here - GaBi Software

here - GaBi Software

here - GaBi Software

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

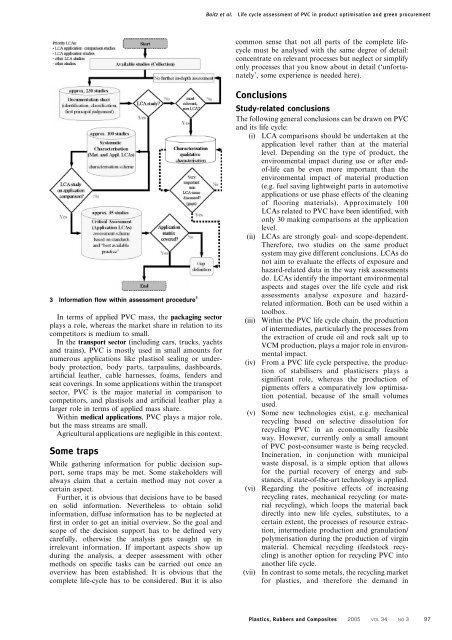

3 Information flow within assessment procedure 1<br />

In terms of applied PVC mass, the packaging sector<br />

plays a role, w<strong>here</strong>as the market share in relation to its<br />

competitors is medium to small.<br />

In the transport sector (including cars, trucks, yachts<br />

and trains), PVC is mostly used in small amounts for<br />

numerous applications like plastisol sealing or underbody<br />

protection, body parts, tarpaulins, dashboards,<br />

artificial leather, cable harnesses, foams, fenders and<br />

seat coverings. In some applications within the transport<br />

sector, PVC is the major material in comparison to<br />

competitors, and plastisols and artificial leather play a<br />

larger role in terms of applied mass share.<br />

Within medical applications, PVC plays a major role,<br />

but the mass streams are small.<br />

Agricultural applications are negligible in this context.<br />

Some traps<br />

While gathering information for public decision support,<br />

some traps may be met. Some stakeholders will<br />

always claim that a certain method may not cover a<br />

certain aspect.<br />

Further, it is obvious that decisions have to be based<br />

on solid information. Nevertheless to obtain solid<br />

information, diffuse information has to be neglected at<br />

first in order to get an initial overview. So the goal and<br />

scope of the decision support has to be defined very<br />

carefully, otherwise the analysis gets caught up in<br />

irrelevant information. If important aspects show up<br />

during the analysis, a deeper assessment with other<br />

methods on specific tasks can be carried out once an<br />

overview has been established. It is obvious that the<br />

complete life-cycle has to be considered. But it is also<br />

Baitz et al. Life cycle assessment of PVC in product optimisation and green procurement<br />

common sense that not all parts of the complete lifecycle<br />

must be analysed with the same degree of detail:<br />

concentrate on relevant processes but neglect or simplify<br />

only processes that you know about in detail (‘unfortunately’,<br />

some experience is needed <strong>here</strong>).<br />

Conclusions<br />

Study-related conclusions<br />

The following general conclusions can be drawn on PVC<br />

and its life cycle:<br />

(i) LCA comparisons should be undertaken at the<br />

application level rather than at the material<br />

level. Depending on the type of product, the<br />

environmental impact during use or after endof-life<br />

can be even more important than the<br />

environmental impact of material production<br />

(e.g. fuel saving lightweight parts in automotive<br />

applications or use phase effects of the cleaning<br />

of flooring materials). Approximately 100<br />

LCAs related to PVC have been identified, with<br />

only 30 making comparisons at the application<br />

level.<br />

(ii) LCAs are strongly goal- and scope-dependent.<br />

T<strong>here</strong>fore, two studies on the same product<br />

system may give different conclusions. LCAs do<br />

not aim to evaluate the effects of exposure and<br />

hazard-related data in the way risk assessments<br />

do. LCAs identify the important environmental<br />

aspects and stages over the life cycle and risk<br />

assessments analyse exposure and hazardrelated<br />

information. Both can be used within a<br />

toolbox.<br />

(iii) Within the PVC life cycle chain, the production<br />

of intermediates, particularly the processes from<br />

the extraction of crude oil and rock salt up to<br />

VCM production, plays a major role in environmental<br />

impact.<br />

(iv) From a PVC life cycle perspective, the production<br />

of stabilisers and plasticisers plays a<br />

significant role, w<strong>here</strong>as the production of<br />

pigments offers a comparatively low optimisation<br />

potential, because of the small volumes<br />

used.<br />

(v) Some new technologies exist, e.g. mechanical<br />

recycling based on selective dissolution for<br />

recycling PVC in an economically feasible<br />

way. However, currently only a small amount<br />

of PVC post-consumer waste is being recycled.<br />

Incineration, in conjunction with municipal<br />

waste disposal, is a simple option that allows<br />

for the partial recovery of energy and substances,<br />

if state-of-the-art technology is applied.<br />

(vi) Regarding the positive effects of increasing<br />

recycling rates, mechanical recycling (or material<br />

recycling), which loops the material back<br />

directly into new life cycles, substitutes, to a<br />

certain extent, the processes of resource extraction,<br />

intermediate production and granulation/<br />

polymerisation during the production of virgin<br />

material. Chemical recycling (feedstock recycling)<br />

is another option for recycling PVC into<br />

another life cycle.<br />

(vii) In contrast to some metals, the recycling market<br />

for plastics, and t<strong>here</strong>fore the demand in<br />

Plastics, Rubbers and Composites 2005 VOL 34 NO 3 97