MD Product Description - Glencoe

MD Product Description - Glencoe

MD Product Description - Glencoe

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

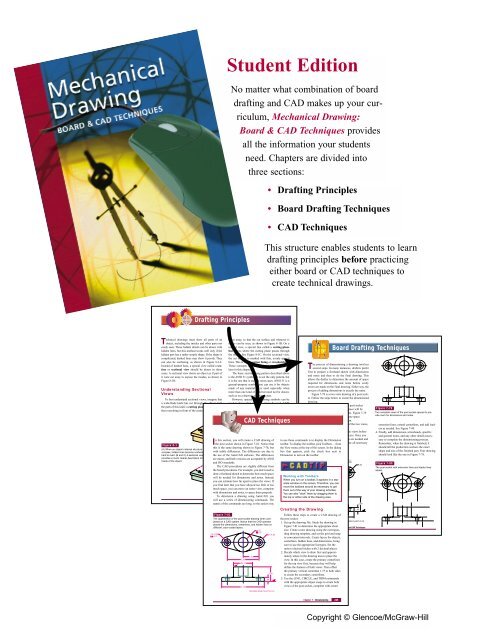

Student Edition<br />

No matter what combination of board<br />

drafting and CAD makes up your curriculum,<br />

Mechanical Drawing:<br />

Board & CAD Techniques provides<br />

all the information your students<br />

need. Chapters are divided into<br />

three sections:<br />

• Drafting Principles<br />

• Board Drafting Techniques<br />

• CAD Techniques<br />

This structure enables students to learn<br />

drafting principles before practicing<br />

either board or CAD techniques to<br />

create technical drawings.<br />

Drafting Principles<br />

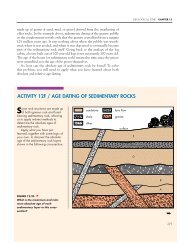

T<br />

echnical drawings must show all parts of an taken away, so that the cut surface and whatever is<br />

object, including the insides and other parts not inside can be seen, as shown in Figure 8-1B. On a<br />

easily seen. These hidden details can be drawn with normal view, a special line called a cutting-plane<br />

hidden lines, but this method works well only if the line shows where the cutting plane passes through<br />

hidden part has a rather simple shape. If the shape is the object. See Figure 8-1C. On the sectional view,<br />

complicated, dashed lines may show it poorly. They the cut surface is marked with thin, evenly spaced<br />

can also be confusing, as shown in Figure 8-1A. lines. This is called section lining or crosshatching.<br />

Instead of dashed lines, a special view called a section<br />

or sectional view should be drawn in these later in this chapter.<br />

These concepts will be discussed in greater detail<br />

he process of dimensioning a drawing involves<br />

Tseveral steps. In many instances, drafters prefer<br />

cases. A sectional view shows an object as if part of The basic section lining pattern described above<br />

first to prepare a freehand sketch with dimensions<br />

it were cut away to expose the insides, as shown in is the ANSI 31 symbol. It is not the only pattern, but<br />

and notes and then to do the final drawing. This<br />

Figure 8-1B.<br />

it is the one that is used in most cases. ANSI 31 is a<br />

allows the drafter to determine the amount of space<br />

general-purpose symbol; you can use it for objects<br />

required for dimensions and notes before costly<br />

made of any material. It is used especially when<br />

errors are made on the final drawing. Either way, the<br />

Understanding Sectional<br />

more than one kind of material need not be shown,<br />

process of adding dimensions is exactly the same.<br />

Views<br />

such as on a drawing of a single part.<br />

Figure 7-78 is a two-view drawing of a post socket.<br />

Follow the steps below to create the dimensioned<br />

To best understand sectional views, imagine that However, special section lining symbols can be<br />

a wide-blade knife has cut through the object. Call used to show what materials are to be used. ANSI<br />

drawing.<br />

the path of this knife a cutting plane. Then imagine provides for many symbols to stand for different<br />

