Corporate Social Responsibility Report (810 KB) - Tognum AG

Corporate Social Responsibility Report (810 KB) - Tognum AG

Corporate Social Responsibility Report (810 KB) - Tognum AG

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

02 <strong>Corporate</strong> <strong>Social</strong> <strong>Responsibility</strong> | <strong>Report</strong>, June 2008 | Products and technology<br />

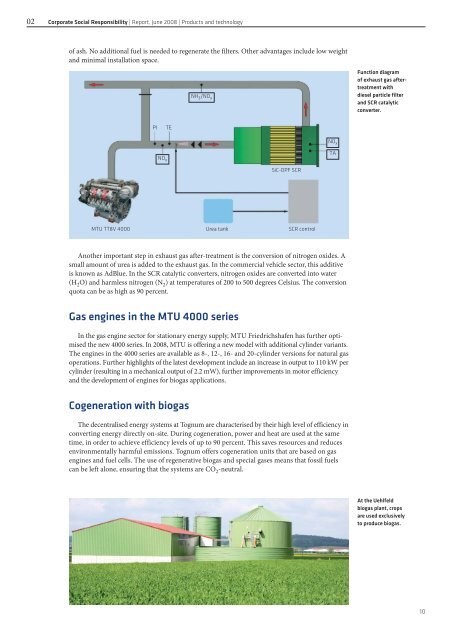

of ash. No additional fuel is needed to regenerate the filters. Other advantages include low weight<br />

and minimal installation space.<br />

PI TE<br />

NO x<br />

Another important step in exhaust gas after-treatment is the conversion of nitrogen oxides. A<br />

small amount of urea is added to the exhaust gas. In the commercial vehicle sector, this additive<br />

is known as AdBlue. In the SCR catalytic converters, nitrogen oxides are converted into water<br />

(H 2O) and harmless nitrogen (N 2) at temperatures of 200 to 500 degrees Celsius. The conversion<br />

quota can be as high as 90 percent.<br />

Gas engines in the MTU 4000 series<br />

In the gas engine sector for stationary energy supply, MTU Friedrichshafen has further optimised<br />

the new 4000 series. In 2008, MTU is offering a new model with additional cylinder variants.<br />

The engines in the 4000 series are available as 8-, 12-, 16- and 20-cylinder versions for natural gas<br />

operations. Further highlights of the latest development include an increase in output to 110 kW per<br />

cylinder (resulting in a mechanical output of 2.2 mW), further improvements in motor efficiency<br />

and the development of engines for biogas applications.<br />

Cogeneration with biogas<br />

NH 3 /NO x<br />

SiC-DPF SCR<br />

MTU TT8V 4000 Urea tank SCR control<br />

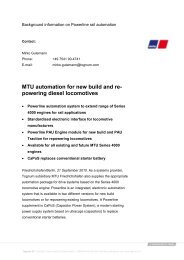

The decentralised energy systems at <strong>Tognum</strong> are characterised by their high level of efficiency in<br />

converting energy directly on-site. During cogeneration, power and heat are used at the same<br />

time, in order to achieve efficiency levels of up to 90 percent. This saves resources and reduces<br />

environmentally harmful emissions. <strong>Tognum</strong> offers cogeneration units that are based on gas<br />

engines and fuel cells. The use of regenerative biogas and special gases means that fossil fuels<br />

can be left alone, ensuring that the systems are CO 2-neutral.<br />

NO x<br />

TA<br />

Function diagram<br />

of exhaust gas aftertreatment<br />

with<br />

diesel particle filter<br />

and SCR catalytic<br />

converter.<br />

At the Uehlfeld<br />

biogas plant, crops<br />

are used exclusively<br />

to produce biogas.<br />

10