APPLICATION REFERENCE - Bonfiglioli

APPLICATION REFERENCE - Bonfiglioli

APPLICATION REFERENCE - Bonfiglioli

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Discharge and spillage conveyors<br />

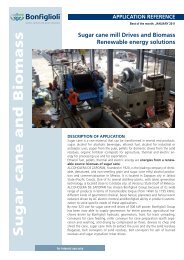

DESCRIPTION OF <strong>APPLICATION</strong><br />

for internal use only<br />

<strong>APPLICATION</strong> <strong>REFERENCE</strong><br />

Best of the month: JUNE 2010<br />

Discharge and spillage<br />

conveyors solutions<br />

ThyssenKrupp Material Handling supports clients in large scale material handling<br />

applications specifically in the areas of open pit mining, minerals processing and<br />

bulk material handling. ThyssenKrupp has choosen <strong>Bonfiglioli</strong> to supply drives for<br />

discharge and spillage conveyors on Lihir Gold Limited’s Million Ounce Plant Upgrade<br />

(MOPU) Project (Lihir Island is located in New Ireland, a province of Papua<br />

New Guinea). The application consists of two Jaw crushing lines operating in parallel.<br />

Each Line has two conveyors; one for discharging and one for spillage.<br />

The discharge conveyors have a throughput of 1200 wtph, while the spillage conveyors<br />

receive 20% of that throughput in finer ores from spillage. The upgrade will<br />

increase total annual gold production on average by approximately 240,000 ounces<br />

(about 6804 kg) per annum from 2012 over the remaining life of the operation.<br />

More than one million ounces of gold (about 28350 kg) is already mined each year<br />

at Lihir Island. However, due to process plant constraints only 600,000 – 700,000<br />

(about 17010 - 19845 kg) ounces is processed per annum. The remaining ore is<br />

stockpiled until it can be processed in the years following the completion of mining.<br />

The investment by Lihir in additional processing capacity through MOPU will<br />

increase plant throughput so that it is more closely matched to mine production.<br />

This will enable more of the mined ore to be processed, improving operational efficiencies<br />

and bringing forward returns for stakeholders.

Discharge and spillage conveyors<br />

Discharge Conveyors<br />

for internal use only<br />

<strong>APPLICATION</strong> <strong>REFERENCE</strong><br />

GENERAL NEEDS OF THE <strong>APPLICATION</strong><br />

Application requires to operate 24 hours a day, 7 days a week, 52 weeks per year.<br />

Discharge conveyors need to have right angle bevel helical with rigid flange couplings,<br />

backstops, fluid couplings. Spillage conveyors need to be shaft mounted<br />

gear motors with torque arm. Bearing L-10 life should be greater that 60,000 hrs<br />

and gear life should be 100, 000 hrs.<br />

BONFIGLIOLI SOLUTION<br />

<strong>Bonfiglioli</strong> Australia’s DSC came up with an “Alignment Free” input design which<br />

negates the need for a costly baseplate.<br />

The “Alignment Free” input is basically a large bell housing that contains the<br />

fluid coupling, fan and provides a standard IEC interface for the flange mounted<br />

motor. This type of input also saves time and labour during commissioning of the<br />

drive as the alignment of the transmission components has already been done.<br />

Vents cut in the bell housing allow air from the fan to be forced along a path to<br />

provide optimum cooling for the gearbox.<br />

The bell housing also has a additional benefit as it provides a collection point for<br />

fluid lost by the fluid coupling in case<br />

of a blowout. <strong>Bonfiglioli</strong> Australia<br />

won the job simply by providing<br />

more benefits at a lower cost to<br />

the customer.<br />

Description<br />

<strong>Bonfiglioli</strong> products<br />

2 x HDO110 3 24.6 LPB R1 VP B3 FAN MOP A CW TK OLG<br />

Alignment Free drives fitted with free issued Teco 75 kW 4 pole motors<br />

Spillage Conveyors A703 US 72.5 P132 fitted with free issued Teco 5.5 kW motors<br />

authors:<br />

Brad Maurice<br />

BMaurice@bonfiglioli.com.au<br />

<strong>Bonfiglioli</strong> Transmission Australia