1. Prepare a freehand sketch of the post socket<br />

that everything in front of the cutting plane has been materials, as shown in Figure 8-2. Under this system,<br />

views to determine how much space will be<br />

required for dimensions and notes. Figure 7-79<br />

shows the two views with adequate space<br />

CAD Techniques<br />

allowed between and around them.<br />

2. Prepare an instrument drawing of the two views,<br />

complete with centerlines.<br />

3. Study the shape and details of the views before<br />

beginning the dimensioning process. Once you<br />

n this section, you will create a CAD drawing of to use these commands is to are display sure about the Dimension which dimensions are needed and<br />

Ithe post socket shown in Figure 7-81. Notice that toolbar. To display the toolbar, where pick they Toolbars… should be from placed, draw all necessary<br />

Figure 8-1X<br />

this is the same drawing shown in Figure 7-78, but the View menu at the top of the screen. In the dialog<br />

(A) When an object’s internal structure is<br />

complex, hidden lines become confusing or with subtle differences. The differences are due to box that appears, pick<br />

Figure<br />

the check<br />

7-78X<br />

box next to<br />

hard to read. (B and C) A sectional view the use of the AutoCAD A software. The differences Dimension to turn on the toolbar.<br />

Finished drawing of the post socket.<br />

provides a much clearer description of the are minor, and both versions are acceptable by ANSI<br />

inside of the object.<br />

ARROW SHOWS<br />

2X Ø.38<br />

Ø1.12<br />

and ISO standards.<br />

DIRECTION OF<br />

Ø.75<br />

1.00<br />

SECTIONAL<br />

R.60<br />

The CAD procedures are slightly different from<br />

VIEW<br />

the board procedures. For example, you don’t need to<br />

CUTTING PLANE<br />

draw a freehand sketch to determine how much LINE space<br />

will be needed for dimensions and notes. Instead,<br />

Working with Toolbars<br />

When you turn on a toolbar, it appears in a separate<br />

window on the screen. Therefore, you can<br />

you can estimate how far apart to place the views. If<br />

you find later that you have CUT SURFACE allowed IS too SHOWN little BY or SECTION too LINES<br />

1.75<br />

B<br />

move the toolbars around as necessary to get<br />

much space, you can move an entire C view, complete<br />

them out of the way of your drawing activities. 3.50<br />

with dimensions and notes, to space them properly. You can also “dock” them by dragging them 2.10to<br />

To dimension a drawing using AutoCAD, you<br />

Chapter 8 • Sectional Views 277 the top or either side of the drawing area.<br />

