INSTALLATION AND USE MANUAL Control Panel and ... - G.m.v.

INSTALLATION AND USE MANUAL Control Panel and ... - G.m.v.

INSTALLATION AND USE MANUAL Control Panel and ... - G.m.v.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

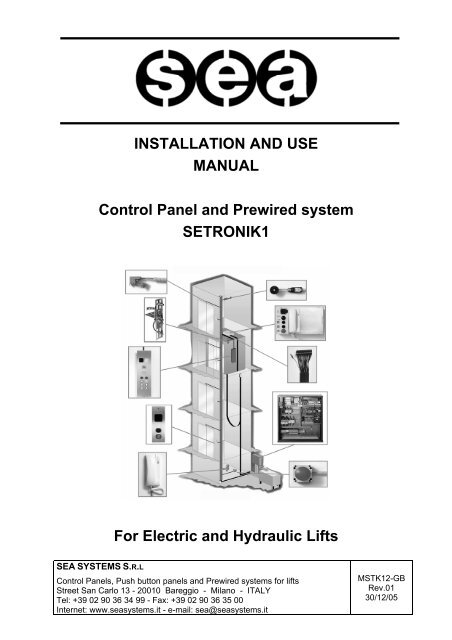

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong><br />

<strong>MANUAL</strong><br />

<strong>Control</strong> <strong>Panel</strong> <strong>and</strong> Prewired system<br />

SETRONIK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

SEA SYSTEMS S.R.L<br />

<strong>Control</strong> <strong>Panel</strong>s, Push button panels <strong>and</strong> Prewired systems for lifts<br />

Street San Carlo 13 - 20010 Bareggio - Milano - ITALY<br />

Tel: +39 02 90 36 34 99 - Fax: +39 02 90 36 35 00<br />

Internet: www.seasystems.it - e-mail: sea@seasystems.it<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

INTRODUCTION<br />

Our compliments for choosing the SETRONIK1 controller as the controller for your lift.<br />

Please carefully read this booklet so that you will be able to underst<strong>and</strong> all the qualities of<br />

this device <strong>and</strong> its potential.<br />

The SETRONIK1 family controllers are microprocessor-controlled controllers specially<br />

designed for the control of 1 Speed, 2 Speeds <strong>and</strong> Variable Speed, Hydraulic <strong>and</strong> Rope<br />

Lifts operating in APB, Simplex (up <strong>and</strong>/or down collective), Duplo <strong>and</strong> Pick-Up operation.<br />

The STK2-PM programmer allows to set a secret Access Code, know the conditions the lift<br />

is operating in, which <strong>and</strong> how many times failures <strong>and</strong> malfunctions have occurred,<br />

control the lift <strong>and</strong> doors motion <strong>and</strong> modify the operating characteristics of the lift itself.<br />

Several functions specific to a particular lift can be programmed without having to act on<br />

the <strong>Control</strong>ler wiring.<br />

As far as the operating Diagnostics is concerned, help is provided by the failure <strong>and</strong><br />

malfunction indications on the Programmer displays <strong>and</strong> by the indications<br />

supplied by the board LEDs.<br />

Warning<br />

Since our products are in constant evolution, all information contained in this manual can<br />

be modified by SEA SYSTEMS without notice.<br />

In the case of special lifts, any accessory documentation relating to additional or modified<br />

functions is provided.<br />

SETRONIK1 Pagina 2 di 54

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

TABLE OF CONTENTS<br />

1. FUNCTIONAL CHARACTERISTICS ................................................... 5<br />

2. <strong>INSTALLATION</strong>..................................................................................... 6<br />

2.1. GENERAL NOTES.........................................................................................................7<br />

2.2. SAFETY RULES............................................................................................................8<br />

2.3. GLOSSARY ..................................................................................................................8<br />

2.4. PRELIMINARY OPERATIONS...........................................................................................9<br />

2.5. FIXING <strong>AND</strong> CONNECTION OF THE CONTROL PANEL ......................................................10<br />

2.6. FIXING <strong>AND</strong> CONNECTION IN THE SHAFT.......................................................................11<br />

2.7. FIXING <strong>AND</strong> CONNECTION ON THE CAR ROOF ................................................................14<br />

2.8. INSULATION TEST ......................................................................................................23<br />

2.9. SYSTEM COMMISSIONING ...........................................................................................24<br />

3. PROGRAMMING................................................................................. 25<br />

3.1 PROGRAMMER CONNECTION (STK2-PM) ....................................................................25<br />

3.2. EXAMPLE OF PROGRAMMER <strong>USE</strong> .................................................................................26<br />

3.3. PROGRAMMING THE CUSTOMER SECRET ACCESS CODE...............................................27<br />

3.4. PARAMETERS STORING. .............................................................................................28<br />

3.5. PROGRAMMING THE LIFT, OPERATION, SELECTOR........................................................29<br />

3.6. PROGRAMMING THE MAIN FLOOR, PARKING FLOOR, PREFERENTIAL FLOOR, FIREMEN <strong>AND</strong><br />

FIRE-FIGHTING FLOOR, DUPLO VERTICAL RISE FLOORS..................................................30<br />

3.7. PROGRAMMING THE OPERATOR..................................................................................31<br />

3.8. PROGRAMMING MAX FLOOR RE-LEVELLINGS, POSITION INDICATIONS. ............................32<br />

3.9. PROGRAMMING OF SPEED <strong>AND</strong> STOP MODE DURING INSPECTION, MOVABLE PLATFORM,<br />

ADVANCE DOORS OPENING, RE-LEVELLING, GONG .......................................................33<br />

3.10. PROGRAMMING OF OVERLOAD CONTACT...................................................................34<br />

3.11. PROGRAMMING OF SERVICES. ..................................................................................35<br />

3.12. SHAFT PROGRAMMING: ............................................................................................36<br />

3.13. PROGRAMMING OF TIMERS:......................................................................................37<br />

3.14. INPUT PROGRAMMING: .............................................................................................38<br />

3.15. OUTPUT PROGRAMMING: .........................................................................................39<br />

4. DIAGNOSIS......................................................................................... 40<br />

4.1. LIFT STATUS DISPLAY ................................................................................................40<br />

4.2. DISPLAY <strong>AND</strong> CANCELLATION OF FAILURES / MALFUNCTIONS.........................................41<br />

4.3. COUNT OF RUNS <strong>AND</strong> RE-LEVELLINGS PERFORMED. .....................................................42<br />

4.4. COMM<strong>AND</strong>S FOR LIFT OPERATION IN THE MACHINE ROOM: .............................................43<br />

4.5. LED SIGNALLING LEGEND OF CARDS STK1-B, STK1-E <strong>AND</strong> AL01................................44<br />

4.6. ERROR CODE LEGEND ...............................................................................................47<br />

SETRONIK1 Pagina 3 di 54

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

5. MAINTENANCE ................................................................................ 50<br />

5.1. BATTERY REPLACEMENT.............................................................................................50<br />

5.2. SHAFT SENSORS........................................................................................................50<br />

5.3. STK1-B BASIC ELECTRONIC BOARD REPLACEMENT .....................................................51<br />

5.4. CS1 SAFETY CIRCUIT REPLACEMENT ..........................................................................52<br />

6. BASIC TROUBLESHOOTING PROCEDURES.................................. 53<br />

6.1. ALARMED CARD (ALL LED ON)....................................................................................53<br />

6.2. ERRONEUS READOUT OF THE SHAFT SENSORS .............................................................53<br />

7. TECHNICAL DATA ............................................................................. 54<br />

SETRONIK1 Pagina 4 di 54

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

1.FUNCTIONAL CHARACTERISTICS<br />

LIFT TYPES<br />

- ROPE 1 - 2 SPEEDS , ACVV , VVVF<br />

- HYDRAULIC : DIRECT , STAR DELTA , SOFT STARTER , SOFT STOP, SCC,<br />

ELECTRONIC VALVES<br />

OPERATIONS<br />

NUMBER OF STOPS<br />

DOOR CONTROL<br />

VARIOUS CONTROLS<br />

CAR <strong>AND</strong> L<strong>AND</strong>ING<br />

SIGNALS ( 24V. )<br />

SHAFT<br />

EMERGENCY<br />

- APB FOR INDIVIDUAL LIFT<br />

- DOWN COLLECTIVE SIMPLEX<br />

- DOWN-UP COLLECTIVE SIMPLEX<br />

- DUPLO<br />

- PICK UP<br />

- FOR APB <strong>AND</strong> DOWN COLLECTIVE:<br />

6 BASIC STOPS / 6 SERVICES<br />

EXTENSION OF 6 STOPS \ 6 SERVICES (TOTAL 12 STOPS \ 12 SERVICES)<br />

- FOR UP <strong>AND</strong> DOWN COLLECTIVE:<br />

4 BASIC STOPS \ 4 SERVICES<br />

EXTENSION 4 STOPS \ 4 SERVICES (TOTAL 8 STOPS \ 8 SERVICES)<br />

- <strong>MANUAL</strong> ON L<strong>AND</strong>INGS <strong>AND</strong> CAR<br />

