non-return valves PN 250-500 High-pressure DN 10-50 ... - Filter

non-return valves PN 250-500 High-pressure DN 10-50 ... - Filter

non-return valves PN 250-500 High-pressure DN 10-50 ... - Filter

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Type series booklet<br />

7692.1/4-<strong>10</strong><br />

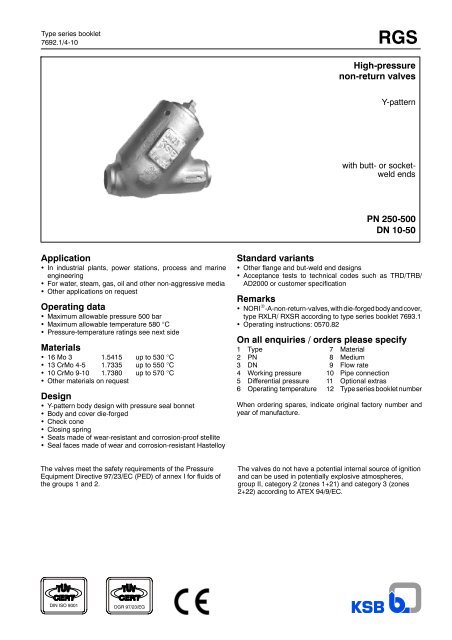

Application<br />

In industrial plants, power stations, process and marine<br />

engineering<br />

For water, steam, gas, oil and other <strong>non</strong>-aggressive media<br />

Other applications on request<br />

Operating data<br />

Maximum allowable <strong>pressure</strong> <strong><strong>50</strong>0</strong> bar<br />

Maximum allowable temperature 580 C<br />

Pressure-temperature ratings see next side<br />

Materials<br />

16 Mo 3 1.5415 up to 530 C<br />

13 CrMo 4-5 1.7335 up to 5<strong>50</strong> C<br />

<strong>10</strong> CrMo 9-<strong>10</strong> 1.7380 up to 570 C<br />

Other materials on request<br />

Design<br />

Y-pattern body design with <strong>pressure</strong> seal bonnet<br />

Body and cover die-forged<br />

Check cone<br />

Closing spring<br />

Seats made of wear-resistant and corrosion-proof stellite<br />

Seal faces made of wear and corrosion-resistant Hastelloy<br />

The <strong>valves</strong> meet the safety requirements of the Pressure<br />

Equipment Directive 97/23/EC (PED) of annex I for fluids of<br />

the groups 1 and 2.<br />

DIN ISO 9001 DGR 97/23/EG<br />

RGS<br />

<strong>High</strong>-<strong>pressure</strong><br />

<strong>non</strong>-<strong>return</strong> <strong>valves</strong><br />

Y-pattern<br />

with butt- or socketweld<br />

ends<br />

<strong>PN</strong> <strong>2<strong>50</strong></strong>-<strong><strong>50</strong>0</strong><br />

<strong>DN</strong> <strong>10</strong>-<strong>50</strong><br />

Standard variants<br />

Other flange and but-weld end designs<br />

Acceptance tests to technical codes such as TRD/TRB/<br />

AD2000 or customer specification<br />

Remarks<br />

NORI R -A-<strong>non</strong>-<strong>return</strong>-<strong>valves</strong>,with die-forgedbody andcover,<br />

type RXLR/ RXSR according to type series booklet 7693.1<br />

Operating instructions: 0570.82<br />

On all enquiries / orders please specify<br />

1 Type 7 Material<br />

2 <strong>PN</strong> 8 Medium<br />

3 <strong>DN</strong> 9 Flow rate<br />

4 Working <strong>pressure</strong> <strong>10</strong> Pipe connection<br />

5 Differential <strong>pressure</strong> 11 Optional extras<br />

6 Operating temperature 12 Type series booklet number<br />

When ordering spares, indicate original factory number and<br />

year of manufacture.<br />

The <strong>valves</strong> do not have a potential internal source of ignition<br />

and can be used in potentially explosive atmospheres,<br />

group II, category 2 (zones 1+21) and category 3 (zones<br />

2+22) according to ATEX 94/9/EC.

