Corporate Social Responsibility Report (810 KB) - Tognum AG

Corporate Social Responsibility Report (810 KB) - Tognum AG

Corporate Social Responsibility Report (810 KB) - Tognum AG

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

01 <strong>Corporate</strong> <strong>Social</strong> <strong>Responsibility</strong> | <strong>Report</strong>, June 2008 | Environmental protection, production and sites<br />

bon dioxide that others. <strong>Tognum</strong> is aiming to steadily reduce its emissions. Parts of our systems<br />

are involved in European emissions trading. The aim is to reduce emissions in the second trading<br />

period (2008-2010) to such an extent that <strong>Tognum</strong> will not have to exhaust its quota of emissions<br />

rights.<br />

Power and heat for manufacturing <strong>Tognum</strong> products are increasingly being generated by<br />

combined heat and power (cogeneration). This technology comes from the <strong>Tognum</strong> companies<br />

MDE, MTU and CFC Solutions. Using cogeneration units and a fuel cell, the company makes<br />

highly efficient use of the energy and thus reduces CO 2 emissions.<br />

As of June 2008, a high-temperature fuel cell at the Friedrichshafen site will supply the company's<br />

health insurance fund building (currently under construction) with heat and power. The<br />

'HotModule' from CFC Solutions, a subsidiary of <strong>Tognum</strong>, uses natural gas to generate 30 percent<br />

more electrical energy than a conventional power plant of the same size. The fuel cell generates<br />

245 kilowatts of power and 180 kilowatts of heat. The offices are heated by the warm water<br />

and the power is fed into the public mains grid. Energy is generated through an electrochemical<br />

process in the fuel cell module, i.e. without combustion. No sulphur dioxide or nitrogen oxides<br />

are produced. The exhaust air from the HotModule consists only of water vapour, nitrogen and<br />

the residual oxygen from the air.<br />

Cogeneration units are in operation at both <strong>Tognum</strong> sites in Friedrichshafen: the second<br />

natural gas cogeneration unit was started up in 2007. Using technology from the in-house<br />

corporate association, the two cogeneration units cover approximately a quarter of power and<br />

heat requirements. The combination of power and heat means that the company uses 73 percent<br />

of the energy contained in the natural gas. This high level of efficiency results in savings of 1,700<br />

tons of CO 2 a year in comparison to the separate generation of power and heat (see diagram).<br />

Operating for 7,500 hours a year, the cogeneration unit generates 13,900 MWh of power and<br />

8,800 MWh of heat per year.<br />

At the Augsburg site, the <strong>Tognum</strong> subsidiary MDE uses a natural gas cogeneration unit to provide<br />

economical and environmentally friendly power and heat for the production hall, warehouse<br />

and administrative building. In comparison to a conventional energy supply, MDE thus manages to<br />

reduce carbon dioxide emissions by 50 percent and also reduces primary energy use by 35 percent.<br />

Power savings through brightness-dependent lighting control<br />

Lighting in large workshops is controlled on a need-orientated basis with over 30 kW of<br />

light, in order to save energy and automatically ensure ergonomic and even lighting. In lighter<br />

environments, a third of the lights are switched off automatically in turn. The control system<br />

also takes the early and late shifts into account. These switch-offs result in an annual power<br />

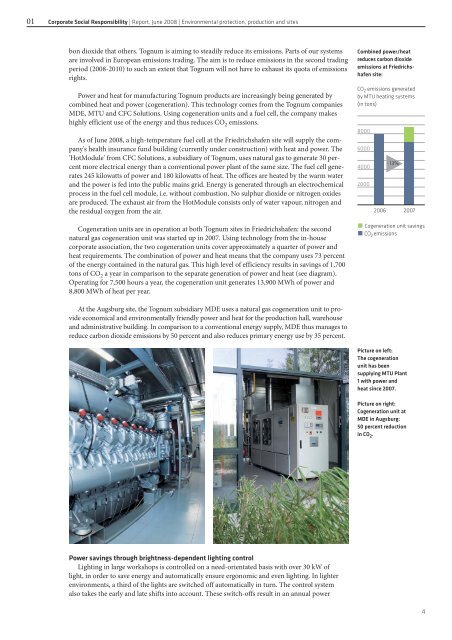

Combined power/heat<br />

reduces carbon dioxide<br />

emissions at Friedrichshafen<br />

site:<br />

CO 2 emissions generated<br />

by MTU heating systems<br />

(in tons)<br />

8000<br />

6000<br />

4000<br />

2000<br />

- 13%<br />

2006 2007<br />

Cogeneration unit savings<br />

CO 2 emissions<br />

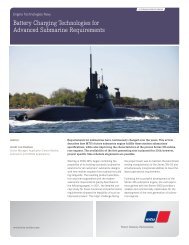

Picture on left:<br />

The cogeneration<br />

unit has been<br />

supplying MTU Plant<br />

1 with power and<br />

heat since 2007.<br />

Picture on right:<br />

Cogeneration unit at<br />

MDE in Augsburg:<br />

50 percent reduction<br />

in CO 2 .<br />

4