DYNAFOAM® 7440FC - Saint-Gobain Performance Plastics Foams

DYNAFOAM® 7440FC - Saint-Gobain Performance Plastics Foams

DYNAFOAM® 7440FC - Saint-Gobain Performance Plastics Foams

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

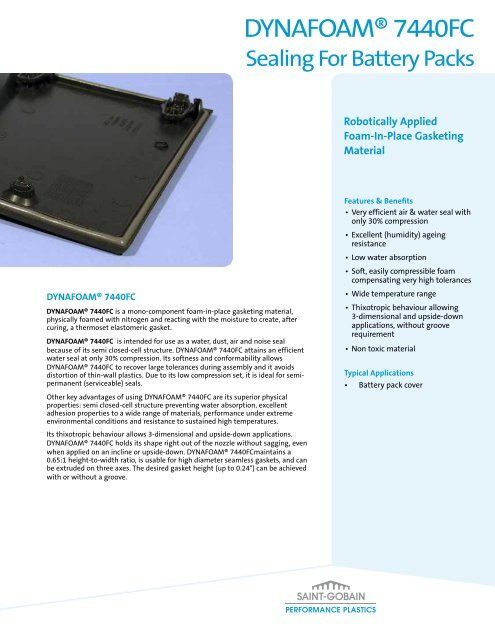

<strong>DYNAFOAM®</strong> <strong>7440FC</strong><br />

<strong>DYNAFOAM®</strong> <strong>7440FC</strong> is a mono-component foam-in-place gasketing material,<br />

physically foamed with nitrogen and reacting with the moisture to create, after<br />

curing, a thermoset elastomeric gasket.<br />

<strong>DYNAFOAM®</strong> <strong>7440FC</strong> is intended for use as a water, dust, air and noise seal<br />

because of its semi closed-cell structure. <strong>DYNAFOAM®</strong> <strong>7440FC</strong> attains an efficient<br />

water seal at only 30% compression. Its softness and conformability allows<br />

<strong>DYNAFOAM®</strong> <strong>7440FC</strong> to recover large tolerances during assembly and it avoids<br />

distortion of thin-wall plastics. Due to its low compression set, it is ideal for semipermanent<br />

(serviceable) seals.<br />

Other key advantages of using <strong>DYNAFOAM®</strong> <strong>7440FC</strong> are its superior physical<br />

properties: semi closed-cell structure preventing water absorption, excellent<br />

adhesion properties to a wide range of materials, performance under extreme<br />

environmental conditions and resistance to sustained high temperatures.<br />

Its thixotropic behaviour allows 3-dimensional and upside-down applications.<br />

<strong>DYNAFOAM®</strong> <strong>7440FC</strong> holds its shape right out of the nozzle without sagging, even<br />

when applied on an incline or upside-down. <strong>DYNAFOAM®</strong> <strong>7440FC</strong>maintains a<br />

0.65:1 height-to-width ratio, is usable for high diameter seamless gaskets, and can<br />

be extruded on three axes. The desired gasket height (up to 0.24") can be achieved<br />

with or without a groove.<br />

<strong>DYNAFOAM®</strong> <strong>7440FC</strong><br />

Sealing For Battery Packs<br />

Robotically Applied<br />

Foam-In-Place Gasketing<br />

Material<br />

Features & Benefits<br />

• Very efficient air & water seal with<br />

only 30% compression<br />

• Excellent (humidity) ageing<br />

resistance<br />

• Low water absorption<br />

• Soft, easily compressible foam<br />

compensating very high tolerances<br />

• Wide temperature range<br />

• Thixotropic behaviour allowing<br />

3-dimensional and upside-down<br />

applications, without groove<br />

requirement<br />

• Non toxic material<br />

Typical Applications<br />

• Battery pack cover

<strong>DYNAFOAM®</strong> <strong>7440FC</strong><br />

<strong>DYNAFOAM®</strong> <strong>7440FC</strong> is applied directly onto the part. By changing the angle of the nozzle, the flow rate and/or the robot speed,<br />

the gasket can be adapted to the desired height.<br />

Designed for automation, <strong>DYNAFOAM®</strong> <strong>7440FC</strong> enhances productivity in large volume applications and results in significant<br />

savings in labour and materials by eliminating the die-cut scrap and by reducing the material inventory. Parts can be handled<br />

quickly and easily, eliminating production bottlenecks. Unlike hand-applied gaskets, it offers a repeatable process from cycle to<br />

cycle.<br />

<strong>DYNAFOAM®</strong> <strong>7440FC</strong> is a non toxic material which does not require special ventilation to meet industry safety standards. It<br />

is free of cadmium, lead, chrome (VI), mercury and other substances subject to declaration in the International Material Data<br />

System list.<br />

Properties Test Method Value<br />

Density (foamed & cured), kg/m3 ASTM D1056 200 - 240<br />

Standard color - Grey*<br />

Hardness, Shore OO ASTM D2240 35 -55<br />

Compression set, % ASTM D1667 < 15<br />

Max. recommended compression, % - 70<br />

Tensile strength, N/cm² DIN 53571 > 20<br />

Elongation @ break, % DIN 53571 > 100<br />

Water absorption, % ASTM D1056 < 10<br />

Tempertaure range, °F -40 to +257<br />

* Color may slightly vary from lot to lot, without affecting product performances.<br />

Parameter values are not guaranteed and will differ from lot to lot. For specification writing, contact the Application Engineering Department.<br />

Packaging : 20 lit pails - net weigth 16 kg<br />

200 lit drums - net weight 180 kg<br />

Shelf life : 6 months after production date<br />

Storage & transport : 86°Fmaximum - no exposure to sunshine<br />

<strong>Saint</strong>-<strong>Gobain</strong> <strong>Performance</strong> <strong>Plastics</strong><br />

Hoosick Falls, New York 12090-0320<br />

Customer Service: (800) 962-2666<br />

Tel: (518) 686-7301<br />

Fax: (800) 562-8479, (518) 686-4840<br />

DYNAFOAM is a registered trademark.<br />

Limited Warranty: For a period of 6 months from the date of first sale, <strong>Saint</strong>-<strong>Gobain</strong> Performanc <strong>Plastics</strong> Corporation warrants this product(s) to be free from defects in manufacturing. Our only obligation<br />

will be to provide replacement product for any portion proving defective, or at our option, to refund the purchase price thereof. User assumes all other risks, if any including the risk of injury, loss or damage,<br />

whether direct or subsequential, arising out of the use, misuse, or inability to use this product(s). SAINT-GOBAIN PERFORMANCE PLASTICS DISCLAIMS ANY AND ALL OTHER WARRANTIES, EXPRESSED OR<br />

IMPLIED, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.<br />

NOTE: <strong>Saint</strong>-<strong>Gobain</strong> <strong>Performance</strong> <strong>Plastics</strong> Corporation does not assume any responsability or liability for any advice furnised by it, or for the performance or results of any installation or use of the<br />

product(s) or of any final product into which the product(s) may be incorporated by the purchaser and/or user. The purchaser and/or user should perform its own tests to determine the suitability and<br />

fitness of the product(s) for the particular purpose desired in any given situation.<br />

SPE5128-pdf-07/12 www.protectionplus.saint-gobain.com ©2012 <strong>Saint</strong>-<strong>Gobain</strong> <strong>Performance</strong> <strong>Plastics</strong>