Reduction<br />

Ø Visual <strong>and</strong> Aesthetic Benefits<br />

Ø Increased Lifetime Expectancy<br />

of Waterproofing Membrane<br />

Phone: (269) 471-7408<br />

Benefits of a Modular <strong>Green</strong> Roof<br />

Ø Ability to Fully Establish the Trays BEFORE Installation<br />

Ø Lower Cost<br />

Ø Easier <strong>and</strong> Less Intrusive Leak Detection<br />

Ø Faster <strong>and</strong> Easier Installation<br />

Ø Your Customer Will Love the Way it Looks<br />

Reasons to Install an<br />

<strong>Eco</strong>-<strong>Roofs</strong> <strong>Green</strong> Roof<br />

Ø 45 Years of Horticultural Growing Experience<br />

Ø Flexible <strong>and</strong> Helpful Sales <strong>and</strong> Support Staff<br />

Ø Accredited <strong>Green</strong> Roof Professionals (GRP)<br />

Ø Healthiest <strong>and</strong> Strongest Plant Establishment<br />

Ø One Source for All Types of <strong>Green</strong> <strong>Roofs</strong><br />

Ø Trays Delivered on Rolling Racks<br />

Ø Easier <strong>and</strong> Faster Installation<br />

Ø Lower Price<br />

Background photos of <strong>Eco</strong>-<strong>Roofs</strong>’ modules grown on spec in the summer of 2010<br />

Fax: (269) 471-2495<br />

3

Pre-Grown<br />

Three Year<br />

Progression<br />

Installation (Top) in 2009<br />

2nd Year (Right) in 2010<br />

3rd Year (Below) in 2011<br />

Corporate Headquarters,<br />

Wisconsin<br />

www.eco-roofs.com<br />

The <strong>Eco</strong>-<strong>Roofs</strong><br />

Difference<br />

questions@eco-roofs.com<br />

4

The Pre-Grown Advantage<br />

Research <strong>and</strong> experience has proven that pre-establishment<br />

of a green roof is the single most important<br />

factor in long term survivability <strong>and</strong> performance on a<br />

green roof. A roof is a harsh, unnatural environment so<br />

to achieve plant establishment on the roof after installation<br />

requires additional resources, equipment, labor<br />

<strong>and</strong> costs. All of this can be greatly reduced by allowing<br />

a few weeks of pre-establishment at the Nursery<br />

prior to installation. <strong>Eco</strong>-<strong>Roofs</strong>’ pre-grown systems<br />

instantly provide all of the green roof benefits such as<br />

storm water management, heat isl<strong>and</strong> cooling, energy<br />

use reduction <strong>and</strong> noise reduction. Last but not least,<br />

they look fantastic immediately upon installation.<br />

RIGHT: By June, the pre-grown trays<br />

are in full bloom while the just plugged trays<br />

are showing little if any change.<br />

These trays only received natural rainfall.<br />

RIGHT: Finally in June 2011,<br />

all of the trays are at equal establishment<br />

but only after regular fertilizing<br />

<strong>and</strong> watering. Pre-growing<br />

proved better results <strong>and</strong> faster establishment<br />

with much less effort<br />

<strong>and</strong> overall cost.<br />

Phone: (269) 471-7408<br />

Installation Day, 2011, Chicago, IL<br />

A Comparison Test<br />

LEFT: March 2009, shortly after installation.<br />

Top rows of trays were pre-grown in 2008, left outside<br />

overwinter with no care <strong>and</strong> installed. Bottom<br />

rows of trays were plugged shortly before installation.<br />

LEFT: One year later, March 2010, <strong>and</strong> still no growth<br />

on the just plugged trays while the top trays, though still in<br />

winter dormancy, are full <strong>and</strong> ready for spring.<br />

Fax: (269) 471-2495<br />

5

www.eco-roofs.com<br />

12 - 15 Week<br />

Summer Growing Lead Time<br />

All it takes to get the <strong>Eco</strong>-<strong>Roofs</strong>’ pre-grown advantage is about 12-15 weeks<br />

of summer growing lead time. 45 years in the nursery business growing green roof<br />

plants, groundcovers <strong>and</strong> perennials has taught us that plants are as alive <strong>and</strong> capricious<br />

as humans <strong>and</strong> animals. We don’t make exact determinations of when summer<br />

growing starts or finishes, we’ll work with you to achieve the most established plants<br />

available within your time constraints.<br />

Experience has also taught us some general guidelines. Typically we like to get<br />

spring batches growing in late April or early May with an anticipated ready date in<br />

August; June for September, July for October. Once we get past July, the days get<br />

short too fast <strong>and</strong> the plants start slowing down into dormancy, getting ready for winter.<br />

We can still start growing but they don’t usually fully establish until mid-June of<br />

the following year.<br />

All of these time frames are based on the st<strong>and</strong>ard Sedum plant selections. Custom<br />

plant choices may take longer to establish depending on the varieties chosen.<br />

questions@eco-roofs.com<br />

6

Production Line<br />

We take great pride in our modules.<br />

<strong>Eco</strong>-<strong>Roofs</strong> has an exclusive<br />

agreement* with Twixwood Nursery to<br />

grow our modules.<br />

In the mid 1960s, George <strong>and</strong><br />

Lou Kimmel took the centennial family<br />

farm from a productive fruit <strong>and</strong> vegetable<br />

farm to a cutting edge groundcover<br />

<strong>and</strong> perennial nursery. 45 years<br />

later, Twixwood Nursery is one of the<br />

top 100 growers in the nation <strong>and</strong> has<br />

4 growing facilities with nearly 1.5<br />

million square feet under plastic <strong>and</strong><br />

hundreds of acres of outdoor container<br />

<strong>and</strong> stock fields. We’re still growing<br />

groundcovers on the family farm here<br />

in the heart of America.<br />

Over the years, Twixwood has<br />

provided many plants for built-in-place<br />

green roof systems as well as keeping<br />

Midwestern l<strong>and</strong>scapers <strong>and</strong> garden<br />

centers provided with quality groundcovers<br />

at an affordable price.<br />

With this exclusive agreement we<br />

keep the entire process in our control;<br />

from filling the flats <strong>and</strong> planting the<br />

plants, to providing all the care they<br />

need until they ship out the door to you.<br />

Just Plugged Modules<br />

Phone: (269) 471-7408<br />

By keeping everything<br />

in house we also save costs<br />

allowing us to pass the savings<br />

on to you without any<br />

reduction in quality.<br />

*Occasionally, on a perjob<br />

basis, <strong>Eco</strong>-<strong>Roofs</strong> will contract<br />

with local growers to meet regional<br />

specifications.<br />

Fax: (269) 471-2495<br />

7

www.eco-roofs.com<br />

Plugs vs. Cuttings<br />

<strong>Eco</strong>-<strong>Roofs</strong> partnership with Twixwood Nursery gives<br />

us the backing of 45 years of experience growing groundcovers<br />

<strong>and</strong> perennials. When the Kimmels started Twixwood Nursery,<br />

they were not new to the green industry. Their ancestors had settled<br />

the county <strong>and</strong> farmed it for generations. One of the basic principles<br />

that farmers <strong>and</strong> nurserymen know is that when it comes to plants, what<br />

is below ground matters far more than what is above. That is why we<br />

choose to use plugs rather than cuttings in our green roof trays as much as<br />

possible.<br />

<strong>Eco</strong>-<strong>Roofs</strong> decided surface beauty wasn’t enough, so we take cuttings<br />

<strong>and</strong> carefully nurture them in a controlled greenhouse environment until they<br />

are solidly rooted. You can pick them up <strong>and</strong> the whole plug, soil <strong>and</strong> tops,<br />

will come out solid <strong>and</strong> held together by the roots. Then we put them outside<br />

<strong>and</strong> harden them off so they are tough <strong>and</strong> ready for the roof.<br />

