You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

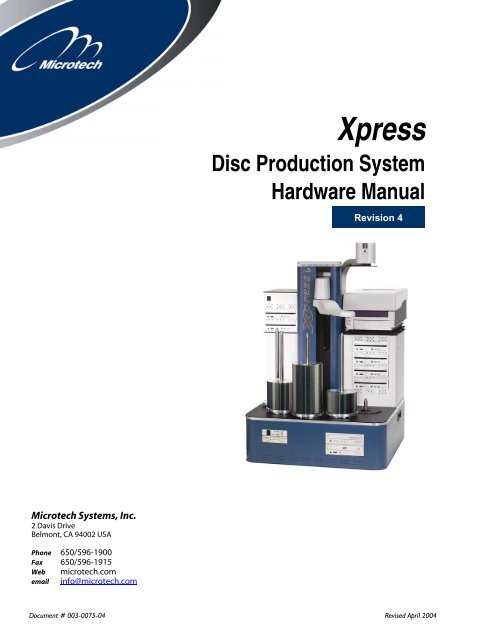

Microtech Systems, Inc.<br />

2 Davis Drive<br />

Belmont, CA 94002 USA<br />

Phone 650/596-1900<br />

Fax 650/596-1915<br />

Web microtech.com<br />

email info@microtech.com<br />

<strong>Xpress</strong><br />

Disc Production System<br />

Hardware Manual<br />

Revision 4<br />

Document # 003-0075-04 Revised April 2004

Regulatory Compliance<br />

Statements<br />

Notice for USA<br />

Federal Communications<br />

Commissions (FCC) Statement<br />

This equipment has been tested and found to comply with<br />

the radiated energy limits for a Class A digital device, in<br />

accordance with FCC CFR 47 Part 15 Rules and Regulations.<br />

(1) This device may not cause harmful<br />

interference, and (2) this device must accept any<br />

interference received, including interference that<br />

may cause undesired operation.<br />

Notice for Europe<br />

European Standards<br />

This equipment conforms to the EMC Directive<br />

(89/336/EEC) by compliance with the following European<br />

standards:<br />

EN 55022:1998 + A1:2000, CISPR 22:1997 + A1:2000 (Emissions):<br />

EN 50024:1998 + A1:2001, CISPR 24:1997 + A1:2001 (Immunity):<br />

EN 60950:2001 First Edition (Safety)

Contents<br />

Introduction ....................................................................................................................................... 1<br />

Introducing <strong>Xpress</strong>........................................................................................................................................2<br />

<strong>Xpress</strong>’s Parts .............................................................................................................................................................2<br />

<strong>Xpress</strong> Specifications................................................................................................................................................4<br />

Setting Up <strong>Xpress</strong>.............................................................................................................................. 5<br />

Disc Production Workspace....................................................................................................................................6<br />

Checking In Your Shipment ...................................................................................................................................7<br />

Unpacking <strong>Xpress</strong> .....................................................................................................................................................7<br />

<strong>Xpress</strong> Contents.........................................................................................................................................................8<br />

<strong>Xpress</strong> Assembly Procedures ..................................................................................................................................9<br />

<strong>Xpress</strong> Basics .................................................................................................................................... 13<br />

Powering Up <strong>Xpress</strong> ...............................................................................................................................................14<br />

The <strong>Xpress</strong> Desktop................................................................................................................................................15<br />

Checking the <strong>Xpress</strong> Software Configuration..................................................................................................16<br />

Initial System Calibration.....................................................................................................................................17<br />

Testing <strong>Xpress</strong> .........................................................................................................................................................19<br />

Placing Discs on Spindles.....................................................................................................................................20<br />

Shutting Down <strong>Xpress</strong> ...........................................................................................................................................21<br />

Calibrating <strong>Xpress</strong>........................................................................................................................... 23<br />

Calibrating <strong>Xpress</strong> ..................................................................................................................................................24<br />

Microtech Support..................................................................................................................................................25<br />

Index .................................................................................................................................................. 27<br />