- <strong>MANUAL</strong> ON L<strong>AND</strong>INGS <strong>AND</strong> WITHOUT DOORS IN THE CAR – BY SAFETY<br />

CELL<br />

- <strong>MANUAL</strong> ON L<strong>AND</strong>INGS <strong>AND</strong> AUTOMATIC IN THE CAR<br />

- AUTOMATIC ON L<strong>AND</strong>INGS <strong>AND</strong> IN THE CAR UP TO 2 LIFTS BY ALTERNATE<br />

\SIMULTANEOUS \ SELECTIVE OPENING<br />

- PHOTOCELL, DOOR PRESSURE SWITCH , DOORS OPENING/CLOSING<br />

PUSHBUTTON<br />

- PARKING WITH OPEN/CLOSED DOORS DIFFERENTIATED AT THE VARIOUS<br />

L<strong>AND</strong>INGS<br />

- TIMED CONTROL OF DOORS MOTORS<br />

- DISPLAY <strong>AND</strong> CANCELLATION OF FAILURE \ MALFUNCTION CODES<br />

- SAFETY DEVICES CONTROL<br />

- CONTROL OF THE STICKING \ FAILED EXCITATION OF CONTACTORS<br />

- MOBILE PLATFORM \ FULL LOAD \ OVERLOAD<br />

- OIL TEMPERATURE <strong>AND</strong> PRESSURE<br />

- MOTOR WINDING TEMPERATURE<br />

- SEQUENCE <strong>AND</strong> PHASE FAILURE<br />

- TIMERS MANAGEMENT (RUN TIME, LOW SPEED TIME)<br />

- 15’ DESPATCH (HYDRAULIC LIFTS)<br />

- MAIN FLOOR PARKING<br />

- LEVELLING SPACE SETTING<br />

- ADVANCE DOORS OPENING<br />

- RESERVED /PREFERENTIAL /FIREMEN / FIRE-FIGHTING OPERATION<br />

- CUSTOMER SECRET ACCESS CODE<br />

- DOOR PROGRAMMING<br />

- AVAILABLE INPUT-OUTPUT PROGRAMMING (SPECIAL OPERATIONS)<br />

- PRESENT / BUSY / COMING (ON L<strong>AND</strong>INGS)<br />

- OCCUPIED (IN THE CAR / ON L<strong>AND</strong>INGS)<br />

- POSITION LAMPS <strong>AND</strong>/OR DISPLAYS BY COMMON NEGATIVE DECODING,<br />

DENIED BCD, GRAY CODE<br />

- NEXT DIRECTION ARROWS (IN THE CAR / ON L<strong>AND</strong>INGS)<br />

- OVERLOAD<br />

- GONG<br />

- NORMAL, SHORT <strong>AND</strong>/OR CLOSE FLOORS CONTROL<br />

- ALARM , 12V EMERGENCY LIGHT<br />

- SETTING FOR DEVICE OF DESCENT <strong>AND</strong> DOOR OPENING IN EMERGENCY<br />

WITH MOTOR 48V FOR HYDRAULIC LIFT (B12E Board)<br />

SETRONIK1 Pagina 5 di 54

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

2.<strong>INSTALLATION</strong><br />

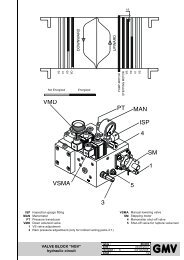

Fig.2.1. Pre-wiring Layout Drawing, including reference paragraphs for installation purposes<br />

SHAFT:<br />

- Par. 2.6<br />

CAR ROOF:<br />

- Par. 2.7<br />

MACHINE ROOM:<br />

- Par. 2.5<br />

SETRONIK1 Pagina 6 di 54

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

2.1.GENERAL NOTES<br />

NOTE<br />

Carefully read any warning information in the present operating instructions as<br />

holding important safety, operating <strong>and</strong> service instructions.<br />

• Installation <strong>and</strong> service to be carried out in compliance with regulations in force,<br />

according to the manufacturer specifications <strong>and</strong> by authorised, trained <strong>and</strong> qualified<br />

personnel only.<br />

• A wrong installation or an improper service could lead to damages to people, animals<br />

or objects, which the manufacturer is not liable for.<br />

• Should the machine be sold or transferred to a different owner, check that the present<br />

operating instructions are always available, as to be duly used by the new owner or<br />

operator.<br />

• Hereby listed documents are to be sued for a correct installation set-up:<br />

-Installation project drawing (not supplied by Sea);<br />

-<strong>Control</strong> <strong>Panel</strong> STK1: Installation <strong>and</strong> Maintenance Manual (this manual);<br />

-<strong>Control</strong> board programming <strong>and</strong> troubleshooting operating instructions;<br />

-<strong>Control</strong> <strong>Panel</strong> electric wiring;<br />

-<strong>Control</strong> <strong>Panel</strong> Installation electric wiring (in this manual).<br />

•The installation manager must store any enclosed documents in a safe place, within<br />

reach, thus providing for a correct lift set-up <strong>and</strong> service. Operating instructions are an<br />

integral part to the installation <strong>and</strong> therefore they are not allowed to be damaged. Avoid<br />

tearing pages <strong>and</strong> when consulted, it is necessary to avoid damaging to provide for any<br />

possible future correct reference.<br />

• Guarantee terms are on the product transportation document back. SEA SYSTEMS<br />

will support its products through the guarantee, in case of defects with a specified time<br />

period. Should the product not be correctly operated or its performance anyhow modified,<br />

differently from factory original specifications, the guarantee no longer applies.<br />

• When necessary, get in touch with the company Service Department always<br />

providing for the installation serial number.<br />

The serial number is specified:<br />

- on the adhesive label on the outside of the control board unit;<br />

- On the first page of the board electric wiring;<br />

- On the <strong>Control</strong> board programming paper<br />

- On the Board Declaration of Conformity<br />

• The serial number is to be always specified to identify the installation technical<br />

specifications.<br />

The safety department address <strong>and</strong> telephone number are available on the present<br />

operating instructions cover.<br />

SETRONIK1 Pagina 7 di 54

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

2.2.SAFETY RULES<br />

•The unit can only be installed by qualified <strong>and</strong> authorised personnel, who is liable for the<br />

specific compliance to st<strong>and</strong>ards according to the technical best practice available.<br />

•Before any cleaning or serve, cut the unit from the power supply by means of the<br />

installation cut-out switch.<br />

• Always wear the dem<strong>and</strong>ed personal protections (fig. 2.1),<strong>and</strong> more precisely:<br />

- Cask.<br />

- Gloves.<br />

- Overall, closed at the wrist level.<br />

- Protective shoes.<br />

- Safety belts.<br />

- Headphones.<br />

Fig. 2.1 – Safety signalling<br />

• Never wear loose objects <strong>and</strong>/or clothing (necklaces, watches, ties), avoid long hair.<br />

• Never store cutting or pointed objects (screwdriver, scissors …) in the shirt pocket.<br />

• Never tamper, wear or hide warning signs or labels. When wore <strong>and</strong> dem<strong>and</strong>ed,<br />

immediately replace the.<br />

• In order to lift heavy loads, always used suitable tools, thus avoiding any damage to the<br />

spine cord depending on the unit manual h<strong>and</strong>ling.<br />

2.3.GLOSSARY<br />

NOTE<br />

It provides personnel with specific <strong>and</strong> valuable information.<br />

WARNING<br />

It provides personnel with information which, when not complied with, can lead to<br />

light people or installation damages<br />

CAUTION<br />

It provides personnel with information on a specific operation, which, if not taken<br />

into account in compliance with safety regulations in force, can lead to possible<br />

severe physical damages.<br />

SETRONIK1 Pagina 8 di 54

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

2.4.PRELIMINARY OPERATIONS<br />

Before starting the installation, check what follows:<br />

A)<strong>INSTALLATION</strong> PLACE SET UP<br />

• Check the existing operating lighting.<br />

• Check the unit <strong>and</strong> pit cleaning<br />

• Check that the mains electric installation is connected to a suitable earthing<br />

