206958 DF_RTP_NFF

206958 DF_RTP_NFF

206958 DF_RTP_NFF

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

GE Healthcare<br />

Data file 28-9257-93 AB<br />

Filtration<br />

ReadyToProcess<br />

Normal Flow Capsule Filters<br />

ReadyToProcess Normal Flow Capsules are single-use filters<br />

designed for laboratory through process scale applications,<br />

with typical volumes ranging from a few mls to thousands of<br />

liters of solution.<br />

ReadyToProcess <strong>NFF</strong> Capsules Offered:<br />

<strong>RTP</strong> ULTA Pure SG capsule: provides sterilizing grade filtration<br />

of biopharmaceutical solutions<br />

<strong>RTP</strong> ULTA Pure HC capsule: provides sterilizing grade filtration<br />

of difficult-to-filter biopharmaceutical solutions<br />

ReadyToProcess<br />

ReadyToProcess Normal Flow Capsules are part of a suite of<br />

products that are designed to bring a comprehensive offering<br />

of ready to use cell culture, purification, and fluid<br />

management products such as:<br />

• Cross flow filters (CFF)<br />

• Normal flow filters (<strong>NFF</strong>)<br />

• Chromatography columns<br />

• Bio-reactors<br />

• Mixers<br />

• Aseptic tube sealers/connectors<br />

Use of ReadyToProcess products and technology will<br />

• Decrease risk of process cross-contamination<br />

• Simplify and speed bioprocessing<br />

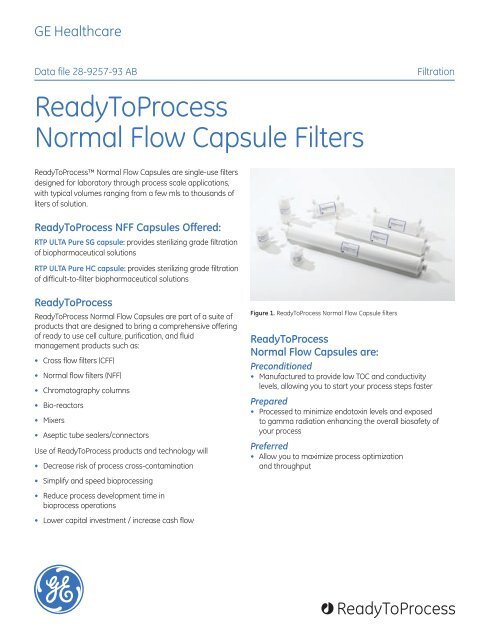

Figure 1. ReadyToProcess Normal Flow Capsule filters<br />

ReadyToProcess<br />

Normal Flow Capsules are:<br />

Preconditioned<br />

• Manufactured to provide low TOC and conductivity<br />

levels, allowing you to start your process steps faster<br />

Prepared<br />

• Processed to minimize endotoxin levels and exposed<br />

to gamma radiation enhancing the overall biosafety of<br />

your process<br />

Preferred<br />

• Allow you to maximize process optimization<br />

and throughput<br />

• Reduce process development time in<br />

bioprocess operations<br />

• Lower capital investment / increase cash flow

<strong>RTP</strong> ULTA Pure SG capsules<br />

Pleated Capsules with Sterilizing Grade Polyethersulphone<br />

Membranes <strong>RTP</strong> ULTA Pure SG capsule utilizes the<br />

special properties of a patented microbially retentive<br />

polyethersulphone membrane to provide sterile filtration<br />

to meet the specific needs of the pharmaceutical industry.<br />

Features<br />

• Gamma compatible<br />

• Microbially retentive and validated to ASTM F838-83<br />

methodology<br />

• Asymmetrical pore structure resulting in high throughputs<br />

and flow rates<br />

• Low protein binding characteristics<br />

• Wide range of chemical compatibility with low<br />

extractable levels<br />

Materials of construction<br />

• Polyethersulphone membrane<br />

• Polyester support layers<br />

• Nylon housing and components: cage and core<br />

• Nylon end caps<br />

<strong>RTP</strong> ULTA Pure HC capsules<br />

Pleated Capsules with Polyethersulphone Membranes<br />

<strong>RTP</strong> ULTA Pure HC capsule filters have been specifically<br />

designed for the effective and economical processing<br />

of difficult to filter solutions often associated with<br />

biopharmaceutical production.<br />