Contents

Introduction

Hoist<br />

Reject Spindle<br />

Spindle #4<br />

Spindle #3<br />

Spindle #2<br />

Spindle #1<br />

Control Panel<br />

Floppy Disc Drive<br />

2 Introduction<br />

Introducing <strong>Xpress</strong><br />

This section will provide all the information you need to unpack, install,<br />

configure and use this system.<br />

<strong>Xpress</strong>’s Parts<br />

The following section shows and identifies all the important parts of<br />

your <strong>Xpress</strong>. These components will be referred to later in the manual;<br />

take a few moments to become familiar with them.<br />

The main parts of the <strong>Xpress</strong> production system are indicated below<br />

(front view).<br />

Elevator<br />

Digital Camera for<br />

(ImageAligner) option<br />

Disc Readers<br />

Light Shield/<br />

Camera Mount Disk<br />

Camera Support Boom<br />

Handhold<br />

Disc Printer<br />

Arm<br />

Printer Plate<br />

Drive Enclosure<br />

Disc Writers<br />

Base Unit (PC Enclosed)

Light Shield/Camera Mount Disc<br />

Camera Support Boom<br />

Drive Enclosure<br />

Base Unit<br />

Printer<br />

The elevator contains all automation elements including the hoist and<br />

the disc transport arm.<br />

The hoist is part of the elevator and raises/lowers the arm.<br />

The arm contains a disc gripper mechanism which holds discs during<br />

transport. The arm can rotate to reach all disc positions (spindles, disc<br />

writer drives and printer).<br />

The drive enclosure holds the disc writers and acts as a platform for the<br />

printer.<br />

The disc writers are the drives that write to blank discs. The exact<br />

number of writers installed (from 1 to 4) depends on your particular<br />

system. Writers can be CD-R, DVD-R, or a mix.<br />

The PC module contains the entire PC including disc readers, hard disk<br />

and power supply.<br />

The disc readers read master discs to be duplicated and other tasks.<br />

Typically, one reader will be a CD-ROM reader and the other will be a<br />

DVD-ROM drive.<br />

The disc spindles hold discs in various stages of processing. There are<br />

four full height spindles for holding blank and completed discs, and one<br />

shorter reject spindle. All spindles can be lifed off and on for easy disc<br />

handling.<br />

<strong>Xpress</strong> Back View<br />

Camera<br />

Elevator<br />

Printer Base Plate<br />

Introduction 3

Power Switch<br />

4 Introduction<br />

<strong>Xpress</strong>’s Control Panel<br />

The control panel on the front of <strong>Xpress</strong>’s base unit contains the power<br />

switch and several indicator lights.<br />

Besides the labeled indicator lights for power and the hard drive, there<br />

are four lights in a column, these lights are used to indicate the activity<br />

on drives or buses.<br />

<strong>Xpress</strong> Specifications<br />

• Dimensions:<br />

23” w X 23” d X 31” h [58mm x 58mm x 79mm]<br />

• Weight:<br />

System without printer: 135 lb. [61 kg]<br />

System with printer: 155 lb. [70 kg]<br />

Disc Drive<br />

Activity Lights<br />

Floppy Drive

Setting Up <strong>Xpress</strong>

Important Unpacking<br />

Information<br />

Be sure to save all packing<br />

material in case you need<br />

to move or ship your<br />

system.<br />

Microtech Systems will<br />

only accept merchandise<br />

returned in the original<br />

shipping container.<br />

6 Setting up <strong>Xpress</strong><br />

Disc Production Workspace<br />

The workspace for the <strong>Xpress</strong> disc production system should be in an<br />

