EIGER LHSD LABORATORY DISPERSER - ThomasNet

EIGER LHSD LABORATORY DISPERSER - ThomasNet

EIGER LHSD LABORATORY DISPERSER - ThomasNet

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

EMI <strong>LABORATORY</strong> MIXER & <strong>DISPERSER</strong><br />

<strong>LABORATORY</strong> & PILOT SCALE<br />

BATCH PROCESSING<br />

Mixing & Dispersing Applications<br />

• Ideal for producing laboratory samples and<br />

small production batches.<br />

• Heavy-duty motor provides constant<br />

RPM & constant torque even under load.<br />

• General purpose or explosion proof<br />

electrical motors & controls.<br />

• AC variable frequency driven.<br />

• Digital gauges to monitor RPM,<br />

amperage, power, time, temperature<br />

& power (kwh) available.<br />

• Mixing & dispersing blades, rotor stator<br />

head & batch bead milling systems<br />

available.<br />

• Quiet operation.<br />

• System includes electrical operator controls<br />

and variable frequency drive panel.<br />

For information or demonstration contact:<br />

0.5, 1, 2, 3 Horsepower<br />

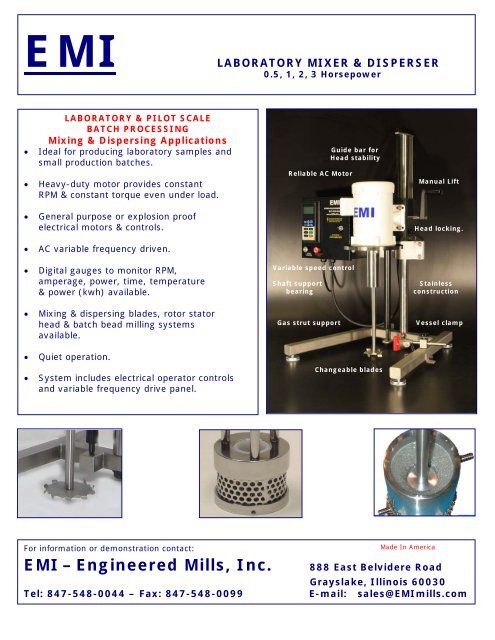

Reliable AC Motor<br />

Variable speed control<br />

Guide bar for<br />

Head stability<br />

Manual Lift<br />

Head locking.<br />

Shaft support Stainless<br />

bearing construction<br />

Gas strut support Vessel clamp<br />

Changeable blades<br />

HIGH SHEAR <strong>DISPERSER</strong> ROTOR/STATOR MIXER BATCH BEAD MILL<br />

Made In America<br />

EMI – Engineered Mills, Inc. 888 East Belvidere Road<br />

Grayslake, Illinois 60030<br />

Tel: 847-548-0044 – Fax: 847-548-0099 E-mail: sales@EMImills.com

EMI - <strong>LHSD</strong><br />

Laboratory High Speed Disperser / Mixer<br />

Efficient dispersion of organic and inorganic materials by<br />

providing enough mechanical energy to breakdown the forces<br />

holding the particles together. The <strong>LHSD</strong> disperser is designed to<br />

emulsify, homogenize, mix and disperse solids into liquids. Used<br />

for efficient wetting of particles or the pre-dispersion of products<br />

before milling.<br />

Selection of the correct unit is determined by a number of<br />

factors including batch volume, viscosity, rpm range and the<br />

container sizes most often used and the environment they are to<br />

be working in.<br />

Ease of operation with speed control via operator dial speed<br />

control. Manual lift assisted by pneumatic cylinder. Vessel held in<br />

place with container clamp.<br />

DIMENSIONS: INCHES/CENTIMETERS<br />

BASE: 14” X 17” / 36 X 43CM<br />

LOWERED HEIGHT: 28” / 71 CM<br />

RAISED HEIGHT: 40 “ / 101 CM<br />

Note: Smaller or larger frames available to meet<br />

customer requirements.<br />

EMI<br />

Engineered Mills, Inc.<br />

888 E. Belvidere Road – U214<br />

Grayslake, Illinois 60030 847-548-0044<br />

E-Mail: sales@EMImills.com<br />

Made in America<br />

Explosion Proof Mixer<br />

Rotor-Stator mixing heads increase<br />

mixing intensity by adding mechanical<br />

impact forces along with hydraulic<br />

shearing forces for dispersing, particle<br />

reduction, emulsifying & homogenizing.<br />

The VFD drive system provides smooth<br />

adjustable speed and constant torque to<br />

the mixing system. Process speeds from 0<br />

to 5000 rpm.<br />

Monitoring of the process functions<br />

including power, temperature, speed and<br />

time will allow the processing results to be<br />

used to correlate to production<br />

equipment.<br />

Sizes available:<br />

0.5, 1, 2, 3 Horsepower<br />

General Purpose & Explosion proof<br />

electrical controls, gauges and safety<br />

systems available.<br />

Frame: Stainless “H” Base design.<br />

Contact EMI for additional information<br />

and to discuss your application in detail.<br />

Equipment can be modified to meet<br />

individual requirements