Only then do we take those plugs <strong>and</strong> plant them into our green roof<br />

trays, care for them for another 12-15 weeks (see previous pages) <strong>and</strong> ship a<br />

solid, healthy, fully rooted plant to you with beautiful foliage.<br />

Custom grown trays vary as specified, but in our st<strong>and</strong>ard pre-grown<br />

tray options we use 8-15 plugs per tray with 6-8 different varieties of<br />

Sedum to give each tray the best chance possible of long term survival<br />

on virtually every roof. The establishment time at the Nursery gives<br />

you solid, carpet like coverage while still providing the texture<br />

of height <strong>and</strong> color variations among the individual species to<br />

interest the eye.<br />

Background Photo:<br />

Pre-Grown Speculation<br />

Trays, Summer 2011<br />

questions@eco-roofs.com<br />

8

Phone: (269) 471-7408<br />

Stock Fields for<br />

Quality<br />

As part of our commitment<br />

to affordable quality, <strong>Eco</strong>-<strong>Roofs</strong><br />

<strong>and</strong> Twixwood Nursery maintain<br />

large fields of stock plants<br />

so we are not dependant on others<br />

to provide for our needs. We<br />

currently grow dozens of varieties<br />

of Sedum <strong>and</strong> are continually<br />

adding new varieties. We also<br />

grow hundreds of other varieties<br />

of groundcovers <strong>and</strong> perennials.<br />

This unique position allows<br />

us to provide pre-grown<br />

trays, plugs, cuttings, vegetated<br />

mat, roof gardens, planters, <strong>and</strong><br />

more.<br />

Fax: (269) 471-2495<br />

9

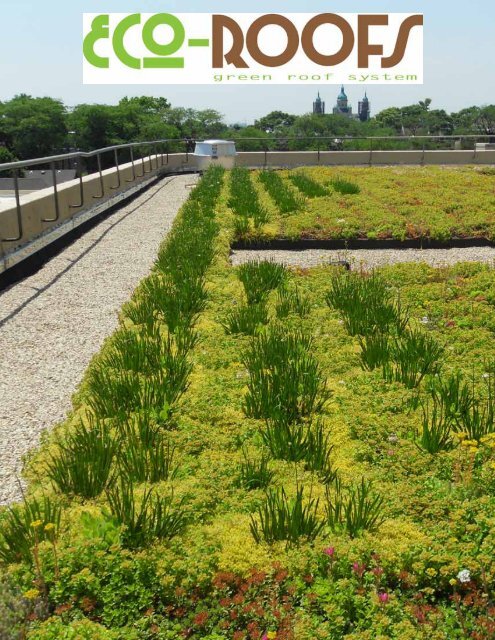

<strong>Eco</strong>-<strong>Roofs</strong>’ Cover Photo<br />

Project Case Study<br />

This project shown in our cover photograph was a<br />

2010 installation in the Chicagol<strong>and</strong> area featuring a custom<br />

grow based on the customer’s plant selection <strong>and</strong> design.<br />

The cover photo was taken during the second year,<br />

June 2011. <strong>Eco</strong>-<strong>Roofs</strong>’ St<strong>and</strong>ard 4” deep trays (see pages<br />

11-16) were pre-grown with 3 separate plant mixes to create<br />

the final design. The project was over 6000 square feet<br />

in size.<br />

Installation of the dormant green roof trays began in<br />

November.<br />

www.eco-roofs.com<br />

The contractor<br />

on this project chose<br />

to use <strong>Eco</strong>-<strong>Roofs</strong>’<br />

double crane cradle<br />

(see page 36) to lift<br />

the rolling racks to<br />

the roof (photo left.)<br />

A non-woven geotextile slip sheet was used for a protection<br />

fabric (see pages 28-29) <strong>and</strong> black aluminum edging<br />

(see page 34) was used for the perimeter containment.<br />

Less than a year later they are lush, full, blooming <strong>and</strong><br />

beautiful.<br />

questions@eco-roofs.com<br />

10

St<strong>and</strong>ard Trays

TRAY SPECIFICATIONS FOR<br />

• Size: 12” x 24” (2 square feet)<br />

STANDARD TRAYS<br />

• Depth: 3.3” st<strong>and</strong>ard<br />

— 4” <strong>and</strong> 6” soil depth options available with biodegradable liner<br />

• Weight:<br />

Maximum fully saturated weight with mature plant foliage:<br />

3.3”: 23 pounds per square foot (average dry weight: 18 lbs/sf)<br />

4”: 29 pounds per square foot (average dry weight: 21 lbs/sf)<br />

6”: 45 pounds per square foot (average dry weight: 33 lbs/sf)<br />

• Material: 100% recycled high density polyethylene (HDPE) plastic<br />

4” & 6” deep trays: 100% recycled biodegradable coir liner<br />

• Wall Thickness: 150 mil<br />

• Color: Black<br />

• H<strong>and</strong>les: Each end<br />

green roof system<br />

• Drainage: 46 holes (3/8”) in bottom of tray; Molded channels in both<br />

directions in bottom of tray.<br />

• Water Reservoirs: Minimal to avoid root rot<br />

• Media: Engineered growing media meets German FLL guidelines<br />

• Plant Types: St<strong>and</strong>ard Sedum. Can be grown to full establishment<br />

(95%+ coverage) with enough lead time. Other approved plants may<br />

be possible.<br />

www.eco-roofs.com<br />

questions@eco-roofs.com<br />

12<br />

St<strong>and</strong>ard Trays

<strong>Eco</strong>-<strong>Roofs</strong>’<br />

St<strong>and</strong>ard Trays<br />

H<strong>and</strong>le<br />

Phone: (269) 471-7408<br />

Molded<br />

Drain<br />

Channels<br />

Drainage<br />

Holes<br />

Minimal<br />

Water<br />

Reservoirs<br />

Narrow<br />

Sidewalls<br />

Molded<br />

Drain<br />

Channels H<strong>and</strong>le<br />

Drainage<br />

Holes<br />

Sedum <strong>and</strong> most<br />

other plants will die<br />

faster from having their<br />

roots in puddles of water<br />

than they will from drying<br />

out. While stormwater<br />

management is one<br />

of the great benefits of<br />

green roofs, it is critical<br />

to plant survival that<br />

excess water be moved<br />

away from the roots.<br />

More than 40, 3/8”<br />

diameter drainage holes,<br />

shallow drainage wells<br />

<strong>and</strong> molded channels (in<br />

both directions) allow<br />

excess water to flow to<br />

the roof drains.<br />

Molded finger grips<br />

at each end provide a<br />

solid h<strong>and</strong>le to easily<br />

<strong>and</strong> safely carry the trays<br />

during installation.<br />

150 mil sidewalls<br />

give strength <strong>and</strong> stability<br />

to the tray so it won’t<br />

bow or cave while maintaining<br />

a narrow profile<br />

for invisibility under<br />

mature plant foliage.<br />

Fax: (269) 471-2495<br />

13<br />

St<strong>and</strong>ard Trays

www.eco-roofs.com<br />

Biodegradable<br />

Recycled Coir Liner<br />

<strong>Eco</strong>-<strong>Roofs</strong>’<br />

St<strong>and</strong>ard Trays<br />

4” & 6” Deep<br />

Options<br />

To service those roofs where the<br />

specifications call for deeper modules<br />

or where more soil depth is required<br />

due to desired plant varieties, <strong>Eco</strong>-<br />

<strong>Roofs</strong> has developed deeper options<br />

to our St<strong>and</strong>ard 3.3” deep trays.<br />

Deep modules are custom grown<br />

<strong>and</strong> require 12-15 weeks of summer<br />

growing lead time (see page 5). Edging<br />

or perimeter containment is required<br />

to hold the biodegradable liner.<br />

There is no difference in performance<br />

between the 3.3” deep <strong>and</strong> 4”<br />

deep modules. The 6” deep option<br />

does allow for a greater plant selection.<br />

Supplemental irrigation will exp<strong>and</strong><br />

the plant selection further.<br />

Please call for more details.<br />

Below: 3.3” <strong>and</strong> 4”<br />

Comparison<br />

Left: Newly Planted<br />

4” Deep Modules<br />

questions@eco-roofs.com<br />

14<br />

St<strong>and</strong>ard Trays

<strong>Eco</strong>-<strong>Roofs</strong>’<br />

St<strong>and</strong>ard Trays Related Supplies<br />

<strong>Eco</strong>-<strong>Roofs</strong>’ expertise <strong>and</strong> speciality is in the plants <strong>and</strong> growing.<br />

We offer the following supplies as a service to our customers <strong>and</strong><br />

make minimum recommendations where we feel they are needed.<br />

More information on the individual items can be found in the Supplies<br />

section beginning on page 27.<br />

<strong>Eco</strong>-<strong>Roofs</strong>’ recommends that at minimum, a slip sheet is used<br />

between the green roof trays <strong>and</strong> the roofing membrane. Roofing<br />

membrane manufacturers, roofing specialists, specifications or others<br />

may ask for a specific material that could override these recommendations.<br />

Minimum slip sheet recommendation:<br />

8 oz. non-woven geotextile.<br />

Enhanced protection & root barrier recommendation:<br />

30 mil LLDPE/HDPE.<br />

The beauty of <strong>Eco</strong>-<strong>Roofs</strong>’ 3.3” St<strong>and</strong>ard trays is in their simplicity.<br />

Roll out a slip sheet or protection fabric <strong>and</strong> set the trays out<br />

<strong>and</strong> you will have an exceptional green roof. Edging can be used for<br />

its aesthetic appeal or for other reasons <strong>and</strong> the deeper trays (4” <strong>and</strong><br />