environment free of dust and debris. Contamination can adversely affect<br />

production yield, degrade the quality of the discs produced, and reduce<br />

the life of the equipment. A typical office environment will provide the<br />

necessary cleanliness, temperature, and humidity control required to<br />

maximize system performance and service life.<br />

The workspace should have the following features:<br />

Sturdy workspace<br />

A working surface sturdy enough to support a total weight of<br />

200 lbs.<br />

Large workspace<br />

A large enough workspace: a recommended minimum of<br />

60” W x 48” D x 36” H, with 36” of clearance above.<br />

Electrical power<br />

The production system needs adequate power and enough power<br />

receptacles. Ensure that the power receptacles are properly grounded.<br />

The average power requirement for the entire system is 250 watts. The<br />

peak requirement may reach 400 watts. Microtech recommends using a<br />

surge protector and/or power conditioner for optimal setup.<br />

Adequate lighting<br />

There should be enough light both for operating the equipment and for<br />

examining the discs you produce and print. In addition, if the<br />

ImageAligner option is installed, adequate lighting for the digital camera<br />

to capture disc images is necessary (adequate light must be available<br />

even when the system is running jobs unattended after-hours). Direct<br />

sunlight or spotlights can adversely affect the robotic sensors of the<br />

<strong>Xpress</strong> as well as affecting the performance of the ImageAligner.<br />

Document storage<br />

Keep the documentation and software handy for future assistance,<br />

trouble shooting, etc.

Moving <strong>Xpress</strong>: Never pick<br />

up the main unit up by<br />

grasping the tower, as this<br />

can damage the unit.<br />

Always lift it using the<br />

handholds in the sides of<br />

the unit’s base<br />

Checking In Your Shipment<br />

Before unpacking <strong>Xpress</strong>:<br />

• Check shipping cartons against table below<br />

• Check for shipping damage<br />

The shipment should include the following number of cartons:<br />

SYSTEM CONFIGURATION NUMBER OF CARTONS<br />

No printer 3<br />

System with printer 4<br />

System with printer and<br />

IMAGEALIGNER option<br />

Please examine all of the shipping cartons. If any cartons are missing or<br />

damaged, notify the shipping carrier as soon as possible, then contact<br />

Microtech technical support at (650) 596-1900. Technical support is available<br />

Monday through Friday from 7:30 AM to 6:00 PM Pacific Time. Please<br />

contact us with any questions or problems during the unpacking,<br />

installation, and set up of the <strong>Xpress</strong> disc production system. If the<br />

shipping cartons are present and not damaged, start setting up a<br />

workspace for your production system.<br />

Unpacking <strong>Xpress</strong><br />

There are four basic <strong>Xpress</strong> configurations:<br />

1. Basic system only (no printer)<br />

2. Basic system with the Signature IV or Signature Pro (inkjet)<br />

printer<br />

3. Basic system with the Perfect Image (thermal transfer) printer<br />

4. Basic system with the Perfect Image (thermal transfer) printer and<br />

ImageAligner for printing on pre-printed discs<br />

A printer (and ImageAligner for printing on pre-printed discs) can be<br />

added to a basic system. Ask your dealer or sales representative about<br />

upgrade kits.<br />

All <strong>Xpress</strong> configurations are equipped with up to four CD-R or DVD-R<br />

writer drives and an additional 1 or 2 reader drives.<br />

Setting up <strong>Xpress</strong> 7<br />

5

Optional<br />

<strong>Xpress</strong> Contents<br />

8 Setting up <strong>Xpress</strong><br />

Box # 1 Contains<br />

Base Unit (housing PC Module)<br />

Keyboard<br />

Mouse<br />

Software Key<br />

Cables (<strong>Xpress</strong> Power Cord, and Serial Cable)<br />

Box #2 Contains<br />

Drive Enclosure<br />

Elevator<br />

Arm<br />

Printer Base Plate (w/ Printer Option Only)<br />

Box #3 Contains<br />

Monitor<br />

Cables<br />

Box #4 Contains<br />

Printer<br />

Cables (Data Cable, Power Cord, Control Cable {Signature Pro only})<br />

Box #5 Contains<br />

Digital Camera<br />

Camera Support Boom<br />

Light Shield/Camera Mount Disk<br />

Thumbscrews (3 Male and 1 Female)<br />

Camera Cable<br />

Calibration Disc<br />

During unpacking, visually inspect parts for dents, scratches or other<br />

damage. If any parts are damaged, call Microtech’s Customer<br />

Support Department at 650-596-1900 7:30 – 5:30 PST<br />

Microtech Systems will only accept merchandise returned in the<br />

original shipping container.

