Sample 4 FAT Report Rev 0

Sample 4 FAT Report Rev 0

Sample 4 FAT Report Rev 0

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

RPP-RPT-49670, <strong>Rev</strong>. 0<br />

Washington River Protection Solutions 242-A<br />

Evaporator KI Exhaust Ventilation Systems<br />

Factory Acceptance Test <strong>Report</strong><br />

W.T. Domigan<br />

Washington River Protection Solutions<br />

Richland, WA 99352<br />

U.S. Department of Energy Contract DE-AC27,O8RVI 4800<br />

EDT/ECN: V 1 UC:<br />

Cost Center: N/A Charge Code: N/A<br />

B&R Code: N/A Total Pages: 3-7 &o<br />

Key Words: 242-A, Ki Exhauster, Factory Acceptance Test, ASME AG-i<br />

Abstract: The 242-A KL Exhaust Ventilation System was designed, fabricated, and tested by Premier<br />

Technology, Inc. out of Blackfoot, I1). This report documents the testing approach, acceptance criteria,<br />

testing results, and completion of testing for the equipment provided to WRPS.<br />

TRADEMARK DISCLAIMER. Reference herein to any specific commercial product, process, or service by trade name,<br />

trademark, manufacturer, or otherwise, does not necessarily constitute or imply its endorsement, recommendation, or<br />

favoring by the United States Government or any agency thereof or its contractors or subcontractors.<br />

SEP 01 2<br />

OAT: tAC<br />

1; 1 I Loo11<br />

Release-Approval Date Release Stamp<br />

Approved For Public Release<br />

STA. D<br />

A-6002-767 (REV 2)

Note:<br />

Premier Technology, Inc.<br />

Factory Acceptance Test <strong>Report</strong><br />

242-A Evaporator HVAC K1 Exhaust Ventilation System Upgrade<br />

RPP-RPT-49670 <strong>Rev</strong> 0<br />

Factory Acceptance Testing (<strong>FAT</strong>) was initiated by Premier Technology, Inc. (Premier) using revision 5 of<br />

the Factory Acceptance Plan which had been approved with comments by Washington River Protection<br />

Solutions (WRPS) authorizing Premier to proceed with specific sections of the <strong>FAT</strong>. As such, certain<br />

sections of the <strong>FAT</strong> were signed off using revision 5 of the <strong>FAT</strong> Plan. These sections can be found in<br />

Attachment B of this report.<br />

Premier revised the <strong>FAT</strong> Plan and submitted rev 6 which addressed the majority of the outstanding<br />

WRPS comments, however not all of them, such that WRPS approved rev 6 of the <strong>FAT</strong> Plan with<br />

comments and authorized Premier to proceed with additional sections of the <strong>FAT</strong>. As such, certain<br />

sections of the <strong>FAT</strong> were signed off using revision 6 of the <strong>FAT</strong> Plan. These sections can be found in<br />

Attachment A of this report.<br />

Lastly, Premier again revised the <strong>FAT</strong> Plan and submitted rev 7 which fully and satisfactorily<br />

incorporated all outstanding WRPS comments such that WRPS approved rev 7 of the <strong>FAT</strong> Plan and fully<br />

authorized Premier to proceed with all remaining sections of the <strong>FAT</strong>. It is this revision that makes up<br />

the main body of this report and the appropriate references to either revision 5 or 6 in attachments B or<br />

A, respectively, are made therein.

A Premiar T'echnaowg, ISC.<br />

1 858 W, Bridge Streest<br />

BlackfOotZD, 83221<br />

(208) 785-2274<br />

www.ptius.niet<br />

Washington River Protection Solutions 242-A Evaporator K1<br />

Exhaust Ventilation Systems Factory Acceptance Test<br />

Approvals Nm:Signature: Date:<br />

Preparer<br />

Technical J<br />

~ - c1illi<br />

Quality Assurance ~A~<br />

<strong>Rev</strong>ision 7<br />

CONTROLLED

(~?IEMIE -P<br />

PRxEER TECHNOLOGY, INC. Project No. 006765.0.000<br />

-242-A Evaporato Ki Exhaust Contract 40167<br />

\~k~ ag e hno ; I c.V entilation S stem No.<br />

RPP-RPT-49670 <strong>Rev</strong> 0<br />

1FACTORY ACCEPTANCE TEST PLAN S p e No0. R.PSev 0 06<br />

Table of Contents<br />

1.Purpose and Scope;............................................. ....... ..........<br />

1. pups .......................................<br />

. .........................<br />

~.......................... ...............<br />

1 oiscope e............................... ......................<br />

1.5 ..............................................<br />

1. efernScoe .......................... ......... ...... ...... ........ ...........<br />

IA. IformtIo.....................................................................---.... -*...4*<br />

1 .1 Tef ras d.............iti<br />

.. n......................................4<br />

.....<br />

2. TstPesone........................... ........................ 6<br />

2.4<br />

2.1<br />

Genelitu.........................................................<br />

Tes Exde ntions .................. : . ............................... I.................... . . . . . 7<br />

.6 rmRso A e. . . ... .................................<br />

........................................... 7<br />

* 2.71 Syise ..... I................................................<br />

2.8 an RCUD~S uspnsiD Tst.................................<br />

o Tet<br />

2.9 TesPeonneihl .............. ........................................<br />

8<br />

.4 Preuinend info ations..................................................................<br />

3.1 Prsonel sfety.............................. ..................... 9<br />

.2<br />

.6<br />

es Eipen ........................................................<br />

Aar m es pons... ........................................................................................<br />

.<br />

1<br />

.1<br />

4.1.Test.Spe..fic.p....o........i................................<br />

I..................1 7<br />

.2 Spsei1 Stools, Equ...pment........d..Suppli............ .. . . . . . . ............ ........<br />

.8 Susensionof.T.t..n..........et......................... ..............<br />

6.9 TesnusidelifFA............................<br />

6. ~.................<br />

...........................<br />

...................<br />

1<br />

.2 Vaers/Da-aper -................. Te.........*... ...................... 3<br />

6.3 Pessure.rop........................ Damers -<br />

....................... 14<br />

4.2 entandSi~ pecal ools, lies....................................<br />

E uip<br />

6.4 DanpersSeat&.........C<br />

Sch du v ....<br />

:...................................................................A..<br />

1. Pemn O ide e ology,..........................<br />

.....

PREMIER TECHNOLOGY, INC. 1'rojectNo. 006765.0.000<br />

VWS - 242-A Evaporator KI Exhaust Contract 40167<br />

Ventilation System<br />

No.<br />

FACTORY ACCEPTANCE TEST PLAN Spec No. Re 0<br />

RPP-RPT-49670 <strong>Rev</strong> 0<br />

6.5 FilterTran -PessureBoundaryLekage ........................I.....I<br />

....................................... 17<br />

6.6 Instrumentation and power wiring - Continuity and megger testing.........................................is<br />

6.7 Pre-Filter Diffetial Pressure indicators - Verify Differential Pressure Indicator Function............. 19<br />

6.8 Local I' Stage BEPA Section Pressure Indicators - Verify Differential Pressure Indicator Function ... 20<br />

-6.10<br />

6.9 Loal "~Stge EP Sctin resure idcatr- Verify Differential Pressure Indicator Function ... 21<br />

Exhaust Stack <strong>Sample</strong> Pitot Tube and Transport Lines - Leak test & Pitot Tube Alignment............. 22<br />

6.11 Mass Flow Controller Record <strong>Sample</strong>r and Vacuum Pump .................................................. 22<br />

6.12 Mass Flow Controller CAM and Vacuum Pump ......... ... I...............................................2<br />

6.13 Vacum Pump -Verify Purmp operation .......................................................... ......... 24<br />

6.14 Continuous Air Monitoring -Verify CAM Alarm and Interlock Set point .......~........I...............24<br />

6.15 <strong>Sample</strong>r line Vacuum. Indicator - Functional Test (P1-1)................................................... 25<br />

6.16 <strong>Sample</strong>r Line Vacuum Indicator -Functional Test (P1.1l-2)...........I....................................... 25<br />

6.17 CAM Operation - Verify'No Electromagnetic Radation Interference ............ ......................... 25<br />

6.18 Sampling system instrumentation and wiring - Continuity and megger testing............................. 25<br />

6.19 <strong>Sample</strong> Cabinet cooling fan -Functional test ................................................................. 26<br />

620 Verabar Flow Sensor - Verify Exhiauster Flow Indication ................................................... 26-<br />

6.21 Sampling Manifold - Qualification of Filter Sampling System .............................................. 27<br />

6.22 Fan and Motor .- Vibration (Drive motor rotating elements) & Sound ...................................... 28<br />

6.23 Intake Plemn & Expansion Joints - Pressure, Decay Test & Bubble Leak Test............................<br />

7 Procedure..........................................................<br />

.....................................<br />

29<br />

29<br />

7.1 Valves/Dampers - Visual inspections ............... t........................ ................................ 29<br />

7.2 Valve/Dampers - Verify Isolation Valve Position Indication and Function................................. 31<br />

7.3 Filter Train - Visual Inspection ........ 7 . ............ I......................................................... 33<br />

7.4 242-4 Evaporator KI Exhaust - Pressure Decay Test & Bubble Leak Test................................. 35<br />

7.5 Power Instriuent and Control Cabling -Proper voltage and phase sequence at equipment served....39<br />

7.6 Dampers - Damper Cycle Time and Operation ................................. I..................... ......... 40<br />

7.7 KI-S2M Motor and VFD - Proper voltage at equipment served .................................. . ........ 1.42<br />

7.8 KI-5-2 Fan and Motor -Vibration Test (Minimum System Loss)........................................... 46<br />

7.9 Kl-5-2 Fan and Motor - Sound Test...........................................................................<br />

7.0 Section 1 Valves/Dampers - System Pressure Boundary Leak Test......................................... 50<br />

7.1 1( -5-2 Fan and Motor - Vibration Test (Maximum System Loss) .......................................... 51<br />