will use a series of dimensioning commands. The<br />

names of the commands are long, so the easiest way<br />

1.60<br />

Creating the Drawing<br />

.44<br />

Figure 7-81X<br />

Follow these steps to create a CAD drawing of<br />

(4.70)<br />

The appearance of the post socket drawing when completed<br />

on a CAD system. Notice that the CAD operator<br />

ROUNDS AND FILLETS R.10<br />

the post socket:<br />

1. Set up the drawing file. Study the drawing in<br />

placed the dimensions, centerlines, and hidden lines on<br />

Figure 7-81 to determine<br />

264<br />

the appropriate Mechanical sheet<br />

different, color-coded layers.<br />

Drawing: Board and CAD Techniques<br />

ø1.12<br />

size. Create a new drawing using the corresponding<br />

drawing template, and set the grid and snap<br />

1.00<br />

2X ø.38<br />

2X R.60<br />

ø.75<br />

to convenient intervals. Create layers for objects,<br />

centerlines, hidden lines, and dimensions, being<br />

sure to use the appropriate linetypes. Set the<br />

units to decimal inches with 2 decimal places.<br />

2. Decide which view to draw first and approximately<br />

where in the drawing area to place the<br />

1.75<br />

3.50<br />

view. In this case, create the primary centerlines<br />

Ø2.10<br />

for the top view first, because they will help<br />

define the features of both views. Then offset<br />

the primary vertical centerline 1.75 to both sides<br />

1.60<br />

to create the secondary centerlines.<br />

.44 3. Use the LINE, CIRCLE, and TRIM commands<br />

with the appropriate object snaps to create both<br />

(4.70)<br />

views of the post socket, complete with center<br />

ROUNDS AND FILLETS R.10<br />

Board Drafting Techniques<br />

Figure 7-79X<br />

Two complete views of the post socket spaced to provide<br />

room for dimensions and notes.<br />

extension lines, extend centerlines, and add leaders<br />

as needed. See Figure 7-80.<br />

4. Finally, add dimensions, arrowheads, specific<br />

and general notes, and any other details necessary<br />

to complete the dimensioning process.<br />

Remember, when the drawing is finished, it<br />

should tell the production workers the exact<br />

shape and size of the finished part. Your drawing<br />

should look like the one in Figure 7-78.<br />

Figure 7-80X<br />

The post socket with extension lines and leader lines<br />

added.<br />

Chapter 7 • Dimensioning 265<br />

Copyright © <strong>Glencoe</strong>/McGraw-Hill

V-BLOCK<br />

The Student Edition also includes:<br />

Chapter Review—Contains<br />

a list of summary points and<br />

review questions to help students<br />

check their understanding<br />

of the material presented<br />

in the chapter.<br />

CHAPTER<br />

Chapter Summary<br />

■ Pictorial drawings are useful in engineering,<br />

architecture, advertising, and manufacturing.<br />

■ In isometric drawing, measurements can be<br />

made only on isometric lines.<br />

■ In isometric drawings, circles appear as ellipses.<br />

■ Isometric drawings can be dimensioned using<br />

either aligned or unidirectional dimensioning<br />

methods.<br />

■ Isometric, dimetric, and trimetric are the three<br />

types of axonometric projections.<br />

■ In oblique pictorial drawing, two axes are parallel<br />

to the picture plane.<br />

■ Oblique drawings can be made as cabinet, normal,<br />

and cavalier.<br />

■ A perspective drawing is a three-dimensional<br />

representation of an object as it appears to the<br />

eye from a particular point or location.<br />

■ A technical illustration is a pictorial drawing that<br />

provides technical information using visual<br />

methods.<br />

n Isometric and oblique drawings can be created<br />

using either 2D or 3D techniques in AutoCAD.<br />

Perspective drawings are created in 3D.<br />

Review Questions<br />

1. Describe two uses for pictorial drawings.<br />

2. What are the three most common types of pictorial<br />

drawing?<br />

3. Which type of pictorial drawing is most natural<br />

in appearance?<br />

4. What do you call a line that is not parallel to<br />

any of the three isometric axes?<br />

T<br />

5. Is an isometric projection larger or smaller than<br />

an isometric drawing?<br />

6. Explain why measurements can be taken only<br />

along isometric lines in an isometric drawing.<br />

7. Describe a situation in which a reversed isometric<br />

drawing might be useful.<br />

8. What is the major practical difference between<br />

isometric and dimetric drawings?<br />

9. In what way is an isometric drawing different<br />

from an oblique drawing?<br />

10. In an oblique drawing, how many axes are parallel<br />

to the picture plane?<br />

11. When creating an oblique drawing, how should<br />

you place the object?<br />

12. What is the difference between a cabinet and a<br />

cavalier drawing?<br />

13. Describe the general procedure for developing<br />

a circle on an oblique drawing using board<br />

drafting techniques.<br />