<strong>Xpress</strong> Assembly Procedures<br />

Base Unit<br />

1. Place Base Unit on Work surface.<br />

2. Set keyboard, mouse, Software Key, and cables aside for later<br />

connection.<br />

Drive Enclosure<br />

1. Remove thumbscrews (2) from the back of the Drive Enclosure –<br />

set aside.<br />

2. Remove back plate of Drive Enclosure.<br />

3. Place Drive Enclosure on top of Base Unit (back of enclosure fits<br />

flush with back of the Base Unit.)<br />

Caution – do not pinch any wires!<br />

4. Finger-tighten thumbscrews (6) inside Drive Enclosure to secure<br />

it to Base Unit.<br />

Elevator<br />

1. Place Elevator securely onto pegs on Base Unit (center of Drive<br />

enclosure).<br />

Caution – do not pinch any wires!<br />

2. Finger-tighten thumbscrews (2) inside Drive Enclosure to secure<br />

Handler Module to Drive Enclosure.<br />

Cabling<br />

1. Drive Power Cable (indicated by blue dot) – connect the Drive<br />

Power cable to port with the corresponding blue dot.<br />

2. Fan Power Cable (indicated by yellow dot) – connect the Fan<br />

Power Cable to port with the corresponding yellow dot.<br />

3. Control Cable (indicated by red dot) –- connect the Control<br />

Cable to port with the corresponding red dot.<br />

4. Connect two ribbon cables from under fans to the Arm located<br />

on the Elevator – Undo the twist-tie holding them together –<br />

push into connectors firmly until connector locks.<br />

5. Connect Drive Cables (4)<br />

6. Replace back of Drive Enclosure.<br />

7. Replace and tighten thumbscrews.<br />

Setting up <strong>Xpress</strong> 9

10 Setting up <strong>Xpress</strong><br />

Arm to Elevator<br />

1. Remove threaded knob from underside of Hoist (on Elevator).<br />

2. Line up holes on rear end of Arm with pins on Hoist.<br />

3. Replace threaded knob and finger tighten to secure Arm to<br />

Hoist.<br />

4. Connect Arm to Hoist with small “phone” cord.<br />

5. Place long Spindles on locations 1 – 4.<br />

6. Place short Spindle on location 5.<br />

7. Replace packing material in shipping box and store for<br />

moving/shipping.<br />

Disc Printer Option<br />

1. Slide Printer Base Plate (from Box #2) into slots on top of drive<br />

enclosure.<br />

2. Finger-tighten two thumbscrews to secure Printer Base Plate to<br />

Drive Enclosure.<br />

3. Place Printer onto pegs on surface of Printer Base Plate.<br />

Printer Connection<br />

Perfect Image<br />

1. Connect data cable between port on back of Printer and COM1<br />

on back of <strong>Xpress</strong> Base Unit.<br />

2. Connect Printer Power Cord to port on back of Printer, plug<br />

opposite end into standard electrical outlet.<br />

3. Install Software Key into any USB port on back of <strong>Xpress</strong> Base<br />

Unit.<br />

Note: If using ImageAligner Option, insure that Software Key is installed<br />

in Parallel Port on back of <strong>Xpress</strong> Base Unit.<br />

Signature Pro<br />

1. Connect Data Cable between port on back of Printer and port on<br />

back of <strong>Xpress</strong> Base Unit.<br />

2. Connect Control Cable between port on back of Printer and port<br />

on back of Drive Enclosure.<br />

3. Connect Printer Power Cord to port on back of Printer, plug into<br />

standard electrical outlet.<br />

4. Install Software Key into any USB port on back of <strong>Xpress</strong> Base<br />

Unit.<br />

PRINTER IS READY FOR INITIAL TESTING

Installing ImageAligner Option<br />

1. Place Camera Support Boom on top of Printer Base Plate behind<br />