7.12 K1-5-3M Motor and VFD - Proper voltage at equipment served ............................................ 53<br />

2 Premier Technology, Inc.<br />

006765.0.OOO-<strong>FAT</strong>-OO1-1 (<strong>Rev</strong> 7)<br />

49

PREMIER TECHNOLOGY, INC. Project No. 006765.0.000<br />

[U WEpS - 242-A Evaporator KI Exhaust Contract 40167<br />

\~wv'Thhfll~g4 ~Ventlation System No.<br />

& Te~clno 09y Inc.PPC-36062<br />

FACTORY ACCEPTANCE TEST PLAN Spec No. <strong>Rev</strong> 0<br />

RPP-RPT-49670 <strong>Rev</strong> 0<br />

7.13 KI1-5-3 Fan and Motor - Vibration Test (Minimum System Lass).......................................... 57<br />

6<br />

7.14 Kl1-5-3 Fan and Motor - Sound Tog..................I......................................................<br />

7.15 Section 2 Valves/Dampers - System Pressure Boundary Leak Test.....*................................... 61<br />

7.16 Stack Joint -Bubble leak est....................................................<br />

............................ 62<br />

7.17 KI-5-3 Fan and Motor - Vibration Test (Maximum System Loss)......................................... 63 L<br />

7.18<br />

7.19<br />

Filter Train A - Airflow Distribution (Full System).........................................................64A<br />

Filter Train B - Airflow Distibution (Full System)-...I...........I...................................<br />

...... 66<br />

7.20<br />

7.21<br />

7.22<br />

7.23<br />

Filter Train C -Airflow Distribution (Full Systemf)........................................................6<br />

Stack Sampling location -Angular or Cyclonic flow ......................................................<br />

6<br />

Stack Sampling Location - Contaminant Concentration and Velocity Profiles .........................<br />

.. 71<br />

Exhaust Stack Sarle; Line - Heat Trace Thermostat for CAM airborne Radiation Detector (GS)I....73<br />

8. -Completion of<strong>FAT</strong> Test.............'.........1 ...........- ..................... I..................1<br />

9. Attachment List.................... ............................................................................<br />

1. Purpose and Scope<br />

1.1 purpose<br />

This pro cedure was created for the purpose of performing Factory Acceptance Testing<br />

(<strong>FAT</strong>) of the 242-A Evaporator K1 Exhaust ventilation System provided by Premier<br />

Technology, Inc. for Washington River Protection Solutions (WRJ'S).<br />

The objective of this document is to provide a description of the processes that will be<br />

followed at the manufacturer's facility in order to performi t Factory Acceptance Testing<br />

of the 242-A Evaporator KI Exhaust Ventilation System in order to verify that the unit<br />

comp lies with the requirements of WRPS Specification RPP-SPEC-3 6062, <strong>Rev</strong>. 0 and the<br />

applicable flow down Specifications listed tberem".<br />

) 5M P49WD FA<br />

This Procedure will address all applicable components supplied by this order. These<br />

components are listed i section 6 and 7 of this <strong>FAT</strong> test The findings of each test shall be<br />

recorded in separate section of this document for each component.<br />

The testing will be performed at Premier Technology's facility.<br />

3 Premier Technology, Inc.<br />

fM -M&(hSAP ~ (7r. ~<br />

I 7 7L~ --<br />

OO6765.O.00-<strong>FAT</strong>-O01-1<br />

84<br />

(<strong>Rev</strong> 7)

(i ET<br />

RPP-RPT-49670 <strong>Rev</strong> 0<br />

MIERT<br />

PREMIER TECHNOLOGY, INC.<br />

W.RPS - 242-A Evaporator KI Exhaust<br />

Project No.<br />

Contract<br />

006765.0.000<br />

40167<br />

'Fehooy n.Ventilation System No.<br />

FACTORY ACCEPTANCE TEST PLAN ISpec No. IPPSev -300<br />

7.24 Continuous Air Monitoring - Verify CAM bypass feature .................................................. 74<br />

7.25 Vacuum Pump - Verify Pump operation...................................................................... 76<br />

7.26 C AM Operation - Verify No Electromagnetic Radiation Interference ...................................... 77<br />

7.27 <strong>Sample</strong> Cabinet cooling fan - Functional test ....................... ......................................... 78<br />

7.28 Inlet Plenum & Expansion Joints - Pressure Decay Test & Bubble Leak Test ............................. 79<br />

7.29 Exhaust Stack <strong>Sample</strong> Pitot Tube and Transport Lines - Leak test & Pitot Tube Alignment............. 81<br />

7.30 <strong>Sample</strong>r line Vacuum Indicator - Functional Test (PI1) .................................................... 82<br />

3a Premier Technology, Inc. 006765.O.OOO-<strong>FAT</strong>-0O1-1 (<strong>Rev</strong> 7)

PREMIER TECHNOLOGY, INC. ProjectNo. 006765.0.000<br />

ER WRS 242-A Evaporator Ki Exhaust conwmct<br />

p"DEM<br />

(Z -Tlchnowg Inc. Ventilation Systm No. 40167<br />

1.2 Scope<br />

RPP-RPT-49670 <strong>Rev</strong> 0<br />

FACTORY ACCEPTANCE TEST PLAN Spec No RPPSPEC-36062<br />

<strong>Rev</strong> 0<br />

This procedure is to demonstrate that the 242-A Evaporator KI Exhaust Ventilation System<br />

preforms properly in accordance with the WRPS Specification RPP-SPEC-36062, <strong>Rev</strong>. 0,<br />

NEMA MG-i 2007, ASME AG-I, TFC-ENG-STD-07, and ANSIN13.1.<br />

1.3 Not in Scope<br />

"None"<br />

1.4 Assumptions<br />

Test configuration matches onsite conditions 'with the following exceptions:<br />

* Temporary wiring will be used between major components. (Permanent wire will be<br />

provided new and unused)<br />

* Facility Differential pressure will be simulated by throttling filter housing inlet.<br />

butterfly valves.<br />

6 VCS and MCS are not available, communication will be verified by continuity<br />

checks<br />

0 Temporary power will be used in place. of facility power.<br />

These assumptions have no impact on execution or results of the <strong>FAT</strong>.<br />

1.5 References<br />

1.5.1 -ASHR.AIE 52 2007<br />

1.5.2 IMEE 112 2004<br />

1.5.3 AMCA 500 1989<br />

1.5.4 ANSI N13.1 1999<br />

1.5.5 ASMEfiB31-1 2007<br />

1.5.6 AMCA 2041996<br />

1.5.7 ASME AG-i 2003<br />

1.5.8 40OCFR 60<br />

2. Information<br />

2.1 Terms and Definitions<br />

2.1.1 <strong>FAT</strong> Factory Acceptance Test<br />

4 Premier Technology, Inc. 006765.0.000-<strong>FAT</strong>-001-1 (<strong>Rev</strong> 7)

PREMIER TECHNOLOGY, INC. Project No. 00616&.0.000<br />

WRPS - 242-A Evaporator Ki Exhaust Contract 40167<br />

eMhoo~~Inc. Ventilation System<br />

FACTORY ACCEPTANCIE TMS PLAN Spec No. 0<br />

RPP-RPT-49670 <strong>Rev</strong> 0<br />

2.1.2. RPS Washington River Protection Solutions<br />

2.1.3 QA Quality Assurance<br />

2.1.4 NQA Nuclear Quality Assurance<br />

2.1.5 ASMB American Society Of Mechanical Engineers<br />

2.1.6 AMC Air Monitoring Corporation<br />

2.1.7 PPE personal Protective Equipment<br />

2.1.8 OAT operational acceptance test<br />

2.1.9 VCS Ventilation Control System<br />

2.1.10 SCF Standard Cubic Feet<br />

2.1.11 CAM Continuous Air Monitor<br />

2A1.12 VFD Variable Frequency'Drive<br />

2.1.13 SWC Snall Logic.Controller<br />

2.1.14 )MM, DigitalMultimeter<br />

2.1.15 P1)11 Pressure Differenitial1 Indicating Transmitter<br />

2.1.6 PID '"Proportional Integral Derivative<br />

2.1.17 H~MI. Human Machine Intrface<br />

2.1.18 PLC Programmable Logio Controller<br />

2.1.19 BUMP To briefly energize<br />

2.1.20 M&TE Measurment and Testing Equipment<br />

2.1.21 MCS Monitoring control. system<br />

2.1.22 AWG America Wire Gauge<br />

2.1.23 CAT Construction Acceptance Test<br />

2.1.24 ENSUR Confirm that an activity or condition has occurred in conformance with<br />

specified requirements, and take action to make it so if the condition is<br />

NOT found to be in conformanc-e.<br />

2.1.25 VERIFY Perfor-m a comparison with stated requirements. No manipulation of<br />

equipment of other subsequent actions by the checker are involved.<br />

Verifications normally require initials or signature.<br />

2.1.26 STEADY STATE OPERATION<br />

Fan running at equilibrium at a set flow rate and system warmed up.<br />

2.2 units<br />

2.2.1 % Percent<br />

2.2.2 F Fahrenheit<br />

2.2.3 Hp Horsepower<br />

2.2.4 A Amps<br />

5 Premier Technology, Inc.<br />

006765.O.OOO-<strong>FAT</strong>-OO1-1 (<strong>Rev</strong> 7)

PREMIER TECHNOLOGY, INC. Project ~q 0 006765.0.000<br />

WRPS - 242-A Evaporator K1 Exhaust Contract 40167<br />

RPP-RPT-49670 <strong>Rev</strong> 0<br />

(E~EMIERNo<br />

Tecnkg Ventilation System N.~ ~ C66<br />

Tecnoogy Ic- FACTORY ACCEPTANCE TEST PLAN SpecNo. RP-SEC366<br />

2.2.5 VAC Volts Alternating Current<br />

2.2.6 dBA decibels (weighted on 'A' scale)<br />

2.2.7 psi Pounds per square inch<br />

2.2.8 in inch<br />

2.2.9 mm millimeter<br />

2.2.10 in Hg Inches of mercury<br />

2-2.11 AWG American Wire Gage<br />

2.2.12 IN~ W.G. Inches Water Gauge<br />

2.2.13 IN W.C. Inches Water Column<br />

2.2.14 SCFM Standard Cubic Feet per Minute<br />

2.2.15 rpm revolutions per minute<br />

2.3 Test Personnel<br />

The Following personnel are required to conduct the Factory Acceptance Testingfte22<br />

A Evaporator Ki Exhaust Ventilation SystemA<br />

2.3.1 Test Director<br />

The test director will be present for all testing. This individual will be the Project<br />