(otherwise stop setting the installation up, until a suitable earthing or grounding is<br />

available).<br />

• Check that the unit inlets are perfectly closed.<br />

• A storage area next to the unit is to be available, easily accessible to operators <strong>and</strong><br />

protected from any adverse weather condition.<br />

• Check any cable tray <strong>and</strong> passing holes suitable for electric cabling, always to be<br />

easily inspected <strong>and</strong> well-refined.<br />

B)MATERIAL UNLOADING <strong>AND</strong> WAREHOUSING<br />

• Check the <strong>Control</strong> <strong>Panel</strong> specifications (<strong>Control</strong> <strong>Panel</strong> type, Contactors, Starting,…)<br />

must comply with dem<strong>and</strong>ed specifications on the order confirmation.<br />

• Check the availability of any suitable material to be used during assembly, referring<br />

to the checklist accompanying the board documents.<br />

• Check any unit <strong>and</strong> material condition when delivery to the site, to check possible<br />

damages which arrived during transportation. Immediately prevent SEA SYSTEMS<br />

Srl in the case of missing units or damages<br />

• Store electric <strong>and</strong> electronic unit in a dry <strong>and</strong> cold room, in the original packaging.<br />

• Should it not be possible, whatever reason, to immediately install the unit,<br />

periodically check stored units to avoid damages depending on a long storage<br />

under unfavourable conditions.<br />

C)SCAFFOLDING<br />

When setting the unit up, use st<strong>and</strong>ard scaffolding, exhibiting operating floors at any stop,<br />

at about 0.5 meter lower than the stop.<br />

CAUTION<br />

Scaffolding completely or partially in metal, to be connected to a suitable<br />

grounding, in compliance with safety regulations in force.<br />

SETRONIK1 Pagina 9 di 54

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

2.5.FIXING <strong>AND</strong> CONNECTION OF THE CONTROL PANEL<br />

1. Drill the wall of the machine room, taking the locating holes of the angle bar<br />

provided as a reference, so that the height at which the panel hangs makes its use<br />

easy <strong>and</strong> convenient;<br />

2. Anchor the angle bar to the upper section of the panel by means of appropriate<br />

bolts <strong>and</strong> cage nuts;<br />

3. Fasten the angle bar to the wall of the machine room with corresponding wall plugs.<br />

HIGHLIGHT<br />

Should the control panel be secured on premises other than the st<strong>and</strong>ard<br />

machine room (ex: local cabinet, Pit, Shaft,...), the above procedure may be<br />

inappropriate. In this case, follow the instructions specified for the system.<br />

4. Make sure that the QM master switch is set to OFF (DOWN position);<br />

5. Connect the appliances to the control panel as per the installation diagrams<br />

HIGHLIGHT<br />

The control panel has been pre-set with terminal board attachments to allow car<br />

movements with a temporary push-button panel. Attachments to the terminal<br />

board of both the control panel <strong>and</strong> push-button panel are outlined on the preassembly<br />

diagram.<br />

SETRONIK1 Pagina 10 di 54

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

2.6.FIXING <strong>AND</strong> CONNECTION IN THE SHAFT<br />

2.6.1.SHAFT LINE<br />

1. The shaft line is formed by a taped coil of single-pole, colour-coded <strong>and</strong> numbered<br />

wires, including plugged-in connectors with labels to the control panel side.<br />

2. Fasten the wireway (P/N P-00060) with appropriate plugs (P/N P-00075) next to the<br />

l<strong>and</strong>ing push-button panels, making sure to keep a maximum distance of 1 m from<br />

the doors. If a dual-operator lift has been installed, fit the wireway closer to the most<br />

widely used side<br />

HIGHLIGHT<br />

Set the plug with the clamp (P/N P-00074) already inserted into the eyebolt<br />

before securing it (Fig. 2.2);<br />

3. Temporarily secure the coil on top of the shaft <strong>and</strong> lower it into the shaft from the<br />

top, letting the side fitted with plugged-in connectors in, to the control panel (Fig.<br />

2.3);<br />

Fig. 2.2. Fig. 2.3<br />

4. Connect the frame connectors to the control panel as per installation diagrams<br />

5. Lay down the coil, starting from the control panel section, using clamps to rivet it to<br />

the retaining plugs of the wireway, all the way to the upper end of the shaft;<br />

WARNING<br />

If cable quantity is too large on the upper side, cut the wires <strong>and</strong> insulate them<br />

with electric tape or use the previously removed connectors.<br />

SETRONIK1 Pagina 11 di 54

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

2.6.2.CONNECTIONS WITH BRANCH POINT TO THE SHAFT LINE<br />

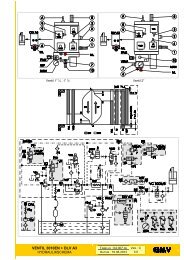

Use red <strong>and</strong> blu connectors (Cod. P-00084, P-00085) following the operations in figure 2.4<br />

for the connections with branch point to the shaft line (see installation diagrams).<br />

Fig. 2.4 –Sequence of operations for the connection with branch point<br />

HIGHLIGHT<br />

Generally the devices that need a connection with branch points are:<br />

- Run limit switch;<br />

- Floor push buttons;<br />

- Alarm siren;<br />

- Stop in the pit<br />

2.6.3.CONNECTIONS IN SERIES TO THE SHAFT LINE<br />

Use orange connectors (BC1 <strong>and</strong> BC2) following the operations in figure 2.7 for the<br />

connections in series to the shaft line (see installation diagrams).<br />

Connect the last device of the series according to the figure 2.5, <strong>and</strong> the first devices of<br />

the series according to the figure 2.6<br />

WIRE COLOURS:<br />

PINK<br />

ORANGE<br />

Fig. 6.4.3Fig. 6.4.4<br />

Upper End L<strong>and</strong>ing ConnectorIntermediate L<strong>and</strong>ings Connectors<br />

YELLOW / GREEN<br />

Fig. 2.5 Fig. 2.6<br />

Last connection in the series<br />

First connections in the series<br />

HIGHLIGHT<br />

Generally the devices that need a connection in series are:<br />

- Safety contacts for floor door lockings<br />

SETRONIK1 Pagina 12 di 54

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

Press the conductors between no-pull,<br />

sealing arms<br />

Position the upper <strong>and</strong> lower sections of<br />

the connector…<br />

…. <strong>and</strong> tighten with a wrench.<br />

Male connector plugging into a female<br />

connector<br />

3-pin open female connector:<br />

- 3- cutting blade<br />

4- L cable (phase) cut <strong>and</strong> contacted, no peeling<br />

5- Contacted ground cable, no peeling<br />

Fig. 2.7 – Sequence of operations to plug in series to the shaft line<br />

SETRONIK1 Pagina 13 di 54

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

2.7.FIXING <strong>AND</strong> CONNECTION ON THE CAR ROOF<br />

2.7.1.JUNCTION BOX FIXING <strong>AND</strong> FLEXIBLE CABLE CONNECTIONS:<br />

1. Fasten the junction box with appropriate retaining screws;<br />

2. Bring the flexible cables coil into the shaft pit;<br />

3. Connect the flexible cables (ground side, with eyebolts) to the car box connectors as<br />

per installation diagrams <strong>and</strong> secure them to the box with appropriate clamps (P/N P-<br />

00074);<br />

4. Rivet the flexible cables to the car through the appropriate cable brackets (P/N P-<br />

00089) <strong>and</strong> plugs (P/N P-00102) on the roof <strong>and</strong> beneath the car (see fig. 2.1);<br />

5. Connect the flexible cables (ground side, no eyebolts) to the control panel as per<br />

installation diagrams;<br />

6. Fasten the wedge side bracket (P/N P-00086) to the shaft, about halfway, with<br />

appropriate plugs (P/N P-00102);<br />

7. Anchor the flexible cables to the wedge side bracket in such a point that when the car<br />

has been lowered all the way down, the flexible cables box does not touch the<br />

bottom of the pit (see fig.2.1);<br />

WARNING<br />

To solve the issue in connection with too big a box <strong>and</strong> too many flexible cables in<br />

the pit, shift the wedge side bracket upwards.<br />

Take into account that every time the bracket gets 1 meter higher, the box rises<br />

approximately by ½ meters.<br />

8. Make sure that flexible cables are not entangled in the pit, otherwise, unplug the<br />

connectors from the control panel, pull them straight <strong>and</strong> reconnect them;<br />