6”) do require perimeter containment due to the biodegradable liners<br />

that will break down over time.<br />

St<strong>and</strong>ard recommendation:<br />

Mill finish aluminum metal edging<br />

<strong>Eco</strong> recommendation (economical & ecologically friendly):<br />

100% recycled PVC edging<br />

Recommendations by tray depth:<br />

3.3” deep St<strong>and</strong>ard trays:<br />

8 oz. non-woven geotextile or 30 mil LLDPE<br />

4” deep St<strong>and</strong>ard trays:<br />

8 oz. non-woven geotextile or 30 mil LLDPE<br />

4” aluminum or PVC edging<br />

6” deep St<strong>and</strong>ard trays:<br />

8 oz. non-woven geotextile or 30 mil LLDPE<br />

6.5” aluminum or 6” PVC edging<br />

Photos are of the installation of a green<br />

roof on the Otter House at the Potawatomi<br />

Zoo, South Bend, Indiana using a nonwoven<br />

geotextile slip sheet <strong>and</strong> mill finish<br />

aluminum edging.<br />

The installation was an early spring installation<br />

while the 3.3” deep St<strong>and</strong>ard trays<br />

(pre-grown on speculation in 2010 to full<br />

coverage) were still dormant.<br />

Phone: (269) 471-7408<br />

Fax: (269) 471-2495<br />

15<br />

St<strong>and</strong>ard Trays

<strong>Eco</strong>-<strong>Roofs</strong><br />

For Every Application<br />

Think your project is too small for a green roof? Think again! The photo above is of <strong>Eco</strong>-<strong>Roofs</strong>’ St<strong>and</strong>ard trays being<br />

installed at a community garden in Wisconsin. The design is patterned after a Norwegian Torvtak, a sod roof. <strong>Eco</strong>-<strong>Roofs</strong><br />

has supplied many trays for small projects from chicken coops to patio decks. Much of this is possible because of our pregrown<br />

spec trays.<br />

<strong>Eco</strong>-<strong>Roofs</strong> maintains a large stock of pre-grown<br />

trays which are usually available for immediate shipment.<br />

These trays are planted with 8-15 plugs of 6-8 varieties of<br />

Sedum <strong>and</strong> have proven to be solid performers year after<br />

year on roofs all over the country.<br />

Think you missed a deadline <strong>and</strong> it’s too late in the<br />

year? Can’t wait 3-4 months for a custom grow? <strong>Eco</strong>-<strong>Roofs</strong><br />

has you covered.<br />

The trays we pre-grow are maintained outdoors so<br />

they are acclimated <strong>and</strong> can be installed throughout the year.<br />

<strong>Eco</strong>-<strong>Roofs</strong> recommends that trays be installed after spring<br />

frosts <strong>and</strong> before fall frosts, but with the right planning even<br />

midwinter, dormant installations are possible when temperatures<br />

are above freezing.<br />

Spec trays are available on a first come, first served<br />

basis until reserved with a down payment.<br />

Right: Dormant Installation in January,<br />

Washington D.C.<br />

www.eco-roofs.com<br />

questions@eco-roofs.com<br />

16

advanced green roof built-up / bio-diverse<br />

CHRISTIAN REFORMED CHURCH IN NORTH AMERICA’S OFFICE Gr<strong>and</strong> Rapids, MI<br />

Advanced <strong>Green</strong> Roof Trays<br />

eco-roofs, llc • P.O. Box 8, Berrien Springs, MI 49103 • Phone: 269.471.7408 • Fax: 800.854.1756 • questions@eco-roofs.com • www.eco-roofs.com<br />

advanced green roof<br />

Patent Pending Technology developed by Advanced <strong>Green</strong> Architecture<br />

PATENT PENDING TECHNOLOGY<br />

eco-roofs, llc • P.O. Box 8, Berrien Springs, MI 49103 • Phone: 269.471.7408 • Fax: 800.854.1756 • questions@eco-roofs.com • www.eco-roofs.com

TRAY SPECIFICATIONS FOR<br />

green roof system<br />

ADVANCED GREEN ROOF TRAYS<br />

Patent Pending Technology developed by Advanced <strong>Green</strong> Architecture<br />

• Size: 18” x 18” (2.25 square feet)<br />

• Depth: 4.25” soil depth st<strong>and</strong>ard<br />

— 1” base available for built-up options<br />

— 2”, 4.25”, 6” <strong>and</strong> 8” soil depth options available with biodegradable walls<br />

• Weight:<br />

Maximum fully saturated weight with mature plant foliage:<br />

2”: 13 pounds per square foot (average dry weight: 10 lbs/sf)<br />

4.25”: 24 pounds per square foot (average dry weight: 18 lbs/sf)<br />

6”: 45 pounds per square foot (average dry weight: 33 lbs/sf)<br />

8”: 60 pounds per square foot (average dry weight: 44 lbs/sf)<br />

• 1” Base Drainage Layer<br />

• Material: 100% recycled high density polyethylene (HDPE) plastic<br />

• Color: Black<br />

• Drainage: 109 holes in bottom of tray; Molded channels in both directions<br />

• Water Reservoirs: Minimal to avoid root rot<br />

• Irrigation: Tubing channel; Drip irrigation line*; Capillary mat (see below)<br />

• Interlocking: Overlaps <strong>and</strong> interlocks with adjoining trays<br />

• Capillary Irrigation Mat<br />

• Material: 100% recycled nonwoven polyester mechanically bonded to<br />

a synthetic absorbent mat inert to biological degradation <strong>and</strong> naturally<br />

encountered chemicals, alkalies <strong>and</strong> acids<br />

• Function: Capillary dispersion layer <strong>and</strong> geotextile filter<br />

• Biodegradable Walls<br />

• Material: Recycled paper <strong>and</strong> wax product<br />

• St<strong>and</strong>ard: 4” for a 4.25” soil depth; combined for 6” <strong>and</strong> 8” depths<br />

• Media: Engineered growing media meets German FLL guidelines<br />

• Plant Types: St<strong>and</strong>ard Sedum. Can be grown to full establishment (95%+<br />

coverage) with enough lead time. Other approved plants may be possible.<br />

*(Drip irrigation line does not include: connectors, line to the water source, pumps, valves, timers, etc.)<br />

www.eco-roofs.com<br />

questions@eco-roofs.com<br />

18<br />

Advanced <strong>Green</strong> Roof Trays

IRRIGATION LINE ADDED,<br />

SUPPLIES WATER TO KISSS MAT<br />

Phone: (269) 471-7408<br />

IRRIGATION PIPE INSTALLED THROUGH THE<br />

CHANNEL WHICH FEEDS INTO ADJACENT<br />

TRAYS/CHANNELS<br />

<strong>Eco</strong>-<strong>Roofs</strong>’<br />

AGR Trays<br />

6<br />

AGR is designed to promote <strong>and</strong> maximize all the environmental<br />

<strong>and</strong> economic benefits of a green roof system. A combination<br />

of a modular <strong>and</strong> a built-up system, it maximizes all green<br />

roof benefits <strong>and</strong> provides a fully integrated system to more closely<br />

imitate nature.<br />

Integrated, water efficient sub-surface irrigation provides<br />

an ideal option for greater plant diversity, urban agriculture or for<br />

those parts of the country where supplemental irrigation would be<br />

necessary.<br />

The capillary irrigation mat draws out the irrigation from the<br />

drip line for even, sub-surface irrigation. With natural rainfall, the<br />

mat acts as a retention mat holding in additional stormwater <strong>and</strong><br />

allowing evapotranspiration to occur over a greater time period.<br />

8<br />

Fax: (269) 471-2495<br />

19<br />

Advanced <strong>Green</strong> Roof Trays

<strong>Eco</strong>-<strong>Roofs</strong>’<br />

AGR Trays<br />

agr capillary irrigation mat<br />

leveling feet<br />

MSU GREEN ROOF RESEARCH CENTER Traverse City, MI<br />

AGR Trays are also designed for sloped roof applications. See below where the base is used<br />

alone in a built-up application with snap in soil stabilizers for slope retention. Soil stabilizers can be used<br />

in pre-grown applications as well. The integrated irrigation makes even steep slope applications feasible.<br />