Manager for the project unless otherwise designated.<br />

2.3.2 Test Technicians<br />

Test Technicians will assist the Test Director in the preparation of hardware and<br />

equipment for the <strong>FAT</strong> tests. These individuals will be familiar with the equipment.<br />

being used.<br />

2.3.3 QA Personnel<br />

Quality Assurance personnel will be present for all listed functions of the testing. The<br />

QA designee will record the results and test data of the testing.<br />

2.4 General Information<br />

2.4.1 Editorial changes may be made to thids procedure as required to accommodate<br />

procedural/editorial deficiencies that do not affect technical content Redline changes<br />

shall be entered using red ik, initialed and dated by the Test Director.<br />

2.4.2 Testing performed in the fabrication shop shall comply with shop Lock and Tag<br />

policy requirements. Fabricator shall verify general requirements, roles, and<br />

responsibilities.<br />

*6 Premier Technology, In c. 006765.0.000-<strong>FAT</strong>-0O1-1 (<strong>Rev</strong> 7)

PREMIR TECHNOLOGY, INC. Project No. 006765.0.000<br />

(~ T f R WRPS - 242-A Eaporator KI Exhaust contract 406<br />

\&/olo yI±E Ventilation SEste<br />

FACTORY ACCEPTANCE, TEST PLAN spec No. RPPSev-3<br />

RPP-RPT-49670 <strong>Rev</strong> 0<br />

2 .4.3 Verifiation of each test shall be documented at the end of each test section by having<br />

the Test Director and the QA Personnel Sign and date the test section.<br />

2.5 Test Exceptions<br />

2.5.1 Test exceptions are used to document unexpected tes euttcnclpoeua<br />

deficiencies, and identify appropriate action.<br />

2.5.2 A description and a resolution for the test exceptions shall be documented in<br />

Attachment 1 <strong>FAT</strong>, Test Exception Record<br />

2.5.3 In the event of an equipment malfunction or other anomaly, the Test Director shall<br />

document the condition with a&Test Exception Record and assess the effect on<br />

equipment and direct either<br />

* Continuation of the test in. the same section.<br />

*proceeding to another attachrmbnt or section of the test.<br />

* Suspensibn of the test nd tstablishnidtit of a safe condition for equipment<br />

(See Section I!).<br />

2.5.4 Test exceptions and discrepancires that cannot be orreted in- accordance with this<br />

procedure will he documented and addressed on a non-conformnce report, per<br />

Premier Technology, Inc. NQA-l Quality Assurance Program.<br />

2.6 Alarm Response<br />

2.6.1 This procedure identifies all alarms expected as a result of testing, and provides<br />

instructions for responding to those alarms, During testing of Hfigh or Low set points,<br />

High and Low alams are also anticipated.<br />

2.6.2 Unexpected alarms received during testing shall be logged as test exceptions in<br />

Attachment 2, Test Exception Log and evaluated by the Test Director for effect on<br />

the test.<br />

2.6.3 All test exceptions, must be recorded in Attachment 2, <strong>FAT</strong> Test Exception Log,' and<br />

explained in detail in the Attachment 1, <strong>FAT</strong> Test Exception Record.<br />

2.6.4 Variation between EIM alarm terminology and alarm terminology provided in this<br />

<strong>FAT</strong> is not cause to stop testing. The variance shall be evaluated by the Test Director<br />

to confirm desired system response and documented on Attachment 3, <strong>FAT</strong> Test Log.<br />

2.7 System-Status<br />

2.7.1 Record all abnormalities in equipment configuration, comments, observations by<br />

participants, and all other data pertinent to the test in the Attachment 3 <strong>FAT</strong> Test<br />

7 Premier Technology, Inc.<br />

006765.O.OO-<strong>FAT</strong>OO01-1 (Rtev 7)

PREMIER TECHNOLOGY, INC. Project No. 006765.0.000<br />

(P~ IE AI~ R WRPS - 242-A Evaporator K1 Exhaust Contract 40167<br />

RPP-RPT-49670 <strong>Rev</strong> 0<br />

' Teho gyi.Ventilation System .No. RI-PC30<br />

FACTORY ACCEPTANCE TEST PLAN Spec No. RuPSev 0 06<br />

Log. If applicable, initiate a test exception by identifying the condition in the<br />

Attachment 2, <strong>FAT</strong> Test Exception Log.<br />

27.8 Suspension of Test and Resuming Test<br />

2.8.1 The Test Director may, at his discretion, stop testing and place equipment in a safe<br />

condition. All suspension of testing due to exceptions shall be documented in the<br />

Attachmnent 3, <strong>FAT</strong> Test Log.<br />

2.8.2 If a section of the test is suspended for any reason prior to completing all steps, the<br />

Test Director shall establish initial conditions necessary to resume testing for that<br />

section. Previously completed sections need not be repeated unless directed by the<br />

Test Director to establish conditions required to resume the test.<br />

2.8.3 WEPS is to be advised of the condition(s) that resulted in the suspension of any test<br />

along with the expectd resplution. Prior to resuming any terminated test WR.PS is to<br />

be notified.<br />

2.8.4 Sections of this procedure may be performed out of sequence as lon g as components<br />

or-tests are NOT altered. Steps within ech section must be performed in order except<br />

section 7.1 which is pre-.requisite to 7.2 and 7.3 which is a pre-requisite to 7.4 and as<br />

indicated in sections 7.8-7.11, 7.13-7.17, and 7.18-7.22. these tests must be<br />

performed in order.<br />

2.9 Responsibilities<br />

2.9.lIThe Test Directr shall-<br />

8 Premier Technology, Inc.<br />

* .Verify prerequisites are completed prior to start of testing.<br />

*Maintain control of the testing process and change record authorization for<br />

this procedure.<br />

a Ensure all required data is collected.<br />

* Ensure safe working conditions and practices.<br />

'Ensure compliance with test documents.<br />

*Ensure review and approval of all modifications to test procedures are<br />

* complete prior to return to testing.<br />

*Act as direct line of communication and centralized point of control during<br />

normal, abnormal, and casualty situations.<br />

*Conduct pre-test briefings as required.<br />

* Schedule and reschedule tests as required.<br />

*Conduct pre-test system walk-downs.<br />

*<strong>Rev</strong>iew test documents to validate acceptance.<br />

006765.O.OO-<strong>FAT</strong>-OOI-l (<strong>Rev</strong> 7)

P MR TECHNOLOGY, INC. Project No. 006765.0.000<br />

WRPS - 242-A, Evaporator Ki Exhaust Contract 40167<br />

RPP-RPT-49670 <strong>Rev</strong> 0<br />

(~T~CI11OOg)~X1C entilation SYStem No<br />

FACTORY ACCEPTANCE TEST PLAN Spec NO. <strong>Rev</strong>.PR-306<br />

*Record equipment statuis and data in accordance with this procedure.<br />

*<strong>Rev</strong>iew, approve and record data exceptions and their resolutions and other<br />

*notes as required on the applicable attachinents.<br />

*Prepare post-testing documents<br />

*verify component ID is correct for the component being tested.<br />

* verify comnpletion. of each test section.<br />

& Verify proper valve andAlectrical alignment before each test section.<br />

* Provide technical support during testing.<br />

a <strong>Rev</strong>iew test documents to validate acceptance.<br />

* verif current version of software.<br />

0 Sign verification of data on calculation attachments.<br />

. <strong>Rev</strong>iew-recorded data for completeness -and accuracy.<br />

<strong>Rev</strong>iew and approve test exoepiQ~s. and tl~eir resolutions.<br />

*<strong>Rev</strong>iew <strong>FAT</strong> for compltenss w' acqI;1OQW Y.<br />

2.9.2 QA Personnel shall:<br />

* Verify component ID is correct for thecomponent being tested.<br />

* <strong>Rev</strong>iew procedure for accuracy and comnpleteness.<br />

. <strong>Rev</strong>iew the PAT for accuracy and completeness.<br />

* <strong>Rev</strong>iew and approve test exceptions and their resolutions.<br />

2.9.3 The Quality Control Inspector shall:<br />

a Witness testing.<br />

* <strong>Rev</strong>iew recorded data for accuracy and completeness.<br />

-- Verify completion of each test section.<br />

*Verify completion of test exceptions and their resolutions.<br />

2.9.4 Test Technicians shall:<br />

0 Provide assistance during testing.<br />

* provide equipment for performance of this procedure.<br />

3I Precautions and Limitations<br />

3.1 Personnel Safety<br />

All persons within the test area shall wear the appropriate Personal Protective Equipment<br />

(PPE). At a minimum this shall include eye protection. Gloves should be worn where there<br />

is a likelihood of contactig sharp edges or when handling rigging equipment.<br />

9 Premier Technology, Inc.<br />

006765.O.OWO<strong>FAT</strong>-OO1-l (<strong>Rev</strong> 7)

PREMIER TECHlNOLOGY, INC. Project No. 006766.0.000<br />

RPP-RPT-49670 <strong>Rev</strong> 0<br />

(~1 NA ER WRS - 242-A Evaporator Ki Exhaust Contract 40167<br />

TcnlgInc. Ventilation System No.<br />

FACTORY ACCEPTANCE TEST PLAN Spec N~o. RPPeC-306<br />

All persons within the test area are authorized to immediately halt testing should they<br />

observe an unsafe condition that could compromise the safety of themselves, other persons<br />

in the test area or the safety of the equipment Concerns should be addressed to the test<br />

director to ensure an orderly and controlled shutdown of the equipment being tested.<br />

NOTE: Energized circuits and leads are contained inside cabinets, Failure to comply with<br />

appropriate electrical PPE and safety procedures can cause serious personnel injury or death<br />

from electrocution.<br />

3.2 Equipment Safety<br />

3.2.1 A pre-test briefing should be conducted to identify unusual and for hazardous<br />

conditions<br />

3.2.2 Shop'safety rules should be stzictly adhered to during the performance of ths test<br />

3.2.3 Shop Lack and Tag requirements should be followed at all times during the<br />

performance of this test<br />

4. Prerequisites<br />

4.1 Test Specific pre-configurations<br />

4.1.1 Any settings, configurations, etc, which are required for specific tests (prior.to<br />

beginning the numbered test steps) shall be determined by the test director, who shall<br />

direct personnel to make any necessary configuration changes. Prerequisites listed.<br />

elsewhere in this test procedure but not required for a particular test do not have to be<br />

performed, at the discretion of the test director. This includes ensuring that all gaskets<br />

have been installed, holes have been sealed, and any valves have been properly positioned.<br />

