Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

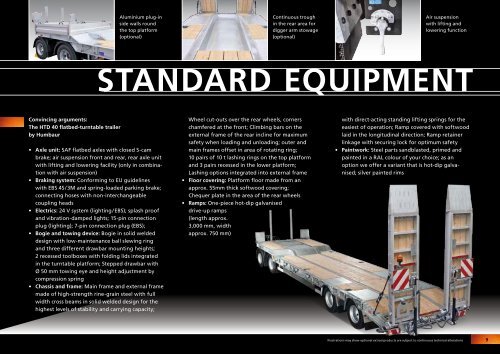

Aluminium plug-in<br />

side walls round<br />

the top platform<br />

(optional)<br />

Continuous trough<br />

in the rear area for<br />

digger arm stowage<br />

(optional)<br />

Air suspension<br />

with lifting and<br />

lowering function<br />

STANDARD EQUIPMENT<br />

Convincing arguments:<br />

The HTD 40 flatbed-turntable trailer<br />

by <strong>Humbaur</strong><br />

• Axle unit: SAF flatbed axles with closed S-cam<br />

brake; air suspension front and rear, rear axle unit<br />

with lifting and lowering facility (only in combination<br />

with air suspension)<br />

• Braking system: Conforming to EU guidelines<br />

with EBS 4S / 3M and spring-loaded parking brake;<br />

connecting hoses with non-interchangeable<br />

coupling heads<br />

• Electrics: 24 V system (lighting / EBS); splash proof<br />

and vibration-damped lights; 15-pin connection<br />

plug (lighting); 7-pin connection plug (EBS);<br />

• Bogie and towing device: Bogie in solid welded<br />

design with low-maintenance ball slewing ring<br />

and three different drawbar mounting heights;<br />

2 recessed toolboxes with folding lids integrated<br />

in the turntable platform; Stepped drawbar with<br />

Ø 50 mm towing eye and height adjustment by<br />

compression spring<br />

• Chassis and frame: Main frame and external frame<br />

made of high-strength rine-grain steel with full<br />

width cross beams in solid welded design for the<br />

highest levels of stability and carrying capacity;<br />

Wheel cut-outs over the rear wheels, corners<br />

chamfered at the front; Climbing bars on the<br />

external frame of the rear incline for maximum<br />

safety when loading and unloading; outer and<br />

main frames offset in area of rotating ring;<br />

10 pairs of 10 t lashing rings on the top platform<br />

and 3 pairs recessed in the lower platform;<br />

Lashing options integrated into external frame<br />

• Floor covering: Platform floor made from an<br />

approx. 55mm thick softwood covering;<br />

Chequer plate in the area of the rear wheels<br />

• Ramps: One-piece hot-dip galvanised<br />

drive-up ramps<br />

(length approx.<br />

3,000 mm, width<br />

approx. 750 mm)<br />

with direct-acting standing lifting springs for the<br />

easiest of operation; Ramp covered with softwood<br />

laid in the longitudinal direction; Ramp retainer<br />

linkage with securing lock for optimum safety<br />

• Paintwork: Steel parts sandblasted, primed and<br />

painted in a RAL colour of your choice; as an<br />

option we offer a variant that is hot-dip galvanised;<br />

silver painted rims<br />

Illustrations may show optional extras / products are subject to continuous technical alterations<br />

9