Autosampler A-900 and A-905 - GE Healthcare Life Sciences

Autosampler A-900 and A-905 - GE Healthcare Life Sciences

Autosampler A-900 and A-905 - GE Healthcare Life Sciences

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>GE</strong> <strong>Healthcare</strong><br />

Data file 18-1177-97 AB<br />

Liquid chromatography system accessories<br />

<strong>Autosampler</strong> A-<strong>900</strong> <strong>and</strong> A-<strong>905</strong><br />

<strong>Autosampler</strong> A-<strong>900</strong> <strong>and</strong> A-<strong>905</strong> allow automatic <strong>and</strong> accurate<br />

sample injection by using a novel method of reproducible<br />

sample withdrawal of sample volumes from 0.1 µl up to 1 ml.<br />

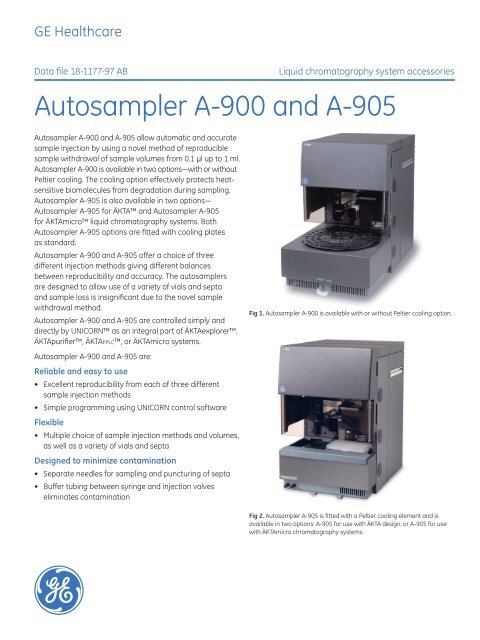

<strong>Autosampler</strong> A-<strong>900</strong> is available in two options—with or without<br />

Peltier cooling. The cooling option effectively protects heatsensitive<br />

biomolecules from degradation during sampling.<br />

<strong>Autosampler</strong> A-<strong>905</strong> is also available in two options—<br />

<strong>Autosampler</strong> A-<strong>905</strong> for ÄKTA <strong>and</strong> <strong>Autosampler</strong> A-<strong>905</strong><br />

for ÄKTAmicro liquid chromatography systems. Both<br />

<strong>Autosampler</strong> A-<strong>905</strong> options are fitted with cooling plates<br />

as st<strong>and</strong>ard.<br />

<strong>Autosampler</strong> A-<strong>900</strong> <strong>and</strong> A-<strong>905</strong> offer a choice of three<br />

different injection methods giving different balances<br />

between reproducibility <strong>and</strong> accuracy. The autosamplers<br />

are designed to allow use of a variety of vials <strong>and</strong> septa<br />

<strong>and</strong> sample loss is insignificant due to the novel sample<br />

withdrawal method.<br />

<strong>Autosampler</strong> A-<strong>900</strong> <strong>and</strong> A-<strong>905</strong> are controlled simply <strong>and</strong><br />

directly by UNICORN as an integral part of ÄKTAexplorer,<br />

ÄKTApurifier, ÄKTAfplc, or ÄKTAmicro systems.<br />

<strong>Autosampler</strong> A-<strong>900</strong> <strong>and</strong> A-<strong>905</strong> are:<br />

Reliable <strong>and</strong> easy to use<br />

• Excellent reproducibility from each of three different<br />

sample injection methods<br />

• Simple programming using UNICORN control software<br />

Flexible<br />

• Multiple choice of sample injection methods <strong>and</strong> volumes,<br />

as well as a variety of vials <strong>and</strong> septa<br />

Designed to minimize contamination<br />

• Separate needles for sampling <strong>and</strong> puncturing of septa<br />

• Buffer tubing between syringe <strong>and</strong> injection valves<br />

eliminates contamination<br />

Fig 1. <strong>Autosampler</strong> A-<strong>900</strong> is available with or without Peltier cooling option.<br />