TOP VIEW<br />

not to scale<br />

Illustrations are to conceptually assist professionals in designing AGR installations. AGA does not accept responsibility for engineer<br />

based on illustrations. A qualified roofing specialist should be consulted to determine appropriate waterproofing <strong>and</strong> roof deck materia<br />

eco-roofs, llc<br />

agr plants<br />

engineered green roof media<br />

agr biodegradable side wall<br />

agr Irrigation channel<br />

(for drip-line)<br />

drainage layer<br />

Ergonomic h<strong>and</strong>les<br />

agr slope<br />

stabilization features<br />

P.O. Box 8, Berrien Springs, Michigan 49103<br />

Phone: 269.471.7408 • Toll Free Fax: 800.854.1756<br />

questions@eco-roofs.com • www.eco-roofs.com<br />

PERSPECTIVE VIEW<br />

advanced green roof sloped built-up<br />

www.eco-roofs.com<br />

Tray Placement<br />

Dripline Insertion<br />

18”<br />

18”<br />

3.25”<br />

patent pending technology<br />

1”<br />

questions@eco-roofs.com<br />

20<br />

Advanced <strong>Green</strong> Roof Trays

ed green roof <br />

<strong>Eco</strong>-<strong>Roofs</strong>’<br />

AGR Tray<br />

Options<br />

advanced green roof <br />

Peripheral Options<br />

PRE-GROWN<br />

n Roof See our Supplies section beginning<br />

on page 27 for more infor-<br />

warded mation an on these <strong>and</strong> other peripheral<br />

options.<br />

d at the<br />

Advanced <strong>Green</strong> <strong>Eco</strong>-<strong>Roofs</strong> Roof recommends the<br />

was Prosperity use of a slip sheet or protection layer<br />

recently awarded an<br />

between our trays <strong>and</strong> your roofing<br />

honorary o in material. award at At the a minimum we recom-<br />

EPA P3 People mend an Prosperity 8 oz. non-woven geotextile.<br />

C. while<br />

<strong>and</strong> Planet Expo Edging in or some type of perim-<br />

aboration eter containment is necessary for our<br />

Washington D.C. while<br />

AGR trays due to the biodegrad-<br />

State working in able collaboration<br />

liner.<br />

with n upcoming<br />

Michigan 1/2” State drip irrigation line is in-<br />

University cluded on an in upcoming a sufficient quantity to<br />

arch study. “snake” through all of the purchased<br />

green roof trays. research You will study. need to provide the<br />

focused The EPA remaining expo on focused irrigation on components.<br />

products promoted which Sloped promoted roof soil stabilizers are<br />

sold separately. Stabilizers must be<br />

sustainability providing<br />

roviding ordered before production of pre-<br />

solutions grown for environmental<br />

trays starts.<br />

nvironmental<br />

<strong>and</strong> sustainability Leveling feet can be purchased<br />

lity challenges separately worldwide. if the trays are being<br />

placed on uneven surfaces. Notched<br />

rldwide. leveling is designed into each corner<br />

of the tray <strong>and</strong> the feet are sold by<br />

the piece.<br />

Some of the base trays in the<br />

photos are green while the specifications<br />

refer only to black. The plastic<br />

base can be colored, but there is an<br />

additional cost <strong>and</strong> would require<br />

additional lead time.<br />

<strong>Specifications</strong>, roofing installers<br />

or roofing materials manufacturers<br />

may require additional or different<br />

materials so be sure to check<br />

before ordering.<br />

Phone: (269) 471-7408<br />

1” base tray fitted with<br />

capillary mat. The irrigation<br />

tubing channel can be seen<br />

along the left side.<br />

Biodegradable wall set<br />

on base <strong>and</strong> filled with engineered<br />

growing media meeting<br />

German FLL guidelines.<br />

Planted with 9-17 plugs<br />

can be grown to full plant establishment<br />

(95%+ plant coverage)<br />

with 12-15 weeks of<br />

summer growing.<br />

Fully established, interlocking trays are placed on the roof. Irrigation<br />

lines are run through the irrigation channels. Your green roof is beautiful <strong>and</strong><br />

ready for a lifetime of enjoyment.<br />

Fax: (269) 471-2495<br />

21<br />

Advanced <strong>Green</strong> Roof Trays

green roof <br />

CH<br />

varieties increases green roof<br />

biodiversity maximizing green<br />

nced <strong>Green</strong> Roof (AGR)<br />

roof benefits such as stormwater<br />

nerated management from green <strong>and</strong> plant roof transpira-<br />

3 years tion which of research in turn increases <strong>and</strong> en-<br />

the Advanced<br />

ergy savings.<br />

<strong>Green</strong> Roof<br />

The engine of advanced<br />

earch green at Michigan roof is integrated State sub-<br />

t temperature surface irrigation. <strong>and</strong> moisture Drippings<br />

slope deliver degree water <strong>and</strong> to capillary slope mats<br />

which spread water throughout<br />

ation is<br />

the<br />

very<br />

trays directly<br />

important<br />

to the<br />

on<br />

plant’s<br />

is designed root system. to Overhead be applied spray ir-<br />

at green rigation roof can applications.<br />

be wasteful in a roof<br />

environment <strong>and</strong> also encourag-<br />

t both sloped <strong>and</strong> flat green<br />

es surface rooting which is vul-<br />

n they nerable are irrigated to extreme even temperatures if it<br />

ation in <strong>and</strong> periods moisture of stress. drought. AGR’s<br />

re plant<br />

integrated<br />

varieties<br />

subsurface<br />

can<br />

irrigation<br />

be<br />

system delivers water directly to<br />

of biodiversity the roots. which in turn<br />

efits across the board such<br />

lant transpiration which in<br />

vings.<br />

Irrigation Channel<br />

<strong>Eco</strong>-<strong>Roofs</strong>’<br />

The engine of Advanced <strong>Green</strong> Roof is integrated<br />

subsurface irrigation. Drip lines deliver water to<br />

capillary AGR mats which Trays spreads water throughout the<br />

trays directly to the plants root system. Where as<br />

overhead Rooted spray in irrigation Research can be waste full in a roof<br />

environment <strong>and</strong> also encourages surface rooting,<br />

The development of advanced green roof (AGR)<br />

which is vulnerable to extreme temperatures <strong>and</strong><br />

was guided by data generated from more than 3 years of<br />

moisture stress. AGR's integrated subsurface irrigation<br />

green roof research studies. <strong>Green</strong> roof research at Michigan<br />

State University system has delivers shown that water temperature directly to <strong>and</strong> the moisture roots.<br />

are directly affected by slope degree <strong>and</strong> slope orientation<br />

meaning irrigation is very important for successful sloped<br />

roof applications. AGR is designed to be applied on slopes<br />

as well as flat green roof applications.<br />

Research has shown that both sloped <strong>and</strong> flat green<br />

roofs perform better when they are irrigated even if it is only<br />

supplemental irrigation in periods of drought. Plants are<br />

healthier <strong>and</strong> more plant varieties can be used. More plant<br />

Capillary<br />

Irrigation<br />

mat connection<br />

points (all 4 sides) PATENT PENDING TECHNOLOGY<br />

eco-roofs, llc • P.O. Box 8, Berrien Springs, MI 49103 • Phone: 269.471.7408 • Fax: 800.854.1756 • questions@eco-roofs.com • www.eco-roofs.com<br />

www.eco-roofs.com<br />

Space for irrigation mat<br />

to slide under for dripline<br />

water/mat contact<br />

Leveling feature(s)<br />

Slope<br />

stabilization<br />

feature<br />

Advanced <strong>Green</strong> Roof was recently awarded<br />

an honorary award at the EPA P3 People Prosperity<br />

<strong>and</strong> Planet Expo in Washington D.C. while<br />

working in collaboration with Michigan State University<br />

on an upcoming green roof research study.<br />

The EPA Expo focused on products which promot-<br />

The engine of Advanced ed sustainability <strong>Green</strong> Roof providing is integrated<br />

subsurface irrigation. solutions Drip for environmental<br />

lines deliver water to<br />

<strong>and</strong> sustainability challeng-<br />

capillary mats which spreads water throughout the<br />

es worldwide.<br />

trays directly to the plants root system. Where as<br />

overhead spray irrigation can be waste full in a roof<br />

environment <strong>and</strong> also encourages surface rooting,<br />

which is vulnerable to extreme temperatures <strong>and</strong><br />

questions@eco-roofs.com<br />

22<br />

Advanced <strong>Green</strong> Roof Trays

Built-in-Place Systems

<strong>Eco</strong>-<strong>Roofs</strong>’<br />

Built-In-Place <strong>Green</strong> <strong>Roofs</strong><br />

Built-in-place or built-up green roofs are those where the individual<br />

components that go into the roof are assembled on the roof itself.<br />

Starting with a waterproofed roof, from the bottom up, built-up<br />

green roofs usually start with a drainage layer to allow excess water to<br />

get to the roof drains, then filtration to keep soil <strong>and</strong> plants in place, followed<br />

by the growing media <strong>and</strong> finally the plants. Each of these basic<br />

layers can be one or a combination of several products <strong>and</strong> layers can<br />

sometimes be repeated.<br />

While nearly anyone can install a basic green roof tray system <strong>and</strong><br />

even maintain it with relatively little training, built-up green roofs require<br />

an extensive knowledge of l<strong>and</strong>scaping <strong>and</strong> horticulture including<br />

an underst<strong>and</strong>ing of plant selection <strong>and</strong> performance, soil <strong>and</strong> growing<br />

media selection, etc. This knowledge must be specific to the roof environment<br />

<strong>and</strong> can be very different from traditional l<strong>and</strong>scaping needs.<br />