9. Secure one of the cable brackets (P/N P-00089) to the pit wall, where flexible cables<br />

start rising vertically along the shaft.<br />

2.7.2.CAR PUSH BUTTON <strong>AND</strong> DOOR OPERATOR CONNECTION<br />

Connect the car push button <strong>and</strong> the operator according to the installation diagrams.<br />

HIGHLIGHT<br />

In case it’s necessary to use the wireway (Cod. P-00087) to fit the cables on the<br />

car roof, fix it at the roof with screws (cod. P-00101)<br />

SETRONIK1 Pagina 14 di 54

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

2.7.3.FIXING <strong>AND</strong> CONNECTION OF THE SHAFT SENSORS FOR HYDRAULIC LIFTS<br />

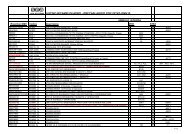

The shaft sensor kit can be of tree different type according to the type of brackets used for<br />

sensors <strong>and</strong> magnets as the following tablet.<br />

The tablet reports also the code of the diagram of the shaft sensor disposition included in<br />

this paragraph.<br />

SENSORS <strong>AND</strong> MAGNETS<br />

A TYPE<br />

KIT BRAKET<br />

B TYPE<br />

KIT BRAKET<br />

C TYPE<br />

KIT BRAKET<br />

Sensors IS, ID, C, D, FCE(optional) CFR CFR G-CFR<br />

Sensors SR, DR, DS CVR SR, DR, DS SR, DR, DS<br />

Magnet bars to comm<strong>and</strong> IS, ID, C, D MFR MFR G-MFR<br />

Round magnet couple to comm<strong>and</strong> SR MVR-SR No Bracket G-MVR-SR<br />

Round magnet couple to comm<strong>and</strong> DR MVR-DR No Bracket G-MVR-DR<br />

Round magnet couple to comm<strong>and</strong> DS MVR-DS No Bracket G-MVR-DS<br />

Diagram for sensor <strong>and</strong> magnet disposition See diagram<br />

CVIA<br />

See diagram<br />

CVIA<br />

See diagram<br />

CVIC<br />

HIGHLIGHT<br />

We recommend that you choose A System or C System for the installation of<br />

magnets. The system ensures tighter fastening of the magnets, a better magnetic<br />

field, less exposure to various bodies (grease, iron fillings….)<br />

With the B System, the magnets without bracket have to be fixed directly on the<br />

guide.<br />

SETRONIK1 Pagina 15 di 54

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

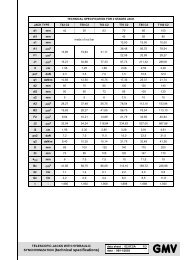

CVIA<br />

SHAFT SENSORS PLACING FOR HYDRAULIC LIFT WITH A OR B SHAFT SENSOR KIT<br />

HIGHLIGHT<br />

With the B System, the magnets without bracket have to be fixed directly on the<br />

guide.<br />

SHAFT FRONTAL VIEW<br />

CAR ROOF VIEW<br />

SLOWING DISTANCE K<br />

SPEED<br />

K<br />

0.2 m/s 20cm<br />

0.4 m/s 40 cm<br />

0.6 m/s 60 cm<br />

0.8 m/s 80 cm<br />

SETRONIK1 Pagina 16 di 54

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

CVIC<br />

SHAFT SENSORS PLACING FOR HYDRAULIC LIFT WITH C SHAFT SENSOR KIT<br />

SHAFT FRONTAL VIEW<br />

CAR ROOF VIEW<br />

SLOWING DISTANCE K<br />

SPEED<br />

K<br />

0.2 m/s 20cm<br />

0.4 m/s 40 cm<br />

0.6 m/s 60 cm<br />

0.8 m/s 80 cm<br />

SETRONIK1 Pagina 17 di 54

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

A) FIXING <strong>AND</strong> CONNECTION OF THE STOP SENSORS AT THE FLOORS:<br />

1. Drive IS <strong>and</strong> ID sensors to the ends of the bracket slots <strong>and</strong> verify that the timer 4.12<br />

is 0000 (no delay);<br />

2. Fix on the car roof the bracket equipped with sensors (CFR) <strong>and</strong> at every floor on<br />

the guide the brackets equipped with magnets (MFR) so that, with the car at the<br />

l<strong>and</strong>ing floor, both sensors <strong>and</strong> magnets are perfectly aligned according to the<br />

diagram CVIA (with A system or B system) or the diagram CVIC (with C system);<br />

3. Connect IS, ID, C, D sensors as per the installation diagrams;<br />

4. Make some calls at the floors, going up <strong>and</strong> down verifying that the car stops with<br />

the floor aligned at the l<strong>and</strong>ing floor.<br />

HIGHLIGHT: Floor Alignment Adjustment<br />

If the stop is advanced, move away the bracket CFR from MFR; if the stop is<br />

delayed, approach the bracket CFR to the MFR.<br />

HIGHLIGHT: Relevelling Zone Adjustment<br />

Should a levelling zone be required, follow the instructions in the Paragraph<br />

2.6.3_Relevelling Zone Adjustment<br />

B) FIXING OF SPEED-CHANGE SENSORS:<br />

1. Fix the speed-change sensors SR, DR, DS on the car roof <strong>and</strong> fix the magnet<br />

couples to the guide so that the sensors <strong>and</strong> the magnets are aligned according to<br />

the diagram CVIA (with A system or B system) or the diagram CVIC (with C system);<br />

2. Connect SR, DS, DR sensors according to the installation diagrams;<br />

3. Adjust the pairs of magnets to match slowing distance K from the l<strong>and</strong>ing as per the<br />

table attached to the diagram CVIA (with A system or B system) or the diagram<br />

CVIC (with C system);<br />

WARNING<br />

To make sure that sensors switch over properly, ascertain that:<br />

- The distance between contiguous magnets on the same axis is major than 5<br />

cm;<br />

- the sensor <strong>and</strong> its corresponding magnet are kept 1÷1.5 cm apart<br />

SETRONIK1 Pagina 18 di 54

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

C) RELEVELLING ZONE ADJUSTMENT FOR HYDRAULIC LIFTS<br />

HIGHLIGHT: Relevelling Zone<br />

The Relevelling Zone is the space of misalignment between the car <strong>and</strong> the floor<br />

without the car relevels. When the car exceeds this space the relevelling control<br />

starts.<br />

4. Move the sensor IS toward the centre of a length equal to the space of relevelling<br />

zone required.<br />

5. Gradually increase the value of timer 4.12 so that, when upward runs are repeated,<br />

the car stops aligned with the floor sill.<br />

The timer value depends on the required speed <strong>and</strong> Relevelling Zone.<br />

6. Move the sensor ID toward the centre so that, in coming down to the l<strong>and</strong>ing, the car<br />

stops aligned with the sill.<br />

WARNING<br />

The relevelling control with open doors is permitted by the safety circuit (CS1<br />

device <strong>and</strong> C, D sensors).<br />

When the led C <strong>and</strong> D of the CS1 device are on, the relevelling control is<br />

permitted; if one or both of the leds are off the relevelling control with open doors<br />

is interrupted.<br />

SETRONIK1 Pagina 19 di 54

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

2.7.4. FIXING <strong>AND</strong> CONNECTION OF THE SHAFT SENSORS FOR ELECTRIC LIFTS<br />

The shaft sensor kit can be of two different type according to the type of brackets used for<br />

sensors <strong>and</strong> magnets as the following tablet.<br />

The tablet reports also the code of the diagram of the shaft sensor disposition included in<br />

this paragraph.<br />

SENSORS <strong>AND</strong> MAGNETS<br />

A TYPE<br />

KIT BRAKET<br />

B TYPE<br />

KIT BRAKET<br />

Sensors IS, ID CVF IS, ID<br />

Sensors SR, DR CRF SR, DR<br />

Two round magnet couples for the stop MVF No Bracket<br />

Round magnet couple for speed-change in upward MVR-IS No Bracket<br />

Round magnet couple for speed-change in downward MVR-ID No Bracket<br />

Round magnet couple for speed-change at the upper floor MVR-SR No Bracket<br />

Round magnet couple for speed-change at the lower floor MVR-DR No Bracket<br />

Diagram for sensor <strong>and</strong> magnet disposition <br />

See diagram<br />

CVFA<br />

See diagram<br />

CVFA<br />

HIGHLIGHT<br />

We recommend that you choose A System for the installation of magnets. The<br />

system ensures tighter fastening of the magnets, a better magnetic field, less<br />

exposure to various bodies (grease, iron fillings….)<br />

With the B System, the magnets without bracket have to be fixed directly on the<br />

guide.<br />

SETRONIK1 Pagina 20 di 54

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

CVFA SHAFT SENSORS PLACING FOR ELECTRIC LIFT WITH A SHAFT SENSOR KIT<br />

HIGHLIGHT<br />

With the B System, the magnets without bracket have to be fixed directly on the<br />

guide.<br />

SLOWING DISTANCE K<br />

SPEED<br />

K<br />

0.6 m/s 60cm<br />

0.8 m/s 80 cm<br />

1 m/s 120 cm<br />

1.2 m/s 140 cm<br />

Zf<br />

Zp<br />

h<br />

Stop Zone (5 cm apart)<br />

Door opening Zone<br />

5 cm apart<br />

SETRONIK1 Pagina 21 di 54

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

A) FIXING <strong>AND</strong> CONNECTION OF THE STOP SENSORS AT THE FLOORS:<br />