Elevator.<br />

2. Tighten attached knobs (3) to secure Camera Support Boom to<br />

threaded holes in Printer Base Plate.<br />

3. Line up pegs (2) and threaded rod on top of Light<br />

Shield/Camera Mount Disk with holes on bottom of Camera<br />

Support Boom.<br />

4. Finger tighten knob onto threaded rod to secure Light<br />

Shield/Camera Mount Disk to Camera Support Boom.<br />

5. Open Camera Lens.<br />

6. Attach Camera to Mount by finger tightening attached<br />

thumbscrew.<br />

7. Connect Camera Cable between port on top of Camera and port<br />

on back of <strong>Xpress</strong> Base Unit.<br />

8. Secure Camera Cable to Camera Support Boom using attached<br />

cord clips<br />

PRINTER IS READY FOR INITIAL TESTING<br />

Additional Cables<br />

1. Connect <strong>Xpress</strong> Main Power Cord to port on back of Base Unit,<br />

plug into standard 110v electrical outlet.<br />

2. Install Software Key into any USB port on back of Base Unit.<br />

Note: With ImageAligner option, install Software Key into Parallel Port on<br />

back of Base Unit.<br />

3. Connect Serial Cable from back of Base Unit in COM2 to back of<br />

Drive Enclosure.<br />

XPRESS IS READY FOR INITIAL TESTING<br />

Setting up <strong>Xpress</strong> 11

<strong>Xpress</strong> Basics

14 <strong>Xpress</strong> Basics<br />

Once <strong>Xpress</strong> is set up, test it to make sure everything is operating<br />

properly. This chapter covers two quick test procedures. The first is an<br />

automated test, that confirms that the system mechanics are working,<br />

and that discs can be picked up, dropped and moved around correctly.<br />

The second part of the test actually makes disc copies to verify that the<br />

system’s electronics and disc writer drives are working properly.<br />

Powering Up <strong>Xpress</strong><br />

• Press and release the power switch (located on the control panel on<br />

the front; see page 3 for its location.)<br />

• <strong>Xpress</strong> is a Microsoft Windows-based system that needs to go<br />

through its boot-up process. As shipped from Microtech, each<br />

system is set up to log you in as the user Administrator, with no<br />

password (leave the password field blank in the login dialog). Once<br />

the system is set up and running on your network, create a new user<br />

account and make a practice of logging in as that user.<br />

After your login information has been validated, the Windows desktop<br />

will appear, and you may begin using the system.

The <strong>Xpress</strong> Desktop<br />

Important icons and other parts of the desktop<br />

The MyDisc icon<br />

Starts the standard MyDisc program used to create master images of<br />

custom discs from which to make copies. Using MyDisc for making discs<br />

is covered in the software manual.<br />

The ImageMaker EZ icon<br />

Starts the disc duplication program used to make disc copies.<br />

Instructions for using ImageMaker EZ are covered in the software<br />

manual.<br />

The DiscPrint icon<br />

Starts the DiscPrint program, the “stand-alone” version of the<br />

ImageMaker EZ disc layout editor, used to create and modify disc<br />

printing layouts.<br />

The ImageMaker MJ (“Classic”) icon<br />

Starts the optional ImageMaker MJ software for disc duplication. Please<br />

refer to the software manual.<br />

The <strong>Xpress</strong> Calibration icon<br />

Starts the <strong>Xpress</strong> calibration utility used for calibrating the system.<br />