Built-up green roofs also require an extensive knowledge of the roofing<br />

materials themselves including the filtration <strong>and</strong> drainage layers necessary<br />

to keep the growing media <strong>and</strong> other green roof materials up on the<br />

roof <strong>and</strong> how all of those layers will integrate with the critical waterproofing<br />

membrane that is going to keep the building occupants dry. It<br />

may be necessary to cooperate <strong>and</strong> confer with specialists that can fill<br />

out the area(s) where you may be lacking in expertise.<br />

It is <strong>Eco</strong>-<strong>Roofs</strong>’ belief that there are right places <strong>and</strong> right times for all types of green roofs. We encourage you to<br />

explore <strong>and</strong> ask questions to find the one that will work best for your roof, situation <strong>and</strong> budget <strong>and</strong> we will be here to help<br />

<strong>and</strong> support you with any<br />

<strong>and</strong> all of them.<br />

Tight on budget or<br />

need something fast? Try<br />

our St<strong>and</strong>ard trays. Want<br />

to go a little further but<br />

don’t have a lot of time?<br />

Try our AGR trays with<br />

irrigation. Ready to go all<br />

out with a rooftop garden<br />

<strong>and</strong> get your h<strong>and</strong>s<br />

dirty? We’ll help guide<br />

you through the built-up<br />

options.<br />

The following pages<br />

will go into greater depth<br />

on how the layers are assembled<br />

<strong>and</strong> what options<br />

are available.<br />

www.eco-roofs.com<br />

Photos: In Progress<br />

<strong>and</strong> Finished<br />

A Built-Up, Intensive<br />

<strong>Green</strong> Roof<br />

Installed 2012 in<br />

Chicago, Illinois<br />

questions@eco-roofs.com<br />

24<br />

Built-In-Place Components

<strong>Eco</strong>-<strong>Roofs</strong>’ Built-Up Recommendations<br />

All of <strong>Eco</strong>-<strong>Roofs</strong>’ green roof systems start above a waterproofed roof. Coming from a nursery background, we take<br />

pride in our plant growing expertise <strong>and</strong> choose to refer you to likewise experienced roofing, construction, engineering or<br />

architectural professionals for anything from the waterproofing on down. From the waterproofing on up, here is what we<br />

recommend, <strong>and</strong> the options available. Prior to installing the first green roof layer, the waterproofing membrane or other<br />

material should be tested <strong>and</strong> shown to be leak free <strong>and</strong> should be clean of all debris. The next section (Supplies, page 27)<br />

provides more information on the individual components.<br />

Protection Fabric: This layer is to protect the integrity of the waterproofing <strong>and</strong> roofing materials from the green roof<br />

materials above. Root barriers are strongly recommended <strong>and</strong> are usually composed of 30-40 mil<br />

linear low density polyethylene (LLDPE) or high density polyethylene (HDPE.) Root barriers are<br />

impermeable (water won’t go through them) so they must be the bottom layer. If additional protection<br />

is desired, an 8 ounce or heavier non-woven geotextile is recommended on top of the root barrier.<br />

<strong>Specifications</strong>, roofing membrane manufacturers or roofing installers may have other requirements or<br />

recommendations which should be followed. These may include a “throw-away” layer of the roofing<br />

membrane, or a layer of other roofing material such as TPO.<br />

Drain Board: Drain boards come in many styles, but are basically cup shaped hard plastic sheets designed to allow<br />

easy passage of any excess water away from the growing media <strong>and</strong> plant roots. These can be open<br />

<strong>and</strong> allow free water flow to the roof drains or they can be designed to retain some water for additional<br />

stormwater management. Caution should be used with retention types as they can add significantly<br />

to the weight on the roof, cause freezing issues, create unhealthy stagnant ponds, etc. Local climate<br />

<strong>and</strong> rainfall will greatly affect this choice. Another option for this layer is to use a layer of aggregate.<br />

Filter Fabric: This layer keeps the soil <strong>and</strong> plants from washing away <strong>and</strong> down the drains. <strong>Eco</strong>-<strong>Roofs</strong> recommends<br />

a 4 ounce non-woven geotextile. Filter fabric should wrap up the edging or perimeter containment<br />

around drains <strong>and</strong> all green roof edges.<br />

Composites: Some composite materials are available that have a drain board core with a filter fabric on the top <strong>and</strong><br />

an impermeable layer on the bottom.<br />

Growing Media:<br />

See Pages 28 <strong>and</strong> 29 for more information on all of the protection, filtration <strong>and</strong> drain board options.<br />

See Page 30 for more information.<br />

Plants: See Pages 31 - 33 for more information.<br />

Perimeter Containment:<br />

<strong>Eco</strong>-<strong>Roofs</strong> recommends the<br />

use of GeoEdge aluminum edging<br />

or TECO-Edg recycled PVC<br />

edging for perimeter containment<br />

to hold in the soil <strong>and</strong> other layers<br />

around the roof edge, drains,<br />

equipment, etc. See page 34 for<br />

more information. Other options<br />

include fire walls <strong>and</strong> parapet<br />

walls. All edging or walls should<br />

be wrapped up the inside with filter<br />

fabric to contain loose media.<br />

Phone: (269) 471-7408<br />

Plants<br />

Growing Media<br />

Filter Fabric<br />

Drain Board<br />

Slip Sheet<br />

Root Barrier<br />

Protection Fabrics<br />

Roong Materials<br />

Roof Deck up to<br />

Waterproof Membrane<br />

Fax: (269) 471-2495<br />

25<br />

Built-In-Place Components

Photos of Completed Rooftops<br />

with <strong>Eco</strong>-<strong>Roofs</strong>’ Trays<br />

www.eco-roofs.com<br />

Private Residence<br />

Installed in the summer of 2011 using<br />

a combination of pre-grown trays <strong>and</strong><br />

built-in-place green roof methods.<br />

questions@eco-roofs.com<br />

26

<strong>Green</strong> Roof Supplies

<strong>Eco</strong>-<strong>Roofs</strong>’<br />

Slip Sheets, Protection Fabrics<br />

<strong>and</strong> other Materials<br />

<strong>Eco</strong>-<strong>Roofs</strong> is not a fabric specialist so we make no<br />

claims on these products other than what we see in manufacturer’s<br />

specifications. We offer these fabrics as a service<br />

to our customers <strong>and</strong> do not require you to purchase them<br />

from us even if they are required for your project. Typical<br />

uses <strong>and</strong> our recommendations are noted below. Please call<br />

if you have questions or if you need manufacturer’s spec<br />

sheets.<br />

The fabrics are arranged in the order in which they<br />

would typically be used starting with the lowest layer <strong>and</strong><br />

working up away from the roof.<br />

Root Barrier 30 or 40 mil LLDPE or HDPE<br />

Plant roots can sometimes be aggressive in their quest for nutrients, moisture <strong>and</strong> to provide stability. This can lead<br />

them to work their way into roofing membranes <strong>and</strong> the roof deck where they could potentially create leaks or possibly even<br />

structural damage. This is rare especially if just Sedum plants are used as they have very shallow <strong>and</strong> non-aggressive roots<br />

but the added protection may still be desirable. Root barrier material is similar to a pond liner.<br />

<strong>Eco</strong>-<strong>Roofs</strong> recommends the use of this material under tray systems. It should definitely be used as the base layer of<br />

built-up systems. It is impermeable, moisture will not go through it so it must be the bottom layer, directly on top of the<br />

waterproofing membrane. Caution should also be used to avoid trapping moisture under it where it will have no way of<br />

evaporating. In order to provide complete root barrier protection the seams should be sealed, bonded or taped. Adequate root<br />

barrier protection can be obtained using a minimum 24” seam overlap in place of seam sealing. See manufacturer’s recommendations<br />

for proper seam application.<br />

When used for root barrier protection there has been no performance difference shown between LLDPE (linear low<br />

density polyethylene) <strong>and</strong> HDPE (high density polyethylene.)<br />

A root barrier is sometimes the lower layer of composite drain board material (see below.)<br />

Per specifications or with the recommendation of roofing membrane manufacturers or roofing specialists an LLDPE/<br />

HDPE root barrier may be substituted with a heavier material such as TPO or a “throw-away” layer of membrane.<br />

TRAYS: Premium recommendation for slip sheet/protection fabric under the trays.<br />

BUILT-UP: Lowest, base layer directly on top of the waterproofing membrane usually below the drainage layer.<br />

Slip Sheet/Protection Fabric<br />

8 oz. Non-Woven Geotextile<br />

Non-woven geotextile is a felt-like material used to<br />

provide a minimum layer of protection over the waterproofing<br />

membrane. <strong>Eco</strong>-<strong>Roofs</strong> recommends the use of<br />

this material as a minimum protection layer under all of<br />

our tray systems. It is not usually used in built-up systems.<br />

Order extra to allow for a 12” seam overlap. Non-woven<br />

geotextile does not provide any root barrier protection.<br />

TRAYS: Minimum recommendation for slip sheet/<br />

protection layer under the trays.<br />

BUILT-UP: Not usually used.<br />

www.eco-roofs.com<br />

questions@eco-roofs.com<br />

28<br />

Supplies

Drainage Board ½” or 1” Prefabricated Composite<br />

Drain board is usually made of fairly strong <strong>and</strong> semi-rigid plastic. It is designed to allow space for the free flow of<br />

excess water to the roof drains. Drain board may also incorporate “cups” that would hold a certain amount of moisture for<br />

added stormwater retention. Caution must be used with this type of retention material as it will add to the weight on the roof<br />