4.1.2 Ensure that all apparatus on the 242-A Evaporator KI Exhaust Ventilation Systemn<br />

necessary for the performance of the Test Procedure have been installed and are fully<br />

operational. This includes ensuring that all gaskets have been installed, holes have<br />

been sealed and any valves have been properly positioned.<br />

4. 1.3 Ensure that the equipment to be tested is free of dirt, chips, scale or any other debris<br />

that would hinder testing. Cutting fluids and residual oils shall be removed from the<br />

surfaces of the housing and components.<br />

10 Premier Technology, Inc. 006765.O.00-<strong>FAT</strong>-0O1-1 (<strong>Rev</strong> 7)

I 6.1<br />

RPP-RPT-49670 <strong>Rev</strong> 0<br />

P E M T E C N O L G Y , I N C<br />

WRpS<br />

.<br />

- 242'-,A Evaporator Ki Exhaust Contract J' N 40167 0 7 . . 0<br />

Ventlation 'RstemnNo<br />

& echnology, Inc. P P. M-VC362<br />

FACTORY ACCwzTANCE TEST I LAN SWe N& Rv,<br />

PP LEMIER<br />

4.1.4 Test Procedure <strong>Rev</strong>iew - The test director shaI enure that all Persons participating<br />

in testing as Test Technicians have reviewed and understood the requirements Of the<br />

test procedure and the equipment to be tested.<br />

4.1.5 The signature in Testing Outside of <strong>FAT</strong> serves as confirmation by Premier<br />

indicating that the subject documentation was reviewed, verified, complete, and<br />

accepted.<br />

4.2 Special Tools, Equipmentand Sutpplies<br />

& Compressed air source (0.25 00)<br />

9 covers to seal te~t boundaries<br />

* clock or tinmer capable of reading seconds,<br />

apressuro-indicatg device accurate to t 0.1 in:.wg [02(25 kPA (gage)]*<br />

*flow meter or totalizing gas volume meter accurate to 15%/ (conant-presSure<br />

method)*<br />

*temperafure-indicaiof device accurate to 6-05TF (0.25*C)o<br />

*bubble solution for detecting air leaks (bubble method)<br />

* optional portable electronic sound detection equipment (audible leak method)*<br />

" barometer*<br />

" Amp Meter*<br />

" Volt Metr*<br />

NOTE: *Calibration information required,<br />

5. Schedule<br />

The schedule is.deennned by the test director according to scheduling of subcontractors<br />

and pre-requisites to each specific test listed in section 7.<br />

6,. Testing Outside of <strong>FAT</strong><br />

Testing that was accomplished or will be accomplished by vendors, contractors, and<br />

standard NQA-I manufacturing practices that can be used to validate any <strong>FAT</strong> are verified<br />

in this section.<br />

Electric D~rive Motor - Motor RuD Test<br />

MAT=I REFERENCE - line 1, 2, & 3<br />

11 Premier Technology, Inc.<br />

006765.O.000-<strong>FAT</strong>-0O1-1 (<strong>Rev</strong> 7)

PRELMIER. TECHNOLOGY, INC. Project No. 006765.0.000<br />

(UP E M4IER WRPS - 242-A Evaporator KI Exhaust Contract 40167<br />

\ 4~cn~oy ic Ventilation System No.<br />

Techollgy, nc.RPP-SPEC-36062<br />

FACTORY ACCEPTANCE, TEST PLAN Spec No. <strong>Rev</strong> 0<br />

RPP-RPT-49670 <strong>Rev</strong> 0<br />

BACKGROUND - This test is to show that electric drive motors are in accordance with<br />

IEEE standard 112.<br />

COMPONENT BEING TESTED:<br />

* Kl-5-2-M<br />

* KI-5-3-M<br />

ACCEPTANCE CRITERIA:<br />

0 Motor is free of mechanical and electrical defects and is within mnanufacturers<br />

tolerance<br />

* Efficiency shall equal or exceed 94.1%<br />

* Locked motor current shall not exceed 543 A for 75 Hp motor at 460 VAC<br />

* Motor is certified to NEMA MG-1<br />

TEST PROCEDURE:<br />

6.1.1 RECORD motor efficiency from motor nameplate.<br />

6.1.2 RECORD motor locked rotor amps form motor nameplate.<br />

6.1.3 REVIEW manufacturer's certification documents in Attachment 6.1 (see Baldor<br />

Reliance Product Information Packet ECP843 16T-4 page 8 of 8 & Baldor<br />

Petroleum/Chemical Solutions Cataloged page 5 841XL Motor).4k<br />

Motr*.<br />

IKs-5-24W<br />

Nameplt Certification<br />

Effciecy ockd aps<br />

Efdcy LdamsEfficiency Locked amp'sIs<br />

95A 542 SA4Z-<br />

Intals<br />

Test IQA<br />

Director I nsixotor<br />

KI-5-3-M 954426<br />

6.1.4 CONFIRM the acceptance criteria have been met. I "<br />

6.1.5 Test Director VERIFY test is complete.<br />

Test Director Signature<br />

12 Premier Technology, Inc.<br />

D ate<br />

006765.04000-<strong>FAT</strong>-O01-1 (<strong>Rev</strong> 7)

PREMIER TECHNOLOGY, INC. Projectflo. 006765.0.000<br />

(P ZI M I R WRP - 242-A Evaporator Ki Exhaust Contract 40167 *<br />

N'v~I~echnolog~ inc Ventilation System_____nPSE-66<br />

FACTORY ACCEPTANCE TEST PLAN SpecNo. R" 0<br />

6.1.6. QA Inspector VERUFY test is complete.<br />

QA Inspector Signature<br />

6.2 Valies/Dampers - Shell Leak Test<br />

MATRI REFER~ENCE - line 16 & 17<br />

Date<br />

RPP-RPT-49670 <strong>Rev</strong> 0<br />

BACKGROUND - This test is to show that valves meeting the ASME B3 1.1 requirements<br />

have no visual detectable leaks.<br />

COMPONENT BEING TESTED:<br />

*KI-HV-001<br />

9 ,-3V02<br />

KI-HV-003<br />

*KI-HV-00<br />

*KI-HV-017<br />

K 1l-HV-024<br />

ACCEPTANCE CRITERIA:<br />

*Visually detectable leakage through the pressure boundary is not acceptable. The<br />

pressure boundary includes, along with the body, bonnet, or Cover, all gasketed<br />

joints; however, leakage through the stem seals or stem packing shall not be cause<br />

for rejection. Stem seals or stem packing exempted from the shell test pressure<br />

leakage requirement shall be capable of retaining pressure up to the 38 0 C (I100 0 F)<br />

pressure rat ing without visible leakage.<br />

*Ultra High molecular Weight Polyethylene (UIIM PE) seats shall be tested in<br />

accordance with API 598 hydrostatic high-pressure closure test at 110% of the<br />

design differential pressure at the 100*F rating<br />

TEST PROCZDURE:<br />

6.21 REVWW manufacturer's certification documents located in Attachment 6.2 (see<br />

ABZ Valves & Controls Summary & Manufacture drawing 30" 402-205-Gear).<br />

6.2.2 -CONFIRM the acceptance criteria have been met by initialing data table.<br />

FIAT 6.2 ASME B31.1 Iiil<br />

13 Premier Technology, Inc.<br />

006765.0.000-<strong>FAT</strong>-OO1-1 (<strong>Rev</strong> 7)

PREMIER TECHNOLOGY, INC. Project No. 006765.0.000<br />

(i EM IER WRPS - 242-A Evaporator KI Exhaust Contract 40167<br />

\iw'Technology, '11c. Ventilation System No.<br />

RPP-RPT-49670 <strong>Rev</strong> 0<br />

FACTORY ACCEPTANCE TEST PLAN SpecNo. RPP.SPEC-36062<br />

<strong>Rev</strong><br />

Valve List Satifed Unsatisied Test QA<br />

KCI-HV-001 K___________<br />

ICI-HV-002 3<br />

K-IIV-003<br />

KI-HV-010<br />

X<br />

11<br />

'f<br />

K1-HIV-024,y<br />

6.2.3 Test Director VERIFY test is complete.<br />

Test Director Signature Date<br />

6.2.4 QA Inspector VERIFY test is complete.<br />

QA Inspector Signature Date<br />

6.3 Dampers - Pressare Drop<br />

MATRIX REFERENCE - line 18<br />

BACKGROUND - ASME AG-i, DA-51 10 Pressure drop data shall be based on tests<br />

performed in accordance with AMQA Standard 500. The AMCA Standard number used<br />

shall be stated with the pressure drop data.,<br />

COMPONENT BEING TESTED:<br />

* Kl-MOV-001<br />

* KI-MOV-002<br />

0 KI-BDD-001<br />

* Kl-BDD-002<br />

e K1-)DMPR-001<br />

0 Kl-DMPR-002<br />

K ACCEPTANCE CRITERIA - Pressure drop wil be within 10% of value used to size the<br />

fan. Test data or manufacturer certification on damper style is acceptable..<br />

