HOUTTUIN B.V. - Filter

HOUTTUIN B.V. - Filter

HOUTTUIN B.V. - Filter

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

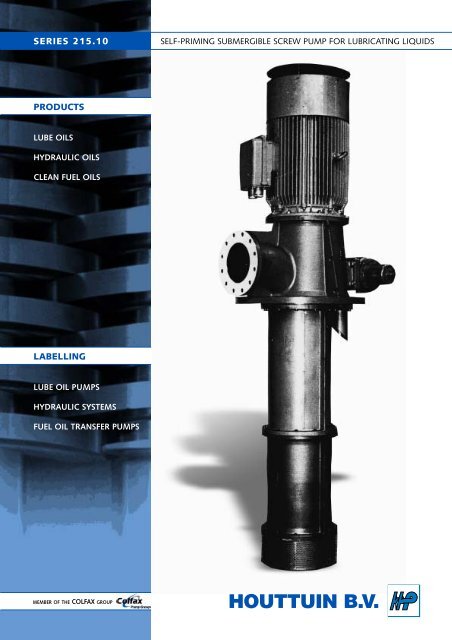

SERIES 215.10<br />

PRODUCTS<br />

LUBE OILS<br />

HYDRAULIC OILS<br />

CLEAN FUEL OILS<br />

LABELLING<br />

LUBE OIL PUMPS<br />

HYDRAULIC SYSTEMS<br />

FUEL OIL TRANSFER PUMPS<br />

MEMBER OF THE COLFAX GROUP<br />

SELF-PRIMING SUBMERGIBLE SCREW PUMP FOR LUBRICATING LIQUIDS<br />

<strong>HOUTTUIN</strong> B.V.

SERIES 215.10<br />

AVAILABLE MATERIALS<br />

GENERAL INFORMATION<br />

Principle<br />

The Houttuin double entry screw pumps<br />

series 215 are rotating self-priming positive<br />

displacement pumps. The pump is constructed<br />

for submergible application and has<br />

therefore a very good NPSH-value.<br />

Two inter-meshing screws rotating in a pump<br />

casing ensure high pumping efficiency with<br />

constant axial flow and unequalled suction<br />

power.<br />

Construction<br />

The spindles are supported and axially held in<br />

position by ball bearings. The transmission of<br />

torque from the driven spindle to the idler<br />

spindle is effected by product lubricated<br />

timing gears in an attached gearbox. The ball<br />

bearings and timing gears maintain a small<br />

clearance between the screws, thus preventing<br />

metal to metal contact.<br />

Shaft sealing<br />

Product lubricated single unbalanced<br />

mechanical seal.<br />

Overload protection<br />

For protection against overload a built-on<br />

spring loaded relief valve can be supplied.<br />

Applications<br />

For pumping lubricating oils, hydraulic oils<br />

or other lubricating liquids which do not<br />

contain abrasive substances nor chemically<br />

attack the pump materials.<br />

As lub oil pumps in ship and offshore engineerings,<br />

as filling pumps in tank farms and<br />

in hydraulic systems.<br />

Products<br />

- Lubricating oils<br />

- Hydraulic oils<br />

- Clean fuel oils<br />

FOR PUMP AND MECHANICAL SEAL:<br />

Labelling<br />

- Main lub oil pumps<br />

- Auxiliary lub oil pumps<br />

- Hydraulic systems<br />

- Fuel oil transfer systems<br />

Performance data<br />

Capacity Q up to 490 m 3<br />

/h<br />

Viscosity range<br />

Temperature of<br />

V 20 to 760 cSt<br />

pumped liquid t up to 80 o<br />

C<br />

Inlet pressure not applicable<br />

Outlet pressure<br />

Difference<br />

pd up to 10 bar<br />

pressure ∆p up to 10 bar<br />

Speed n up to 2900 rpm<br />

Flanges according to DIN or ANSI<br />

Pump Mechanical seal according to DIN 24960 / API<br />

Screw shafts Casing and Covers Seal faces Springs ‘O’ -rings<br />

- Carbon Steel - Cast Iron - Chrome Steel - Stainless - Viton<br />

- Nodular Cast Iron against Steel<br />

Cast Iron - Carbon (Type 300)<br />

1

SERIES 215.10<br />

m 3 /h<br />

m 3 /h<br />

PERFORMANCE GRAPHS<br />

0<br />

440<br />

14.5 29 43.5 58 72.5<br />

n=950<br />

87 101.5 116 130.5 145<br />

1936<br />

420<br />

1848<br />

400<br />

380<br />

360<br />

340<br />

320<br />

300<br />

280<br />

260<br />

240<br />

220<br />

200<br />

180<br />

160<br />

140<br />

120<br />

100<br />

80<br />

0 1 2 3 4 5 6 7 8 9 10<br />

500<br />

450<br />

400<br />

350<br />

300<br />

250<br />

200<br />

150<br />

100<br />

∆p PSI<br />

210<br />

180<br />

165<br />

150<br />

0 14.5 29 43.5 58 72.5 87 101.5 116 130.5 145<br />

n=1150<br />

210<br />

180<br />

165<br />

150<br />

0 1 2 3 4 5 6 7 8 9 10<br />

Flow rate/pressure at minimum and maximum viscosity according to pump size.<br />