<strong>and</strong> could present other complications with freezing, stagnant water, etc.<br />

Drain board is not usually used with tray systems as the<br />

tray incorporates these features into its design. They can be<br />

used if the roof does not drain well or for added moisture retention<br />

if done with caution.<br />

In a built-up green roof, the drain board is usually the second<br />

layer from the bottom, on top of the root barrier <strong>and</strong> below<br />

the filter fabric.<br />

Drain board often comes in a composite material with the<br />

filter fabric <strong>and</strong>/or the root barrier fused to it. This is the material<br />

<strong>Eco</strong>-<strong>Roofs</strong> offers.<br />

TRAYS: Used only if specified or needed for additional<br />

drainage or retention.<br />

BUILT-UP: Used between the root barrier <strong>and</strong> filter fabric<br />

or as a composite combining these layers.<br />

Filter Fabric 4 or 6 oz. Non-Woven Geotextile<br />

Filter fabric is used to keep the growing media <strong>and</strong> plants from washing away. It is used mostly in built-up systems<br />

where it goes under the growing media <strong>and</strong> on top of the drainage layer. Extra should be ordered to allow for a minimum<br />

12” seam overlap <strong>and</strong> to wrap up the sides, perimeter containment, edging, around drains, etc. The 4 oz. is usually adequate.<br />

Heavier geotextiles can become clogged <strong>and</strong> slow the drainage of excess moisture.<br />

Filter fabric is also used in tray systems to wrap edging <strong>and</strong> around drains <strong>and</strong> equipment when it is necessary to cut<br />

the trays <strong>and</strong> leave the growing media exposed. Some tray systems have used a filter fabric inside the tray but <strong>Eco</strong>-<strong>Roofs</strong><br />

has found this can cause water to backup inside the tray <strong>and</strong> can kill the plants.<br />

Filter fabric may come as the top material in a composite drain board layer (see gray layer above.)<br />

TRAYS: Only necessary when using cut trays.<br />

BUILT-UP: Holds in the growing media. Usually used directly below media <strong>and</strong> above the drainage layer.<br />

Slip Sheet/Protection Fabric/Moisture Retention Mat 10 or 12 oz. Non-Woven Geotextile<br />

This non-woven geotextile is heavier than the 8 oz. which means that it will absorb <strong>and</strong> retain a minimal amount of<br />

water similar to a sponge. It can replace the 8 oz. for greater protection or it can be added to a built-up system for water<br />

retention. For this use it is usually placed below the filter fabric <strong>and</strong> above the drainage layer. Order extra to allow for a 12”<br />

seam overlap.<br />

Caution should be used with any moisture retention mat. Retaining water on a roof can cause problems with drainage<br />

especially when frozen <strong>and</strong> will increase the weight load on the roof depending on how much water is retained.<br />

TRAYS: An option for heavier protection <strong>and</strong> moisture retention.<br />

BUILT-UP: Moisture retention layer below filter fabric <strong>and</strong> above drainage layer.<br />

Erosion Blanket<br />

Biodegradable Coir Blanket<br />

This is used for built-up green<br />

roofs to reduce wind <strong>and</strong> other erosion.<br />

It can be used to cover cuttings. Plugs<br />

<strong>and</strong> plants can be planted through this<br />

material. Purchase includes one biodegradable<br />

stake per cubic yard. Additional<br />

stakes (4” or 6”) can also be<br />

purchased.<br />

TRAYS: Not used, pre-grown<br />

BUILT-UP: Above media<br />

Phone: (269) 471-7408<br />

Fax: (269) 471-2495<br />

29<br />

Supplies

<strong>Eco</strong>-<strong>Roofs</strong>’<br />

Growing Media<br />

<strong>Eco</strong>-<strong>Roofs</strong>’ growing media<br />

is a low organic, high mineral<br />

composition growing mix composed<br />

of porous aggregate <strong>and</strong><br />

compost.<br />

It has been tested to meet<br />

the FLL st<strong>and</strong>ards for green roof<br />

growing media.<br />

<strong>Eco</strong>-<strong>Roofs</strong>’ growing media is designed both for optimal plant performance <strong>and</strong> for stormwater retention. Two of the greatest<br />

benefits of green roofs are their ability to retain stormwater runoff <strong>and</strong> the ability to cool the city’s heat isl<strong>and</strong> effect. Both of<br />

these benefits find their basis in the growing media. It is the media itself that retains most of the stormwater runoff <strong>and</strong> it is the<br />

media that sustains the growth of the plants who cool the heat isl<strong>and</strong> mostly through the process of evapotranspiration; slowly<br />

releasing the captured moisture back into the air to cool it.<br />

We have chosen to keep our growing media within the FLL guidelines. <strong>Green</strong> roofs are relatively new in the United<br />

States while Europe has many more years of experience. In Germany, the Forschungsgesellschaft L<strong>and</strong>schaftsentwicklung<br />

Lanschaftsbau (FLL, translates as the L<strong>and</strong>scape Research, Development <strong>and</strong> Construction Society) established specific<br />

guidelines for green roof growing media. These guidelines are now accepted around the world as the st<strong>and</strong>ards for green<br />

roof growing media.<br />

<strong>Eco</strong>-<strong>Roofs</strong>’ growing media is mixed <strong>and</strong> composed in Chicago <strong>and</strong> Michigan which allows it to qualify for most of the<br />

local guidelines for programs such as LEED throughout much of the Midwest.<br />

Growing Media can be customized but this may require additional cost <strong>and</strong> lead times for additional testing. <strong>Eco</strong>-<br />

<strong>Roofs</strong> is unable to guarantee performance or results of other custom mixes <strong>and</strong> may choose not to accept a custom mix job<br />

if we feel it will not perform.<br />

<strong>Eco</strong>-<strong>Roofs</strong> ships our growing media in several formats. For most situations, <strong>Eco</strong>-<strong>Roofs</strong> recommends the use of Jumbo<br />

Sacks. These sacks are designed to be lifted with a crane <strong>and</strong> opened to dump the media onto the roof. They contain 2 cubic<br />

yards (54 cubic feet) of growing media. The sacks are delivered on a flat bed truck <strong>and</strong> can be lifted directly from the truck<br />

bed to the roof. Other options include loose, bulk media which is delivered <strong>and</strong> dumped in a loose pile on site or smaller<br />

sacks (1, 1.5 or 2 cubic feet each). These small bags can be carried by an individual for hard to access roofs.<br />

www.eco-roofs.com<br />

questions@eco-roofs.com<br />

30<br />

Supplies

<strong>Eco</strong>-<strong>Roofs</strong>’ Finished Plants, Plugs<br />

<strong>and</strong> Cuttings<br />

<strong>Eco</strong>-<strong>Roofs</strong>’ association with Twixwood Nursery allows us to<br />

offer one of the largest selections of groundcovers <strong>and</strong> perennials for<br />

green roofs from one of the Top 100 Growers in the nation.<br />

Please call <strong>Eco</strong>-<strong>Roofs</strong> <strong>and</strong> request a current Twixwood Nursery<br />

catalog <strong>and</strong> availability list or contact Twixwood Nursery directly<br />

<strong>and</strong> tell them <strong>Eco</strong>-<strong>Roofs</strong> referred you. Plants, plugs <strong>and</strong> cuttings will<br />

generally be sold to you directly from Twixwood Nursery.<br />

For nearly 45 years Twixwood Nursery has been growing <strong>and</strong><br />

selling the groundcovers <strong>and</strong> perennials used on green roofs. While<br />

the Nursery’s primary area is the Midwest, Twixwood’s reputation<br />

for quality has led to regular customers across the United States <strong>and</strong><br />

Canada. Many of those plants have gone to beautify famous places<br />

including some of the earliest <strong>and</strong> largest green roofs in the United<br />

P. O. Box 247, Berrien Springs, MI 49103<br />

States such as Chicago’s Millennium Park.<br />

Phone: 269-471-7408<br />

The Illinois L<strong>and</strong>scape Contractors Association <strong>Green</strong> Roof<br />

Fax: 269-471-2495 or 800-854-1756<br />

Awards of Excellence in 2010 <strong>and</strong> 2011 went to projects supplied<br />

with plants from Twixwood Nursery. The 2010 project also included<br />

E-mail: info@twixwood.com pre-grown trays from <strong>Eco</strong>-<strong>Roofs</strong>. The 2009 <strong>Green</strong> <strong>Roofs</strong> for Healthy<br />