Fig 2. <strong>Autosampler</strong> A-<strong>905</strong> is fitted with a Peltier cooling element <strong>and</strong> is<br />

available in two options: A-<strong>905</strong> for use with ÄKTA design; or A-<strong>905</strong> for use<br />

with ÄKTAmicro chromatography systems.<br />

imagination at work

Excellent reproducibility using different<br />

sample injection methods<br />

Each of the three selectable sample injection methods for<br />

<strong>Autosampler</strong> A-<strong>900</strong> <strong>and</strong> A-<strong>905</strong> provide excellent sampling<br />

reproducibility:<br />

• Flushed loop: Sample loop is completely filled with<br />

sample. Sampling reproducibility using this method is<br />

better than 0.3% RSD (relative st<strong>and</strong>ard deviation).<br />

• Partial loopfill: Sample loop is partially filled with sample<br />

allowing programmable injection volumes. Partial loopfill<br />

sample injection provides sampling reproducibility better<br />

than 0.5% RSD.<br />

• µl pick-up: Sample volume is transported into the loop with<br />

transport liquid (mobile phase) after aspiration from the vial.<br />

Using this method offers minimal sample loss <strong>and</strong> maximum<br />

accuracy with a reproducibility better than 1% RSD.<br />

Different dispenser syringe sizes <strong>and</strong><br />

injection volumes provide greater flexibility<br />

Four sizes of dispenser syringes are available for<br />

<strong>Autosampler</strong> A-<strong>900</strong> <strong>and</strong> A-<strong>905</strong>: 100, 250, 500, <strong>and</strong> 1000 µl.<br />

Injection volumes for <strong>Autosampler</strong> A-<strong>900</strong> range from a<br />

few microliters to 1 ml. <strong>Autosampler</strong> A-<strong>905</strong> for ÄKTA allows<br />

injection volumes from 0.1 µl to 1 ml, making it an excellent<br />

choice for the small sample volumes injected during<br />

analytical purification.<br />

Simple programming from UNICORN<br />

<strong>Autosampler</strong> A-<strong>900</strong> is remotely controlled by UNICORN<br />

software. The UNICORN method wizard allows fast <strong>and</strong><br />

easy programming by the user <strong>and</strong> includes extensive data<br />

h<strong>and</strong>ling features (Fig 3). For <strong>Autosampler</strong> A-<strong>900</strong> <strong>and</strong><br />

A-<strong>905</strong>, an extended evaluation package, UNICORN analysis<br />

module, provides:<br />

• Quantitation by internal or external st<strong>and</strong>ards<br />

• Determination of molecular size by gel filtration<br />

• Quantitation of sample amount <strong>and</strong> sample<br />

concentration<br />

• Recovery calculations<br />

12<br />

11<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

A1<br />

Multiple choice of sample vials<br />

Almost every type of vial with an outer diameter (o.d.) of<br />

12 mm or 7 mm can be used with <strong>Autosampler</strong> A-<strong>900</strong>. By<br />

using inserts, volumes of st<strong>and</strong>ard vials can be reduced.<br />

Two types of tray segments are available for <strong>Autosampler</strong><br />

A-<strong>900</strong>; st<strong>and</strong>ard trays, <strong>and</strong> microvial trays (Fig 4).<br />

<strong>Autosampler</strong> A-<strong>900</strong> is fitted with eight of the st<strong>and</strong>ard<br />

12 mm tray segments. Each segment holds 12 vials giving a<br />

maximum capacity of 96 vials. Each microvial tray segment<br />

holds twenty 7-mm vials giving a maximum capacity of<br />

160 vials.<br />

<strong>Autosampler</strong> A-<strong>905</strong> is supplied with a 96-well low microplate<br />

<strong>and</strong> 96-well high microplate for 7 mm vials, a 384-well<br />

low microplate, 48-vial adapter for 12 mm st<strong>and</strong>ard vials,<br />

<strong>and</strong> 10 ml transport solvent/wash vials (Fig 5). Samples<br />

can be directly applied to the microplates or to microvials<br />

positioned on the plates.<br />

12<br />

11<br />

10<br />

20<br />

19<br />

18<br />

17<br />

9<br />

8<br />

7<br />

16<br />

15<br />

14<br />

13<br />

6<br />

12<br />

11<br />

10<br />

9<br />

5<br />

4<br />

3<br />

8<br />

7<br />

6<br />

5<br />

2<br />

1<br />

A1<br />

4<br />

3<br />

21<br />

D1<br />

20<br />

19<br />

18<br />

17<br />

16<br />

15<br />

14<br />

13<br />

1<br />

11<br />

Fig 4. The two types of tray segments available for the A-<strong>900</strong> are (top)<br />

st<strong>and</strong>ard vials of o.d. 12 mm <strong>and</strong> (bottom) microvials of o.d. 7 mm.<br />