7. Fix on the roof car the IS <strong>and</strong> ID sensors <strong>and</strong> at every floor on the guide the magnet<br />

couples so that, with the car at the l<strong>and</strong>ing floor, both sensors <strong>and</strong> magnets are<br />

perfectly aligned according to the diagram CVIA (with A system or B system) or the<br />

diagram CVIC (with C system);<br />

8. Connect IS, ID sensors as per the installation diagrams;<br />

9. Adjust the pairs of magnets so that, going up <strong>and</strong> down, the car stops with the floor<br />

aligned at the l<strong>and</strong>ing floor.<br />

B) FIXING OF SPEED-CHANGE SENSORS:<br />

10. Fix next at every floor on the guide the round magnet couples, so that they are<br />

aligned to the sensors IS <strong>and</strong> ID according to the diagram CVFA;<br />

11. Fix on the car roof the sensors SR <strong>and</strong> DR <strong>and</strong> next to the upper floor <strong>and</strong> the lower<br />

floor on the guide the round magnets so that the sensors <strong>and</strong> magnets are aligned<br />

as specified in the layout L02;<br />

12. Connect SR, DR sensors according to the installation diagrams;<br />

13. Adjust the pairs of magnets to match slowing distance K from the l<strong>and</strong>ing as per the<br />

table attached to diagram CVFA.<br />

WARNING<br />

To make sure that sensors switch over properly, ascertain that:<br />

• The distance between contiguous magnets on the same axis is major than 5<br />

cm;<br />

• the sensor <strong>and</strong> its corresponding magnet are kept 1÷1.5 cm apart<br />

SETRONIK1 Pagina 22 di 54

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

2.8.INSULATION TEST<br />

Before carrying out the flash tests reported in the following table, perform the following<br />

operations:<br />

1 Bring the car out of the l<strong>and</strong>ing zone;<br />

2 De-energise QM master switch <strong>and</strong> QF light switch;<br />

3 Pull out <strong>and</strong> insulate the ground cables that reach the panel;<br />

4 Unplug the phone line from the dialling key.<br />

FROM<br />

TO<br />

GROUND<br />

_____<br />

___<br />

_<br />

Master Switch,<br />

Motors<br />

R,S,T, U,V,W,<br />

U1,V1,W1<br />

U2,V2,W2<br />

Safety dev.,<br />

Brake,<br />

Retractable<br />

Sliding block<br />

1..10, F+,F-,<br />

PR+,PR-<br />

Master<br />

Switch,<br />

Motors<br />

R,S,T,<br />

U,V,W,<br />

U1,V1,W1<br />

U2,V2,W2<br />

Safety dev.,<br />

Brake,<br />

Retractable<br />

Sliding<br />

block<br />

1..10, F+,F-,<br />

PR+,PR-<br />

Three-phase<br />

Motor, Doors<br />

MP,MP,MP,<br />

MP1,MP1,MP1<br />

Car<br />

Lighting<br />

L1,L,N<br />

d.c. Motor,<br />

Doors<br />

+,-,30,32,<br />

MP,MP<br />

Signals<br />

OCC,FD,FS,<br />

PS1,PS2…<br />

<br />

NO <br />

NO NO <br />

Alarm<br />

<br />

AL+, AL-, AL NO NO <br />

Car Lighting<br />

<br />

L1,L,N NO <br />

Signals<br />

OCC,FD,FS,PS1<br />

NO<br />

Safety Circuit<br />

<br />

DI,XC2,CI,XC1 NO NO <br />

= Insulation test to be carried out.<br />

SETRONIK1 Pagina 23 di 54

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

2.9.SYSTEM COMMISSIONING<br />

1. Make sure that the maintenance push-button panel switch placed on the car roof is set<br />

to NORMAL;<br />

2. Turn ON the control panel <strong>and</strong> ascertain that the following leds are switched ON:<br />

1, 2, 8, 10, CM, 01, +5 (in case of Hydraulic lift also TC <strong>and</strong> PST);<br />

3. Should any problems arise (ex: alarmed card: ALL leds ON), refer to Paragraph 6:<br />

Basic Troubleshooting Procedures.<br />

SETRONIK1 Pagina 24 di 54

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

3.PROGRAMMING<br />

3.1PROGRAMMER CONNECTION (STK2-PM)<br />

ab<br />

1. Check that the ON\OFF switch of the Keyboard is in the OFF position.<br />

2. Insert the connection cable in connector FC3 on the STK1-B board.<br />

3. Bring the ON\OFF switch in the ON position.<br />

4. All the 7 displays show the number 8 for about 2”: this function is used to check that<br />

all displays are working correctly.<br />

5. After the 2”, the displays show 0.00.XXXX (X indicates any number), or 0.00.0000<br />

with the last four digits flashing. In this second case it means that an access code<br />

has been stored <strong>and</strong> that it is therefore necessary to enter the digits of the access<br />

code in the last 4 displays (DG3..DG6) <strong>and</strong> then to press .<br />

d e f<br />

g c<br />

a= Displays indicating the Parameter Code, marked as DG0, DG1 <strong>and</strong> DG2.<br />

b= Displays indicating the Parameter Value, marked DG3, DG4, DG5, DG6.<br />

c= DIN guide release<br />

d= ON\OFF switch.<br />

e= Connection cable to connector FC3 on the STK1-B board.<br />

f= Pushbutton to select the display from DG0 to DG6, scrolling from left to right<br />

whenever it is pressed. The selected display flashes.<br />

g= Pushbuttons , to modify the number of the display previously selected.<br />

(Please refer to ‘Example of programmer use’ Par. 3.2)<br />

SETRONIK1 Pagina 25 di 54

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

3.2.EXAMPLE OF PROGRAMMER <strong>USE</strong><br />

The example below shows how it is possible to set the timer for the parking time on the<br />

l<strong>and</strong>ing (or of occupied). (Please refer also to paragraph ‘Timers Programming’)<br />

1. Set Parameter Code 4.02 on displays DG0,DG1,DG2:<br />

1.1. Select DG0, by pressing pushbutton until DG0 flashes:<br />

DG0 DG1 DG2 DG3 DG4 DG5 DG6<br />

DG0 flashes<br />

1.2. Set 4 on DG0 using pushbuttons , :<br />

DG0 DG1 DG2 DG3 DG4 DG5 DG6<br />

4<br />

DG0 flashes<br />

1.3. Select DG1 <strong>and</strong> DG2, by pressing the pushbutton once<br />

(DG1 <strong>and</strong> DG2 flash):<br />

DG0 DG1 DG2 DG3 DG4 DG5 DG6<br />

4<br />

DG1<strong>and</strong> DG2 flash<br />

1.4. Set 2 on DG1,DG2 by pushbutton:<br />

DG0 DG1 DG2 DG3 DG4 DG5 DG6<br />

4 0 2<br />

DG1 <strong>and</strong> DG2 flash<br />

2. Set the timer time on displays DG3..DG6:<br />

2.1. Select displays DG3, DG4, DG5, DG6 by pressing the pushbutton once<br />

DG0 DG1 DG2 DG3 DG4 DG5 DG6<br />

4 0 2<br />

DG3..DG6 flash<br />

2.2. Set the time (i.e. 8 seconds = 80 tenths of a second) by pushbutton<br />

DG0 DG1 DG2 DG3 DG4 DG5 DG6<br />

4 0 2 0 0 8 0<br />

DG3..DG6 flash<br />

NOTA<br />

The value set is operational by pressing once, but it is not stored.<br />

For the storing please refer to paragraph 3.4_Parameters Storing..<br />

SETRONIK1 Pagina 26 di 54

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

3.3.PROGRAMMING THE CUSTOMER SECRET ACCESS CODE.<br />

1. Set Parameter Code 0.10 on displays DG0,DG1,DG2 .<br />

DG0 DG1 DG2 DG3 DG4 DG5 DG6<br />

0 1 0<br />

ACCESS CODE<br />

The old access code stored is displayed. If no code has been entered, value 0000 is<br />