Cities Award of Excellence for Extensive Industrial/Commercial<br />

www.twixwood.com<br />

Projects was a project supplied with plants from Twixwood Nursery.<br />

Plants<br />

<strong>Eco</strong>-<strong>Roofs</strong> defines finished plants as pots that<br />

are usually 4” or larger. These would include st<strong>and</strong>ard<br />

#1 nursery containers <strong>and</strong> quart size pots. These<br />

are typically only used in intensive systems due to<br />

their size. Spacing, performance, soil coverage, environmental<br />

needs all vary greatly given the wide selection<br />

possible. Your Twixwood Nursery Customer<br />

Service Rep will be able to help you in your selection<br />

as can <strong>Eco</strong>-<strong>Roofs</strong>.<br />

www.eco-roofs.com<br />

questions@eco-roofs.com<br />

32<br />

Supplies

Plugs<br />

<strong>Eco</strong>-<strong>Roofs</strong> defines<br />

plugs as plants in pots 4” <strong>and</strong><br />

smaller. Typically these will<br />

be in liners or flats <strong>and</strong> sold<br />

by the flat. <strong>Green</strong> roof plugs<br />

are most commonly 2” - 3”<br />

plugs. See Page 8 for more<br />

information on plugs. Twixwood<br />

Nursery maintains a<br />

large quantity of various sizes<br />

<strong>and</strong> varieties of Sedum plugs<br />

as well as other plants commonly<br />

used on green roofs.<br />

If exact varieties or sizes are<br />

desired they can be custom<br />

grown, but please allow at<br />

least 2-6 months, possibly<br />

longer depending on the plant<br />

selections. A down payment<br />

may be required.<br />

<strong>Eco</strong>-<strong>Roofs</strong> recommends<br />

the use of 2.5” plugs (32ct<br />

Twixwood Nursery flats) with a minimum spacing of 6” on center (approximately 4/sf.) Other options include 4” nominal<br />

quarts (10ct Twixwood Nursery flats) with a spacing of 8” on center (approximately 2.25/sf.) More exact plant counts can<br />

be obtained at www.l<strong>and</strong>scapecalculator.com. Spacing <strong>and</strong> size recommendations will vary depending on plants chosen.<br />

Phone: (269) 471-7408<br />

Cuttings<br />

<strong>Eco</strong>-<strong>Roofs</strong> defines cuttings as cut pieces of Sedum<br />

plants with a length <strong>and</strong> viability sufficient to begin<br />

rooting <strong>and</strong> growth. See Page 8 for more information.<br />

Large stock fields are available to take cuttings<br />

from either as a grower’s choice mix or as specific variety<br />

requests.<br />

Cuttings are highly perishable <strong>and</strong> can rot or<br />

desiccate quickly. They must be cut, transported <strong>and</strong><br />

installed within a few days at most. Because of this,<br />

purchase of cuttings requires a non-cancellable ship<br />

date 5-10 days in advance of delivery. Availability will<br />

vary by species <strong>and</strong> time of year as viable cuttings can<br />

only be taken from the plants at certain times. There<br />

is no warranty or replacement on cuttings. Cuttings<br />

must be watered daily until they have established roots<br />

<strong>and</strong> weekly during the first year. Replacement is often<br />

necessary, usually the second season <strong>and</strong> full establishment<br />

may not occur for 2-3 years. A biodegradable<br />

erosion blanket may be necessary to keep birds off, retain<br />

moisture, reduce wind loss, etc. See page 29 for<br />

more information.<br />

<strong>Eco</strong>-<strong>Roofs</strong> recommends an installation rate of<br />

10 lbs per 100 sf covered by the erosion blanket <strong>and</strong><br />

supplemented with plugs planted through the erosion<br />

blanket.<br />

Fax: (269) 471-2495<br />

33<br />

Supplies

<strong>Eco</strong>-<strong>Roofs</strong>’ Edging<br />

Perimeter Containment<br />

<strong>and</strong> Drain Covers<br />

<strong>Eco</strong>-<strong>Roofs</strong> is not a metal fabricator or edging specialist so<br />

we make no claims on these products other than what we see in<br />

manufacturer’s specifications. We offer these products as a service<br />

to our customers <strong>and</strong> do not require you to purchase them from us<br />

even if they are required <strong>and</strong> you are purchasing other products<br />

from us. Typical uses <strong>and</strong> our recommendations are noted below.<br />

Please call if you have questions or if you need manufacturer’s<br />

spec sheets.<br />

General Edging Uses <strong>and</strong> Recommendations<br />

Edging is used primarily for perimeter containment in order to hold the soil <strong>and</strong> plants in place. It is not required in<br />

all applications, but may still be desired for aesthetic reasons or for added wind control. Edging adds wind control especially<br />

against wind uplift by tying together a whole section of trays especially if the edging is attached to the trays with<br />

self-tapping screws. In some cases edging may not be required if there is a fire wall, parapet wall or other type of existing<br />

perimeter containment.<br />

<strong>Eco</strong>-<strong>Roofs</strong> does recommend the use of edging with all of our tray systems when it is necessary to cut them to fit into<br />

an area unless the cut edges can be against other trays or another solid surface. Filter fabric should also be used with cut<br />

trays <strong>and</strong> should be wrapped up the edging or perimeter containment. See page 29.<br />

<strong>Eco</strong>-<strong>Roofs</strong>’ 3.3” deep St<strong>and</strong>ard trays do not require any perimeter edging because they are fully contained in the tray.<br />

If edging is used for aesthetic or wind control purposes, <strong>Eco</strong>-<strong>Roofs</strong> recommends 4” tall aluminum or PVC edging be used.<br />

<strong>Eco</strong>-<strong>Roofs</strong>’ 4” <strong>and</strong> deeper St<strong>and</strong>ard trays <strong>and</strong> <strong>Eco</strong>-<strong>Roofs</strong>’ AGR trays do require edging or some type of perimeter<br />

containment because the sidewalls are at least partially biodegradable so the soil is not permanently contained. Height<br />

recommendations are as follows:<br />

4” deep St<strong>and</strong>ard Trays 4” tall Aluminum or PVC<br />

6” deep St<strong>and</strong>ard Trays 6.5” tall Aluminum or 6” tall PVC<br />

4.25” deep AGR Trays 5.5” tall Aluminum or 6” tall PVC<br />

6” deep AGR Trays 6.5” tall Aluminum<br />

8” deep AGR Trays 8.5” tall Aluminum<br />

Built-up green roofs also require edging or perimeter containment. Height would be determined by the system height.<br />

Typically the base of the edging is placed just under the filter fabric with the filter fabric wrapping up the edging to keep<br />

media fines from washing out the drainage holes. If this method is used, the edging height would equal the depth of the<br />

growing media. If the base of the edging is to go under other system components, the height would need to include the<br />

height of those layers. The base of the edging should never go under an impermeable layer such as a root barrier. This can<br />

cause damming <strong>and</strong> could have disastrous results.<br />

Edging Options<br />

Edging is sold by the linear foot <strong>and</strong> comes in 8’ lengths for<br />

aluminum or 10’ lengths for PVC. Both types can be formed on site<br />

for corners <strong>and</strong> angles or pre-made 90 0 corners are available.<br />

The PVC edging is made from 100% post-consumer recycled<br />

PVC making it a very “green” option. It comes st<strong>and</strong>ard in black<br />

<strong>and</strong> is available in two sizes (height x base): 4” x 4” or 6” x 6”.<br />

Aluminum edging can be customized for specific height or<br />

other design specifications. Mill finish as shown in the photo at the<br />

top of the page is st<strong>and</strong>ard, but black is available. Available sizes<br />

include (height x base): 3” x 3.25”, 3.5” x 4.5”, 4” x 3.25”, 4.5” x<br />

3.25”, 4.5” x 4.5”, 5.5” x 6.5”, 6.5” x 5.5”, 7.5” x 8.5” or 8.5” x 7.5”.<br />

Aluminum drain boxes are available with all of the same<br />

height/base options as the edging. 12” or 24” square or 14” or 20”<br />

round boxes are available with optional lids.<br />

www.eco-roofs.com<br />

GeoEdge Aluminum Edging by<br />

permaloc®<br />

100% Recycled PVC Edging<br />

TECO-Edg by Oly-Ola<br />

questions@eco-roofs.com<br />

34<br />

Supplies

Installation & Maintenance

<strong>Eco</strong>-<strong>Roofs</strong>’<br />

Shipping Process<br />

ü <strong>Eco</strong>-<strong>Roofs</strong> ships our trays on enclosed semitrailers<br />

to protect the live plant material.<br />

ü <strong>Eco</strong>-<strong>Roofs</strong> trays are loaded on rolling metal<br />

racks for easy maneuverability on site.<br />

ü <strong>Eco</strong>-<strong>Roofs</strong> offers the use of steel cradles for<br />

safe <strong>and</strong> easy lifting.<br />

<strong>Eco</strong>-<strong>Roofs</strong> ships our trays on enclosed semi-trailers so that the live plant material in the trays is protected. One or two<br />

people can move our rolling racks to the back of the truck where they can be unloaded with a forklift. Trailers with lift gates<br />

are available upon request. Given the weight of the loaded racks (even with their wheels) it is advisable to have a forklift on<br />

site to move them around.<br />

<strong>Eco</strong>-<strong>Roofs</strong>’ rolling racks will move best on hard, relatively flat surfaces. It may be necessary to lay plywood planking<br />

or use a forklift to traverse rough areas. 3/4” - 5/8” plywood should be used on the roof as a “l<strong>and</strong>ing area” to support the<br />

racks. Plywood provides a path to roll the racks on the roof while protecting the roof materials.<br />

