FROM SAINT-GOBAIN PAM - Saint Gobain Pipe Systems

FROM SAINT-GOBAIN PAM - Saint Gobain Pipe Systems

FROM SAINT-GOBAIN PAM - Saint Gobain Pipe Systems

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

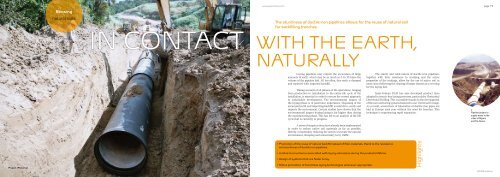

Project (Panama).<br />

Reusing<br />

natural soils<br />

www.pamline.com page 19<br />

The sturdiness of ductile iron pipelines allows for the reuse of natural soil<br />

for backfilling trenches.<br />

IN CONTACT WITH THE EARTH,<br />

NATURALLY<br />

Laying pipelines may require the excavation of large<br />

amounts of earth, which may be as much as 5 to 10 times the<br />

volume of the pipeline laid. All too often, this earth is dumped<br />

and replaced with imported backfill.<br />

Taking account of all phases of the operations, ranging<br />

from production to installation to the entire life cycle of the<br />

installation, is essential in order to ensure the correct approach<br />

to sustainable development. The environmental impact of<br />

the laying phase is of particular importance. Disposing of the<br />

excavated earth and importing backfill is restrictive, costly and<br />

impacts the environment. Certain studies have shown that the<br />

environmental impact during laying is far higher than during<br />

the manufacturing phase. This has led to an analysis of the life<br />

cycle that is currently in progress.<br />

A series of simple actions have already been implemented<br />

in order to reduce native soil materials as far as possible,<br />

thereby considerably reducing the need to excavate the natural<br />

environment, dumping and unnecessary lorry traffic.<br />

The sturdy and solid nature of ductile iron pipelines,<br />

together with their resistance to cracking and the active<br />

properties of the coatings, allow for the use of native soil in<br />

most cases (following the clearing of larger stones) as a covering<br />

for the laying bed.<br />

<strong>Saint</strong>-<strong>Gobain</strong> <strong>PAM</strong> has also developed product lines<br />

adapted to trench-free laying processes, particulalry Horizontal<br />

Directional Drilling. This is possible thanks to the development<br />

of the new anchoring systems featured in our Universal Ve range.<br />

As a result, several tens of kilometres of ductile iron pipes are<br />

laid in Europe each year without the need for trenches. This<br />

technique is experiencing rapid expansion.<br />

• Promotion of the reuse of natural backfill instead of filler materials, thank to the resistance<br />

and sturdiness of ductile iron pipelines.<br />

• Limited inconvenience associated with laying extensions during the products lifetime.<br />

• Design of systems that are faster to lay.<br />

• Active promotion of trenchless laying technologies whenever appropriate. Highlights<br />

<strong>Pipe</strong>line project to<br />

supply water to the<br />

cities of Algiers<br />

and Tizi-Ouzou<br />

2008 edition