displayed.<br />

Enter the new access code on displays DG3..DG6.<br />

(Value 0000 removes the access code)<br />

2. Set Parameter Code 0.11 on displays DG0, DG1, DG2.<br />

DG0 DG1 DG2 DG3 DG4 DG5 DG6<br />

0 1 1<br />

ACCESS CODE<br />

Enter the same access code entered in point 2 on displays DG3..DG6. If the code is<br />

different, the same is not accepted, therefore the old code previously stored, if any, is<br />

valid.<br />

(Value 0000 removes the access code)<br />

3. Perform the storing. (Please refer to the Par.3.4_Parameters Storing).<br />

SETRONIK1 Pagina 27 di 54

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

3.4.PARAMETERS STORING.<br />

This parameter execute the comm<strong>and</strong> for the permanent storing of the parameters<br />

modified. If this operation is not performed, any modifications made remain valid until the<br />

power supply to the STK1_B boards is cut off.<br />

1. Set Parameter Code 0.12 on displays DG0, DG1, DG2.<br />

DG0 DG1 DG2 DG3 DG4 DG5 DG6<br />

0 1 2 0 0 0 0<br />

2. Press : DG3..DG6 flash.<br />

DG0 DG1 DG2 DG3 DG4 DG5 DG6<br />

0 1 2 0 0 0 0<br />

3. Press for one second, then displays DG3..DG6 indicate the following result of the<br />

operation:<br />

DG0 DG1 DG2 DG3 DG4 DG5 DG6<br />

0 1 2 0 0 0 2<br />

STORING HAS CORRECTLY<br />

TAKEN PLACE<br />

Or<br />

DG0 DG1 DG2 DG3 DG4 DG5 DG6<br />

0 1 2 0 0 0 3<br />

STORING INCORRECT.<br />

Repeat the comm<strong>and</strong> or replace the board.<br />

SETRONIK1 Pagina 28 di 54

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

3.5.PROGRAMMING THE LIFT, OPERATION, SELECTOR.<br />

In order to be able to modify the parameter values, it is necessary to disconnect the FA<br />

automatic valve while, to only display the same, this is not necessary.<br />

DG0 DG1 DG2 DG3 DG4 DG5 DG6<br />

1 0 0<br />

MASTER / SLAVE<br />

0= Single Lift<br />

1= Master control panel for Duplo with two signalings<br />

‘Coming’<br />

2= Master control panel for Duplo with one signaling<br />

‘Coming’<br />

3= Slave control panel for Duplo<br />

4= Not used<br />

SELECTOR TYPE<br />

0= Shaft with magnetic switches without safety circuit<br />

(CS1)<br />

1= Shaft with magnetic switches with safety circuit<br />

(CS1)<br />

OPERATION TYPE<br />

0= APB<br />

1= Not enabled<br />

2= Down collective<br />

3= Up <strong>and</strong> down Collective<br />

4= Pick-Up<br />

LIFT TYPE<br />

0= 1 speed Electric lift<br />

1= 2 speed Electric lift<br />

2= 2 speed Electric lift with ACVV<br />

3= Electric lift for Inverter without encoder<br />

4= Electric lift for Inverter with encoder<br />

5= Hydraulic lift<br />

DG0 DG1 DG2 DG3 DG4 DG5 DG6<br />

1 0 1<br />

NUMBER OF SERVICES<br />

NUMBER OF STOPS<br />

SETRONIK1 Pagina 29 di 54

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

3.6.PROGRAMMING THE MAIN FLOOR, PARKING FLOOR, PREFERENTIAL FLOOR,<br />

FIREMEN <strong>AND</strong> FIRE-FIGHTING FLOOR, DUPLO VERTICAL RISE FLOORS<br />

DG0 DG1 DG2 DG3 DG4 DG5 DG6<br />

1 0 2<br />

- PARKING FLOOR (TIMER 4.08)<br />

- PREFERENTIAL OPERATION FLOOR<br />

MAIN FLOOR<br />

DG0 DG1 DG2 DG3 DG4 DG5 DG6<br />

1 0 3<br />

FIREMAN FLOOR #2<br />

(Input Function 9)<br />

FIREMAN FLOOR #1<br />

(Input Function 8 o 22)<br />

DG0 DG1 DG2 DG3 DG4 DG5 DG6<br />

1 0 4<br />

NUMBER OF DUPLO VERTICAL RISE FLOORS<br />

(to be programmed on the panel of the lower lift)<br />

NOTA<br />

Floors numbering starts from number 1 corresponding to the lower external floor<br />

SETRONIK1 Pagina 30 di 54

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

3.7.PROGRAMMING THE OPERATOR<br />

DG0 DG1 DG2 DG3 DG4 DG5 DG6<br />

1 0 5<br />

OPERATOR A:<br />

OPERATOR B<br />

See Operator A<br />

Floor Doors Car Doors Limit switches Notes<br />

00 No Available No Available No Available<br />

01 Manual Manual Nothing<br />

02 Manual safety photocell Nothing<br />

03 Manual Automatic Closing <strong>and</strong> Opening (1)<br />

04 Manual Automatic Opening (1)<br />

05 Manual Automatic Nothing (2)<br />

09 Automatic Automatic Closing <strong>and</strong> Opening (1), (4)<br />

10 Automatic Automatic Closing <strong>and</strong> Opening (1)<br />

11 Automatic Automatic Opening (1)<br />

12 Automatic Automatic Nothing (2)<br />

13 Automatic Automatic Nothing (2), (3)<br />

(1) = Set the timer 4.04 (for Operator A) end/or the timer 4.05 (for operator B) twice the<br />

door closing time;<br />

(Limit switches are controlled: see error codes from 76 to 79)<br />

(2) Set the timer 4.04 (for Operator A) end/or the timer 4.05 (for operator B) equal to the<br />

door closing time;<br />

(3) = The door opening/closing signal is turned off when the set with the timer 4.04<br />

end/or 4.05 is over;<br />

(4) = Set the timer 4.06 (for both operators A <strong>and</strong> B) to delay the door ri-opening after<br />

the photocell activation (with 4.06.0000 = immediate ri-opening)<br />

Operators with Motor power supplied during the run with closing limit switch:<br />

In case of operators that need to be power supplied during le lift run, it is necessary to use<br />

the input programmable functions 30 <strong>and</strong> 31 (see par. 3.14)<br />

SETRONIK1 Pagina 31 di 54

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

3.8.PROGRAMMING MAX FLOOR RE-LEVELLINGS, POSITION INDICATIONS.<br />

DG0 DG1 DG2 DG3 DG4 DG5 DG6<br />

1 0 6<br />

TYPE OF POSITION INDICATIONS<br />

00= Positional (one output for each position)<br />

01= Denied BDC display (Relative to Main Floor)<br />

02= Absolute Gray code display<br />

03= Relative Gray Code display (Relative to Main<br />

Floor)<br />

04= Binary Code display<br />

MAX. NUMBER OF FLOOR RE-LEVELLINGS<br />

Once the lift has reached the value set, the lift goes<br />

out of service (Only for hydraulic lifts)<br />

If set on 00, this function is not considered.<br />

SETRONIK1 Pagina 32 di 54

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

3.9.PROGRAMMING OF SPEED <strong>AND</strong> STOP MODE DURING INSPECTION, MOVABLE<br />