Fig 3. Simple programming using the method wizard of UNICORN control<br />

software.<br />

2 28-9496-70 AA

A)<br />

B)<br />

C)<br />

A<br />

B<br />

C<br />

D<br />

E<br />

F<br />

G<br />

H<br />

I<br />

J<br />

K<br />

L<br />

M<br />

N<br />

O<br />

P<br />

A<br />

B<br />

C<br />

D<br />

E<br />

F<br />

A<br />

B<br />

C<br />

D<br />

E<br />

F<br />

G<br />

H<br />

1 2 3 4 5 6 7 8 9 101112131415161718192021222324<br />

1 2 3 4 5 6 7 8<br />

1 2 3 4 5 6 7 8<br />

1 2 3 4 5 6 7 8 9 10 11 12<br />

Fig 5. Microplates for <strong>Autosampler</strong> A-<strong>905</strong>: (A) 384-well; (B) 48-vial adapter;<br />

(C) 96-well.<br />

<strong>Autosampler</strong> A-<strong>900</strong> <strong>and</strong> A-<strong>905</strong> minimize<br />

contamination<br />

Separate needles for puncturing <strong>and</strong> sampling<br />

An air needle <strong>and</strong> sample needle are incorporated in<br />

<strong>Autosampler</strong> A-<strong>900</strong> <strong>and</strong> A-<strong>905</strong>; the air needle punctures<br />

the septum of the vial <strong>and</strong> provides headspace pressure,<br />

while the sample needle transports sample from the vial<br />

into the loop of the valve. PEEK sample needles are available<br />

as an alternative to the steel sample needle for use with<br />

biosensitive materials.<br />

Buffer tubing between syringe <strong>and</strong> injection valves<br />

minimizes contamination<br />

<strong>Autosampler</strong> A-<strong>900</strong> <strong>and</strong> A-<strong>905</strong> use a syringe to aspirate<br />

the sample from a vial into the sample loop. To prevent<br />

contamination of the syringe, the autosamplers are<br />

equipped with buffer tubing between the syringe <strong>and</strong> the<br />

injection valve. The wash solvent removes the sample from<br />

the buffer tubing <strong>and</strong> the sample needle <strong>and</strong> also rinses<br />

both components.<br />

A<br />

B<br />

C<br />

D<br />

E<br />

F<br />

Technical specifications<br />

<strong>Autosampler</strong> A-<strong>900</strong>*<br />

Sampling<br />

Sample capacity<br />

St<strong>and</strong>ard tray:<br />

96 vials of 1.5 ml,<br />

12 vials per segment<br />

Microvial tray:<br />

160 vials of 0.5 ml,<br />

20 vials per segment<br />

Vial dimensions (cap included) Maximum vial height: 47 mm<br />

Minimum vial height: 32 mm<br />

Loop volume 5–1000 µl<br />

Dispenser syringe<br />

100 µl, 250 µl (st<strong>and</strong>ard), 500 µl, or<br />

1000 µl syringe<br />

Vial detection<br />

Missing vial detection by vial sensor<br />

Headspace pressure<br />

Built-in compressor<br />

Injection valve switching time < 100 ms<br />

Piercing precision needle ± 0.6 mm<br />

Wash solvent<br />

250 ml internal wash solvent bottle<br />

Wetted parts<br />

PEEK, stainless steel, PTFE, glass,<br />

Tefzel, alumina, ceramic, <strong>and</strong><br />

inert polymer<br />

Analytical performance<br />

Reproducibility<br />

Memory effect<br />

Environment<br />

< 0.3% RSD for flushed loop<br />

injections<br />

< 0.5% RSD for partial loopfill<br />

injections > 5 µl injection volumes<br />

(5 µl sample, 100 µl sample loop,<br />

< 2.5 MPa; 10 µl sample, 20 µl<br />

sample loop, < 25 MPa)<br />

< 1.0% RSD for µl pick-up injections<br />

> 5 µl injection volumes<br />

< 0.1% with programmable<br />

needle wash<br />

Operational conditions +4°C to +40°C, 20%–95% relative<br />

humidity<br />

Sound pressure level < 70 dB (A)<br />

Installation category Category II, according to IEC 1010<br />

Pollution degree Degree 2, according to IEC 1010<br />

Dimensions<br />

Dimensions (W × H × D) 280 × 440 × 540 mm<br />

Weight<br />

A–<strong>900</strong> 22 kg<br />

A–<strong>900</strong> with cooling 30 kg<br />

Power requirements<br />

Power supply voltage 100–240 V, 50–60 Hz<br />

Power requirement<br />

250 VA<br />

28-9496-70 AA 3

Communication<br />

Serial communication port UniNet-1<br />

Additional specifications for <strong>Autosampler</strong> A-<strong>900</strong> with cooling †<br />