Features<br />

• Optimized membrane configuration allows up to ten<br />

times the throughput<br />

• Integral prefilter layer minimizes areas for greater<br />

processing economy<br />

• Correlated integrity test assures sterility<br />

• Low adsorption of proteins for minimal loss of expensive<br />

pharmaceutical product<br />

Materials of construction<br />

• Polyethersulphone membrane over<br />

Polyethersulphone prefilter layer<br />

• Polyester support layers<br />

• Nylon housing and components: cage and core<br />

• Nylon end caps<br />

Recommended capsule<br />

operating conditions<br />

Up to 70°C (158°F) continuous operating temperature<br />

and higher short-term temperatures:<br />

Maximum<br />

Maximum<br />

Temperature forward dp reverse dp (1)<br />

(ºC) (bar) (psi) (bar) (psi)<br />

20 5.0 72 2.0 29<br />

40 4.0 58 1.5 22<br />

60 3.0 44 1.0 15<br />

80 2.0 29 0.5 7<br />

90 1.0 15 not recommended<br />

Capsules may be operated up to a temperature of 40°C (104°F) at line<br />

pressures up to 5.0 bar (72 psig) for liquids and 4.0 bar (58 psi) in air/gas<br />

Biological safety<br />

Materials conform to the relevant requirements of 21CFR<br />

Part 177 and current USP Plastics Class VI - 121°C and<br />

ISO10993 equivalents.<br />

Non-volatile extractables (NVE)<br />

Total NVE’s extracted in the first five liter flush of WFI for<br />

a 6 inch equivalent gamma sterilized device is < 5 mg.<br />

Oxidizable substances<br />

<strong>RTP</strong> ULTA Pure HC and SG capsule products meet current<br />

USP quality standards for oxidizable substances.<br />

TOC/Conductivity<br />

The effluent quality from a 6 inch equivalent <strong>RTP</strong> ULTA Pure<br />

HC and SG capsule device conforms to the requirements of<br />

USP 28(TOC) and USP 28 (conductivity) following<br />

a three liter flush.<br />

Endotoxins<br />

Aqueous extracts from the <strong>RTP</strong> ULTA Pure HC and SG capsule<br />

products contain < 0.125 Eu/ml when tested in accordance<br />

with the standard LAL test.<br />

Retention characteristics<br />

<strong>RTP</strong> ULTA Pure SG and <strong>RTP</strong> ULTA Pure HC capsules are<br />

validated to give an LRV of at least 7 when challenged with<br />

Brevundimonas diminuta in accordance with methods<br />

specified in ASTM F838-05 (10 7 organisms / cm 2 minimum).<br />

2 Data File 28-9257-93 AB

Area Specifications/Integrity<br />

Specifications<br />

All filters are flushed with pharmaceutical grade purified<br />

water prior to packaging.<br />

Product Name 6" Capsule 4" Capsule 2" Capsule Water Wet Bubble<br />

Point Integrity Spec<br />

<strong>RTP</strong> ULTA Pure SG capsule 0.22m 2 (2.3 ft 2 ) 0.11m 2 (1.2 ft 2 ) 0.05m 2 (2.3 ft 2 ) 3.4 barg (49 psig)<br />

Diffusion Specification 6.1 mL/min @ 2.8 barg 3.0 mL/min @ 2.8 barg 1.4 mL/min @ 2.8 barg<br />

w/Water Wet Filter (40.6 psig) @ 20°C (40.6 psig) @ 20°C (40.6 psig) @ 20°C<br />

<strong>RTP</strong> ULTA Pure HC capsule 0.22m 2 (2.3 ft 2 ) 0.11m 2 (1.2 ft 2 ) 0.05m 2 (2.3 ft 2 ) 3.4 barg (49 psig)<br />

Diffusion Specification 6.1 mL/min @ 2.8 barg 3.0 mL/min @ 2.8 barg 1.4 mL/min @ 2.8 barg<br />

w/Water Wet Filter (40.6 psig) @ 20°C (40.6 psig) @ 20°C (40.6 psig) @ 20°C<br />