PLATFORM, ADVANCE DOORS OPENING, RE-LEVELLING, GONG<br />

DG0 DG1 DG2 DG3 DG4 DG5 DG6<br />

1 0 7<br />

GONG ACTIVATION<br />

0= Upon speed change only for external calls<br />

1= On floor only for external calls<br />

2= Upon speed change for internal or external calls<br />

3= On floor for internal or external calls<br />

ADVANCE DOORS OPENING <strong>AND</strong> FLOOR LEVELLINGS<br />

0= No function enabled<br />

1= Advance door opening enabled during run, safety<br />

circuit required (CS1)<br />

2= Floor levelling enabled, safety circuit required<br />

(CS1)<br />

3= Advance doors opening <strong>and</strong> floor levelling, safety<br />

circuit required (CS1).<br />

MOVABLE PLATFORM (*)<br />

0= NA contact, in APB operation when closed it<br />

disables external calls<br />

1= NA contact, in APB operation <strong>and</strong> upon call when<br />

closed it enables internal calls<br />

2= NC contact, in APB operation when open it<br />

disables external calls<br />

3= NC contact, in APB operation <strong>and</strong> upon call when<br />

open it enables internal calls<br />

SPEED <strong>AND</strong> STOP MODE DURING MAINTENANCE<br />

0= Low speed, stop on resetters<br />

1= High speed, stop on resetters<br />

2= High speed, stop on pre-limit switches<br />

3= Low speed, stop on pre-limit-switches<br />

(*) MOVABLE PLATFORM= If there isn’t the movable platform, program to 0<br />

SETRONIK1 Pagina 33 di 54

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

3.10.PROGRAMMING OF OVERLOAD CONTACT<br />

DG0 DG1 DG2 DG3 DG4 DG5 DG6<br />

1 0 8<br />

OVERLOAD CONTACT (INPUT CE)<br />

0=Contact NO;<br />

1=Contact NC<br />

SETRONIK1 Pagina 34 di 54

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

3.11.PROGRAMMING OF SERVICES.<br />

In order to modify the parameters values, it is necessary to disconnect the FA automatic<br />

valve while, to only display the same, this is not necessary.<br />

DG0 DG1 DG2 DG3 DG4 DG5 DG6<br />

2<br />

TYPE OF OPENING <strong>AND</strong><br />

DOOR STATUS IN PARKING FOR B ACCESS:<br />

See Type of Opening <strong>and</strong> Door status in parking for A<br />

Access<br />

B ACCESS TYPE:<br />

See A access Type<br />

TYPE OF OPENING <strong>AND</strong><br />

DOOR STATUS IN PARKING FOR A ACCESS:<br />

0= Selective, doors open parking<br />

1= Simultaneous, doors open parking<br />

2= Selective, doors closed parking<br />

3= Simultaneous, doors closed parking<br />

A ACCESS TYPE:<br />

0= There is no service<br />

1= Simplex Access (*)<br />

2= Duplo Access (*)<br />

STOP<br />

01= Stop1<br />

02= Stop2<br />

03= Stop3<br />

04= Stop4<br />

.<br />

.<br />

.<br />

12= Stop12<br />

(*) Simplex / Duplo Access= The Access has to be programmed Simplex if the relative<br />

stop is served by only one lift (in this case the Simplex access has to be<br />

programmed on this lift);<br />

The access has to be programmed Duplo if the relative stop is served by both the<br />

lifts (in this case the Duplo Access has to be programmed on both the lifts).<br />

SETRONIK1 Pagina 35 di 54

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

3.12.SHAFT PROGRAMMING:<br />

In order to modify the parameters values, it is necessary to disconnect the FA automatic<br />

valve while, to only display the same, this is not necessary.<br />

DG0 DG1 DG2 DG3 DG4 DG5 DG6<br />

3 00<br />

INTER-FLOOR TYPE (*)<br />

00= Normal Floors<br />

(Interfloor > 2K)<br />

01= Short Floors<br />

(Interfloor < 2K <strong>and</strong> > 1K)<br />

02= Close Floors<br />

(Interfloor < 1K <strong>and</strong> > 2 brackets)<br />

03= Very Close Floors<br />

(Interfloor < 2 brackets: a second bracket is<br />

required)<br />

INTER-FLOOR SELECTION<br />

01= Inter-floor between floor 1 <strong>and</strong> 2<br />

02= Inter-floor between floor 2 <strong>and</strong> 3<br />

03= Inter-floor between floor 3 <strong>and</strong> 4<br />

04= Inter-floor between floor 4 <strong>and</strong> 5<br />

05= Inter-floor between floor 5 <strong>and</strong> 6<br />

06= Inter-floor between floor 6 <strong>and</strong> 7<br />

07= Inter-floor between floor 7 <strong>and</strong> 8<br />

08= Inter-floor between floor 8 <strong>and</strong> 9<br />

09= Inter-floor between floor 9 <strong>and</strong> 10<br />

10= Inter-floor between floor 10 <strong>and</strong> 11<br />

11= Inter-floor between floor 11 <strong>and</strong> 12<br />

(*) = K is the slowing distance: see the layout L01 <strong>and</strong> L02.<br />

SETRONIK1 Pagina 36 di 54

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

3.13.PROGRAMMING OF TIMERS:<br />

DG0 DG1 DG2 DG3 DG4 DG5 DG6<br />

4<br />

TIME<br />

Expressed in tenths of a second<br />

(i.e. 0080 = 8 seconds)<br />

TIMER<br />

00= Max duration of the inter-floor run<br />

01= Max duration run in low speed (if 4.01=0000 the timer is not enabled)<br />

02= Floor parking duration (occupied)<br />

03= Floor parking reduced duration after photocell activation<br />

04= Max duration of the stage side A lift doors opening/closing<br />

(See error codes from 76 to 77)<br />

05= Max duration of the stage side B lift doors opening/closing<br />

(See error codes from 78 to 79)<br />

06= doors opening delay after stop or door re-opening delay with operator 09<br />

07= Max time at start (after the drop out of closing / opening contactors)<br />

08= despatch delay to parking floor<br />

(if 4.08=0000 the timer is not enabled)<br />

09= despatch delay to lower outmost floor (for hydraulic lifts)<br />

(if 4.09=0000 the timer is not enabled)<br />

10= combinable with output functions to be programmed<br />

11= combinable with output functions to be programmed<br />

12= Stop delay to adjust the relevelling space<br />

(see paragraph 2.6.3_‘Relevelling space adjustment’)<br />

13= Max time of the call holding with still car<br />

14= contactors excitation delay at start (this is used to avoid false excitations of operating<br />

contactors due to safety contacts bouncing)<br />

15= doors opening delay due to the activation of the safety circuit (used with door opening<br />

in advance)<br />

SETRONIK1 Pagina 37 di 54

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

3.14.INPUT PROGRAMMING:<br />

DG0 DG1 DG2 DG3 DG4 DG5 DG6<br />

5 00<br />

INPUT FUNCTION<br />

00 None<br />

INPUTS: 01 - Safety photocells (With operators in 02 type);<br />

- Door opening extralimit switch of the 1° <strong>and</strong> 2° operator (with<br />

operator different from 02 type) (NC contact)<br />

Led Term. 02 Oil thermal sensor (NC contact)<br />

00 03 Low point pressure switch (NC contact)<br />

01 X1 X1 04 Peak point pressure switch (NC contact)<br />

02 (*) X2 X2 05 L<strong>and</strong>ing operation stop control (for ACVV or 3VF with old interface)<br />

03 (*) X3 X3 06 Operator A sticking contactor control<br />

04 (*) X4 X4 07 Operator B sticking contactor control<br />

05 (*) X5 X5 08 Fire-fighting operation with despatch to the fire-fighting floor #1<br />

06 X6 J8.4 09 Fire-fighting operation with despatch to the fire-fighting floor #2<br />

07 (*) X7 J9.4 10 Preferential operation<br />

08 X8 J2.4 11 Safety circuit control (err 19, 20)<br />

09 X9 J2.5 12 Very close l<strong>and</strong>ings control (with Additional ID switch)<br />

10 X10 J2.6 13 Very close l<strong>and</strong>ings control (with Additional IS switch)<br />

11 X11 J2.7 14 High/low speed Maintenance<br />

12 FG FG 16 Full load<br />

13 MR MR 17 Alarm with 0094 error, Out-of-service on l<strong>and</strong>ing<br />

14 TC TC 18 Additional extralimit switch in the top_Contact monitoring <strong>and</strong> 0095<br />

error signalling<br />

15 PST PST 19 Alarm with 0096 error, immediate out-of-service<br />

16 MP MP 20 Alarm with 0097 error, Failed start (3VF)<br />

21 Reserved operation<br />

22 Hong Kong Firemen operation<br />

23 Photocell of the operator A independent of the opening push button<br />

(*) = Leds <strong>and</strong><br />

terminals are on the<br />

expansion card<br />

STK1-E<br />

(used with selective opening)<br />

24 Photocell of the operator B independent of the opening push button<br />

(used with selective opening)<br />

25 Out-of-service with despatch to the programmed parking floor with<br />

signalling of error 098<br />

26 BA1 input (NA) for panels without board STK1-E<br />

28 Emergency operation (not with board B12E)<br />

29 CM1 input (NC) for panels without board STK1-E<br />

30 Doors closing limit switch for operator A (NC contact for lifts with<br />

motors powered during the run)<br />

31 Doors closing limit switch for operator B (NC contact for lifts with<br />

motors powered during the run)<br />

32 Low <strong>and</strong> peak point pressure switch (PST) (NC contact; it can be<br />

used only on inputs X6, X9, FG, PST)<br />

NOTE: If it isn’t specified the contacts are N.O.<br />

SETRONIK1 Pagina 38 di 54

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

3.15.OUTPUT PROGRAMMING:<br />

DG0 DG1 DG2 DG3 DG4 DG5 DG6<br />

5 00<br />

OUTPUT FUNCTION<br />

Timer<br />

00 None<br />

01 Door opening comm<strong>and</strong> for operator A (NO) 4.04<br />

Led Term. 02 Door opening comm<strong>and</strong> for operator B (NO) 4.05<br />