Use of the rolling racks in this manner will allow for dozens of square feet to be transported saving a great deal of<br />

labor. Typically you will find the following amounts per rack: 64 sf for 3.3” St<strong>and</strong>ard trays. 56 sf for 4” St<strong>and</strong>ard trays. 4”<br />

AGR trays would have 63 sf.<br />

<strong>Eco</strong>-<strong>Roofs</strong> trays <strong>and</strong> racks have been transported to the rooftop in just about every imaginable way. It seems every roof<br />

has a slightly different roof access. For example, with the ability to roll the racks, they can be taken up in freight elevators.<br />

The most common method of roof access is by crane. <strong>Eco</strong>-<strong>Roofs</strong> offers the use of custom steel lifting cradles for a<br />

safe <strong>and</strong> easy lifting experience. We have both single <strong>and</strong> double models that hold racks accommodating the capacity of<br />

your crane <strong>and</strong> roof. The cradles are equipped with crane certified chains that connect easily to a crane hook. See the orange<br />

double cradles in the photo above.<br />

www.eco-roofs.com<br />

questions@eco-roofs.com<br />

36

Phone: (269) 471-7408<br />

<strong>Eco</strong>-<strong>Roofs</strong>’<br />

Installation Process<br />

Installation of <strong>Eco</strong>-<strong>Roofs</strong>’ trays is quick <strong>and</strong> efficient.<br />

Ø Keep the installation surface clean <strong>and</strong> free of debris<br />

Ø Roll out slip sheet/protection fabric on the waterproofing.<br />

Make sure that root barriers <strong>and</strong> other impermeable fabrics are flat (no<br />

folds) <strong>and</strong> do not cover drains or impede the drainage of excess water.<br />

Ø Place the trays tightly next to each other in nice, straight rows<br />

with even edges.<br />

If plant material is hanging over the edges of the trays, lift it on top of<br />

the trays to allow a tight fit with no plant material between the trays.<br />

<strong>Eco</strong>-<strong>Roofs</strong>’ St<strong>and</strong>ard trays should firmly abut the next tray. The trays<br />

can lay in either direction.<br />

<strong>Eco</strong>-<strong>Roofs</strong>’ AGR trays are placed in a specific arrangement so the<br />

drip line can “snake” through the trays. The trays overlap <strong>and</strong> lock together<br />

to maintain this arrangement.<br />

Built-up green roofs are all unique in their design <strong>and</strong> installation. The<br />

protection, drainage <strong>and</strong> filtration layers are all installed in the arrangement<br />

specified. The growing media is evenly leveled <strong>and</strong> compacted. Erosion nets<br />

<strong>and</strong> vegetated mat, plugs, cuttings or other plants are planted in the arrangement,<br />

spacing, or rate as specified.<br />

These simple explanations are not meant to provide the training necessary<br />

to install green roofs but merely to give an idea of the installation process.<br />

<strong>Eco</strong>-<strong>Roofs</strong> offers an Installer Certification class where perspective green<br />

roof installers can become certified installers of <strong>Eco</strong>-<strong>Roofs</strong>’ systems.<br />

Photos<br />

Top: 10th Floor, Summer 2009, Chicago Illinois<br />

Left: Summer 2011, Chicago, Illinois<br />

Fax: (269) 471-2495<br />

37

<strong>Eco</strong>-<strong>Roofs</strong>’<br />

Maintenance<br />

Recommendations<br />

These recommendations are based<br />

on <strong>Eco</strong>-<strong>Roofs</strong>’ pre-grown tray systems<br />

with st<strong>and</strong>ard Sedum plants. While most<br />

of them apply equally to all green roofs,<br />

there are many variables. Built-up or custom<br />

plant choices will require customized<br />

care until established.<br />

We are happy to assist you in creating<br />

a customized maintenance plan for<br />

your roof.<br />

Biweekly (twice per month) maintenance<br />

inspections should be carried out<br />

during the active growing season (April<br />

through October, longer in some areas.) All activity <strong>and</strong> green roof maintenance should be recorded including the date, time,<br />

name(s) of person(s) involved, activities performed <strong>and</strong> quantities used or applied. Photographs would be great. Records<br />

should also include all access <strong>and</strong> activities by non-green roof personnel such as HVAC repair, window washers, etc. Traffic<br />

should be kept to a minimum.<br />

Biweekly (twice per month) inspections<br />

should check for <strong>and</strong> manage the following:<br />

ü Irrigation: water to full saturation if natural rainfall is below 1” in 4 weeks during the growing<br />

season. This only applies to pre-grown trays with st<strong>and</strong>ard Sedum.<br />

ü Keep traffic on the roof to a minimum.<br />

ü Remove trash <strong>and</strong> debris.<br />

ü Inspect all drains for proper functioning with no obstructions.<br />

ü Remove weeds by h<strong>and</strong>. Do not use any herbicides.<br />

ü Replace displaced growing media.<br />

ü At the beginning of the season apply a slow release fertilizer.<br />

ü At the beginning of the season if desired trim the Sedum to remove dead flower stalks.<br />

Leave clippings on the roof. Use proper protection <strong>and</strong> extreme caution with power equipment.<br />

ü At the end of the season check for any bare spots <strong>and</strong> replant if needed.<br />

ü Stop all irrigation 4 weeks before first frost. Winterize irrigation equipment.<br />

ü Avoid the use of pesticides, herbicides or any chemicals that could contaminate the water<br />

supply.<br />

ü Avoid the use of deicing chemicals <strong>and</strong> salt around plants.<br />

www.eco-roofs.com<br />

questions@eco-roofs.com<br />

38

LEED Info<br />

Warranty & Disclaimers

<strong>Eco</strong>-<strong>Roofs</strong> &<br />

LEED®<br />

Leadership in Energy <strong>and</strong> Environmental Design (LEED) is a certification<br />

system established by the United States <strong>Green</strong> Building Council (USGBC) to provide<br />

3 rd party verification that a building has been designed, constructed <strong>and</strong> maintained<br />

in a green way. The certification process for buildings is based on the type or area of<br />

building (new construction, school, interior, etc.) <strong>and</strong> a number of key areas. Various<br />

levels of certification are available from Silver to Platinum based on the total number of points earned out of a possible 110.<br />

A green roof can contribute to a number of points in several areas.<br />

<strong>Eco</strong>-<strong>Roofs</strong>’ St<strong>and</strong>ard <strong>and</strong> AGR green roof systems are tray or modular systems with an emphasis on green roof<br />

technology. The modular approach when compared to the traditional built-in-place <strong>and</strong> intensive style of green roof is much<br />

lighter, faster <strong>and</strong> easier to install. The <strong>Eco</strong>-<strong>Roofs</strong> system has improved on what most modular systems have done by making<br />

the st<strong>and</strong>ard module one that arrives on the rooftop with 95% or more already established vegetative cover.<br />

With full plant coverage many of the benefits that LEED strives for are realized immediately. Full plant coverage<br />

maximizes the reduction of the urban heat isl<strong>and</strong> effect, stormwater management, water use efficiency, etc. Without preestablishing<br />

full coverage it can take months or even years for the plants to reach full establishment therefore taking much<br />

longer to achieve the full environmental benefits as well. The extra care necessary to fully establish the vegetative coverage<br />

such as supplemental irrigation can reduce or even negate LEED points.<br />

Following is a list of some of the LEED categories <strong>and</strong> the points to which your green roof could possibly contribute.<br />

These are only suggestive of where to begin looking. You should work with a LEED Accredited Professional to find all the<br />

LEED points you qualify for as they can vary greatly by building, area, material <strong>and</strong> many other factors.<br />

www.eco-roofs.com<br />

1. SUSTAINABLE SITES<br />

a. Site Development: Protect & Restore Habitat—SS 5.1; Maximize Open Space—SS 5.2. <strong>Eco</strong>-<br />

<strong>Roofs</strong>’ green roofs will help reclaim areas (rooftops) that in the past, reduced the areas of vegetation.<br />

Using our vegetated roofs could also help provide habitat value <strong>and</strong> could help promote biodiversity.<br />