Cooling capacity<br />

> 11.5°C below ambient<br />

temperature (T) for<br />

16°C < T < 40°C<br />

Typical cooling times 34 min from 23°C to 4°C<br />

(at 45% relative humidity)<br />

60 min from 32°C to 4°C<br />

(at 35% relative humidity)<br />

<strong>Autosampler</strong> A-<strong>905</strong> ‡<br />

Sampling<br />

Sample capacity<br />

96-well microplate (low/high):<br />

Direct filling or 96 microvials<br />

384-well microplate:<br />

Direct filling or 384 microvials<br />

48-vial adapter:<br />

48 vials<br />

Vial dimensions (cap included) Maximum vial height: 47 mm<br />

Minimum vial height: 12.5 mm<br />

Loop volume 5–1000 µl<br />

Dispenser syringe<br />

100 µl (st<strong>and</strong>ard in A-<strong>905</strong> for<br />

ÄKTAmicro, 250 µl, 500 µl, 1000 µl<br />

(st<strong>and</strong>ard in A-<strong>905</strong> for ÄKTA)<br />

Plate detection<br />

Missing plate detection by vial<br />

sensor<br />

Headspace pressure<br />

Built-in compressor<br />

Injection valve switch time < 100 ms<br />

Piercing precision needle ±0.6 mm<br />

Wash solvent<br />

100 ml internal wash solvent bottle<br />

Wetted parts<br />

PEEK, PTFE, glass, Tefzel, alumina,<br />

ceramic, <strong>and</strong> inert polymer<br />

Dimensions<br />

Dimensions (W ×H × D) 280 × 440 × 400 mm<br />

Weight<br />

26 kg<br />

Power requirements<br />

Power supply voltage 100–240 V, 50–60 Hz<br />

Power requirement<br />

250 VA<br />

Communication<br />

Serial communication port UniNet-1<br />

* <strong>Autosampler</strong> A-<strong>900</strong> without cooling requires UNICORN v2.3 or higher.<br />

†<br />

<strong>Autosampler</strong> A-<strong>900</strong> with cooling requires UNICORN v4.0 or higher.<br />

‡<br />

<strong>Autosampler</strong> A-<strong>905</strong> for ÄKTA requires UNICORN v4.12 or higher.<br />

Analytical performance<br />

Reproducibility<br />

Memory effect<br />

Cooling capacity<br />

< 0.3% RSD for flushed loop<br />

injections> 5 µl injection volumes<br />

< 0.5% RSD for partial loop fill<br />

injections > 5 µl injection volumes<br />

(5 µl sample, 100 µl sample loop,<br />

< 2.5 MPa)<br />

< 1.0% RSD for µl pick-up<br />

injections > 5 µl injection volumes<br />

< 0.1% with programmable<br />

needle wash<br />

Max. 12°C below ambient<br />

temperature (T) for 16°C < T < 40°C<br />

Environment<br />

Operating conditions<br />

+4°C to +40°C, 20%–95% relative<br />

humidity<br />

Sound pressure level < 70 dB (A)<br />

Installation category Category II, according to IEC 1010<br />

Pollution degree Degree 2, according to IEC 1010<br />

4 28-9496-70 AA

Ordering information<br />

<strong>Autosampler</strong> units<br />

Product Quantity Code No.<br />

<strong>Autosampler</strong> A-<strong>900</strong> with cooling 1 18-1144-61<br />

<strong>Autosampler</strong> A-<strong>900</strong> without cooling 1 18-1116-61<br />

<strong>Autosampler</strong> A-<strong>905</strong> for ÄKTA 1 18-1175-93<br />

<strong>Autosampler</strong> A-<strong>905</strong> for ÄKTAmicro 1 18-5050-65<br />