14. What is another name for surface shading?<br />

15. Briefly explain how to create an oblique drawing<br />

using AutoCAD.<br />

16. What is the vanishing point in a perspective<br />

drawing?<br />

17. What two factors affect how an object looks in<br />

perspective?<br />

18. In what way can the grid and snap features of a<br />

CAD program help a drafter create an isometric<br />

drawing?<br />

19. How do you create isometric circles using<br />

AutoCAD?<br />

20. What is the purpose of the DVIEW command in<br />

AutoCAD?<br />

C H A P T E R<br />

Drafting Problems<br />

he drafting problems in this chapter are designed<br />

to be completed using board drafting techniques<br />

or CAD.<br />

Figure 12-75 X<br />

2.50<br />

2.50<br />

24 50<br />

13<br />

76 27<br />

6.00<br />

5.50<br />

130<br />

2.50<br />

1.25<br />

1.25<br />

30<br />

.62<br />

A BRICK<br />

B LAP JOINT<br />

C HOLLOW BLOCK<br />

0'-10<br />

1.25 2.25<br />

2.25<br />

.50<br />

1.00<br />

6.00<br />

5.25<br />

4'-0<br />

1'-8<br />

3.25<br />

2.00<br />

.75 1.38<br />

1.00<br />

CONCRETE STEPS<br />

DOOR STOP .25<br />

D BASE PAD<br />

E F<br />

30<br />

60° .75<br />

30°<br />

2.00<br />

2.50<br />

50<br />

4.00<br />

.25<br />

.75<br />

10<br />

150<br />

5.50<br />

.25<br />

2.00<br />

24 70<br />

30<br />

16<br />

2.00<br />

TOY BOAT<br />

METRIC<br />

1'-4<br />

0'-8<br />

For problems 1 through 15, determine an appropriate<br />

scale and create isometric drawings according<br />

to the instructions for each problem. Do not<br />

dimension.<br />

1. Determine an appropriate scale, and create an isometric<br />

drawing of the object(s) assigned from Figure<br />

12-75. Note: These objects may also be used for<br />

oblique and perspective drawing practice.<br />

METRIC<br />

G H I<br />

SAW BRACKET<br />

.75<br />

1.75<br />

90°<br />

454<br />

Mechanical Drawing: Board and CAD Techniques<br />

Chapter 12 • Pictorial Drawing 455<br />

Drafting Problems—Provide<br />

abundant opportunities for students<br />

to apply their drafting skills.<br />

Design Problems—Challenge<br />

students to apply their drafting<br />

and design skills.<br />

Tech Math—Explanations of how to use the technical<br />

math required in various drafting-related careers.<br />

CAD Tip—Procedural tips and<br />

techniques related to the CAD<br />

procedures in each chapter.<br />

Success on the Job—Workplace tips<br />

to help students work successfully in<br />

drafting-related careers.<br />

Copyright © <strong>Glencoe</strong>/McGraw-Hill

SECTIONAL VIEWS<br />

DRAWN BY<br />

Student Workbook<br />

Drafting and Design Problems<br />

This Student Workbook is packed with<br />

drafting and design problems related to<br />

every chapter in the Student Edition. The<br />

problems, which vary in difficulty from<br />

basic to advanced, are designed to meet the<br />

needs of a broad range of students. You will<br />

find familiar, time-tested standards as well<br />

as new problems related to new material in<br />

the Student Edition.<br />

Problem 8-1: Convert the right-side<br />

view to a full section. Use generalpurpose<br />

section lining.<br />

Problem 8-2: Complete the right-side<br />

view as a full section. Use general-purpose<br />

section lining.<br />

Problem 8-3: Complete the right-side<br />

view as a full section. Use generalpurpose<br />

section lining.<br />

Problem 8-4: Draw the front view as a full<br />

section. Use general-purpose section lining.<br />

Problem 8-5: Draw the front view as<br />

a full section. Use general-purpose<br />

section lining.<br />

Problem 8-6: Draw the front view as<br />

a full section. Use general-purpose<br />

section lining.<br />

Copyright © <strong>Glencoe</strong>/McGraw-Hill<br />

DATE DWG NO.<br />

83<br />

Real-World Problems<br />

“Real-world problems” at the end of the<br />

Student Workbook challenge students to<br />

draw upon their drafting knowledge and<br />

skills to complete problems that drafters<br />

in various disciplines may face routinely.<br />

Copyright © <strong>Glencoe</strong>/McGraw-Hill

www.tifaq.com<br />

Student Workbook<br />

Instructor Annotated Edition<br />

Answers in Place<br />

Answers to problems in the Student Workbook are<br />

shown in color in the new Student Workbook<br />

Instructor Annotated Edition. These answers “in<br />

place” make it easy for you to check student<br />

assignments.<br />

Problem 8-1: Convert the right-side<br />

view to a full section. Use generalpurpose<br />

section lining.<br />

Problem 8-2: Complete the right-side<br />

view as a full section. Use general-purpose<br />

section lining.<br />

Problem 8-3: Complete the right-side<br />

view as a full section. Use generalpurpose<br />

section lining.<br />

Problem 8-4: Draw the front view as a full<br />

section. Use general-purpose section lining.<br />

Name ___________________________ Class __________________ Date ___________________________<br />

