Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

TECHNOLOGY<br />

As nuclear power plants are frequently operated according to<br />

Unlike in U-type heaters, the water and steam sides in header-type<br />

heaters are separated by two thick-walled pipes, the inlet and outlet<br />

headers, instead of by a tubesheet. Moreover, the heat exchanger<br />

tubes are arranged in a snake shape instead of U shape, generally<br />

in 3 or 4 water passes through the shell area.<br />

A complete high-pressure heater train generally consists of three<br />

header-type heaters and a separate desuperheater. The heaters<br />

are installed vertically in most cases and only rarely horizontally.<br />

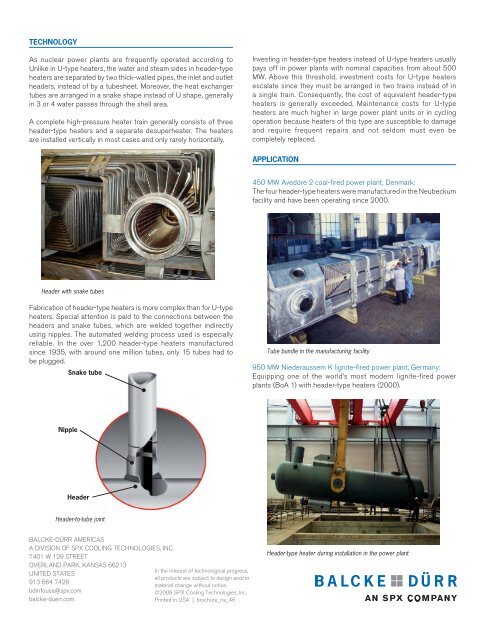

Header with snake tubes<br />

Fabrication of header-type heaters is more complex than for U-type<br />

heaters. Special attention is paid to the connections between the<br />

headers and snake tubes, which are welded together indirectly<br />

using nipples. The automated welding process used is especially<br />

reliable. In the over 1,200 header-type heaters manufactured<br />

since 1935, with around one million tubes, only 15 tubes had to<br />

be plugged.<br />

Nipple<br />

Snake tube<br />

Header<br />

Header-to-tube joint<br />

BALCKE-DÜRR AMERICAS<br />

A DIVISION OF SPX COOLING TECHNOLOGIES, INC.<br />

7401 W 129 STREET<br />

OVERLAND PARK, KANSAS 66213<br />

UNITED STATES<br />

913 664 7428<br />

bdinfousa@spx.com<br />

balcke-duerr.com<br />

In the interest of technological progress,<br />

all products are subject to design and/or<br />

material change without notice.<br />

©2009 SPX Cooling Technologies, Inc.<br />

Printed in USA | brochure_na_46<br />

Investing in header-type heaters instead of U-type heaters usually<br />

pays off in power plants with nominal capacities from about 500<br />

MW. Above this threshold, investment costs for U-type heaters<br />

escalate since they must be arranged in two trains instead of in<br />

a single train. Consequently, the cost of equivalent header-type<br />

heaters is generally exceeded. Maintenance costs for U-type<br />

heaters are much higher in large power plant units or in cycling<br />

operation because heaters of this type are susceptible to damage<br />

and require frequent repairs and not seldom must even be<br />

completely replaced.<br />

APPLICATION<br />

450 MW Avedöre 2 coal-fired power plant, Denmark:<br />

The four header-type heaters were manufactured in the Neubeckum<br />

facility and have been operating since 2000.<br />

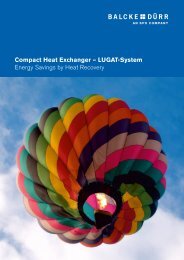

Tube bundle in the manufacturing facility<br />

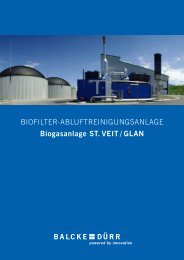

950 MW Niederaussem K lignite-fired power plant, Germany:<br />

Equipping one of the world’s most modern lignite-fired power<br />

plants (BoA 1) with header-type heaters (2000).<br />

Header-type heater during installation in the power plant