MEIKO Trolley washing solutions - GoHospitality

MEIKO Trolley washing solutions - GoHospitality

MEIKO Trolley washing solutions - GoHospitality

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Inflight Catering<br />

Wash-Up Systems<br />

Inflight Catering<br />

Wash-Up Systems<br />

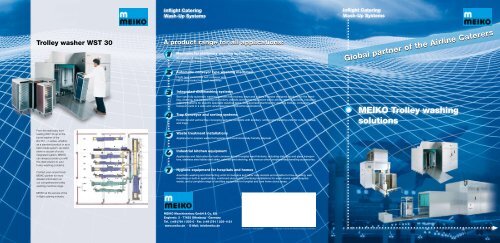

<strong>Trolley</strong> washer WST 30<br />

A product range for all applications:<br />

Machines for stationary <strong>washing</strong> operations<br />

Glasswashers, Dishwashers, pan and utensil washers, multi-purpose <strong>washing</strong> machines, and even a machine for<br />

the <strong>washing</strong> and drying of salad, fruit, and vegetable products.<br />

Global partner of the Airline Caterers<br />

Automatic conveyor type <strong>washing</strong> machines<br />

Flight type continuous belt conveyor and<br />

catch-peg basket transport machines<br />

From the stationary front<br />

loading WST 30 up to the<br />

tunnel washer of the<br />

BA 251 – C series, whether<br />

as a standard product or as a<br />

tailor made system, as stand<br />

alone or as part of a fully<br />

integrated system, <strong>MEIKO</strong><br />

can always provide you with<br />

the ideal solution to your<br />

trolley <strong>washing</strong> problems.<br />

Contact your closest local<br />

<strong>MEIKO</strong> partner for more<br />

detailed information on<br />

our comprehensive trolley<br />

<strong>washing</strong> machine range.<br />

<strong>MEIKO</strong> at the service of the<br />

in-flight catering industry.<br />

Integrated dish<strong>washing</strong> systems<br />

Semi and fully automatic <strong>washing</strong> systems for crockery, trays and cutlery. Purpose designed <strong>solutions</strong> for the handling,<br />

cleaning, and transporting of crockery, utensils and mobile equipment within airline catering facilities. Industrial<br />

<strong>washing</strong> systems for specific specialist <strong>washing</strong> tasks. Conveyorised machines for <strong>washing</strong> trolleys, containers, and<br />

transport carts in a wide and varied selection of industrial applications.<br />

Tray Conveyor and sorting systems<br />

Horizontal and vertical tray conveying systems complete with ancillary sorting and stacking units for cutlery, dishes,<br />

and trays.<br />

Waste treatment installations<br />

Appliances to prepare waste for hygienic and environmentally friendly disposal<br />

Industrial kitchen equipment<br />

Appliances and fabrication for both commercial and hospital ward kitchens, including dish, tray and glass transporters,<br />

stainless steel tables and sinks, cabinets and shelving, and various other complimentary handling accessories.<br />

Hygiene equipment for hospitals and homes<br />

Automatic <strong>washing</strong> and disinfecting units for bedpans and other care utensils and suitable for free-standing, wall<br />

mounting or built-in applications; combined sluice units; plumbing installations for wash rooms within hospital<br />

wards, and a complete range of ancillary equipment for hospital and care home sluice areas.<br />

<strong>MEIKO</strong> <strong>Trolley</strong> <strong>washing</strong><br />

<strong>solutions</strong><br />

<strong>MEIKO</strong> Maschinenbau GmbH & Co. KG<br />

Englerstr. 3 · 77652 Offenburg · Germany<br />

Tel. (+49 )781 / 203-0 · Fax (+49 )781 / 203-1121<br />

www.meiko.de · E-Mail: info@meiko.de<br />

360.030.00.11.06/D/KD/2000<br />

Änderungen im Sinne der Weiterentwicklung vorbehalten.

<strong>MEIKO</strong> - The competent<br />

ware <strong>washing</strong> partner for<br />

the in-flight catering<br />

industry<br />

With today’s ever increasing<br />

hygiene standards,<br />

even smaller in-flight<br />

catering operations are expected<br />

by their clients to<br />

ensure the perfect cleanliness<br />

of all the equipment<br />

they handle, including the<br />

trolleys.<br />

For 30 to 300 trolleys /h,<br />

<strong>MEIKO</strong> has a full range of<br />

solid state trolley <strong>washing</strong><br />

machines and <strong>solutions</strong>,<br />

tailored to the exact needs<br />

of each individual catering<br />

operation.<br />

As compact <strong>washing</strong><br />

chamber or as multi-tank<br />

tunnel <strong>washing</strong> machine,<br />

for above floor installation<br />

or for installation in a pit,<br />

<strong>MEIKO</strong> trolley washers can<br />

be perfectly integrated<br />

into any new or existing<br />

ware <strong>washing</strong> facility.<br />

For professional and<br />

competent consulting<br />

and planning assistance,<br />

your local <strong>MEIKO</strong> partner<br />

is always at your entire<br />

disposal.<br />

A unique <strong>MEIKO</strong> feature: the<br />

all stainless steel belt ensures<br />

unrivalled durability and an<br />

excellent stability of the trolleys<br />

even without arresting the<br />

brakes.<br />

The slanted belt design allows<br />

for better flowing of residual<br />

water from in and outside the<br />

trolley, creating the necessary<br />

pre-conditions required for<br />

outstanding drying results.<br />

The clever design guarantees<br />

the easy access for daily<br />

cleaning and servicing, adding<br />

extra protection of both trolleys<br />

and machine against damages<br />

caused by improper trolley<br />

handling.<br />

The noise absorbing discharge<br />

tunnel significantly reduces the<br />

noise dissipation into the ware<br />

<strong>washing</strong> area and contributes<br />

substantially to improved staff<br />

working conditions.<br />

The most important details<br />

at a glance<br />

G Excellent drying results: Optimally<br />

located air knives on the<br />

ceiling and inner walls ensure<br />

the ideal distribution of large<br />

quantities of heated dry air<br />

onto all surfaces of the trolleys.<br />

G Robust stainless steel lateral<br />

wash-arms with strategically<br />

directed nozzles guarantee<br />

first class <strong>washing</strong> results with<br />

absolutely no spray shadow.<br />

Another unique <strong>MEIKO</strong> feature:<br />

additional powerful wash<br />

systems located underneath<br />

the belt ensure the cleaning of<br />

the underside of the trolleys.<br />

Where trolleys with unsealed<br />

bearings are still in use, the<br />

lower <strong>washing</strong> systems can be<br />

switched off independently.<br />

All water, steam, and pumped<br />

hot water connections, as well<br />

as distributors, valves, meters<br />

and hot water aggregates<br />

are centrally fitted within the<br />

standard <strong>MEIKO</strong> installation<br />

cabinet, offering great operating<br />

comfort and ensuring<br />

easy access for service and<br />

maintenance.<br />

Today’s inflight catering operations<br />

require modern control<br />

systems, providing the user<br />

with daily operating data statistics<br />

and system monitoring.<br />

The optionally available <strong>MEIKO</strong><br />

visualisation system with touch<br />

screen control provides the<br />

operator with extreme operation<br />

comfort and complete<br />

insight in the operating status<br />

of his machines or complete<br />

system. Detailed information<br />

on all machine components at<br />

the tip of the finger.