Pressure-Temperature ratings<br />

2<br />

Nominal bore Material Material no. Remark Working <strong>pressure</strong>s at temperatures in C<br />

<strong>DN</strong> to 300 3<strong>50</strong> 400 425 4<strong>50</strong> 475 <strong><strong>50</strong>0</strong> 5<strong>10</strong> 520 530 540 5<strong>50</strong> 560 570 580<br />

<strong>10</strong>--<strong>50</strong> 16 Mo 3<br />

13 CrMo 4-5<br />

<strong>10</strong> CrMo 9<strong>10</strong><br />

<strong>10</strong>--25 16 Mo 3<br />

13 CrMo 4-5<br />

<strong>10</strong> CrMo 9-<strong>10</strong><br />

32--<strong>50</strong> 16 Mo 3<br />

13 CrMo 4-5<br />

<strong>10</strong> CrMo 9-<strong>10</strong><br />

1.5415<br />

1.7335<br />

1.7380<br />

1.5415<br />

1.7335<br />

1.7380<br />

1.5415<br />

1.7335<br />

1.7380<br />

Butt weld ends machined<br />

see type series booklet<br />

= <strong>PN</strong> 320<br />

Butt weld ends<br />

unmachined<br />

=<strong>PN</strong><strong><strong>50</strong>0</strong><br />

Butt weld ends<br />

unmachined<br />

=<strong>PN</strong>400<br />

1) The <strong>valves</strong> can be used down to -<strong>10</strong> C<br />

Operating <strong>pressure</strong>s to EN <strong>10</strong>92/1 are also permissible<br />

320<br />

320<br />

320<br />

<strong><strong>50</strong>0</strong><br />

<strong><strong>50</strong>0</strong><br />

<strong><strong>50</strong>0</strong><br />

400<br />

400<br />

400<br />

318<br />

320<br />

320<br />

484<br />

<strong><strong>50</strong>0</strong><br />

<strong><strong>50</strong>0</strong><br />

387<br />

400<br />

400<br />

298<br />

320<br />

320<br />

453<br />

<strong><strong>50</strong>0</strong><br />

<strong><strong>50</strong>0</strong><br />

362<br />

400<br />

400<br />

293<br />

320<br />

320<br />

445<br />

<strong><strong>50</strong>0</strong><br />

<strong><strong>50</strong>0</strong><br />

356<br />

400<br />

400<br />

288<br />

320<br />

320<br />

437<br />

<strong><strong>50</strong>0</strong><br />

<strong><strong>50</strong>0</strong><br />

3<strong>50</strong><br />

400<br />

400<br />

283<br />

315<br />

320<br />

429<br />

493<br />

<strong><strong>50</strong>0</strong><br />

343<br />

394<br />

400<br />

179<br />

274<br />

286<br />

290<br />

428<br />

421<br />

226<br />

342<br />

337<br />

136<br />

229<br />

<strong>2<strong>50</strong></strong><br />

231<br />

362<br />

368<br />

180<br />

289<br />

294<br />

<strong>10</strong>7<br />

181<br />

217<br />

184<br />

293<br />

321<br />

143<br />

228<br />

257<br />

86<br />

148<br />

188<br />

146<br />

243<br />

281<br />

113<br />

186<br />

225<br />

119<br />

162<br />

190<br />

243<br />

1<strong>50</strong><br />

194<br />

RGS<br />

93<br />

138 119 <strong>10</strong>2 88<br />

153<br />

212 181 159 137<br />

117<br />

170 145 127 <strong>10</strong>9<br />

Installation<br />

Non-<strong>return</strong> <strong>valves</strong> are installed in the line so that the medium enters the valve underneath the cone and flows out obove it.<br />

