Metal Expansion Joints - ThomasNet

Metal Expansion Joints - ThomasNet

Metal Expansion Joints - ThomasNet

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Multi-ply Bellows<br />

has two or more plies of material that are independently<br />

designed for the full system design<br />

conditions. This is achieved by nesting thin tubes<br />

inside each other before the initial punch stage of<br />

manufacturing.<br />

Multi-ply bellows have the distinct advantage of<br />

containing the same pressure as an equivalently<br />

thick single ply design, but with much lighter spring<br />

rates and much higher cycle life. For example, high<br />

pressure might require a 0.060” thick bellows to<br />

contain hoop stress. A single ply of 0.060” thick<br />

or three plies of 0.020” thick material will both<br />

handle the hoop stress in the bellows, but each ply<br />

in the multi-ply bellows will act individually where<br />

sidewall bending is a concerned. This reduces the<br />

spring rate and significantly increases cycle life.<br />

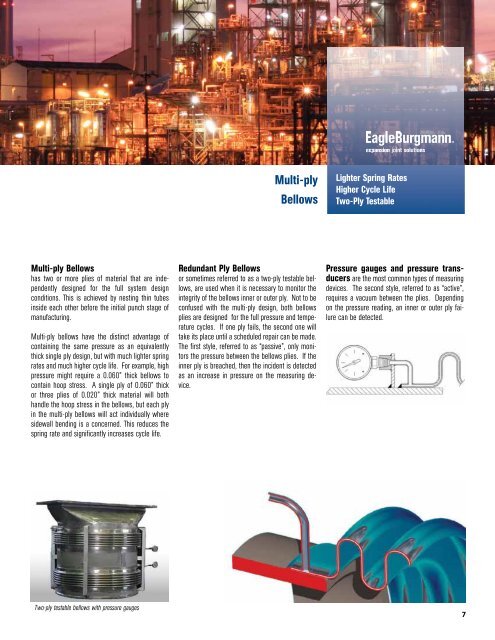

Two-ply testable bellows with pressure gauges<br />

Multi-ply<br />

Bellows<br />

Redundant Ply Bellows<br />

or sometimes referred to as a two-ply testable bellows,<br />

are used when it is necessary to monitor the<br />

integrity of the bellows inner or outer ply. Not to be<br />

confused with the multi-ply design, both bellows<br />

plies are designed for the full pressure and temperature<br />

cycles. If one ply fails, the second one will<br />

take its place until a scheduled repair can be made.<br />

The first style, referred to as “passive”, only monitors<br />

the pressure between the bellows plies. If the<br />

inner ply is breached, then the incident is detected<br />

as an increase in pressure on the measuring device.<br />

Lighter Spring Rates<br />

Higher Cycle Life<br />

Two-Ply Testable<br />

Pressure gauges and pressure transducers<br />

are the most common types of measuring<br />

devices. The second style, referred to as “active”,<br />

requires a vacuum between the plies. Depending<br />

on the pressure reading, an inner or outer ply failure<br />

can be detected.<br />

7