Problem 8-5: Draw the front view as<br />

a full section. Use general-purpose<br />

section lining.<br />

Problem 8-6: Draw the front view as<br />

a full section. Use general-purpose<br />

section lining.<br />

Activity 3<br />

Copy Holder Design<br />

You work for the research and development unit of a company that manufactures office accessories. Your<br />

team has been asked to develop a copy holder for data entry specialists. (A data entry specialist is a person<br />

who enters data from hard copy into a computer database or spreadsheet.) Based on market research, management<br />

has requested the following features:<br />

• adjustable viewing angle<br />

over easily)<br />

• means of illuminating the papers on the copy holder<br />

DATE DWG NO.<br />

• method of keeping papers in place on the copy stand (so that they don’t blow off or curl and fall<br />

• space for a minimum of 100 sheets of paper<br />

Part I: Research<br />

83<br />

SECTIONAL VIEWS<br />

Copyright © <strong>Glencoe</strong>/McGraw-Hill<br />

DRAWN BY<br />

Ergonomics and ease of use are important considerations for any kind of office equipment. For example,<br />

you will need to determine the angles at which the papers are held on the stand, the brightness and direction<br />

of the light, and even the source of the light.<br />

1. Search for information about the best angle for viewing copy while seated at a computer workstation.<br />

Different sources may suggest slightly different angles, but that is good. Recall that your design<br />

specifications include an adjustable viewing angle. List your sources and the angles they suggest on<br />

the lines below. Then indicate the range of angles you will provide in your copy holder design.<br />

__________________________________________________________________________________<br />

Helpful Web sites include those of most major computer manufacturers. Examples include:<br />

__________________________________________________________________________________<br />

www.compaq.com/comfortguide<br />

__________________________________________________________________________________<br />

Range of angles for copy holder: _______________________________________________________<br />

2. What type of lighting is best for this application? Should you specify incandescent or fluorescent<br />

light? How will the light be powered? Will you need a power cord, or will the light be batterypowered?<br />

If a power cord is needed, how long should it be? If a battery is needed, how big will it need<br />

to be, and how will the battery fit into the overall design? Record your notes on the lines below.<br />

Helpful Web sites include:<br />

__________________________________________________________________________________<br />

www.safetyoffice.uwaterloo.ca<br />

__________________________________________________________________________________<br />

__________________________________________________________________________________<br />

www.cdc.gov/niosh/homepage.html<br />

__________________________________________________________________________________<br />

__________________________________________________________________________________<br />

__________________________________________________________________________________<br />

__________________________________________________________________________________<br />

254 Copyright © <strong>Glencoe</strong>/McGraw-Hill<br />

Copyright © <strong>Glencoe</strong>/McGraw-Hill

Instructor Resource Guide<br />

This Instructor Resource Guide is a powerful<br />

resource that provides numerous teaching aids<br />

and activities to help you deliver well-rounded<br />

instruction.<br />

Instructional Plans include:<br />

• Chapter objectives to help you focus and plan lessons<br />

• List of pertinent drafting standards (ANSI and ISO)<br />

• Several student activity ideas<br />

• List of related components in the Mechanical<br />

Drawing program<br />

• Written and performance assessment assignments<br />

• Answers to chapter review questions<br />

Copyright © <strong>Glencoe</strong>/McGraw-Hill

Chapter Handouts reinforce and extend<br />

instruction from the Student Edition. One<br />

of the handouts for each chapter is<br />

a glossary of terms from which students<br />

can build a complete drafting dictionary.<br />

Testing Program helps you<br />

assess student mastery of the<br />

principles and skills developed<br />

in each chapter.<br />

WORKPLACE AND<br />

COMPUTER SKILLS<br />

DRAFTING<br />

RESOURCES<br />

CHAPTER<br />

TESTS<br />

ANSWERS TO TEXTBOOK PROBLEMS<br />

Other resources include tips for managing a technical<br />

drawing program, information about computer/Internet use<br />

and workplace skills, and answers to drafting problems in<br />

the textbook.<br />

Copyright © <strong>Glencoe</strong>/McGraw-Hill

Copyright © <strong>Glencoe</strong>/McGraw-Hill