-56u ie.-r Vrh'-'tI'. ;at AUIE?'QVu C -r 'FaJ'~<br />

TEST PROCEDURE:<br />

14 Premier Technology, Inc. 006765.0.000-<strong>FAT</strong>-001-1 (<strong>Rev</strong> 7)

PiEMIER TECHNOLOGY, INC. ProjectNo. 006165.0.0007<br />

WRIS - 242-A Evaporator Ki Exhaust Cotr 40167<br />

\~ t mhooy n. -Ventilation System No.SEC366<br />

FACTORY ACCEPTANCE TEST PLAN Spec No. <strong>Rev</strong> 0<br />

RPP-RPT-49670 <strong>Rev</strong> 0<br />

6.3.1 REvIEw manufacturer's certification documents located in Attachment 6.3 (see<br />

Quality verification Documentation page 3 and pressure drop chart) and fan sizing<br />

calculation.<br />

6.3.2 CONFIRM the acceptance criterion has bee met by initialing dataL table.<br />

<strong>FAT</strong> 6.3 ASME AG-1, DA-5110 Initials<br />

Test QA<br />

Damper list Satisfied Tisfed 7 kpao<br />

KI-MOV-001 IZ<br />

KI-MOV-001 Fk ' II ..<br />

KI-BDD-002 JL_ __ _ __ _<br />

KI-DNM-401 y C f<br />

R1.DhM-002 y- M h<br />

6.3.3 Test Director VERIFY test is complete.<br />

Test Director Signature<br />

*6.3.4 QA lnspector VERIFY test is complete.<br />

QA Inspector Signature<br />

6.4 Dampers - Seat & Frame Leakage<br />

MATRIX REFEMENCE - line 20 & 21<br />

Date<br />

Date<br />

BACKGROUND - ASME AG-I, DA-5 130, Pressure plates shall be bolted to the inlet and<br />

outlet side of the damper. The chamber created shall be pressurized to the specified frame<br />

design pressure with the blades partially open. Testing industrial style dampers shall be in<br />

accordance with the bubble method. ASME AG-i, DA-5 140, Seat leakage testing shall be<br />

performed or verified after oycle time and cycle repetition testing and frame leakage testing.<br />

COMPONENT BEING TESTED:<br />

e KI-MOV-001<br />

* KI-MOV-002<br />

* Kl-BDD-0Ol**<br />

15 Premier Technology, Inc.<br />

006765.0.0O0-<strong>FAT</strong>-O01-1 (<strong>Rev</strong> 7)

RPP-RPT-49670 <strong>Rev</strong> 0<br />

PREMIER TECHNOLOGY, INC. Prject No. 006765.0.000<br />

EM ER WRPS -242-A Evaporator KI Exhaust Contract 40167<br />

(D<br />

VentilationSystem ___o. ______<br />

FACTORY ACCEPTANCE TEST PLAN Spec No. RPPSevO 60<br />

* Kl.BDD-002**<br />

* KI-DMPR-001<br />

*Kl-DMPR-002<br />

NOTE: "*Dampers that are only required to be cycle tested, frame bubble test will be<br />

conducted in 7. 10 and 7. 15 for customer information only.<br />

ACCEPTANCE CRITERIA:<br />

* The damper shall be bolted to a pressure chamber which is then pressurized to the<br />

specified blade design pressure. A bubble solution (a commercial test solution or a<br />

solution consisting of equal parts liquid detergent, glycerin, and water) shall be<br />

applied to the damper seat area to be tested. A few moments later, but before the<br />

soap solution can dry, check the wetted areas and mark places where bubbles are<br />

being generated. Unless otherwise specified, a leak indication is any bubble 1/6 in.<br />

(1.58 mmn) diameter that forms in I see, or a bubble 9/32 in. (7.14 mm) that forms in<br />

1 mmd. Movement of the blades and actuators and linkage shall be smooth and<br />

without hesitation, and limit switches operate in their intended position.<br />

* Meets Leakage Class IV (DA-I NOTE: (3) Leakage Class TV is for applications<br />

where leakage is of no consideration.)<br />

TEST PROCEDURE:<br />

6.4.1 REVIEW manufacturer's certification documents located in Attachment 6.4 (see test<br />

report for each damper).<br />

6.4.2 CONFIRM th acceptance criteria have been met by initialing data table.<br />

<strong>FAT</strong> 6.4 ASMI AG-i, DA-5130 initials<br />

Dampr atifiedUnstisiedTest<br />

Lst<br />

Damer istSatslcd nsaisfedDirector<br />

QA<br />

Instiector<br />

K1-MOV-001<br />

I-MOV-0O2 VI OrZi~<br />

KI-BDD-002~t2L<br />

______002 X_ _ _ _ _ I-If<br />

6.4.3 Test Director VERIFY test is complete.<br />

/ LJ~t<br />

Test Director Signature Date<br />

16 Premier Technology, Inc. 006765.O.OO-<strong>FAT</strong>-001-I (<strong>Rev</strong> 7)

pRE2!mlIR TECHNOLOGY, INC. Project No. 006766.0-000<br />

(1~'T AM ER WRPS - 242-A Evaporator K1 Exhatust Contract 4016<br />

EMitg Inc. Vetilationi Systeim<br />

& nc.RPP-SPEC-36062<br />

Tecrjoog,<br />

No.<br />

FACTORy ACCE&PTANCE TEST PLAN Spec No. Rei<br />

6.4.4 QA In 3 to 7 VERIFY test is complete.<br />

.6.5 Filter Train -pressure<br />

MAT=I RnwmuNC - line 40<br />

Boundary Leakage<br />

RPP-RPT-49670 <strong>Rev</strong> 0<br />

BACKGROUND - BHEPA jilter' element holding frames at each filter position shall be<br />

press=redecay leak tested in accordance with the requirement of ASME N5 10, Section 7<br />

The filter trains shagl be pressure decay leak tested before test pro-fi1ter and HEPA filters are<br />

installed. Tetsal ecnuted to meet the riquiremetits of, ASM N51 0, Scin6<br />

COMPONENTBEIG TESTED:<br />

e Filter TrainlA<br />

& Filter Train B<br />

* Filter Train C<br />

ACCE'PTANC]& CRITERZIA -The leak rate shall not exceed 0.1% of the housing volume<br />

per hour at the system leak test pressure as defined in ASME AG-1 for leakage Class I<br />

(Table SA-B-13 10)<br />

TEST PROCEDURE:<br />

6.5.j RVIEW xnanufactoreres certification documents located in Attachment 6.5 (see<br />

leak test report for each filter housing)-<br />

6.5.2 CONFIRM the accptance criterion has been Met by initialing data table.-<br />

<strong>FAT</strong> 6.5 AsmE N510 Initials<br />

Tod QA<br />

Filer rati istSaisfedUhsatisfied<br />

Filer rai stisedDiretor Lit<br />

1<br />

Filter Train A<br />

Filter Train B<br />

Filter Train C<br />

17 Premier Technology, Inc,<br />

006765..000<strong>FAT</strong>-001- (<strong>Rev</strong> 7)

RPP-RPT-49670 <strong>Rev</strong> 0<br />

PREMIER TECHNOLOGY, INC. ProjectNo. D06765.0.000*<br />

( KEMIN ER WRPS - 242-A Evaporator Kl Exhaust Crct~ 40167<br />

_ Tchnology Inc Ventilation System - NO.<br />

FACTORY ACCEPTANCE TEST PLAN Spec No. RPP-SPEC-3606Z<br />

<strong>Rev</strong> 0<br />

6.5.3 Test Director VERIFY test is complete.<br />

/ 1 -<br />

Test Director Signature Date<br />

6.5.4 QA Inspector VERIFY test is complete.<br />

QA Inspector Signature bate<br />

6.6 Instrumentation and power wiring - Continuity and megger testing<br />

MIATRIX REWEPXNCE - line 37<br />

BACKGROUND - This test is to show that all wiring is connected properly and meets<br />

industry standards.<br />

ACCEPTANCE CRITERIA -<br />

* Resistance shall be 5 1 ohm for continuity checks for wiring #14 AWG and larger<br />

and:S 3 ohms for wiring #16 AWG and smaller.<br />

* Resistance to ground shall be 50 mega ohm minimum. Conductors rated 2: 600 V<br />

used for services, feeders or branch circuits over 150 V to ground, Phase-to-Phase<br />

and Phase-to-Ground insulation resistance 200 mega ohms. (Voltage output of<br />

megger shall be 1000 V dc nominal).<br />

TEST PROCEDURE:<br />

6.6.1 VERIFY continuity using Exhauster Electrical Assembly Traveler Attachment C -<br />

Continuity (see Attachmient 6.6).<br />

6.6.2 CONFIRM the acceptance criteria have been met<br />

6.6.3 Test Director VERIFY test is complete.<br />

Test Director Signature Date<br />

6.6.4 QA Inspector VERIFY test is complete.<br />

QA Inspector Signature Date<br />

18 Premier Technology, Inc. 006765.0.000-<strong>FAT</strong>-0O1-1 (<strong>Rev</strong> 7)<br />

4

P EMIERINo<br />

RPP-RPT-49670 <strong>Rev</strong> 0<br />

PREAM TECHNOLOGY, INC. Prjc~.0675000 1<br />

WRPS - 242-A Evaporator K1 Exhaust Contract 40167<br />

Inc. Ventilation SstemN.<br />

FACTORY ACCEPTANCE TEST PLAN SPec No. RI<br />

6.7 Pre-Filter Differential Pressure indicators - Verify' Differential Pressure<br />

Indicator Function<br />

MATRIX R~FER~ENCE - line 28<br />

BACKGROUND - Differential pressure is displayed and corresponding 4-20 mA signal is<br />

provided for operating range of -I to 9 inH2O.<br />

COMPONENT BEING TESTED:<br />

*PD1T-Kl -3 06<br />

*PDIT?-Kl -309<br />

*PDrr-K1-312<br />

ACCEPTANCE CRITERIA -Local<br />

output are within -1 to 9 inH2O.<br />

TEST PROCEDURE:<br />

pressure indicationsi and corresponding 4 -20 mA<br />

6.7.1 VERIFY appropriate 4-20 mA using Ehauster Electrical Assembly Traveler<br />

Attachmnent b- Loop Check Table 1. (S69 -WA aMz',n ( .L--<br />

6.7.2 CONFIRM the acceptance criterion has been met.<br />

6.7.3 PD]T-Kl-:306 Test DiretorZ. QA Inspector<br />

6.7A PDIT-Kl-309 Test DiretorX_-N. QA IispectorLkl<br />

6.7.5 PDLT-K1 -3 12 Test DirectorL?2. QA InSpetor~ k<br />

6.7.6 Test Director VERIFY test is complete.<br />

___<br />

Li 1115I<br />

Tes;t irector Signature Date<br />

6.7.7 Q n tor VERIFY test is complete.<br />

QA Inspector Signature<br />

19 Premier Technology, Inc.<br />

Date<br />

006765.O.000-<strong>FAT</strong>-O01-1 (<strong>Rev</strong> 7)