Accessories <strong>and</strong> consumables<br />

Tray segment set 1.5 ml vial (o.d. 12 mm) 1 18-1119-90<br />

Tray segment set 0.5 ml vial (o.d. 7 mm) 1 18-1120-48<br />

Rheflex ferrule 10 18-1119-91<br />

Rheflex nut 10 18-1119-92<br />

Flange tube fitting 1/8” 5 18-1119-93<br />

Flange tube fitting 1/16” 5 18-1119-94<br />

Plunger replacement tip 100 µl 1 18-1119-96<br />

Plunger replacement tip 500 µl 1 18-1119-97<br />

Plunger replacement tip 250 µl 1 18-1119-98<br />

PEEK sample needle, 15 µl 1 18-1119-99<br />

Sample needle, fused silica, 5 µl 1 18-1158-68<br />

Stainless steel sample needle 1 18-1148-65<br />

Buffer tubing 2000 µl 1 18-1120-31<br />

Buffer tubing 500 µl 1 18-1120-32<br />

Wash solvent bottle 250 ml 1 18-1120-33<br />

Syringe 100 µl 1 18-1120-34<br />

Syringe 250 µl 1 18-1120-35<br />

Syringe 500 µl 1 18-1120-36<br />

Syringe 1000 µl 1 18-1120-37<br />

Luer lock connection, female 1 18-1120-38<br />

PEEK loop 20 µl 1 18-1160-49<br />

PEEK loop 100 µl 1 18-1120-40<br />

Syringe waste tubing 1 18-1120-44<br />

Syringe tubing 1 18-1120-45<br />

Wash vial 1 18-1120-46<br />

Union nut air 1 18-1120-47<br />

Stop plug, 1/16” 5 18-1112-52<br />

Union Luer female/1/16” male 2 18-1112-51<br />

Union 1/16” female/M6 male 6 18-1112-57<br />

Union M6 female/1/16” male 8 18-1112-58<br />

Software<br />

UNICORN Analysis Module, v5.0 1 11-0003-60<br />

UNICORN control software, v5.20:<br />

Remote license* 1 28-9432-57<br />

Workstation license 1 28-9432-44<br />

* Requires existing workstation.<br />

28-9496-70 AA 5

For local office contact information, visit<br />

www.gelifesciences.com/contact<br />

www.gelifesciences.com/akta<br />

<strong>GE</strong> <strong>Healthcare</strong> Bio-<strong>Sciences</strong> AB<br />

Björkgatan 30<br />

751 84 Uppsala<br />

Sweden<br />

<strong>GE</strong>, imagination at work, <strong>and</strong> <strong>GE</strong> monogram are trademarks of General Electric Company.<br />

ÄKTA, ÄKTAexplorer, ÄKTAfplc, ÄKTAmicro, ÄKTApurifier, <strong>and</strong> UNICORN are trademarks of<br />

<strong>GE</strong> <strong>Healthcare</strong> companies.<br />

All third party trademarks are the property of their respective owners.<br />

© 2003-2009 General Electric Company—All rights reserved.<br />

First published Oct. 2003<br />

All goods <strong>and</strong> services are sold subject to the terms <strong>and</strong> conditions of sale of the company within<br />

<strong>GE</strong> <strong>Healthcare</strong> which supplies them. A copy of these terms <strong>and</strong> conditions is available on request.<br />

Contact your local <strong>GE</strong> <strong>Healthcare</strong> representative for the most current information.<br />

<strong>GE</strong> <strong>Healthcare</strong> UK Limited, Amersham Place,<br />

Little Chalfont, Buckinghamshire, HP7 9NA<br />

UK<br />

<strong>GE</strong> <strong>Healthcare</strong> Europe, GmbH<br />

Munzinger Strasse 5, D-79111 Freiburg<br />

Germany<br />

<strong>GE</strong> <strong>Healthcare</strong> Bio-<strong>Sciences</strong> Corp.<br />

800 Centennial Avenue, P.O. Box 1327, Piscataway, NJ 08855-1327<br />

USA<br />

<strong>GE</strong> <strong>Healthcare</strong> Bio-<strong>Sciences</strong> KK<br />

Sanken Bldg., 3-25-1, Hyakunincho, Shinjuku-ku, Tokyo 169-0073<br />

Japan<br />

imagination at work<br />

18-1177-97 AB 06/2009

![[PDF] マニュアル GradiFrac](https://img.yumpu.com/22037825/1/190x253/pdf-gradifrac.jpg?quality=85)

![[PDF] Sample preparation for analysis of protein, peptides and ...](https://img.yumpu.com/21549715/1/190x257/pdf-sample-preparation-for-analysis-of-protein-peptides-and-.jpg?quality=85)

![[PDF] Data File: rProtein A Sepharose Fast Flow](https://img.yumpu.com/21549316/1/190x253/pdf-data-file-rprotein-a-sepharose-fast-flow.jpg?quality=85)

![[PDF] MBP-tagged protein purification](https://img.yumpu.com/21548507/1/184x260/pdf-mbp-tagged-protein-purification.jpg?quality=85)

![[PDF] AKTA ready system Data file](https://img.yumpu.com/21540925/1/190x253/pdf-akta-ready-system-data-file.jpg?quality=85)

![[PDF] Data File - rProtein A/Protein G GraviTrap](https://img.yumpu.com/21539052/1/190x253/pdf-data-file-rprotein-a-protein-g-gravitrap.jpg?quality=85)