Capsule Flow Rates - <strong>RTP</strong> ULTA Pure SG capsule<br />

Differential Pressure (mbar)<br />

900<br />

800 4” Size<br />

13<br />

12<br />

700<br />

600<br />

11<br />

10<br />

9<br />

0.2μm 8<br />

500<br />

400<br />

7<br />

6<br />

5<br />

300<br />

200<br />

4<br />

3<br />

100<br />

0<br />

for liquid at 1cp @ 20˚C<br />

2<br />

1<br />

0<br />

0 2 4 6 8 10<br />

Flow (l/min)<br />

Differential Pressure (psi)<br />

Key to Capsule Catalog Numbers<br />

Capsules<br />

Device Type Media Type Special Detail Special Micron Rating Size Size<br />

End Fittings<br />

Inlet Outlet<br />

Digit 1 2 3 4 5 6 7 8 9 10 11 12<br />

K = Capsule<br />

M P H<br />

S<br />

G<br />

H<br />

C<br />

9 2<br />

02 = 2”<br />

04 = 4”<br />

06 = 6”<br />

T = 1.5” TC<br />

H = 1/2” HB<br />

H = 1/2” HB<br />

H = 1/2” HB<br />

Example: <strong>RTP</strong> ULTA Pure SG capsule, Triclamp 1 1/2" inlet, 1/2" Hose barb outlet<br />

KMPHSG9204TH<br />

Data File 28-9257-93 AB 3

For contact information for your local office,<br />

please visit: www.gelifesciences.com/contact<br />

GE Healthcare Bio-Sciences AB<br />

Björkgatan 30<br />

751 84 Uppsala<br />

Sweden<br />

www.gelifesciences.com<br />

GE, imagination at work and GE monogram are trademarks of General Electric Company.<br />

ReadyToProcess and ULTA are trademarks of GE Healthcare companies.<br />

All third party trademarks are the property of their respective owners.<br />

© 2009 General Electric Company - All rights reserved. First published Sept. 2007.<br />

All goods and services are sold subject to the terms and conditions of sale of the<br />

company within GE Healthcare which supplies them. A copy of these terms and<br />

conditions is available on request. Contact your local GE Healthcare representative<br />

for the most current information.<br />

GE Healthcare UK Ltd Amersham Place, Little Chalfont, Buckinghamshire, HP7 9NA, UK<br />

GE Healthcare Bio-Sciences Corp., 800 Centennial Avenue, P.O. Box 1327, Piscataway,<br />

NJ 08855-1327 USA<br />

GE Healthcare Europe, GmbH, Munzinger Strasse 5, D-79111 Freiburg, Germany<br />

GE Healthcare Bio-Sciences KK, Sanken Bldg., 3-25-1, Hyakunincho, Shinjuku-ku, Tokyo<br />

169-0073 Japan<br />

28-9257-93 AB 01/2009

![[PDF] マニュアル GradiFrac](https://img.yumpu.com/22037825/1/190x253/pdf-gradifrac.jpg?quality=85)

![[PDF] Sample preparation for analysis of protein, peptides and ...](https://img.yumpu.com/21549715/1/190x257/pdf-sample-preparation-for-analysis-of-protein-peptides-and-.jpg?quality=85)

![[PDF] Data File: rProtein A Sepharose Fast Flow](https://img.yumpu.com/21549316/1/190x253/pdf-data-file-rprotein-a-sepharose-fast-flow.jpg?quality=85)

![[PDF] MBP-tagged protein purification](https://img.yumpu.com/21548507/1/184x260/pdf-mbp-tagged-protein-purification.jpg?quality=85)

![[PDF] AKTA ready system Data file](https://img.yumpu.com/21540925/1/190x253/pdf-akta-ready-system-data-file.jpg?quality=85)

![[PDF] Data File - rProtein A/Protein G GraviTrap](https://img.yumpu.com/21539052/1/190x253/pdf-data-file-rprotein-a-protein-g-gravitrap.jpg?quality=85)