RPP-RPT-49670 <strong>Rev</strong> 0<br />

PREMIER TECHNOLOGY, INC. Project No. 006765.0.000<br />

E I R WRPS - 242-A Evaporator KI Exhaust Coutract 40167<br />

'A ciooy nVentilation System No.<br />

RPP-SPEC-36062<br />

FACTORY ACCEPTANCE TEST PLAN Spec No. <strong>Rev</strong> 0<br />

6.8 Local I" Stage UEPA Section Pressure Indicators - Verify Differential<br />

Pressure Indicator Function<br />

MATRIX REFERENCE - line 30<br />

BACKGROUND - Differential Pressure is displayed and corresponding 4-20 mA signal is<br />

provided for operating range of -1 to 9 inH 2O.<br />

COMPONENT BEING TESTED:<br />

* PDIT-K1-307<br />

e PDIT-KI-310<br />

* PDrT-Kl-')13<br />

ACCEPTANCE CRITERIA - Local pressure indications and corresponding 4 -20 niA<br />

output are withini 4to 9 ioIHaO.<br />

TEST PROCEDURE:<br />

6.8.1 VERIFY appropriate 4-20 mA using Exhauster Electrical Assembly Traveler<br />

Attachment D - Loop Check Table 1 (see Attachment 6.7).<br />

6.8.2 CONFIRM the acceptance criterion has been met<br />

6.8.3 PDlT-Kl-')07. Test DirectorL ~ QA Inspeco<br />

6..4 PDT-l-10Tet<br />

irctr_& - QAInp c<br />

6 w. DTK 30Ts irco.~§ Q npco<br />

6.8.5 PDIT-Kl-313 Test Director..~. QA Inspector .lw...<br />

6.8.6 Test Director VERIFY test is complete.<br />

Test Director Signature Date<br />

6.8.7 QA Inspector VERIFY test is complete.<br />

QA Inspector Signature Date<br />

20 Premier Technology, Inc. 006765.0.000-<strong>FAT</strong>-O01-1 (<strong>Rev</strong> 7)

RPP-RPT-49670 <strong>Rev</strong> 0<br />

PREMIE TECHNOLOGY, INC. Project No. . 0066..0<br />

(~~1VIE~R WRPS - 242-A Evaporator Ki Exhaust Confrac 40167<br />

P~iTcnlg Rnc Ventilationl Stem NO.<br />

Rr?'.SPC36062<br />

FACTORY ACCEPTANCE MET PLAN LSpeeo. Re 0<br />

6.9 Local 2 nd Stage HEPA Section Pressure indicators - Verify Differential<br />

Pressure Indicator Function<br />

MATRIX REFERENCE - line 33<br />

BaACKGROUND - Diffrrential Pressure is displayed and corresponding 4-20 MA signal is<br />

provided for operating range of -1 to 9 mnH 2O.<br />

COMPONENT B3EING TESTED:<br />

" PDIT-KI -308<br />

" PDIT-Kl-311<br />

" PDIT-Kl-314<br />

ACC1PTANCE CRMPRA - Localpressue indications anid orrspoding4 -20 mX<br />

output are within -I to 9 inH 2O.<br />

TEST PROCEDURE:<br />

6.9.1 vsRIFY appropriate 4-20 mA using Exhauster Electrical AssemblY Traveler<br />

Attachment D - Loop Check Table I (see Attahment 6.7).<br />

6.9.2 CONF]IRM the acceptance criterion hats been met<br />

6.9.3 PDIT-Kl -308 Test Dietr~QA Inspector Ct:-<br />

6.9.4 PDIT-Kl-311 Test Direcorjn,. QA Inspetor.i G.<br />

6.9.5 PDIT-KI-314 Test Director_1L!%- QA Inspector<br />

6.9.6 Test Director VERIFY test is complete.<br />

Test Director Signature<br />

6.9.7 QA Inspector VERIFY test is complete.<br />

QA Inspector Signature<br />

21 Premier Technology, Inc.<br />

Date<br />

Date<br />

006765.0.000-<strong>FAT</strong>-O01-1 (<strong>Rev</strong> 7)

RPP-RPT-49670 <strong>Rev</strong> 0<br />

PREMIER TECHNOLOGY, INC. Project No. 006'765.,000<br />

( E XIER WRPS - 24 2 -A Evapora t or Kl Exhaust Contract 406<br />

FACTORY ACCEPTANCE TEST PLAN ISpec No. I feo<br />

6.1OE xbaust Stack <strong>Sample</strong> Pitot Tube and Transport Lines - Leak test & Pitot<br />

Tube Alignment<br />

MATRIX RIF'ERENCE - line 46<br />

BACKGROUND - The stack sampling system shall be inspected for leaks at the time of<br />

installation in accordance with ANSI N13. 1, Section 6.9. PIC 3 stack allows for inspection<br />

as satisfactory method. Isolate and pressurize sample line to 5 psi.<br />

COMPONENT BEING TESTED:<br />

aExhiaust Stack sample pitot tube and transport lines<br />

ACCEPTANCE CRITERIA - No leaks detected using bubble testing on joints.<br />

TEST PROCEDURE:<br />

6.10.1 REVIEW AMC Factory Acceptance test <strong>Report</strong> section 3.1 (e- *Tktt-6 .io<br />

6.10.2 CONFIRM the acceptance criterion has been met.<br />

6.10.3 Test Director VERITY test is complete.<br />

Test Director Signature Date<br />

6.10.4 QA hInsector VERIFY test is complete. 1<br />

QA Inspector Signature Date<br />

6.11 Mass Flow Controller, Record <strong>Sample</strong>r and Vacuum Pump<br />

MATRIX REFERENCE - line 47<br />

BACKGROUND - RPP-SPEC-3 6062, <strong>Rev</strong>. 0, Section 3.3.4.2, # 10; <strong>Sample</strong> Flow<br />

Instrumentation: Each of the sample loops, including the record sampler loop and the CAM.<br />

sample loop shall include a mass flow controller Hastings model HFC-3 03, or Buyer<br />

approved equal. The flow controller shall send a 4-20 mA signal to the 242-A VCS and<br />

receive a 4-20 mA flew setpoint signal from the 242-A VCS. The sample flow will be held<br />

constant to accommodate the requirements of the collector or analyzer.<br />

COMPONENTS LIST:<br />

*22 Premier Technology, Inc. 006765.0.000-<strong>FAT</strong>-0O1-1 (<strong>Rev</strong> 7)

*<br />

PREMIER TECHNOLOGY, INC. Project No. 0067 5.0.0OO<br />

(~ W1 LIIR WRJ'S - 242-A Evaporator Ki Exhaust Contrat 40167<br />

VeEiltion te No.<br />

RPP-RPT-49670 <strong>Rev</strong> 0<br />

C<br />

RPP.SFEC-36062<br />

FACTORY ACCEPTAJNCE TEST PLAN spee <strong>Rev</strong>.<br />

*Mass Flow Controller Record <strong>Sample</strong>r and Vacuum Pump FCV-2.<br />

ACCEPTANCE CRITERIA -The flow read-out and totalizer function of the control valve<br />

will be within 10% of M&TE equipment (<strong>FAT</strong> only). <strong>Sample</strong> flow is constant as the<br />

exhauster flow is varied. <strong>Sample</strong> flow will be maintained at 85%. Record <strong>Sample</strong>r Flow<br />

Low Alarm at 85%/, indicator lights and strobe will activate.<br />

TEST PROCEDURR:<br />

* 1 6.11.1 REVIEW AMC Factory Acceptance Test <strong>Report</strong> section 4.2, 4.3, & 4.4 (NW sw e(wm<br />

6.11.2 CONflM the acceptance criterion has been met<br />

6.11.3 -Test Director VERIFY test is complete.<br />

Test Director Signature<br />

6.11.4 QA Inspector VERIFY test is complete.<br />

QA Inspector Signature<br />

6.12 Mass Flow Controller CAM and Vacuum PUMP<br />

mATRJX REFERENCE - line 48<br />

Date<br />

Date<br />

BACKGROUND- RPP-SPEC-36062, <strong>Rev</strong>. 0, Section 3.3.4.2, #10; <strong>Sample</strong> Flow<br />

bitrumentation: Each of the sample loops, including the record sampler loop and the CAM<br />

sample loop shall include a mass flow controller Hastings model HFC-303, or Buyer<br />

approved equal. The flow controller siall send a 4-20 mA signal to the 242-A VCS and<br />

receive a 42.20 mA flow set point signal from the 242-A VCS. The sample flow will be held<br />

constant to accommodate the requirements of the collector or analyzer.<br />

COMPONENTS BEING TESTED:<br />

*Mass Flow Controller Record <strong>Sample</strong>r and Vacuum Pump FCV-l<br />

ACCEPTANCE CRITERIA -The flow read -out and totalizer function of the control valve<br />

will be within 10%/ of M&TE equipment (<strong>FAT</strong> only). <strong>Sample</strong> flow is constant as the<br />

exhauster flow is varied. <strong>Sample</strong> flow will be maintained at 85%, CAM Flow Low Alarm<br />

activates at 85%, indicator lights and strobe will activate.<br />

25 Premier Technology, Inc.<br />

006765.O.000-<strong>FAT</strong>-001-1 (<strong>Rev</strong> 7)

PREMIER TECHNOLOGY, INC. Project No. 006765.0.000<br />

WRS-242-A Evaporator 1(1 Exhaust Czontract<br />

.~ehooy Inc. - Ventilation System No. 417<br />

TEST PROCEDURE:<br />

FACTORY ACCEPTANCE TEST PLAN Spec No.IRe0<br />

RPP-RPT-49670 <strong>Rev</strong> 0<br />

6.12.1 REVIEW AMC Factory Acceptance Test <strong>Report</strong> section 4.2,4.3, & 4AW " -- O<br />

6.12.2 'CONFIRM the acceptance criteria have been met.<br />

6.12.3 Test Director VERIFY test is complete.<br />

Test Director Signature Date<br />

6,12.4 QA Inspector VERIFY test is complete.<br />

QA Inspector Signature Date<br />

6.13Vacnu m Pump - Verify Pump operation<br />

NOTE: see section 7.25<br />

6.14 Continuous Air Monitoring - Verify CAM Alarm and Interlock Set point<br />

MATRIX REFERENCE - line 50<br />

BACKGROUND - RPP-SPEC-3 6062, <strong>Rev</strong>. 0, Section 3.3.4.2, #12: The local cabinet will<br />

have an alarm box assembly with indicating amber lights, a flashing beacon, and alarm bell.<br />