The CD-REMOTE icon<br />

Starts the CD-REMOTE background process and is only necessary should<br />

you need to restart the process. CD-REMOTE starts automatically when it<br />

is needed.<br />

The Windows taskbar<br />

When a program is started (e.g. MyDisc), a button for that program will<br />

appear in the taskbar (located at the bottom of the deskstop screen). If a<br />

program has been minimized (still running, but not displayed on screen),<br />

or if it has disappeared behind another program’s window, clicking its<br />

taskbar button will make it appear on screen.<br />

<strong>Xpress</strong> Basics 15

See the software manual<br />

for a complete explanation<br />

of all the ImageMaker<br />

configuration items.<br />

16 <strong>Xpress</strong> Basics<br />

Checking the <strong>Xpress</strong><br />

Software Configuration<br />

Before performing the initial test on the production system, check the<br />

system configuration to ensure that certain items are set properly. This is<br />

done through the ImageMaker (software) configuration utility.<br />

Start the configuration utility.<br />

Click the Windows Start button, located on the lower-left corner of the<br />

desktop. From the menu that pops up, work through the submenus to<br />

select Programs�ImageMaker�Configure ImageMaker. The<br />

configuration dialog, shown below, will open.<br />

Check the following configuration items to make sure they’re set<br />

correctly:<br />

If a printer is installed, it must be identified<br />

Select the printer name in the field labeled My disc printer is …, and set<br />

the port in the following field accordingly. (If there’s no printer, ignore<br />

this setting.)<br />

IF YOUR PRINTER IS A SELECT THIS TYPE ON THIS PORT<br />

Perfect Image (black-only or color thermal transfer) Rimage Printer COM1<br />

Signature IV (color inkjet) CD Color Printer IV LPT1<br />

Signature Pro (color inkjet) CD Color Printer Pro LPT1<br />

Identify the type of ImageAutomator system<br />

In the field labeled The ImageAutomator is a model …, select <strong>Xpress</strong>.<br />

• Save any changes made. If any changes to the configuration have<br />

been made click the Update button before closing the utility. If no<br />

changes have been made, click Close.

Initial System Calibration<br />

One of the programs included with the system is a calibration utility.<br />

This utility includes a quick initial system test for checking the basic<br />

disc-transporting functions. Follow the procedure below to run this test.<br />

Prepare for the checkout procedure<br />

Place a few discs on spindle 3. Start the calibration utility program by<br />

double-clicking the program’s desktop icon, shown here to the left. The<br />

calibration utility’s window will open (shown below).<br />

Set up and run the quick test once<br />

The test will simulate a single disc being copied. Click the single test<br />

cycle button to start the test.<br />

1. A disc will be picked up from spindle 3.<br />

2. The top disc writer drive tray will open and the disc will be placed<br />

into the tray.<br />

3. The disc writer drive tray will close, then open.<br />

4. The disc will be picked up from the disc writer, and the drive tray<br />

will close.<br />

Note: If a printer is installed, the printer tray will open, and the disc will<br />

be placed in the tray: The printer tray will close, and the disc writer drive<br />

tray will close. The printer tray will then open, and the disc will be<br />

picked up from the printer tray, and the printer tray will close.<br />

5. If no printer is installed, the disc will be picked up from the disc<br />

writer drive tray and dropped on spindle 4.<br />

<strong>Xpress</strong> Basics 17

18 <strong>Xpress</strong> Basics<br />

Observe the following carefully during quick test<br />

• Arm centers on spindle<br />

• Disc is dropped in center of drive writer tray<br />

• Disc is dropped onto output spindle<br />

If Printer is installed<br />

• Disc is dropped in center of printer tray<br />

• Disc is dropped directly onto output spindle<br />

If the single initial test fails, run the continuous test to locate the<br />

problem—Make sure there are several discs on spindle 3. Click the<br />

continuous test button at the lower right to run the same test<br />

continuously.<br />

Disc handling problems are not always repeatable. Accurate calibration<br />

is important to achieve reliable operation. It is recommended that you<br />

run the continuous test through several hundred discs to insure proper<br />

calibration.<br />

After starting the test, this button name will automatically change to<br />

Stop Continuous. To stop the test, click this button.<br />

If the problem recurs, calibration (adjustment) of the system is necessary.<br />

(See the following chapter, Calibrating <strong>Xpress</strong> for complete<br />

instructions.)