For exact performance data dependent of viscosity and rpm please refer to the individual<br />

characteristics per pump size.<br />

1760<br />

1672<br />

1584<br />

1496<br />

1408<br />

1320<br />

1232<br />

1144<br />

1056<br />

968<br />

880<br />

792<br />

704<br />

616<br />

528<br />

440<br />

2420<br />

2200<br />

1980<br />

1760<br />

1540<br />

1320<br />

1100<br />

880<br />

660<br />

600<br />

550<br />

500<br />

450<br />

400<br />

350<br />

300<br />

250<br />

200<br />

150<br />

750<br />

700<br />

650<br />

600<br />

550<br />

500<br />

450<br />

400<br />

350<br />

300<br />

250<br />

200<br />

∆p PSI<br />

210<br />

180<br />

165<br />

150<br />

0 1 2 3 4 5 6 7 8 9 10<br />

2640<br />

2420<br />

2200<br />

1980<br />

1760<br />

1540<br />

1320<br />

1100<br />

150<br />

660<br />

0 1 2 3 4 5 6 7 8 9 10<br />

∆p bar ∆p bar<br />

0<br />

650<br />

14.5 29 43.5 58 72.5<br />

n=1450<br />

87 101.5 116 130.5 145<br />

2860 US gpm<br />

0<br />

800<br />

14.5 29 43.5 58 72.5<br />

n=1750<br />

87 101.5 116 130.5 145<br />

3520 US gpm<br />

210<br />

180<br />

165<br />

150<br />

880<br />

660<br />

3300<br />

3080<br />

2860<br />

2640<br />

2420<br />

2200<br />

1980<br />

1760<br />

1540<br />

1320<br />

1100<br />

880<br />

2

SERIES 215.10<br />

CONSTRUCTION<br />

Drive by commercial standard motors,<br />

construction V1, all types of enclosure<br />

possible.<br />

Motor bracket for direct mounting<br />

on the tanktop.<br />

Single unbalanced mechanical seal<br />

lubricated by the liquid pumped.<br />

For overload protection a direct<br />

mounted pressure relief valve is optional.<br />

The length of the intermediate pipe<br />

is on request.<br />

Safe lubricating/cooling of ball bearing,<br />

timing gears by internal circulation of<br />

liquid pumped.<br />

Safe transmission of torque through<br />

the hardened and ground timing gears<br />

lubricated by the liquid pumped.<br />

Amply dimensioned and maintenance<br />

free ball bearings lubricated by the<br />

liquid pumped, which additionally serve<br />

for the axial thrust of the spindles.<br />

Axial forced balanced through double<br />

entry spindles.<br />

The special profile of the spindle<br />

flanks results in continuously and<br />

nearly pulsation-free pumping,<br />

high efficiency, good NPSH-values<br />

and constant pressure course.<br />

Rigid spindles of solid material therefore<br />

contact-free running and compared with<br />

multi-part spindles no crevice corrosion.<br />

Strainer as an integrated part of the pump.<br />

3

SERIES 215.10<br />

DIMENSIONS<br />

Sense of rotation:<br />

clockwise seen from<br />

drive side<br />

Discharge flange<br />

Bottom view<br />

connectionflange<br />

PUMP<br />

SIZE<br />

FLANGES PN16 DIN 2533 PUMP FOOT<br />

A B C D E a b c e s a1<br />

150 250 405 355 12x26 55 850 700 40 780 12x27 505<br />

165 250 405 355 12x26 55 850 700 40 780 12x27 540<br />

180 250 405 355 12x26 55 850 700 40 780 12x27 690<br />

210 350 520 470 16x26 73.5 990 850 45 920 12x27 725<br />

PUMP PUMP DIMENSIONS RELIEF<br />

SIZE<br />

VALVE SIZE<br />

g i j k o p q r L<br />

150 500 405 575 32 250 850 405 200 on request 100<br />

165 500 405 575 32 250 870 405 200 on request 100<br />

180 500 405 575 32 250 880 405 200 on request 100<br />

210 600 515 880 36 300 1010 580 300 on request 160<br />

dimensions in mm, dimensions are subject to alternations.<br />

4

SERIES 215.10<br />

STANDARD PUMPS<br />

NON-STANDARD PUMPS<br />

ENGINEERED PUMPS<br />

<strong>HOUTTUIN</strong> B.V.<br />

Sophialaan 4, 3542 AR Utrecht<br />

The Netherlands<br />

P.O. Box 76, 3500 AB Utrecht<br />

The Netherlands<br />

Phone 31 - (0)30 - 2484611<br />

Telefax 31 - (0)30 - 2411845<br />

Telex 47280<br />

Internet http://www.allweiler.de<br />

MEMBER OF THE COLFAX GROUP<br />

PERFORMANCE DIAGRAMS TOTAL PUMP PROGRAM*)<br />

*) The diagrams show the performance range of the different pump series in our pump program and are for information only.<br />

With Internal Bearings<br />

for lubricating liquids<br />

viscosity range : 20 - 760 cSt<br />

: 98 - 3500 SSU<br />

With External Bearings<br />

for non-lubricating liquids<br />

viscosity range : 0,6 - 1500 cSt<br />

: 32 - 7000 SSU<br />

With Internal and<br />

External Bearings<br />

for lubricating and<br />

non-lubricating liquids<br />

viscosity range : 0,6 - 100.000 cSt<br />

: 32 - 466.000 SSU<br />

With Internal and<br />

External Bearings<br />

for lubricating and<br />

non-lubricating liquids<br />

viscosity range : 0,6 - 100.000 cSt<br />

: 32 - 466.000 SSU<br />

<strong>HOUTTUIN</strong> B.V.<br />

04.03.215.10 E 5