They will sound and illuminate when the alarmn condition exists.<br />

COMPONENT B~EING TESTED:<br />

. CAM Alarm and Interlock<br />

ACCEPTANCE CEJYCERIA - High Beta Alarm activates and exhauster fan shuts down at<br />

2000 CPM. Indicator light, strobe, and bell will alarm. MCS will display condition (signal<br />

output check in <strong>FAT</strong>). Exhauster fan shuts down on Beta monitor loss of signal. Indicator<br />

light and strobe will alarm. MCS will display condition (signal output check in <strong>FAT</strong>.). All<br />

exhauster automatic dampers and valves shall close on all exhauster shutdowns<br />

(continuity/voltage test).<br />

TEST PROCEDURE:<br />

6.14.1 REVIEW AMC Factory Acceptance Test <strong>Report</strong> section 4.6 (e AMW&AA~ur & .10)<br />

24 Premier Technology, Inc. 006765.0.000-<strong>FAT</strong>-001-1 (<strong>Rev</strong> 7)

RPP-RPT-49670 <strong>Rev</strong> 0<br />

PREMIER TECHNOLOGY, INC. project No. 006765.0.000<br />

(~ M ~ E<br />

E Inc.<br />

& Tecnolgy, ic.<br />

RS - 242-A Evapramtor Ki Exhaust<br />

Vettion Sstem<br />

FACTORY &CCEPTANCE TEST PLAN<br />

Contract<br />

No.<br />

SpecNo.<br />

406<br />

RP.SEC0 66<br />

Pwiehooy<br />

6.14.2 CONFIRM the accptanc,_criteria have been met.<br />

6.14.3 Test Djjtr VERIFY test is Complete.<br />

Test Direcator S ignature<br />

6.14.4 QA Inspector VERIFY test is complete.<br />

Date<br />

QA Inspector Signatur ' Date<br />

6.15 <strong>Sample</strong>r line Vacuum Indicator - Functional Test (P1-i1)<br />

NOTE: see section 7.3 0<br />

6.16 <strong>Sample</strong>r Line Vacuum Idicator - Functional Test (P1-2)<br />

NOTE: Section was remnoved; P1-2 does not exist on final design.<br />

6.17 CAM Operation - Verify No Electromagnetic Radiation Interference<br />

NOTE: see section 7.26<br />

6.18 Sampling system instrumnentationl and wiring - Continuity<br />

MATRIX REFERENCE - line 54<br />

BACKGROUND - Testing per RPP-SPEC-3 6062, <strong>Rev</strong>. 0, Section 4.1.9<br />

COMPONENT BEIG TESTED:<br />

.Electrical wiring<br />

*ACCEPTANCE c~iTE1A -Resistance shall be S 1 olum for continuity checks for<br />

wiring #14 AWG and larger and 5 3 ohms for wiring #16 AWG and smaller.<br />

TEST PROCEDUJRE:<br />

6.18.1 REVIEW AMC shop traveler for Instrumentation and Control Enclosure (see<br />

Attachment 6. 18).<br />

6.18.2 CONFIRM the acceptance criteria have been met.<br />

25 Premier Technology, Inc.<br />

006765.O.OOO-<strong>FAT</strong>-OO1-1<br />

(<strong>Rev</strong> 7)

RPP-RPT-49670 <strong>Rev</strong> 0<br />

PREMIER TECHNOLOGY, INC. Project No. 006765.0.000<br />

( WEM4IER<br />

~wiTcn~gy n<br />

WRPS - 242-A Evaporator Ki Exhaust<br />

Ventilation System<br />

ecPP-SPEC-36062<br />

FACTORY ACCEPTANCE TEST PLAN<br />

Contract<br />

No.<br />

Spec No.<br />

40167<br />

RPPSev 0 6<br />

6.18.3 Test Director VERIFY test is complete. .-<br />

Test Director Signature Date<br />

6.18.4 QA Inspector VERIFY test is complete.<br />

/ /c~<br />

QA Inspector Signature Date<br />

6.19 <strong>Sample</strong> Cabinet cooling fan - Functional test<br />

NOTE: see section 7.27<br />

6.20 Flow Sensor - Verify Exhauster Flow Indication<br />

MATRIX REFERENCE - line 58<br />

BACKGROUND - This test is to verify Exhauster Flow Indications.<br />

COMPONENT BEING TESTED: ~ ~<br />

0 Flow Sensor ('~Y~"~IJ<br />

ACCEPTANCE CRITERIA - Flow is indicated at a range of " O e 19,50& scfm<br />

TE ST PROCEDURE:<br />

6.20.1 REVIEW AMC Factory Acceptance Test <strong>Report</strong> Section 4.5, UeF AVIITA~k E1& .IeA4.<br />

6.20.2 CONFIRM the acceptance criterion has been met.<br />

6.20.3 Test Director VERIFY test is complete.<br />

/4 HI'4<br />

Test Director Signature Date<br />

6.20.4 QA Inspector VERIFY test is complete.<br />

QA Inspector Signature Date<br />

26 Premier Technology, Inc. 006765.0.000-<strong>FAT</strong>-001-1 (<strong>Rev</strong> 7)

(~<br />

PREMIER TECHNOLOGY, INC. ProjectNo. 006765.0.000<br />

E I R WRPS - 242-A Elvaporator K1 Exhavist Contract 06<br />

~Ventilationl System ____<br />

RPP-RPT-49670 <strong>Rev</strong> 0<br />

rechrio~og~<br />

rAcTORY ACCEPTANCE TEST PLAN Spec No,.<br />

RMPSPEC-36062<br />

<strong>Rev</strong><br />

6.21 Sampling Manifold - Qualification of Filter Samplingr System<br />

MATRIX REFERENCE - line 44<br />

BACKGROUND - Sampling manifolds shall be qualified to demonstrate that they collect a.<br />

representable sainple equivalent to a single-point sample taken at a point at least ten, duct<br />

diameters downstream of the filters.<br />

COMPONENT BEING TESTED:<br />

* Filter Traia A<br />

* Filter rain B<br />

* Filter Train C<br />

ACCEpTANCE cRrTERIA - Sampling manifolds shall be kWxa to or greater than the<br />

concentration detected with the single-point sample.<br />

TEST PROCEDURE:<br />

6.21.1 REVIEW manufactilrer's certification documents located in Attachment 6.21<br />

6.21.2 CONFIRM the acceptance criterion has been met by initialing data table.<br />

<strong>FAT</strong> 6.21<br />

Sit1ter Thin LWt Saddled<br />

ASME N510<br />

Duisfied<br />

Initials<br />

Test QA<br />

Diretor to<br />

*FilterTr,iaDB<br />

Filter Train A<br />

I-A<br />

e<br />

Cb<br />

iter Train, C X<br />

6.21.3 Test Director VFIUFY test is complete.<br />

* Test Director Signature<br />

6.21.4 QA Inspector VERIFY test is complete.<br />

27 Premier Technolog y, Inc.<br />

Date<br />

006765.O.OOO-<strong>FAT</strong>-OO1-1 (<strong>Rev</strong> 7

RPP-RPT-49670 <strong>Rev</strong> 0<br />

PREMER TECHNOLOGY, INC. Project No. 006765.0.000<br />

(iM IERT~' AWS - 242-A Evaporator KI Exhaust Contract 40167<br />

Tehooy n. -Ventilation System -. No.<br />

FACTORY ACCEPTANCE TEST PLAN spe No RPPSPEC,36062<br />

_______________<br />

________________________ <strong>Rev</strong> 0<br />

QA Inspector Signature Date<br />

6.22 Fan and Motor - Vibration ()Driv*e motor rotating elements) & Sound.<br />

MATRIX REFERENCE - line 5 & 7<br />

BACKGROUND - Prior to taking the vibration measurements, the fans shall be operated at<br />

the'normal operating speed for a ran in period of time until the bearings reach a stable<br />

equilibrium temperature L+3 0 F over 10 minutes).<br />

The fin speed for the impeller over speed test requirement is 15% above the speed with the<br />

fan operating with a motor input frequency of 60Hz. Motor and fan speeds shall be<br />

recorded. Sound power level ratings shall be taken in accordance with either AMCA 300 or<br />

ASEAE 68<br />

COMPONENTS BEING TESTED:<br />

* KI-5-2<br />

9 Kl-5-3<br />

ACCEPTANCE CRITERIA -<br />

* The criteria for low horsepower, industrial process or petrochemical applications,<br />

FanApplication Category BV-3, 3.8 mm/s peak velocity (filter in). The impeller of<br />

each fan shall be over speed tested to a minimum of 15% above its maximum<br />

operating speed for 10 minute duration without increased vibration. Visual<br />

inspection shall serve to further verify that no deformation or cracks have occurred.<br />

" Mechanical equipment noise emissions at the maximum flow rate condition shall<br />

not create noise levels equal to or greater than 85 dBA 8-hour time weighted<br />

average, or equivalent noise dose, takcen 1 m away from source.<br />

TEST PROCEDURE:<br />

6.22.1 REVICEW manufacturer's certification documents located in Attachment 6.22 (see<br />

Twin City Fan Test Procedure/<strong>Report</strong> Fan Vibration test Sound data will be attached<br />

in test report)<br />

6.22.2 CONFIRM the acceptance cr iterion has been met by initialing data table.<br />

<strong>FAT</strong> 6.22 Vibration Initials<br />

28 Premier Technology, Inc. 006765.0.000-<strong>FAT</strong>-001-1 (<strong>Rev</strong> 7)

PREMIER TrECHNOLOGY, INC. ProjeetNo. 006765.0.000<br />

(~T~ AT R<br />

4T<br />

wRPS 242-A Evaporator KI Er~haUgt<br />

~Ventilation sstem<br />

ContrAct 40161<br />

FACTORY ACCEPTANCE TEST P'LAN SpUcNo. It<br />

E~quipmenlt Stsk UuibdD~eda -W<br />

K1-5-2 -4<br />

KI-5-3<br />

Equipment S~dDoo mc<br />

6.22.3 Test Director VBEFY test is complete.<br />

Test Director Signature<br />

6.22.4 QAban ector VXBXFY test is complete.<br />

QA Inspector Signature<br />

Date<br />

Date<br />

RPP-RPT-49670 <strong>Rev</strong> 0<br />

6.23 Inlet Plenum & Expansion Joints - Pressure Dlecay Test & Bubble Leak<br />

Test<br />

7 Procedure<br />

NOTE: see section 7.28<br />

7.1 Valves/Damapers Visual Inspectionls<br />

* ]&.nIX PR PENCF, - linie 22<br />

BACKGROUND - (ASWvI AG-i TA-3510) a visual inspection is to be conducted to verify<br />

all components are istalled in accordance with the Owner's design specification. This<br />

inspection is to be co-nducted prior to releasing the equipment for normal operation.<br />