Testing <strong>Xpress</strong><br />

After the system has passed the previous test, complete the testing<br />

process by actually making disc copies. To do this use the disc<br />

duplication program, ImageMaker EZ using the following procedure:<br />

Start the disc duplication program<br />

Click the program’s desktop icon. The duplication program will open,<br />

and the main window will appear (see illustration below).<br />

Place several blank discs on spindle 3<br />

The third spindle from the left. Refer to the diagram on page 2.<br />

Click the button to make disc copies from a<br />

pre-existing disc image<br />

The window will change when this is done, and some additional input<br />

fields will appear.<br />

Select the disc image to use to make copies from.<br />

Find the field labeled Disc Name near the top. Click the arrow at the<br />

right of this field to open a list box of available images. There are two<br />

images included with every <strong>Xpress</strong> system, one for systems with a<br />

printer installed and one for systems without a printer. (The one for<br />

printer-equipped systems will also print the disc copies.) Click on your<br />

system type to select it.<br />

Click Start to begin the test<br />

If the quantity has not been changed, only one copy will be made. A<br />

blank disc should be picked up from spindle 3 and delivered to one of<br />

the disc writer drives. After the disc is “burned” (and printed if a printer<br />

is installed), it will be picked up from the drive and placed on spindle 4.<br />

<strong>Xpress</strong> Basics 19

Spindle #1<br />

Tertiary Input Spindle (3 rd<br />

200 discs)<br />

Spindle #2<br />

Secondary Input Spindle<br />

(2 nd 200 discs)<br />

20 <strong>Xpress</strong> Basics<br />

Placing Discs on Spindles<br />

As an automated disc production system, <strong>Xpress</strong> transports discs to<br />

various processing stations internally. The operator’s only physical task<br />

is to load blank discs for processing on the input spindle(s) and remove<br />

finished discs from the output spindle(s).<br />

The diagram below shows the location and function of the various<br />

spindles, viewed from above.<br />

Spindle #3<br />

Primary Input Spindle (1 st<br />

200 discs)<br />

Spindle #5<br />

Reject Spindle<br />

Spindle #4<br />

Output Spindle<br />

Each spindle holds 200 discs. To process a total of 600 discs with only 4<br />

spindles, some spindles must be used to hold both blank and written<br />

media (not at the same time). To start, blank media are loaded on<br />

spindles 1, 2 and 3 and spindle 4 is left empty. Blank discs will be<br />

retrieved from spindle 3 and completed discs will be placed on spindle 4.<br />

When all discs have been removed from spindle 3, the whole operation<br />

shifts by one spindle and blank discs will be retrieved from spindle 2 and<br />

completed discs will be placed on (the now empty) spindle 3. When all<br />

discs on spindle 2 have been used, the operation will shift one more time<br />

and blank discs will be retrieved from spindle 1 and completed discs will<br />

be placed on spindle 2. When all 600 discs have completed, there will be<br />

discs on spindles 2, 3 and 4 and nothing on spindle 1.<br />

When the disc production software is started, the production system<br />

automatically resets itself to take discs from spindle 3 and places finished<br />

discs on spindle 4. This is true even if the system was previously taking<br />

discs from spindle 2 or spindle 1.<br />

Whenever the disc production software is started, blank discs must be<br />

loaded on spindles 3, 2 and 1 and spindle 4 must be empty.

CAUTION: Do not shut<br />

down the system if there<br />

are any production jobs<br />

running on it. It may not<br />

be obvious if a job is<br />

running, since a job could<br />

be in the pre-mastering<br />

phase. Use the CD-REMOTE<br />

Management Center to<br />

check the status of current<br />

jobs (see software manual<br />

for details).<br />

Shutting Down <strong>Xpress</strong><br />

When the job completes, please follow the standard Windows shut down<br />

procedures.<br />

<strong>Xpress</strong> Basics 21

Calibrating <strong>Xpress</strong>

Calibrating <strong>Xpress</strong><br />

24 Calibrating <strong>Xpress</strong><br />

To work properly, <strong>Xpress</strong> needs to be correctly calibrated. <strong>Xpress</strong> is<br />