17 01 32 / J8.2 03 Door closing comm<strong>and</strong> for operator A (NO) 4.04<br />

18 02 30 / J8.3 04 Door closing comm<strong>and</strong> for operator B (NO) 4.05<br />

19 (*) 03 42 / J9.2 05 Fixed occupied comm<strong>and</strong>, car light<br />

20 (*) 04 40 / J9.3 06 Retiring cam comm<strong>and</strong><br />

21 05 J7.1 / J7.2 07 Stop comm<strong>and</strong> at stop: for ACVV e 3VF with old interface<br />

22 06 J7.1 / J7.3 08 Soft Starter comm<strong>and</strong><br />

09 Soft Stop comm<strong>and</strong> during upward run 4.10<br />

10 Delta contactor comm<strong>and</strong> 4.11<br />

(*) = Leds <strong>and</strong> terminals 12 Soft Stop comm<strong>and</strong> during upward <strong>and</strong> downward run 4.10<br />

are on the expansion 13 Brake comm<strong>and</strong> with 3VF starting 4.11<br />

card STK1-E<br />

14 Resistors or impedance exclusion comm<strong>and</strong> (SCC) at 4.11<br />

start<br />

15 Resistors exclusion comm<strong>and</strong> upon speed change 4.10<br />

16 CS1 enabling (obsolete)<br />

17 Intermediate speed comm<strong>and</strong> between short floors with<br />

3VF (obsolete)<br />

18 Intermediate speed comm<strong>and</strong> between close floors with<br />

3VF (obsolete)<br />

19 Relevelling comm<strong>and</strong><br />

20 Relay KV1 comm<strong>and</strong> for 3VF<br />

21 Relay KV2 comm<strong>and</strong> for 3VF<br />

22 Door closing comm<strong>and</strong> for both the operators<br />

23 Door opening comm<strong>and</strong> for operator A (NC) 4.04<br />

24 Door opening comm<strong>and</strong> for operator B (NC) 4.05<br />

25 VMP comm<strong>and</strong> with Soft Stop <strong>and</strong> valve 2CH 4.11<br />

26 Alarm filtering comm<strong>and</strong><br />

NOTE: Functions 0016, 0017, 0018 are obsolete with diagrams based on Eprom 4.00 or<br />

later types.<br />

SETRONIK1 Pagina 39 di 54

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

4.DIAGNOSIS<br />

4.1.LIFT STATUS DISPLAY<br />

The parameter value (DG3..DG6) is constantly updated in relation to the current status of<br />

the lift.<br />

If the Car Position is 00 (DG5, DG6), this means that the resetting operation has not been<br />

performed.<br />

DG0 DG1 DG2 DG3 DG4 DG5 DG6<br />

0 0 0<br />

CAR POSITION<br />

0= Lift without resetting<br />

n= Actual position ( from 1 to 12)<br />

OPERATION STATUS<br />

0= Floor parking<br />

1= Doors closing for start<br />

2= High speed motion<br />

3= Low speed motion<br />

4= Doors opening<br />

5= Car still off l<strong>and</strong>ing<br />

LIFT STATUS<br />

0= Normal operation<br />

1= Firemen operation on<br />

2= Fire-fighting operation on<br />

3= Preferential operation on<br />

4= Reserved operation on<br />

5= Safety photocell action<br />

6= Not used<br />

7= Out-of-service for failures at floor<br />

8= Out-of-service for permanent failures<br />

9= Maintenance operation on<br />

SETRONIK1 Pagina 40 di 54

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

4.2.DISPLAY <strong>AND</strong> CANCELLATION OF FAILURES / MALFUNCTIONS<br />

A).DISPLAY OF THE LAST FAILURE:<br />

Set ‘Parameter Code’ 001 on displays DG0, DG1, DG2:<br />

DG0 DG1 DG2 DG3 DG4 DG5 DG6<br />

0 0 1<br />

FAILURE CODE<br />

NUMBER OF TIMES THE BOARD DETECTED THE FAILURE<br />

(MAX 9)<br />

If the parameter value (DG3..DG6) is 0000, this means that no failure or malfunction has<br />

occurred.<br />

B).DISPLAY OF THE LAST 16 FAILURES:<br />

Set ‘Parameter Code’ 0.02 on displays DG0, DG1, DG2 <strong>and</strong> press :<br />

DG0 DG1 DG2 DG3 DG4 DG5 DG6<br />

0 0 2<br />

DG3.. DG6 FLASH<br />

FAILURE CODE<br />

NUMBER OF TIMES THE BOARD HAS DETECTED THE<br />

FAILURE (MAX 9)<br />

By pressing pushbutton<br />

By pressing pushbutton<br />

it is possible to display subsequent failures.<br />

it is possible to display previous failures.<br />

If the parameter value (DG3..DG6) is 0000, this means that no failure/malfunction has<br />

occurred or the end of the failure codes list has been reached.<br />

C).FAILURES CANCELLATION:<br />

1. Set ‘Parameter Code’ 0.03 on displays DG0, DG1, DG2 <strong>and</strong> press :<br />

DG0 DG1 DG2 DG3 DG4 DG5 DG6<br />

0 0 3 0 0 0 0<br />

DG3..DG6 FLASH<br />

2. Press . The parameter value (DG3..DG6) shows 0001 to indicate that failures have<br />

been deleted:<br />

DG0 DG1 DG2 DG3 DG4 DG5 DG6<br />

0 0 3 0 0 0 1<br />

FAILURES DELETED<br />

SETRONIK1 Pagina 41 di 54

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

4.3.COUNT OF RUNS <strong>AND</strong> RE-LEVELLINGS PERFORMED.<br />

A).UP <strong>AND</strong> DOWN RUNS COUNT<br />

DG0 DG1 DG2 DG3 DG4 DG5 DG6<br />

0 0 0<br />

NUMBER OF TENS OF RUNS<br />

04= Count of upward runs<br />

05= Count of downward runs<br />

Displays DG3..DG6 show the tens of runs performed. The maximum value which can be<br />

displayed is 9999 corresponding therefore to 99999 maximum runs.<br />

B).EMERGENCY DOWN RUNS COUNT<br />

DG0 DG1 DG2 DG3 DG4 DG5 DG6<br />

0 0 6 0 0<br />

RUNS NUMBER<br />

The maximum number which can be displayed is 0063 (=63 runs).<br />

C).UP <strong>AND</strong> DOWN RELEVELLINGS COUNT<br />

DG0 DG1 DG2 DG3 DG4 DG5 DG6<br />

0 0 0<br />

NUMBER OF RELEVELLINGS<br />

07= Count of upward Relevellings<br />

08= Count of downward Relevellings<br />

The maximum value which can be displayed is 0031 (=31 re-levellings).<br />

N.B. Count resetting procedure:<br />

1. Position on displays DG3..DG6. The displays continue to show the count.<br />

2. Press .The count is reset to zero.<br />

From now the same will start counting again.<br />

SETRONIK1 Pagina 42 di 54

SEA SYSTEMS<br />

<strong>INSTALLATION</strong> <strong>AND</strong> <strong>USE</strong> <strong>MANUAL</strong><br />

CONTROL PANEL <strong>and</strong> PREWIRED SYSTEM STK1<br />

For Electric <strong>and</strong> Hydraulic Lifts<br />

MSTK12-GB<br />

Rev.01<br />

30/12/05<br />

4.4.COMM<strong>AND</strong>S FOR LIFT OPERATION IN THE MACHINE ROOM:<br />

DG0 DG1 DG2 DG3 DG4 DG5 DG6<br />

0 0 9<br />

B OPERATOR CLOSING\OPENING OPERATION:<br />

A=Doors opening in progress, or already open.<br />

To perform the closing, select DG6 <strong>and</strong> press .<br />

C=Doors closing in progress, or already closed.<br />

To perform the opening, select DG6 <strong>and</strong> press<br />