ASME AG-i TA--1200 DAMPER. INSPECT[ON ITEMS:<br />

* housing and duct interface<br />

. actuator linkage, motor, and controller<br />

0 interferences with moving parts<br />

* damper shaft seal<br />

0 blade edge seals and damper seat<br />

29 Premier Technology, Inc.<br />

006765.O.OO-<strong>FAT</strong>-0O1-1 (<strong>Rev</strong> 7)

RPP-RPT-49670 <strong>Rev</strong> 0<br />

PREMIER TECHNOLOGY, INC Project No. 006765.0.000<br />

. P -., MT ju_/rRS VWPS - 24-2-A Evaporator I Exhaust Contract 40167<br />

\~.L~.~j.J.J..Ll.Ventilation SystemNo<br />

FACTORY ACCEPTANCE TEST PLAN Spec No. RP-SEC366<br />

* limit switches<br />

* supports and attachments<br />

'9 bolting and fasteners<br />

* electrical connections<br />

a as-built configuration in accordance with design drawings<br />

* damper nameplate<br />

m provisions for access for performing tests and maintenance<br />

COMPONENT BEING TESTED:<br />

* KI-MOV-001<br />

* KI-MOV-002<br />

* KI-BDD-001<br />

* Kl-BDD-002<br />

- K1-DhPR-001<br />

a Kl-DNTR-002<br />

ACCEPTANCE CRITERIA - Visual inspections are acceptable when there are no<br />

indications of improper installation, physical damage, structural distress or degradation that<br />

would impair the ability of the component or system to perform its intended fimotion.<br />

TEST PROCEDIJRE:<br />

7.1.1 VERIFY all inspection items listed in ASME AG-lTA-I-1200<br />

7.1.2 CONFIRM the acceptance criteria have been met for each damper.<br />

<strong>FAT</strong> 7.1 ASME AG-i, TA-3510 Iiil<br />

Daprit Improperly Installed Physical Damage Structural Distress Test QA<br />

Iapelis es No Yes No Yes No 'Drector Inkspector<br />

KI-MOV-001<br />

K1-MOV-002 __<br />

KI-BDD-001<br />

KI-BDD-002<br />

Xl-DMPR-001<br />

Kl-DMPR-002<br />

30 Premier Technology, Inc. 006765.0.000-<strong>FAT</strong>-0O1-1 (<strong>Rev</strong> 7)

PREMIER TECENOLOGY, INC. Projeet No. 006765.0.000G<br />

~ ~~M ER WES - 24Z A vaor tor 1(1 EXhaust Conftic 016<br />

P " E IER:<br />

& Tcho]Og, nc FACTQRY ACCEPTANCE TES~PLAN Spec No. Re 0<br />

RPP-RPT-49670 <strong>Rev</strong> 0<br />

~ s-2"k SytemPN. M C-3 6 0 62<br />

7.1.3 .Test Director VERIY test is comaipete4 ve-' wait<br />

Test Director Signature<br />

7.1.4 QA Inspector yERF testis comple<br />

QA inspector Signature<br />

7.2 Valve/Dampers - Verify Isolation Valve Position Indication and Function<br />

MATRIKX FERE9NCE -line 25'<br />

'BACKGROUJND - prior to the initial pressurizing of the dampe conirol system, Pneumatic<br />

system shall be checked for proper installation And 1eak-tightflesS. Dampers having remote<br />

position indicators shall be observed during operation to verify tgat the mechanical damper<br />

position corresponds to the remote indication, power-operated dampers shall be fuly cycled<br />

using a contrul switch or other actuating device to Verify operation.<br />

COMPONEZNT BEING TXSTE<br />

* KI-MOV-001<br />

" Kil-MOV-QO2.<br />

ACCEPTANCE CRMREIA-<br />

*ASME AG-i TA-4244 Verify that thp.dampers indicator corresponds to the remote<br />

indication.<br />

.ASNM AG-I TA-4245 Damper must fully Cycle<br />

*ASME AG-i TA-4246 Maximum time for any of the cycles shall be less than 20<br />

seconds.<br />

TEST PROCEDUPE-<br />

7.2.1 CONFIEM indicator mark position matches actual damper Position.<br />

7.2.2 RECORD the position of the shaft where it enters the duct in the table below (the<br />

mark should be perpendicular to the duct when the damper is Closed).<br />

31 Premier Technology, Inc. 0O75.OJA OI(ev)<br />

Dat<br />

Dt

RPP-RPT-49670 <strong>Rev</strong> 0<br />

PREAMR TECHNOLOGY, WNC. Project No. 006765.0,000<br />

UP~E MA IER WRPS -2Z42-A Evaporator Ki Exhaust Contr-d 40167<br />

~Technology, jic Ventilation SystemN.<br />

FACTORY ACCEPTANCE TEST PLAN Spec No. PP-SPE-36062<br />

____________________<br />

_______________________________<strong>Rev</strong> 0<br />

7.2.3 ENSURE power to the controller/positioner is on (Note MPZ Breaker in the table<br />

below).<br />

7.2.4 'INSTALL temporary power source to TB-6 terminals 13 and 14 (this is to bypass the<br />

high radiation interlock to the fans).<br />

7.2.5 CHECK for Initial Voltage on the "D~amper Closed" terminal to ground - should be<br />

.0 VAC (See location in table below).<br />

7.2.6 CHECK for Initial Voltge on the "Damper Open" terminal to ground - should be<br />

120 VAC.(See location in table below).<br />

7.2.7 REMOVE the "Run Permissive (RPR) Relay" wire to prevent the fan from starting<br />

and protect it from shorting with a wire nut or other appropriate means (Get location<br />

ftrm table).<br />

7.2.8 SELECT Run on the VFD and verify that the dam per moves to the fll open position<br />

(Mark should be parallel with the duct)<br />

7.2.9 RECORD the Final Voltages of the "Damper Open" and "Damper Closed"<br />

terminals (These should be 120 VAC and 0 VAC respectively).<br />

7.2.10 RECORD the Final Observed position of the damper.<br />

7.2.11 RETURN the VFD Run switch to the Stop Position and note that the damper closes.<br />

7.2.12 RE-CONNECT the RPR relay wire.<br />

7.2.13 INITIAL for completion.<br />

7.2.14 REPEAT steps 7.2.2-7.2-12 for the other fan.<br />

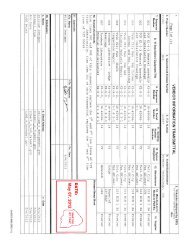

7.2 Isolation Damper Position Initials<br />

ENCIld.i<br />

__ a0 Dam~per Cosed Toradls Damper pn Terminals~<br />

Limpt Dtmt 0rIpe# TtPRQ<br />

Lit RRpesigiti amer ]3k,<br />

By Direotor Inspector<br />

MOV- 1 Tn-S<br />

001 #1<br />

X1. T&S 11<br />

Nov- 2 2<br />

002<br />

7.2.15 CONFIRM damper fully cycles.<br />

32 Premier Technology, Inc. 006765.0.000-<strong>FAT</strong>-001-1 (<strong>Rev</strong> 7)

MBMIXR TECHNOLOGY, INC. Project No. OW6610.000<br />

ER WR PS - 242-A Evaporator KI Exhaust Contract 40167<br />

P noec Ventilation 8 Stemn No.<br />

FACTORY ACCEPTANCE TEST PLAN Spec No, <strong>Rev</strong> 0<br />

7.2.16 MEASUIM the time for the damper to fully open or fully close.<br />

7..7REMOVE temporary power from terminals 13 and 14 on TB-6.<br />

7.2.18 CONFIRM the acceptance criteria have been met for each damper.<br />

MC-MOV-001<br />

matches damper Damper Pully cycdes Te QA<br />

7.2.19 Test Director VERIFY test is competes III<br />

Test Director Signature<br />

7.2.20 QA Insp ector RY eBIteis 011 WV , i~<br />

QA Inspector $ignaline<br />

7.3 Filter Train - Visual Inspectioui<br />

MATRIX DFERENCE, - line 38<br />

Date<br />

Date<br />

RPP-RPT-49670 <strong>Rev</strong> 0<br />

BACKGROUND - (ASMB AG-i TA-3 510) a visual inspection is to be conducted to verify<br />

-all omponejIts ame installed in accordance with the Owner's design specification. This<br />

inspection is to be conducted prior the releasing the equipment for normal operation. A<br />

Visual inspection is to be performed on the filter train, inlet, outlet, cormmon switching<br />

plenum isolation valves, transition to fan inlet, and flexible metal connector sections in<br />

accordance with AG-I<br />

COMPONENTS BEING TESTED:<br />

* Filter Train A<br />

* Filter Train B<br />

* Filter Train C<br />

33 Premier Technology, Inc-<br />

006765..O00<strong>FAT</strong>OO01-1 (<strong>Rev</strong> 7)

RPP-RPT-49670 <strong>Rev</strong> 0<br />

PREMIER TECHNOLOGY, INC. Project No. 006765.0.000<br />

(P& EA4II3R MWIRWS - 242-A Evaporator KI Exhaust Contract 40167<br />

\ciTechnolog. nc. Ventilation System No.<br />

FACTORY ACCEPTANCE TEST PLAN Spec No.<br />

ACCEPTANCE CRMTRIA - Visual inspections are acceptable when there are no<br />

indications of improper installation, physical damage, structural distress or degradation that<br />

would impair the ability of the component or system to perform its intended function.<br />

TEST PROCEDURE:<br />

7.3.1 VERITY all inspection items listed, check box for if item is free of physical damage,<br />

structural. distress or degradation that would impair the ability of the component or<br />

system of perform its intended function.<br />

<strong>FAT</strong> 7.3 ASME AG-i, TA-3510<br />

inpetin tes-Filter Filter Filter<br />