calibrated at the factory and should not need recalibration. Improper<br />

handling during shipping may make this step necessary. If discs are not<br />

picked up from the input spindles, are being dropped off the trays or<br />

output spindles or are going into drive or printer trays cockeyed, the<br />

system must be recalibrated.<br />

Calibration means making adjustments to the disc production system so<br />

the operation runs smoothly.<br />

Prepare for the calibration procedure<br />

Place a few discs on spindles 1, 2 and 3. Start the calibration utility<br />

program by double-clicking its desktop icon. The calibration utility’s<br />

window will open.<br />

Adjust the spindle calibrations<br />

Click the Calibrate Position button and click on the button for the<br />

spindle you wish to calibrate (S1 for example). The disc transport arm<br />

will move over to the top of the spindle, move down close to the top of<br />

the spindle and then stop.<br />

If the arm is not centered exactly over the spindle, the calibration of the<br />

spindle must be corrected. Use the two arrow buttons and to “bump” the<br />

position of the arm counter clockwise or clockwise respectively. When<br />

the arm is centered, click the Save button to accept the change. Recheck<br />

the alignment by repeating this step. Click the Cancel button if no<br />

change is necessary.<br />

Repeat this step for spindles 1-4.<br />

Adjust the calibration of the reject spindle<br />

Click the Calibrate Position button and then the Rej button. A message<br />

warning you to close all printer and drive trays will be displayed. Click<br />

OK when all trays are closed. The disc transport arm will move over and<br />

down to the reject spindle. As above, make any necessary adjustments<br />

and click the Save button to accept the new position.<br />

Adjust the drive calibration<br />

There is no separate calibration for drives 1-4. Only one of the stations<br />

(D1-D4) must be calibrated. Have at least one disc on spindle 3 and one<br />

of the drive trays open. Click the Calibrate Position button and the D1<br />

button. The disc transport arm will pick up a disc from spindle 3 and<br />

move it over to the drive. Once it senses the drive tray, the arm will<br />

move back and stop above the drive tray.<br />

Check that the disc is properly centered above the drive tray and that it<br />

is clear of the front of the drive. Drive trays are slightly beveled so it is<br />

okay if the disc is a bit forward of center. When the position of the disc is<br />

correct, click on the Save button.

Microtech Support<br />

If you are having problems with your <strong>Xpress</strong>, before calling Microtech<br />

Systems support line please check the following:<br />

1. Check all external connections<br />

2. Check for good power<br />

3. Make sure your system is on a sturdy and level surface<br />

4. Check the tightness of the thumbscrews that hold the main<br />

assemblies together<br />

If none of these solutions solve the problem, please have the following<br />

information available before calling Microtech Systems support.<br />

1. Serial number (3-4 digit number located on the back of the system or<br />

under the keyboard),<br />

2. Detailed description of problem(s) experienced.<br />

Microtech Systems<br />

2 Davis Drive<br />

Belmont, CA 94002<br />

650-596-1900<br />

Hours: 7:30 a.m. – 5:30 p.m. PST<br />

support@microtech.com<br />

www.microtech.com<br />

Calibrating <strong>Xpress</strong> 25

Assembly Procedures................................................ 9<br />

Control Panel.............................................................. 4<br />

Desktop Icons ........................................................... 15<br />

Initial System Calibration ....................................... 17<br />

Initial System Checkout .......................................... 19<br />

Microtech Support ................................................... 25<br />

Placing Discs on Spindles ....................................... 20<br />

Shutting Down the System..................................... 21<br />

Index<br />

Software Configuration ...........................................16<br />

Specifications ..............................................................4<br />

Starting the System ..................................................14<br />

System Calibration ...................................................24<br />

Systems Parts ..............................................................2<br />

Windows NT<br />

starting Windows .................................................14<br />

<strong>Xpress</strong> Parts.................................................................8<br />

Index 27