Materials<br />

7692: 3<br />

Ill.: <strong>DN</strong> <strong>10</strong>--25<br />

Part no. Name of parts Temperature Material Remark<br />

Up to 530 C 16 Mo 3 1.5415 Die-forged<br />

<strong>10</strong>0 Bodyy Up to 5<strong>50</strong> C 13 CrMo 4-5 1.7335<br />

Up to 580 C <strong>10</strong> CrMo 9-<strong>10</strong> 1.7380<br />

Sealing Body Up to 580 C Hastelloy hard facing Welded-on<br />

faces Check cone X35CrMo17-1 1.4122 Solid<br />

139 Bonnet 21 CrMo V 5-7 1.7709<br />

351 *) Check cone X35CrMo17-1 1.4122<br />

411.1 *) Gasket Graphite Seamless<br />

414 Thrust plate 13 CrMo 4-5 1.7335<br />

<strong><strong>50</strong>0</strong> Ring 21 CrMo V 5-7 1.7709<br />

<strong>50</strong>1 Segmental ring 21 CrMo V 5-7 1.7709<br />

9<strong>50</strong> *) Spring X 7 CrNiAl 17-7 1.4568<br />

*) Recommended spare parts

Dimensions type RGS<br />

Face-to-face dimension -- see table<br />

Butt-weld ends -- DIN 3239/1<br />

Groove form -- DIN 2559-21<br />

Socket weld ends -- acc. to<br />

ASME B 16.11<br />

DIN 3239/2<br />

Ill.: <strong>DN</strong> <strong>10</strong>--25<br />

Butt-weld ends<br />

7692: 3<br />

Socket-weld ends<br />

<strong>DN</strong> 20-<strong>50</strong>, welded-on<br />

RGS<br />

Different designs of butt-weld ends, socket-weld ends and<br />

welding groove forms are possible, but only within the<br />

dimensions A max. and B min<br />

Butt weld ends to EN 12627 or socket weld ends to EN 12760<br />

possible.<br />

Dimensions Dimensions in mm<br />

Nominal Nominal Face-to-face dimension Butt-weld ends Butt-weld ends acc. to DIN 3239-type 1 Socket-weld ends to ANSI B 16.11 Centre-to-top weight<br />

<strong>pressure</strong> bore Butt-weld Socket weld<br />

Groove forms to DIN 2559-21 height<br />

ends ends<br />

not machined Associated<br />

<strong>PN</strong> <strong>DN</strong> l l øAmax. øBmin. ød2 ød3 *) pipe dimensions øD-- 0.5 øC +0.2 bmin h approx. kg<br />

<strong>2<strong>50</strong></strong> <strong>10</strong> 130 130 38 9 18 12 17.2 x 2.6 27.0 17.6 9.5 95 3.0<br />

320 15 130 130 38 14 22 15 21.3 x 3.2 32.5 21.7 9.5 95 3.0<br />

<strong><strong>50</strong>0</strong> 20 130 200 38 19 28 19 26.9 x 4.0 39.5 27.1 12.5 95 3.0<br />

25 130 200 38 22 35 24 33.7 x 5.0 48.0 33.8 12.5 95 3.5<br />

<strong>2<strong>50</strong></strong> 32 160 240 58 30 44 30.5 42.4 x 6.3 57.0 42.7 12.5 125 6.5<br />

320 40 160 240 58 35 49 36 48.3 x 6.3 64.5 48.8 12.5 125 6.5<br />

400 <strong>50</strong> 190 270 72 46 -- -- -- -- -- -- -- -- -- -- -- -- 145 9.0<br />

*) d 3 =d p acc. to DIN 3239 Butt-weld ends variable acc. to nominal <strong>pressure</strong><br />

3

Pressure seal bonnet<br />

Your benefit<br />

Safe sealing towards the<br />

atmosphere<br />

Compact design<br />

Closing spring as<br />

standard feature<br />

Your benefit<br />

Allows any installation<br />

position<br />

Product Features - to our Customers’ Benefit<br />

Ill.: <strong>DN</strong> <strong>10</strong>--25<br />

KSB Aktiengesellschaft<br />

Bahnhofplatz 1 91257 Pegnitz (Germany)<br />

Tel.: +49 (92 41) 71 0 fax: +49 (92 41) 71 17 95 e-mail: <strong>valves</strong>@ksb.com www.ksb.com<br />

Seal faces made of wear and<br />

corrosion resistant materials<br />

Your benefit<br />

<strong>High</strong> reliability<br />

Long life<br />

RGS<br />

Subject to technical modification without prior notice<br />

01.02.2006<br />

7692.1/4--<strong>10</strong>